GPaudler

Members-

Posts

104 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GPaudler

-

Yes, really clever! I think you could drop a disc of plywood, 1/4" or 3/8", to fill the center of the circular recess so that you'd have a single circle of marbles around the outside.

-

Go with a VFD. They are easy to set-up and reliable and you can find them cheap on eBay. They can be used to control speed and programmed for soft start. In a one-person shop where only one machine is likely to be running at any time, you can have a single VFD with an outlet into which you can plug any machine.

-

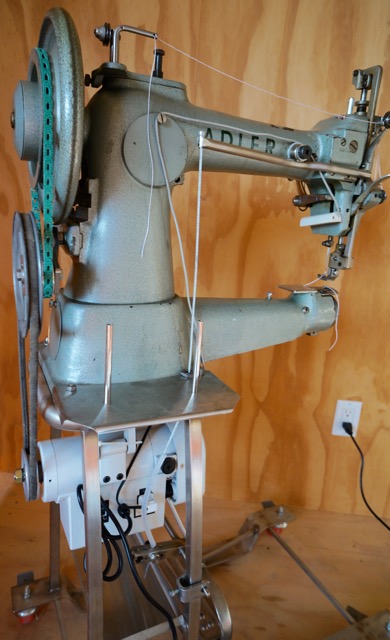

I hadn't tried so thought I'd see what the little Necchi could do in leather. Here's three layers of veg tanned leather totaling an honest 1/4" thickness sewn with 69 thread and a probably too-big needle. I'd just used the same thread and needle to sew two layers of cotton flannel with the same tensions. About 6-1/2 stitches per inch are as long as the machine will sew. Then I sewed a line with the Adler 105, 346 thread, 3-1/2 stitches per inch.

-

I like the way you framed your question and here's my answer to what I think you asked: In 1980 I bought a Necchi Nora at a pawn shop in Pensacola for $50. I used it to make my living doing marine canvas work - awnings, Biminis, dodgers, upholstery, etc. It sews garment-weight leather just fine, does zig-zag, which I use all the time, and a bunch of decorative stitches with cams, that I've never used. It will sew through as many layers of nylon webbing as you can jam under the presser foot. I've rarely used any thread lighter than 69. It's a simple drop-feed and it has never even needed to be re-timed! Not one repair or adjustment in 36 years of hard use. I even use it with the zig-zag length shortened to sew eye splices in 7mm polyester double-braid rope that are as strong as the rope's 2,100 lb. rated strength. They are much more expensive these days, sometimes over $100. I have a Pfaff 335 compound-feed cylinder bed machine, 2 Brother TZ1-B652s, a Singer 29-4 and an Adler 105, all industrial machines with more power, thread size capability and foot lift than the little, portable Necchi, and I'm crazy about each of them, but for anybody just learning the craft, not holsters, saddles or harnesses, I'm happy to recommend something like the Necchi, even if you outgrow it in 6 months. Everything about it makes me happy. Gary

-

Hi Jim, If what you have is a solid, round leather drive belt, I think that they are often just spliced with a hog ring or you can do the same with a short piece of 1/16" wire. If the belt is old and dry, you can make it a lot grippier by oiling it and wiping off the excess. If you'd like to try a new belt, check out the many types available at McMaster-Carr: http://www.mcmaster.com/#=13tqh1j Good luck, Gary

-

Hi Giorgi, To form a lock stitch, a very precise relationship must be maintained between the needle and the shuttle and I can't think of a way to have a rotating horn that contains a bobbin shuttle that doesn't rotate. Even if you could, the shuttle, on either a vertical or horizontal axis, would have to stay on one side of the needle so you'd have that mass preventing you from sewing close to most of the upper and the edge of the sole. I hate to say that something is not possible but what think I understand you are asking for is, at least, very nearly impossible. Gary

-

Hi Giorgi, Would you please ask your question another way? Do you have a particular machine in mind for modification? What are the particular qualities of the McKay that you want to achieve? Thanks, Gary

-

Advice needed for shoe sewing machines

GPaudler replied to jollins's topic in Leather Sewing Machines

Hi Jollins, besides Mike's excellent advice, you might consider that a single needle machine will be more versatile for your needs, you can always sew a parallel line of stitches if you need multiple rows, and if you're going to own one machine, I'd look for a walking foot and a cylinder bed. Gary -

Though it's often cited and is about as scientific as most people care or need to get, a simple measurement of V-belt deflection really isn't very meaningful. It's not important but understanding the mechanics might help someone if slippage should become a problem. It's helpful to think of it in terms of friction due to surface contact. A skinny belt on small wheels has much less surface contact than a fatter belt on big wheels so will need less tension to resist slipping. The material and finish of the wheels makes a difference as do the material, age and condition of the belt. Wiz's suggestion to use belt dressing available from auto parts stores in spray cans or squeeze tubes is good, especially for older, oxidized belts, for achieving maximum friction. So sure, try adjusting for 1/2" of deflection (though how hard are you pushing?) and if it doesn't slip, then you're good. If it still slips, make sure that your V-grooves and belts are clean and rust-free and treat your belts to some dressing.

- 18 replies

-

That is a good description. What if the lower thread fed from beneath the machine, through a hole into the center cylinder of a bobbin, then out of the center cylinder and was wrapped a few times around an otherwise empty bobbin before being picked-up by the top thread? Could that be made to work?

-

Hi Sovran, I've wondered about that too for my 29-4, what's your idea? I'm a decent machinist and weldor and would be glad to help if I can. Or, at least keep us posted as you proceed. Thanks, Gary

-

I would buy one just for it's appearance! I think that lots of conventional, modern dies have 3/8" (9.525mm) shanks so as long as the beautiful, old press has receptacles 10mm or larger, simple adapters could be made. If the holes in the press are smaller, the dies could be turned-down on a lathe. Where are you seeing those great, old presses? Gary

-

This isn't what you asked, I haven't used an Adler 669 but my impression is that it is similar to the Pfaff 335. I have owned an older 335 for 20 years, or so. It's an excellent machine that has been completely dependable and they can easily be found used for around $1,000. Gary

-

Hi Sparky, you're getting lots of good advice here, but besides a machine's ability to push a needle through some thickness, you might consider the size thread that you'd like to use and the stitch length. Those can be important elements of the appearance of the kinds of projects you have in mind and there are plenty of machines that will handle 5mm thickness but only with size 92, or thinner, thread and 8, or more, stitches per inch. That will be plenty strong but might not provide the appearance that you'd like.

-

New Servo Motor Dropped in Easy - Singer 111W155

GPaudler replied to leecopp's topic in Leather Sewing Machines

Thanks Lee, my experience installing two CSM550 servo motors has been similarly rewarding, even though, in each case, I mounted them in stands that I made so didn't have an old motor's mounting holes to work with. I can't think of any downside to a servo motor retrofit. -

Thanks Uwe, I knew you would know.

- 11 replies

-

Guessing at, but not thinking too hard about, the age of my 105-27, I thought that it was in pretty decent shape for a 40 year-old machine but if "ADLER", as opposed to "adler", suggests pre-war, then it's in really good condition for an 80 year-old. During what years were the 105s made? Were they superseded by the 205s or did the two classes coexist for a while? Thanks, Gary

- 11 replies

-

The first place I look for fasteners or just about anything else is McMaster-Carr http://www.mcmaster.com/# They have a shocking variety of materials, tools and parts and it's almost always in-stock and ships today if you call-in your order by 4:30. They have several warehouses sprinkled around the US, their customer service is extraordinary. Their physical catalog is a good 3" thick and their online catalog is easy to navigate and full of useful information. As Uwe suggested, or as I interpreted him, 5mm bolts are commonly available in pitches of .5 and .8, and McMaster does not offer any M5-1 screws, taps or dies.

-

Hi Trox, That's quite a treasure trove of Adler parts. My local Adler dealer tells me that a single presser foot costs about $300. I have purchased zero of them. Here's the photo of the shuttle that I failed to attach last time. It also happens to show a presser foot that I made.

-

New Dürkopp Adler 969 And 967 H Type Machines For X Heavy Work

GPaudler replied to Trox's topic in Leather Sewing Machines

They showed that machine, and a very few others, at the Techtextil show in Houston several months ago, it's visually very impressive in-person. They weren't demonstrating the machines; just guys in suits standing around. I sort of recall a quoted price of $12,000. A colleague had attended Techtextil at Messe Frankfurt and had a great time so I was eager to attend the North American edition but was quite disappointed. It was a dinky show with very low energy and little of interest to me. It was combined in the same small exhibition hall with a small composites expo that was more interesting, especially the Swiss company Staubli's incredible Jacquard machines that can make inch-thick combinations of reinforcing yarns, like glass, carbon, aramid and polyolefin in complex arrays specifically designed to place carefully engineered reinforcement in a composite structure. Their display was back-to-back with the German company Dornier who showed some beautiful looms. I went to the IFAI industrial fabrics show in Anaheim hoping to see lots of machines but it was also quite disappointing with very few sewing machines on display and very little new stuff.- 79 replies

-

- 967 h type

- 969 h type

-

(and 1 more)

Tagged with:

-

"PS. Here is a pic of the old closed shuttle #05 195 for the Adler cl. 4 and 5. It looks like this shuttle is in your machine now, cannot be sure before you take a better picture, though." Hi Tor, Here's the photo for which you asked. What years did Adler make the 105? Thanks for all your insights. Oh yeah, I've searched for the Adler Class 4&5 manual that you mentioned but haven't found it. Could you please direct me to that? I'd love to see the saddlers' attachments that you spoke-of. Adler Shuttle

-

Hi, I'm a terrible tool enabler - not an enabler of terrible tools. If I hadn't recently gotten my Adler 105 up and running, I'd be all over this 45k70: https://santabarbara.craigslist.org/atq/5531412837.html. I don't know the seller and have resisted the urge to waste his time since I don't even have room for the machines I already have. But if anybody here is sincerely interested, I'd be glad to take some thread and needles and go check it out on your behalf. It's been listed for a while, one might be able to get it for $400. Looks like the original treadle stand and is that a little skiver on the table?

-

Wow Tor and Darren! Thanks for all the great information. So far, I'm able to achieve the correct bobbin tension but I've only used 277 and 346 thread. I'll search for the class 5 manual. Gary

-

Thanks Constabulary, that makes sense, I probably fiddled with it with the presser foot in the up position so didn't detect any change. Thanks Uve, I've really enjoyed all the Adler stuff you've posted.

-

After spending an hour here and an hour there for these past months I finally finished the stand for the Adler 105-27. All the materials were left-overs from past projects except for the casters, the motor and the PowerTwist V-belt. I didn't want to modify the machine in any way so I turned a bolt from hex stock that tightens the bobbin winder arm and serves as the pivot for the reduction drive swing arm. I turned the 2" V pulley from aluminum bar and pressed it onto the die-cast V pulley that was salvaged from something long-ago. I bored the pulley assembly for ubiquitous, cheap and reliable skate bearings. It's a total reduction of about 6:1 that, with the servo motor on its slowest setting, gives single-stitch controllability in 1/2" of leather or webbing with 346 thread in a #26 needle. It makes a satisfying ka-chunk sound with every stitch. The fourth photo shows the foot lifter arm that came with the machine. A few other parts were pretty rusty so I duplicated them in stainless. The rest of the machine polished-up pretty nicely and I'm very pleased with how well it sews. Could somebody please tell me what the thumb screw with lock lever on the left, top, front of the head does? (most evident in photo 6, upper right).