-

Posts

193 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by trash treasure

-

+1 Walk away - Only value here would be if you had a complete one that was cracked in half or something, and just needed the casting. Otherwise, nothing but scrap value - Someone's got a lot of nerve asking that much

-

Suggestions for slowing down machine

trash treasure replied to rockthecasbah121's topic in Leather Sewing Machines

Have you checked that shaft with a caliper? It might be 20mm, not 3/4" . -

I like the 2 speed handwheel ! Show us more pitchers, please :~)

-

+1 - Picture #18 shows the little motor on the back - It's just a Chinese 15 class clone, home type machine

-

Anyone recognize this machine

trash treasure replied to GaryTullos's topic in Leather Sewing Machines

7 Class - Very Large -

Singer 91K5 Glove Sewing Machine Parts

trash treasure replied to humanshoes's topic in Leather Sewing Machines

Have you thought about trying to get a looper from one of these Chinese glove machines, and seeing if it might fit, or at least be adapted ? The Chinese often copy and modify existing designs for their sewing machines, and who knows, maybe the looper is the same - Stranger things have happened ........ -

Changing out a handwheel with a motor pulley

trash treasure replied to leecopp's topic in Leather Sewing Machines

It doesn't have to be painful if you use the right pulley - Here's the pulley I used on our Singer 111 - It's a Browning sheave that's specifically made for a 3L belt, which means that the belt rides at the top of it's groove, and forms a nice comfy surface for hand wheeling -

Simple Singer 241 large hand/balance pulley Mod

trash treasure replied to Sledzep01's topic in Leather Sewing Machines

I think he used the shaft collar, in his first link, as a sleeve - It had a 15mm bore and 25mm OD - Pretty close fit for a 1" bore pulley. Oops ! - It looks like already answered - Sorry -

Consew 206RB balance and tension in reverse issue

trash treasure replied to MAlan's topic in Leather Sewing Machines

Uwe is 100% right - We use a #21 needle with 138 thread, for sewing webbing - But that's relatively soft, and the knot buries fine - For leather, you want something larger yet . -

With a machine that heavy, I don't know how much head tilting you'd do anyway - I have an Adler 20, and the normal set up has the machine submerged in the table to the bed top level, and hung by steel straps, about 2½" - 3" down under the table top. At 200+ lbs, you'd need to lift it out, or crawl underneath, like servicing a car

-

Thank you, Uwe ! This is very similar to the way my machine is set up - I will check this out, and see what's what :~) It is a mystery why this info is not in the manual - Maybe they figure you're just supposed to know.

-

This is NOT about a leather sewing machine, but it IS about industrial machine adjustment - I recently picked up a couple Pfaff 463"s with tables & motors, for our shop - Cheap - Just plain high speed garment machines. One had a broken timing belt, and the other (in better shape overall) had a "newer" replacement belt installed. So, I downloaded the service manual, and got the one with the belt set up, but there is an obvious problem - Although the hook / needle timing is on, and it picks up and makes a stitch, the tensions are so far out of whack, that the normal adjustments of the upper and bobbin tension, and take up spring make no difference. At this point, I'm thinking that the upper and lower shafts may be out of sync, and as a result the take up arm is not acting at the right time. I know that Uwe said, in a recent thread, about timing the take up with the thread passing the furthest point of the hook, but I don't know if I want to trust that, as I think the hook may have been moved enough to compensate, somewhat, for the shafts being out. Also, this machine has a rather complicated bobbin case opener, timed to the hook, and the adjustments for that were not quite able to be set in the range the manual shows - So, I'm wondering ....... So - Is there some basic way to check the synchronization of the shafts ? There is NOTHING about timing belt replacement for this machine in the service manual, NO marks on the bed or pulleys, and nothing anywhere I can find on the web

-

Another one to add to the list : Pfaff 438 - Really nice machines http://www.ebay.com/itm/PFAFF-ZIG-ZAG-438-sewing-machine-Industrial-HEAVY-DUTY-Used-/162694648820?hash=item25e15b53f4:g:m8IAAOSwQm9Z0lex

-

Those drive screws can be a bear - Especially when they're holding a fragile raised relief badge like the singer one. I've had pretty good luck with just carefully masking the badges - Scrape the paint off around the badge first, and then mask the badge with painters tape, carefully burnishing the tape over the edge, and trimming with an Exacto knife or razor blade. If you want the badges off, then start with a small straight punch with a good crisp, square tip, and a small hammer. Hold the punch at a low angle against the side of the screw head, and tap the screw a couple times, from different directions, sideways - This will usually loosen it up in it's hole. Then you'll need to get under the edge of the screw head (or the badge itself) with something sharp and sturdy enough to pry with - A small sharp wood chisel will work. Maybe a sharpened putty knife, etc, to start with - Creativity helps here :~) If you need to get new drive screws, you can find them at McMaster Carr - Their stainless ones are kind of attractive ...... Be patient, and good luck

-

What about this machine?

trash treasure replied to WoodysWorkshop's topic in Leather Sewing Machines

NOT a Singer - It's a Japanese 15 class clone. OK domestic machine, but as other's say, not even remotely close to industrial. -

Singer 45k1 Restoration Decals

trash treasure replied to Parfektionisto's topic in Leather Sewing Machines

If you decide to use decals, you might look for something like this : https://www.amazon.com/Micro-Setting-Solution-Microscale-Industries/dp/B0006O9K5Q It's a special solvent type stuff, that softens the decal, and makes it "suck" down onto an irregular surface -

HA! I was just about to post, and suggest this - Like leaf springs on a car ............

-

If you're willing to give a shot at making one, have you tried McMaster Carr ? They have spring steel in many sizes and thicknesses : https://www.mcmaster.com/#standard-spring-steel-sheets/=18t37pq

-

Have you tried this guy : http://www.sewingmachineparts.net/timing_belts.html I'm not sure, but he may be the guy I found a couple years ago, that was RE-MANUFACTURING linen cord belts for old Pfaffs, etc.

-

Also totally off topic, but not about the bars at least That photo of the 8 class machine - How did they control the speed when it was hooked up to a line shaft, like that one was set up for ? Was there a clutch they could feather ?

-

We drove this Adler about a 5 hr trip on a utility trailer - Part highway, and part not-so-nice roads. It was on casters - 2 good ratchet straps - NOT a light machine, and nothing moved a mm, nothing broke. Unless "someone else" is moving it for you, I wouldn't overstress - If you're paying someone to do it, then you can worry That must have been a rough trip, Colt !

-

I can't speak for their polyester, but we had a bad experience with some, supposedly bonded, nylon from Superior. It was 2 spools of black 138, and although sold as "bonded", would literally unravel in your hand, as it came off the spool. It also had a funny, "wrinkly" look to it. We asked for new thread, thinking it was just a bad lot or something - The 2 new spools they sent were the same way. It would start separating as it went through the machine tension - NOT good Just sayin'

-

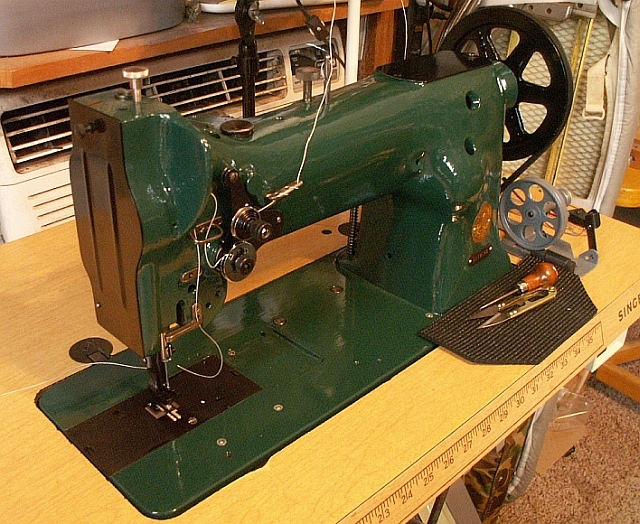

OK, show and tell time - Here's a 111W155 I bought for $50, and finally got around to rebuilding, a bit over a year ago. It was in pretty rough shape, but came with a reasonable table and a truly massive Singer clutch motor. I replaced a lot of parts , new bearings, take up link, etc, etc, etc - It wound up costing a little more than the original $50 ;~) As you can see, it's been "modified" a little, with a nice 6" Browning sheave I found on e-bay for a couple bucks.The best part about the new pulley, is that it's grooved for a 3L belt, so the belt is exactly flush with the pulley edge, making it a comfortable handwheel. I covered the resulting "joint", between the machine and the new wheel, with a "sleeve" I machined - It attaches with a hidden set screw It has a 750w servo motor now, with a 2" pulley, and has a LOT of low end power, and excellent control - A pleasure to use. I also modified the table a little, cutting the left edge and hinging it, to save space . I also put it on wheels, so we can move it around, and use the big work table as an outfeed. We usually use it with V138 thread, mostly for heavy webbing, canvas, sailcloth, etc, but sometimes leather - It has sewn anything we've been able to fit under it, so far. And yes, I know it's green, but I had some green paint, and ............ We just refer to it now as the Green Machine That's what I got for today

- 42 replies

-

- leather sewing machines

- what machine is used for leather

-

(and 13 more)

Tagged with:

- leather sewing machines

- what machine is used for leather

- professional leather sewing machine

- which leather sewing machine is best

- best machine for sewing leather

- sticky???

- sewing leather

- best antique leather sewing machine

- best new leather sewing machine

- leather sewing machines makes and models

- what machine do the pros use

- leather sewing machine reviews

- leather sewing machine opinions

- best sewing machine

- leather sewing machine question

-

Mine is GREEN ................ :~)

-

Get a set of Chapman gunsmith screwdrivers - Wouldn't be without them : https://chapmanmfg.com/collections/slotted-flathead-sets/products/8900-standard-set-12-slotted-bits