-

Posts

193 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by trash treasure

-

Singer 153W 100 Presser Foot Position change

trash treasure replied to JeffHami's topic in Leather Sewing Machines

OOPS ! My mistake - Wrong subclass! I apologize for any confusion caused. We have a 153 K 103, which is most definitely a walking foot machine, and shares feet with other Singer walking foot machines . So the 100 subclass is the needle feed version, and as Bob said, needs the sideways feet. Thanks, Bob. -

I think we're going to need a little more info - Can you take another video, of the upper thread path as you sew. It might be that the take up spring is way out of adjustment, or something . Are your tensions balanced to begin with - Upper tension too tight vs. bobbin, etc? Foot pressure too light, it looks pretty minimal? Could be any number of things. I see Kgg has just answered - Check the foot pressure, as that might be it - Often something very basic.

- 6 replies

-

- industrial machine

- tension problem

-

(and 1 more)

Tagged with:

-

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

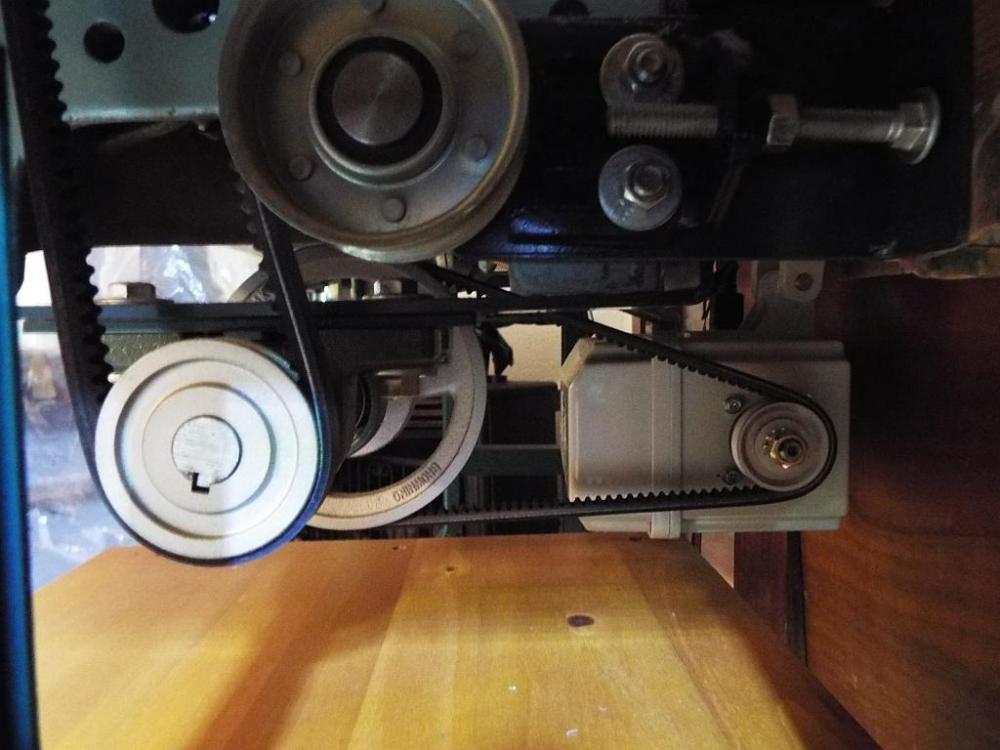

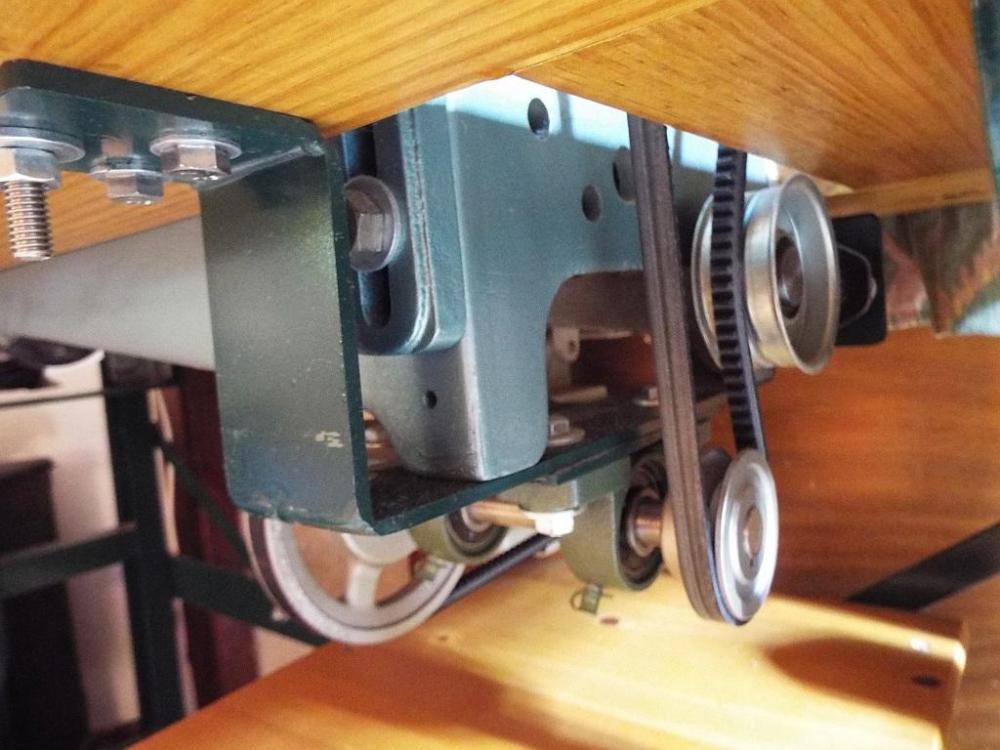

OK - Here's a close up photo of the speed reducer set up, which I guess is what you wanted to see. The Mustang idler is at the top - The long carriage bolt passes through the sliding part that has the idler pulley. The head of the bolt bears against the back of the fixed part, and pushes the slider against the back side of the belt - Once it's adjusted, I lock it down with the 2 nuts. The whole thing, including the reducer pulleys, is fastened to the rear cradle that hold the machine in the table. The Idler set up had to be modified a bit to work like this, but it performs flawlessly, and solves the belt tension problems with homemade speed reducers. Here's a photo of the Adler as found - It was nowhere near in as bad a shape as the 30-1 patcher I just acquired, but it was non-working, and I had to do a couple repairs and replacements to get it there. The seller had never gotten it to sew, and told me that he bought it from "some old guy" that used it to sew buffalo skin rugs together - It WAS clogged up with woolly brown fur, so I guess maybe that was true Here's the last shot, of the whole machine - I sort of re-engineered the table for it, shortening it, and making a new top. I'd seen photos of Adlers used by the German military, and loosely followed that idea, with a cabinet under it. I picked up a nice iron treadle, and fabricated a new lower crossbar, to replace the bent up originals. The table is on casters, as it lives in one end of our kitchen, when we're not using it - It rolls into the shop, through the doorway behind it. My wife said it had to look nice, if it was going to live in the kitchen. And so maybe I "over-restored" it a bit, even to the extent of polishing the handwheel rim - After I polished it, I rubbed it with this anti-corrosive sculptor's wax, and surprisingly, it's stayed rust-free for a couple years now. -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

It's an Adler 20-19 - I'll post a couple more photos, after breakfast :~) -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

Coming from you, a high compliment, indeed - Thank you :~) There was no rocket science involved in sinking the Adler - The photo shows the 3/16" (5mm) steel straps used. You would need to bend these with a powerful bending brake, or cut and weld them - These are welded. Just compensate for the table thickness, and how high you want the bed to stick up above, and design accordingly . They are just hung from the table with carriage bolts & lag screws - Make sure to leave a cutout for the bobbin winder, belt, and front bed access. The machine just sits on them - You could just lift it out, if you were strong enough ;~) The photo also shows my home-brewed speed reducer, which uses a modified fan belt idler pulley from a '78 Ford Mustang, to tension the belt from the backside. With a 750W servo motor, the machine has plenty of power ! -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

I totally agree - I don't like to disassemble more than is really necessary - No problem for me to mask and paint, with the main shaft, etc, still in place. I have lots of brushes, solvent, and time to spend on it :~) I can do decent work on sewing machines, if I take my time and go carefully - Here's a little one I cleaned up a couple years ago. It was a bit crusty, and didn't look, or work, as nice as it does now ( Nothing like as bad as this patcher, though) - It turned out pretty good : -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

OK - As requested, here's some possibly better photos - At least they're against a plainer background. As you can see, everything is there, but some stuff broken . It's missing only one nut from the stand - One of the one's on the end of the treadle axle :~) It's also missing the wooden drawer, but I think I can make one. The wood pitman arm is interesting - I wonder why they chose that material. It seems to work fine, and doesn't seem to have any wear, so I guess they knew what they were doing. It'll be a little while before I can start in on it, but I will refresh the thread with updates, as they happen. Or at least some "After" photos. I've restored a few machines before, so I'm pretty familiar with the drill, but this one is different, and a bit rough - We shall see what I can make of it. And thanks again, for the encouragement ! -

Can you take out the needle plate and feed dog, and show us the needle / hook orientation, when the the hook comes around , and the needle has risen a couple mm? No need to have thread in it for that - Just so we can see the actual situation. Just because a local shop worked on it it, doesn't mean they had any clue - I've bought machines that were supposedly, recently "serviced", and they were way out of whack. Just sayin' ........

-

Singer 153W 100 Presser Foot Position change

trash treasure replied to JeffHami's topic in Leather Sewing Machines

HA! This is an interesting thread, although old - We have a 153 that was re-built by Hoffman Brothers at one point. It has the presser bar oriented in the normal Singer walking foot manner, fore 'n aft, rather than sideways, and we just swap feet between it and our 111 and 211 machines - I never knew it was any other way. So this obviously works - Was there a technical reason Singer originally set it up the other way? Or maybe they did it just to sell special feet ;~) -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

Many Thanks for posting those links, Constabulary - They make a couple things much clearer to me, now. Having never had one of these apart, seeing your work on that 29 K1 gives me hope that I can get this machine at least functioning. I really appreciate the collective knowledge available on this forum :~) -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

OK, here it is, in all it's glory - A real project, but maybe doable, if I don't find too many other broken parts. It is complete, so there is that, to give me confidence, but I may feel differently, once I clean it enough to really see what's wrong. -

Singer / Adler patcher parts swapping

trash treasure replied to trash treasure's topic in Leather Sewing Machines

Sorry, I should have said - It's a green machine, complete with a treadle table. Maybe I'll post a photo, if everyone promises not to beat me up too much for taking on a lost cause. The machine is free moving, but that's about it - Covered in old lithium grease, to the point where I can't tell yet, how bad it is . Tom, headed off to practice his welding........ -

I know there are some here that are pretty knowledgeable on both Singer and Adler patchers, and I'm hoping for some input and advice. So, I picked up an Adler 30-1, for pretty cheap, and it was cheap for a reason :~) One of the parts it needs is what Singer calls the "slide bar" - I have no idea what Adler calls it. Anyway, mine is broken right where the bar joins the ring. I actually found the Singer part for sale (not cheap), but I'd like to find out if it will fit the Adler - I know some parts will, but this one ? I have a TIG welder, and I could try and weld it, if there's no hope of matching the part - I have nothing to lose, at this point Anyway, this is the part :

-

I may be wrong, on this specific machine, but I think you may be looking at the needle bar height (As some specific dimension over the bed), the wrong way. Needle bar height is adjusted as a function of the basic machine timing - When you time the machine, you set it so that, as the needle bar rises about 2mm or so from the bottom of it's stroke, the the hook will pass roughly through the middle of the needle scarf - This is an approximate description, and the actual numbers will vary in different machines. But the point is, that you need to set the needle bar in relation to the HOOK, not the machine bed.

-

It just goes to show - Sometimes you have to be willing to modify things to make them work . Not everything works exactly, off the shelf. I've had to shorten feet, narrow them, etc, etc, many times, to get them to do the work the way we need them to. BTW, grinders are not so scary if you're careful, but maybe that's just me, because I've used them so often - Keeping a little bowl of water nearby is important, though, to cool off the piece, and not burn your fingers - DAMHIKT Sorry for the thread drift ....

-

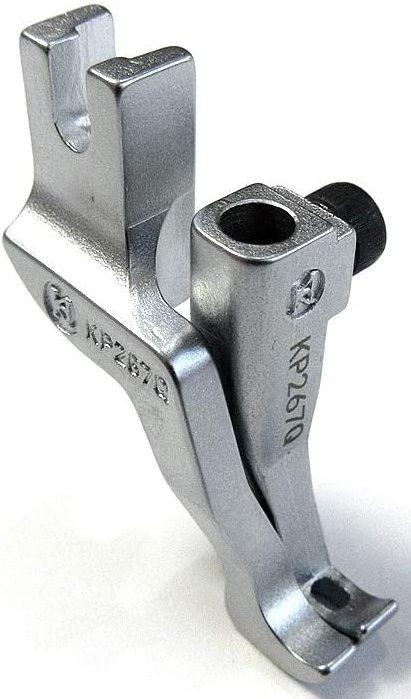

No, AFAIK, that foot set will only fit the Adlers - Very different mounting, and probably why it was expensive. I think it's just satin chromed hard steel, not stainless. I believe that UWE did a little tutorial, a while ago, on grinding and modifying a standard presser foot set to sort of emulate those feet. I think they might have been a little different, though - More in-line with each other. You might look that up, to get some ideas.

-

We've been using a similar foot on our Adler 167 - It does work really well for sewing up close to D-rings, just not the way the ring was sewn in Wiz's photos. Our use is for webbing, where we need to sew up tight to the ring, and turn sharply, to sew box-X patterns, etc, either side - The foot set is nicely made, but NOT cheap.

-

OK - #2 - I'm thinking you mean the threaded hole in the handwheel end of the top shaft ? There's usually a screw there to help adjust the end play - You snug up the screw to get the end play right, and then tighten the set screws on the hand wheel to hold the adjustment. The screw is only needed to help the adjustment - The set screws are actually the the things that hold the handwheel in place - You can also do the adjustment by just tapping the wheel carefully, and then tightening the screws. #3 - If you look at where the reverse lever is attached to the shaft coming out of the lower right end of the machine casting (Clearly visible in your photo, BTW), you see that the lever is clamped to the shaft with a simple pinch bolt - Just loosen the bolt, and you can adjust the position of the lever, on the shaft, in or out, up or down, to suit your preference. Also, by the looks of the handwheel, there was probably a special factory puller, that screwed into those 3 radial holes, and then took a center bolt threaded in to push the wheel off the top shaft - Often the way this kind of thing is done, so you'll just have to improvise, lacking that puller

-

You could try heating the handwheel with a heat gun - It's aluminum, so that might expand it enough to pull off. Other than that, if you've already removed the set screws in the belt groove, you'll need a gear puller, something like this : https://www.harborfreight.com/gear-puller-set-15-pc-62958.html Don't be tempted to use one of those "3 jaw" pullers, as you'd probably destroy the handwheel.

-

Where can I find this part?

trash treasure replied to 4squareleather's topic in Leather Sewing Machines

I don't think they are machine specific - You have to fit them to your machine, which usually involves drilling and tapping holes. -

Screws and Bolts for 111 Walking Foot / Feet

trash treasure replied to suzelle's topic in Leather Sewing Machines

OK - I got to thinking about this while I was in the shower :~) - You probably wanted more concrete advice , rather than just info on thread pitches, etc. Since you live in or near a metropolitan area, look to see where the nearest "Fastenal" store is near you - They sell (among other things) fasteners - Screws, nuts, bolts, washers, etc. Take the screws you want there, and someone will measure them for you - Tell them you want them duplicated with socket head cap screws, and see if they can help you. You'll likely have to buy them by-the-box, and not individual screws, but you'll have lots of extras then. That's all I got, tonight. -

Screws and Bolts for 111 Walking Foot / Feet

trash treasure replied to suzelle's topic in Leather Sewing Machines

Well, if those are the machines in question, then they might be standard metric screws - No way to tell you without measuring screw size and threads. You must keep in mind, that just because the machines take Singer style feet, it does NOT necessarily (and probably not) mean they use Singer screws - Those machines were manufactured on the metric system, and so most likely they all used metric fasteners. -

Screws and Bolts for 111 Walking Foot / Feet

trash treasure replied to suzelle's topic in Leather Sewing Machines

Finding off the shelf screws to fit anything on a Singer machine is going to be tough going - Most every screw is their own proprietary thread. Here's a chart that lists at least some Singer screws and their thread pitches : https://www.singersewinginfo.co.uk/screw_threads As you can see, it's unsure if ANY of them match standard SAE or metric sizes - To do something like you want, you'll probably need to talk to a machinist ...... Good luck -

BZ 15-8 is another name for the Singer 99K, I believe - It's a 3/4 size domestic machine. It was considered a "portable" machine, but not really small, like a 221 "Featherweight". Fine for light domestic garment use, etc - I suppose it could sew very light leather, but certainly not anything heavy at all.