-

Posts

201 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by maxdaddy

-

Mary Rose flask

maxdaddy replied to Brushpopper's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nice flask! Would you mind providing some details on the aquarium paint? I seal my tankards and mugs with beeswax but am always looking for alternatives. -

Love the painted feathers!

-

I bought several of them at Tandy's Black Friday sale when they were $10 and made a bunch of whisky tumblers with them. They made great Christmas gifts.

-

Hi folks, I have a JD Randal & Co creaser for sale. It is very clean and works great. $650 It can be picked up in the Plant City, Florida area or the buyer can pay for shipping.

-

Hi folks, I have a 6" American splitter for sale. It's in great working condition. $750 It can be picked up in the Plant City, Florida area or the buyer can pay for shipping.

-

Hi folks, I have a Landis Model 25 for sale. It's been repainted at some time in it's life, but it's a very clean machine overall. $750. It can be picked up in the Plant City, Florida area or the buyer can pay for shipping.

-

Stitchless wallet

maxdaddy replied to Bolanca's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I like that.... could we see a few more pictures of it without the contents? -

What's Your Handle? (Origins of your maker marks)

maxdaddy replied to Mjolnir's topic in Leatherwork Conversation

Shabang! Leatherworks is what I decided to call my leather 'business'. I considered many alternate names that tied in some other areas of interest; guitars or computers. I'm a computer engineer in my day job and shabang had just enough geek potential to win the day. What's a shabang? Well, if you're writing a script (small program) on a unix computer system, the first line will contain the 'shabang'. It is a couple of characters (#!) that essentially tells the operating system how to interpret the script... which shell to run it in. The logo incorporates both the # and the !.... S#abang! My leatherworker.net handle, maxdaddy, is simply because I have a son named Max, and well, I'm his daddy. :-) -

New wallet

maxdaddy replied to Jbrandon's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

What purpose do the tabs serve? -

Old dog and some new tricks.. 'bout time to share

maxdaddy replied to Subterra's topic in Member Gallery

Dan, That's a wide variety of projects, and they're all nice! Please tell us more about the epoxy plates and how you made them.- 17 replies

-

- leather art

- sculptures

-

(and 1 more)

Tagged with:

-

I like that! What did you seal the inside of the horn with?

-

Fischer Workshops Designer Tire Bag

maxdaddy replied to cicftaiwan's topic in Motorcycles and Biker Gear

Chris, That's a very creative idea and the execution really shows off your techniques. Beautiful! The length of time that you spent on the planning sure paid off. Thanks for sharing the back-story on the inspiration and the other details.- 9 replies

-

- messenger bag

- fischer workshops

- (and 11 more)

-

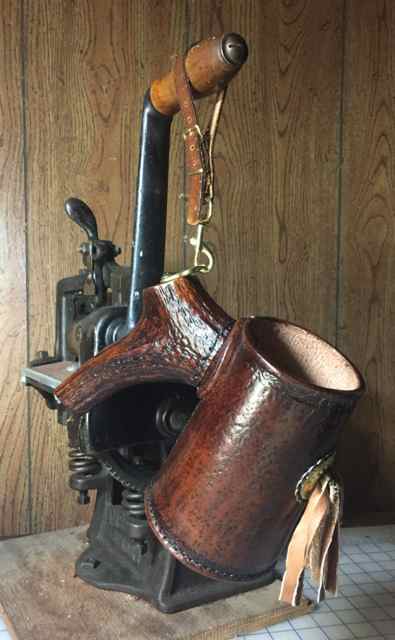

I vote for texturizing and antiquing. You may be able to use the horn itself to texturize the leather and you may find that this makes for a more consistent look than by graveling it. I can't tell for sure if the surface is aggressive enough to use to impress the texture but you could test it out on scrap. I sometimes do this when attaching antler to a mug (as a handle) if I want the leather mug texture to be similar to the antler. Just wet the leather and after a few minutes of dry time, randomly roll the horn over the leather applying strong pressure and maintaining the 'grain' of the texture in a common direction. Look around and you'll find lots of things that you can use to texturize/age a piece of leather. The picture has some of the texturizers that I use.... Tree bark. Rock. Microphone windscreen. Meat tenderizer mallet. And my favorite texturize trick is the box of weird 'nuts' (one of them is circled) that I got from a guy, years ago, in North Carolina. I don't know what kind of tree they come from, but they lay a nice random/weathered texture down. I look like a kid rolling out play-doh snakes when I use the nuts on a piece... back and forth moving over the piece to get full coverage. Antiquing will still be needed to get the color and tints to match and to bring out the texture. I would antique the horn with the same dye as the leather, but would test out the technique on a similar piece. Good luck and be sure to show us the finished product.

-

@CaptQuirk, I've lived in, or within 10 minutes of, Tampa my whole life (51 years) so I can't imagine not being able to pick up a legit Cuban sandwich and a deviled crab on the way home for dinner. Thanks for the suggestion. I haven't tried buffing the wax down to a smooth finish yet, but the process leaves a fairly thick amount on the surface so I don't know if something soft would be productive. Might need something like denim. I'll try it later tonight after dinner. "Hmmmm, what should I have for dinner tonight? I KNOW! Yellow and black with a deviled crab and cuban toast."

-

@CaptQuirk, Cuban food is indeed one of the hallmarks of Tampa. I always recommend that visitors return back home with a bottle of mojo seasoning, a dozen bags of yellow rice and a dozen loaves of Cuban Bread. When they get back home, they can buy a few cans of blackbeans and roast some chicken in the moho and have all of their friends over for a legit Tampa-style Cuban feast. Yellow-rice and chicken with black-beans and Cuban toast! mmMMMmm Thanks for the nice comments on the amp. It's one of the few oddball projects that my wife actually approved of after it was finished. That is, until I plug it in and turn it up. The tankards are fun and are what I intend to make the most of initially. I seal the tankards with beeswax. It works very well. There's a skill to getting a clean looking seal that I haven't mastered yet. I only get smooth-looking applications about 30% of the time. The rest of the time I get visible 'streaks' on the inside. The sealing property is fine even if the look is imperfect, though. The outsides are finished in either Resolene, MinWax Polycrylic, or floor wax. All seem to work well, I can't decide which I like the best. Bottoms are either stitched formed leather or tacked wood.

-

Greetings, I've lurked around here for about four months getting to know many of you by your galleries and postings, and I thought that the time is right to introduce myself and start trying to contribute. I got turned on to working with leather about two years ago when I was converting a 1938 Philco radio cabinet into a guitar amp and decided to cover the top and side panels in leather. Even though the leather was just a minor part of the entire project, I enjoyed working with it and was very happy with the dramatic look that it gave to the finished product. Next I made matching pickguard, strap, and headstock cover for a guitar that I built. Again, leather was a very small part of the entire project but I enjoyed working with it and I was hooked. A friend gave me a few of his basic leather tools (swivel knife, punch, hammer, tooling stamps, etc...) and I started trying to figure out what to do next. A couple of Tandy kits, leatherworker.net tutorials, and lots of YouTube videos taught me some very basic construction techniques and further solidified my resolve to try to take it further. In late summer of this year, I was able to purchase a shop full of tools and supplies from the widow of a very skilled leather crafter. I was fortunate enough to get a couple of splitters, a foot press, a 5-in-1, a 2-ton press, tombstone slabs, fasteners, edgers, knives, hammers, stamps, and more. The only thing that I may need to buy at some point in the future might be a heavy duty sewing machine. Once my little work shop area was setup, I spent every night trying to get better at the basic skills; cutting, punching, stitching, dying, gluing, wet-forming, etc... There's a valuable lesson to be learned every time I pick up a knife and I try to be a good student and learn something with each part of each project. My first projects were tankards, or mugs. I'm not sure which term actually applies to what I am making. I'm using beeswax to seal them and the first ten that I made were given to friends to test the durability at Ren Faires and other gatherings. So far, so good. Pictured are some of the ones that I am working on now. Most of these have not been sealed yet, but I will be doing that in the next week. I'm trying to bring some fun design and construction ideas to the table and I enjoy using antlers, attached lids, butterfly-wing handles, and things like that. I know that I have a lot to learn about every aspect of leather craft, but am hoping that in January I can open my Etsy store and try to sell the mug sets (mug and belt strap) and start earning a little money from this new hobby. I've learned a lot from this forum, and I hope to eventually contribute something to leatherworker.net that helps some of you. Thanks for reading, Dave

-

I am selling a set of four University of Georgia Bulldogs stamps as pictured. The stamps were part of a large lot of tools that I purchased over the summer and being a Florida boy, I don't really see myself ever using them. Included are the four stamps on 4.5 inch handles. Mascot head Left side torso Right side torso "GO DAWGS" Asking $100, shipping included.