GPaudler

Members-

Posts

104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GPaudler

-

Hi 480, I have a lignum vitae maul that I've used a lot with woodcarving chisels and gouges that have wooden handles, mostly Japanese oak and European boxwood, I think. At any rate, the maul (carvers call them mallets) are always striking a softer wood. I've seen lignum vitae mallets that are badly chewed-up from striking steel-handled tools - I wouldn't use mine that way. But I'm with you, the very concept of lignum vitae, its density and feel, are very appealing. Gary

-

I know nothing about these machines so my input is probably useless, but that feed dog looks hand-made and might not correspond to the factory dimensions.

-

I don't think it's a big deal. If I'm not mistaken, automotive seat belts are supposed to be built to withstand loads of 6000-7000lbs., so that's an easy point of reference for all of us. Seat belt webbing is about the dimensions of the webbing you describe and their stitching is there for all to see. Coats specifies Tex 270 or 400 which would be 277, 346 or 415 in our usual thread sizes. But look at the small number of stitches on a seat belt, I think one could easily match or exceed that strength with a greater area of smaller stitches in smaller thread. Design your slings so that there are no loads trying to peel the eyes apart, over-stitch them, keep an eye on chafe and don't use them in any critical applications and you shouldn't have any problems. I've designed, sewn and tested lots of climbing harnesses and made plenty of lifting slings and I don't think I've ever seen stitching fail. Be conservative and design with 2X any expected load in mind. Also, if you sew black webbing with white thread or white webbing with black thread it's a lot easier to keep an eye on the condition of the stitching in use.

-

recomendations for a good heavy duty, walking foot, zig zag

GPaudler replied to mixmkr's topic in Leather Sewing Machines

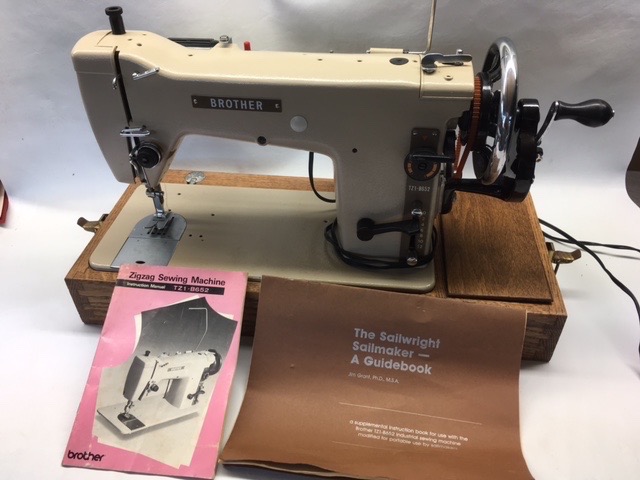

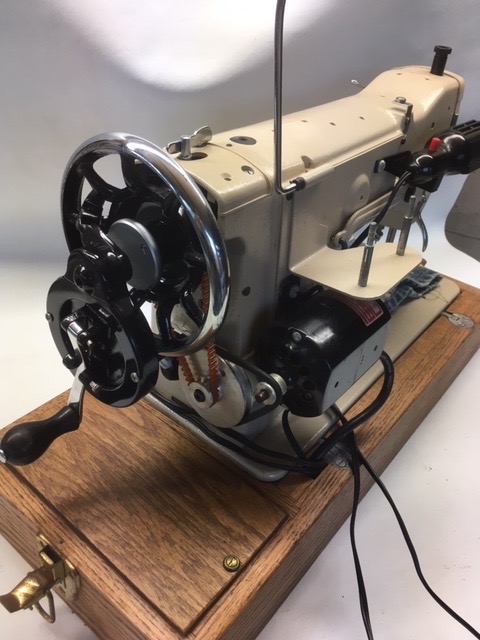

I have a Brother TZ1-B652 that was the basis for the first generation Sailwright Sailmaker. I also have the Sailwright conversion of that Brother that has a hand crank for when you're away from electricity, as well as its motor, all in a wooden carrying case. They are said to sew 12mm wide zig-zags but I think the maximum width is more like 10-11mm. They'll sew straight, as well. I made some slight, reversible, modifications to the Brother so that I can sew eye splices in rope up to 1/2" in diameter with a little 1.5amp motor that I mounted to keep the machine portable. With a very short stitch length, I make two narrow passes and two wide passes, about 3" long, with #92 thread, and the rope breaks, not the splice, at about 8,000lbs. I have a crane and dynamometer that I use for testing I bought the second machine, in the photos, thinking that I'd cannibalize parts if necessary, or maybe just to have another machine. But I really don't need it and would be willing to part with it for $900. It's heavy but way more UPSable than a table-mounted machine with motor. It is in excellent, unmodified condition. As I recall, they were over $2,000, new, a long time ago. Gary -

Brian and Dikman, I should have checked-back earlier. Thanks for the pointer, a longer stitch from this machine would be great.

-

Thanks Uwe, that is fantastic. It wouldn't be hard to build a manual version as it's really only three tale positions, plus the machine height.

-

I have one just like it and haven't dated it but it's 1960s at the earliest and 1980s at the latest. If I could only have one sewing machine, this would be it. Unison feed, 8mm (5/16") foot lift, shortish stitches and smallish maximum thread size - probably 138, but very reliable and versatile.

-

Hi Glen, I bought my old Adler 105 from Nick-O-Sew via eBay and it was just as described, shipped promptly and very well packed. No problems, no surprises. Gary

-

I put a servo motor on my Pfaff 335 without a speed-reduction and it works great. I've bought three from Alberoni's (in Orange County) eBay store or listing for about $115 with free shipping. Plenty of other merchants, as well. They are designed to mount easily in place of the standard clutch motor. If $115 doesn't hurt, you won't be sorry and you could spend that, or more, monkeying with a speed reducer trying to get your clutch motor to behave.

-

Yup, looks like I wasted a hyphen.

-

I really like twist-lock style v-belts like this, at Mcmaster-Carr. https://www.mcmaster.com/#6173k36/=160yn99 They aren't cheap, but they are easily adjustable, which de-criticalizes measurement and provides flexibility should you change pulleys or mounting. Sometimes one can find a good deal on Amazon. A very knowledgeable and meticulous friend of mine uses one to drive the alternator on his airplane's Lycoming O-360. Here's one on my 105. I already had the other belt and the speed-reduction scheme accommodates a wide range of sizes.

-

pressor foot mods. Post any that you have done

GPaudler replied to Gregspitz's topic in Leather Sewing Machines

That's what I mean by bewildering: A machine from a Japanese company specifying a fastener with an Imperial size designation I've never seen. I did find a reference to a 10-28 screw, which might be a distinction without a difference. But why not a M5-.8 or 10-32? It's a rhetorical question, it does keep life interesting. The 100 year-old French Cornely I've been working on has a goofy mishmash of screw sizes too. -

pressor foot mods. Post any that you have done

GPaudler replied to Gregspitz's topic in Leather Sewing Machines

Nice work, as always, Uwe. Is 3/16-28 really a screw size? #10-32 would be pretty close and quite common - though close isn't very helpful when it comes to screw pitch. Sewing machine screws are a constant source of bewilderment. -

pressor foot mods. Post any that you have done

GPaudler replied to Gregspitz's topic in Leather Sewing Machines

I needed to move the edge guide closer to the needle on my Adler 105, but the local dealer said that presser feet for that machine are upwards of $300. Needless to say, I made my own. The bottom portion is cut and bent from a piece of stainless angle and the slotted back is cut from a piece of plate, all TIG-welded together, though, without a welder, one could do the same with silver solder. -

Sneak Peek: UT441 flatbed table attachment for 441 class machines

GPaudler replied to Uwe's topic in Leather Sewing Machines

Beautifully done Uwe! -

Singer 114W103 Chainstitch Embroidery Machine

GPaudler replied to GPaudler's topic in Leather Sewing Machines

Thanks Uwe, I'm unreasonably obsessed with those machines, I wish that I could afford yours. I'm glad you got it up and running. -

Small footprint cylinder bed machine table

GPaudler replied to jacobkoski's topic in Leather Sewing Machines

Yes, very nicely done! I made similarly minimal pedestals for my cylinder bed machines - Singer 29-4, older Pfaff 335 and Adler 105. Each different, but you asked about height: I made them so that the needle plate on the cylinder beds is at the same height as the needle plates of my flat bed machines. That way one chair height works everywhere and the cylinder machines are less top-heavy than they would otherwise be. Having that common, relatively low, height also allows me to have a single supplemental table that I can roll up to any of the machines when I need some flat-beddedness. -

Singer 114W103 Chainstitch Embroidery Machine

GPaudler replied to GPaudler's topic in Leather Sewing Machines

Isn't it still a lockstitch zigzag that sews in the direction of the feed dogs? -

Singer 114W103 Chainstitch Embroidery Machine

GPaudler replied to GPaudler's topic in Leather Sewing Machines

Uwe's Consew is a close copy of the singer 114 and would be perfect for me except I need to spend no more than about $500 for what is essentially an impulse and Uwe's machine is easily worth twice that or more. For my meager budget, I fully expect to make some repairs which, for me, is much of the fun. I can weld or machine as necessary. Thanks Yeti, I'm in Summerland, between Santa Barbara and Ventura, California. Also, I have one of the original Sailrite machines - the Brother TZ1-B652 - in excellent, virtually unused condition, in its original custom carrying case, that I'd be pleased to trade for the Singer 114W103, or similar. -

Singer 114W103 Chainstitch Embroidery Machine

GPaudler replied to GPaudler's topic in Leather Sewing Machines

I'm sure that you are right - most machines don't even breathe hard stitching garment weight leather - but I plan to use the 114 on fabric. And thanks for the Heddels link, I love that stuff! Gary -

Are you crazy? Of course I'm not thinking of using it on leather. But I am now obsessed with this machine and thought that one of you might have one to sell. I'd also consider a Consew 104 or a Cornely (many models, I don't know...) or even a Brand-X copy from Cheapistan. Condition unimportant. Many thanks, Gary

-

"GPaudler, What's your thinking with the single circle of marbles, make it more difficult to revolve?" It's unimportant, you're probably operating at relatively few RPY (revolutions per year), I was just thinking that all those marbles in the middle are just grinding against each other and not contributing much support if the polyethylene disc is easily deflected. But what you have there is perfectly simple and effective.