-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by chasman52

-

PFAFF1445 Need some help judgeing stitching

chasman52 replied to chasman52's topic in Leather Sewing Machines

Thanks BRmax, So, is it better to get a reducer( two pulleys ) first, or straight to a servo? A lot of cleaning! I got in new parts on the tension assembly. it's seems to be working -

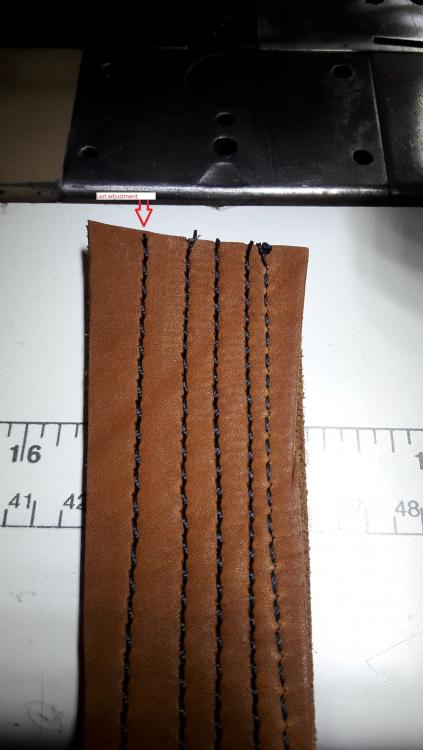

This is my very first sewing machine I'm not sure this is right. I can't believe how damn fast it is. I can't get a straight line or stop it in time. How the *&^% do you all control these machines I had to count all my fingers this first time I lit it up! Anyway,I want to post up some pic's of the stitches in 16OZ I've been able to do after two days for tweaking. If someone could take a look at these pic's and advise on what I should do next. Much appreciated! I did get an owners manual and the parts list. If someone here can advise me on how to post them I'd be happy to. Each is a little larger than the 1.46mb allowed I need the machine to do totes, belts and (hopefully) holsters. I got to slow it down. What servos do the best job.

-

Apologies to Cowboy Bob for Toledo bob. I was born in Toledo, Ohio actually

-

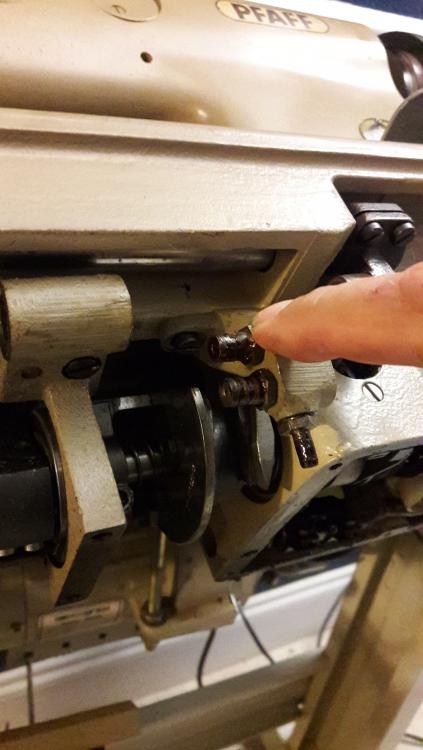

Today after work. I bought a smaller pulley and belt, and Cleaned up the clutch like Toledo Bob had suggested. Now, I can go slower than 120 spm. While I was at it I noticed the oil level wasn't going down at all. That's when I realized I had a problem. It was plugged where I'm pointing. I replaced this line from a valve to the port going to the ring gear under the bobbin assembly. Sorry if I don't know what to call all the parts Question ? How do I know when there's enough oil going from the check valve to the gears? And I used vinyl tubing. So, will that work?

-

Thanks Wiz, I got a few of those #24 with the machine, and I think I ordered a few #23 & #25's

-

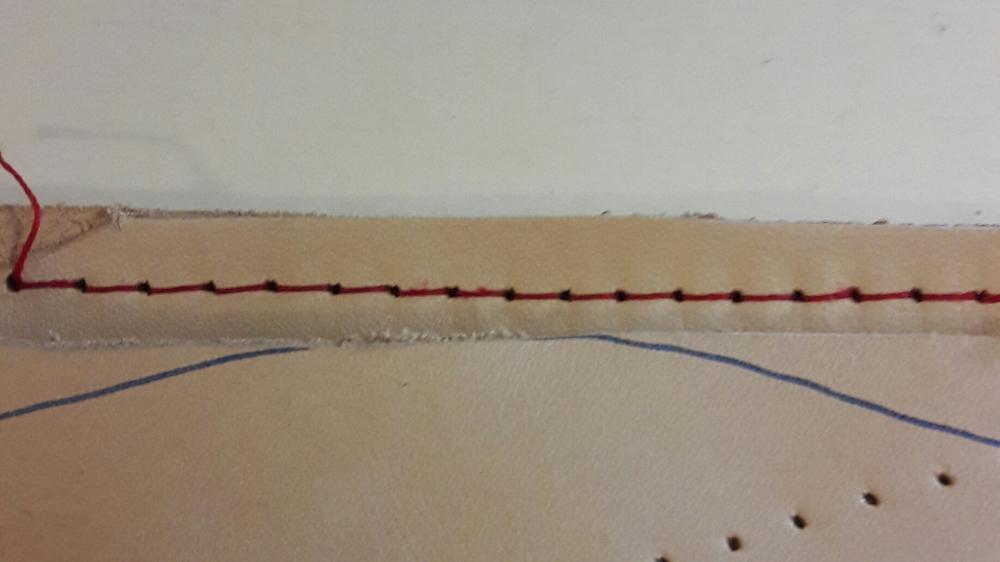

Br max, I agree 277 is reaching for the moon. I can use it to saddle stitch up some holsters , or something else. But I'm going give it a try I want everyone on the forum to know you all have saved me from many hours of frustration. I wouldn't have gotten this far on my own. Thank You!

-

if it runs 277 on top slowly I'll be more than very happy, but if I get stopped at 207 I'll be satisfied. If I keep it I'm gonna need a servo motor

-

I just ordered some 138,207,277 bonded polyester thread and 18,20,23,25 needles from the thread exchange.

-

-

It was the tension alright. I had to center the needle and adjust the needle height. Then back off a ton of tension. I can put a balanced stitch in 4 layers of denim. I still have to wait for thread & needles to come in before I have a go at my leather. I don't have a Lot of scrap. I have 4oz chrome tan I'm making a tote. Does tex138 and a#20 leather needle sound like the right combination?

-

Imstephenjones, I didn't know clutch motors could come with speed controllers built in. I'll look for it when I get home.

-

I just have to figure out how to rotate the whole rod. Do you think I can turn it by loosening the same clamp that adjusts the needle height?

-

Figure #2 and #3 it shows the final guide at the left. My question is" can I rotate the shaft to look like this?

-

My desktop keyboard died. Just had to post this,cause it's starting to work. Please look at Mooselodge .jpg, and view the needle guide. Mine is the same,but I think it may be wrong. Should guide above needle be left of the needle center? Veg. Leather breaks top thread, but 4 layers denim is no prob. 22/140 134/135 reg needle w/ tex90 nylon.

-

Good news today, The bobbin carriage works. I used UWE's example to figure it out. Thank u UWE!! You can see how it uses a notch in the bobbin's lockdown, and the bobbin's tension leaf spring is where it is normally. I was able to thread the machine of a sorts and without power made a few stitches. As it's Valentine day I'm done for the day. Tomorrow'll try to run it under power with some heavy cloth

-

I have no idea how old the thread "came with the machine is, but it smells.lol Stinks actually! The machine was in an airplane hanger for years. it was filthy, but cleaned up nice I didn't consider that , but now that you mention it. I agree totally, I won't make any adjustments based on this old thread

-

I see what you mean. I just have to solve how to make bobbin tension. I ran it unpowered, and it went fine. So, I turned it on unthreaded and it'll punch through some veg tan scrap. It's just so darn fast I can't control it. I can literally sew ( punch holes in)by hand crank 8 oz. veg. I got a users manual and the service manual now. Here's my list of what I can do. Any suggestions appreciated ? 1.How to thread bobbin 2.how to adjust bobbin tension if necessary 3. call Denise at PFAFF to get parts to complete front/top tension assembly

-

I made the pic's 1000 Horz. That's better, Thanks I totally agree that the parts manual shows a different part

-

I did pick it up $355.00 and it is mine. I have a few problems though. I've taken some pictures of the bobbin area. Is this a PFAFF bobbin assembly, cause I can't find anywhere to adjust bottom tension on it. I think sumin's missing.

-

Thanks Brmax, I still cannot find an owners manual so I can be sure to thread it properly anybody got a soft copy of an instruction manual.?

-

I've got a line on a PFAFF1445 here in Miami for $400. I've done a search here and Google. From what I've seen these are strong machines, but parts can be hard to find and expensive. Still I couldn't find anything but a service manual. I'm concerned it won't use a heavy enough thread to make totes, Belts and Holsters. I've never owned an industrial machine. Any tips on how to judge a machine to purchase?

-

From the album: chasman52

Black clip on for a GLock43 -

From the album: chasman52

Black snap on belt loop IWB -

From the album: chasman52

Avenger style holster for a 1911 commander size pistol -

From the album: chasman52

Black clip on for a GLock43-

- glock43

- clip on holster

-

(and 1 more)

Tagged with: