GPaudler

Members-

Posts

104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GPaudler

-

Hi Georgia, Most of what I sew is not leather, but I love my 335 which is a vintage similar to the one in your photo. It has been very reliable sewing through as much webbing as I can fit under the feet which is about 7-8mm. The unison feed is great. The maximum stitch length is somewhat limited and I think that #138 is the largest thread I've used. I think that if I could have only one sewing machine, the Pfaff 335 would be it. Gary

-

BUT! Sometimes one gets lucky. I bought an old Pfaff 335, that came with a hydraulic tensile tester, for $300. I love its unison feed and I've pushed its 5/16" thickness capacity as well as sewing hems on jeans and it has never even needed a timing adjustment. I set-up a 20+ year-old Brother TZ1-B652 drop-feed machine to sew tight zigzag splices with 138 thread in 12mm rope, stronger than the rope itself (see tensile tester, above), and I found an Adler 120-2 for $400at a yard sale that will sew 16mm long stitches with #346 thread through 16mm+ (19mm foot lift). I mention this because I don't want anybody to think they need to spend $3000 (or $13,000!) to practice their craft.

-

Good advice, as always, from Wiz. As to the reliability of older machines, it varies considerably and their condition is not always easy to discern but there are lots of 100 year-old sewing machines that still work beautifully and it's remarkable how many parts remain available. Lots of contemporary machines are fairly direct copies of old machines and some parts are interchangeable. If you want to sit down and sew, buy a new machine from a reputable dealer. If you're interested in learning about machines and enjoy developing mechanical skills and knowledge, then making an old machine work for your needs can be very rewarding. As to cost: If you are patient and diligent in your search, you can find solid old machines for a fraction of the cost of their new counterpart but, as Wiz said, you have to be prepared for some sometimes frustrating self-reliance. Look at Wiz's list of machines he currently owns; I'm guessing only one of them was new when he bought it. Have fun, Gary

-

Thanks Glenn, there's no hurry and the 29-4 version of the spring will be just fine. Congratulations on retirement, mine will have to coincide with my death. Gary

-

Fantastic information Glenn, thanks! Who would have imagined that a guy named Shoepatcher would know so much about these machines? As you said, the spring from my 29-4 is a direct fit for the 30-7; that should have been the first thing I tried. I'm not too concerned with museum-level originality so if you have either a 29 or a 30 spring that you don't mind parting with, I might be your customer. I could also use the sliding V-block thing but don't need the spring adjustment screw that turns into the casting on top. Thanks, Gary

-

That's good to know. Is that also true of the 29-4? Did the 29-4 precede the 29K series?

-

Thanks Dikman and TT, I was thinking multiple leaves too so I could add and subtract to get the proper rate. Also drill rod, which I have, could be tapered. I should have already thought of this - it just occurred to me - I'll see if the spring from my 29-4 works, if so, it will give me something to match with leaves or a rod or something.

-

Thanks Constabulary, I might take you up on the sliding block if I find a spring. I would love to not spend 150€. McMaster is the first place I looked and I too expected to find spring steel in something close to the right thickness, but no luck. Though I might try to approximate the right springiness with a rod instead of a leaf if I can't find the part. Thanks.

-

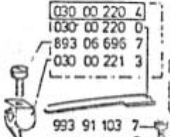

A few weeks ago, the Adler planets aligned and I wound-up with the 120-2, that I already mentioned, and a pretty nice 30-7 on its original treadle stand that is remarkably tight, smooth and silent - the treadle, that is - I haven't gotten the rest of the machine going yet. Missing is the long flat leaf spring. I looked at a 30-1 at a shoe repair shop in Santa Barbara and took some measurements thinking that I'd make a new spring but the correct steel isn't available, as I had expected. I could experiment with other sizes and shapes but thought I'd check with this font of helpfulness first. Here is an image with part numbers from a manual I found online for Adler 30-10, -50 and -70; I don't know if it would be the same for my 30-7. I would also need the thumb-screwed sliding thing. Does anybody have any of these parts that I could buy? Thanks, Gary

-

Looking for Singer 29k thumb nut #113088/nn88w

GPaudler replied to Wizcrafts's topic in Leather Sewing Machines

That parts list snippet also shows a 9/32-28 nut, .015" over 1/4-28. They - Singer, then Juki - really want to make sure you can't just buy a nut at the hardware store. My 130 year-old French Cornely mixes English and Metric but I haven't found any proprietary-size fasteners on it. -

Looking for Singer 29k thumb nut #113088/nn88w

GPaudler replied to Wizcrafts's topic in Leather Sewing Machines

Thanks Evo and Uwe! Pretty diabolical to change a screw size by 0.015". -

Looking for Singer 29k thumb nut #113088/nn88w

GPaudler replied to Wizcrafts's topic in Leather Sewing Machines

Uwe, really 15/64-28? 1/4-28 is common and 0.015" larger than 15/64. I'm not doubting you, it would just be fascinating and disturbing if Juki made a part that was so close to a standard SAE dimension and nowhere near metric. -

Dürkopp 18 Patcher Restoration - long journey...

GPaudler replied to Constabulary's topic in Leather Sewing Machines

What a fantastic hook mechanism! That will be a beautiful machine, the green one in the museum video is gorgeous. -

Sark9 - You are absolutely right! Why struggle with the under-table convention? Thanks Chayse, I'll post images when I get it running.

-

That's kind of what I had in mind. Your 7 looks like there's room to fit the electronics box underneath with the buttons and display facing forward (if sideways). My 120 won't allow that so my installation might not be so tidy. I should try it first without a speed reducer. Thanks, Gary

-

Maybe the mother of all yard sales (MOAYS). A family was selling the extreme accumulation of the Dearly Departed and was eager to be done with it, and it was only about 10 miles from here. It looked like he couldn't say no to a tool but wasn't quite sure how to use them.

-

Frankfurt is fantastic for Messe (trade fairs). You can get on the train right in the airport and get off at the station right in the Messe. I just looked-up the Consew 733 - if it can't be sewn with that machine, it can't be sewn. The 120 weighs 80kg, the 733 is 105kg! Walking feet and 32mm lift. Very nice!

-

Thanks Uwe. I looked-up the 967 and it's a beauty! It will be fun to have some of that capability. Is there a trade show in the US for industrial sewing technology besides Techtextil NA and IFAI? I attended both of those last year and was disappointed. It would be hard to beat the Germans for Messe. A friend attended Techtextil in Germany and said it was incredible. Also Uwe, you are too modest! I just looked at your online shop and it's a beautiful site with great-looking products at very reasonable prices!

-

Thanks for the patcher perspective Constabulary. I've got the 29-4 on a tidy little stand so after the Adler is sewing well, space constraints could be a factor deciding which stays or goes. Yes, suzelle of mysterious gender (and why should it matter in this context?), thank you, it's pretty hefty. I turned the hand wheel around on its shaft to get the v-groove closer to where the motor will be (photo shows original position). Gary

-

I'm pretty excited to have found this Adler 120-2 at a local yard sale! I've been wanting to do some fairly large fabric sculpture and this should be just the right machine for the job. It's a drop-feed with 20mm foot lift and up to 16mm stitch length and it appears to be in good condition. It came on a K-leg table with a clutch motor but I have a servo motor left-over from a project and intend to mount it onto the machine something like this: http://www.sl-spezial.de/sl/index.php/flat-bed-lockstitch-machine-adler-class-120-30-e2.html though I'll add an additional 3-1 reduction and do without the needle positioner. I also found an Adler 30-7 last week - lost my mind and bought it too. A little rougher condition, I'll post images after I clean it up a bit. I'll see how it sews compared to my Singer 29-4 and keep one or the other. How do y'all think they compare, aside from the arm length? Gary

-

Recommend vintage textile machine with reverse

GPaudler replied to Dave4's topic in Leather Sewing Machines

That IS a beautiful thread stand! -

Hydraulic shop press as a clicker press for cutting dies

GPaudler replied to Anubis78's topic in Leather Machinery

Clicker presses are built to be very rigid to keep the upper and lower platens very parallel to each other. You might be able to make an inexpensive shop press work but that's not what they're made to do and you should expect to experience some frustration including short-lived dies and cutting boards, the cost of which could easily add-up to the cost of a suitable die press. The Weaver press will be limited to small dies. You might find a used 2 or 4-post lab press that will be a much more useful tool. Gary- 36 replies

-

- leather cutting die

- clicker press

- (and 9 more)

-

Amazing Quality tools from FENG TOOL, CHINA

GPaudler replied to leathertoolz's topic in Leather Tools

Thanks Jun, Mr. Feng's tools look beautiful. Chinese products sometimes have a bad reputation in the US but that reputation was often thanks, at least in-part, to some Westerner saying "cheaper, cheaper". There is no doubt in my mind that Chinese are capable of making excellent tools, the challenge will be finding customers willing to pay the price for good quality. Compared to sewing machines that are often thousands of dollars, a few hundred dollars for several hand tools is a small investment for a craftsperson who wants to develop their skills and enjoy using good tools. I really applaud Mr. Feng's apparent determination to make excellent tools and thank you for bringing them to our attention. Gary- 2 replies

-

- feng tool

- french edger

-

(and 1 more)

Tagged with: