-

Posts

122 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by HondoMan

-

John Deere Green

HondoMan replied to HondoMan's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

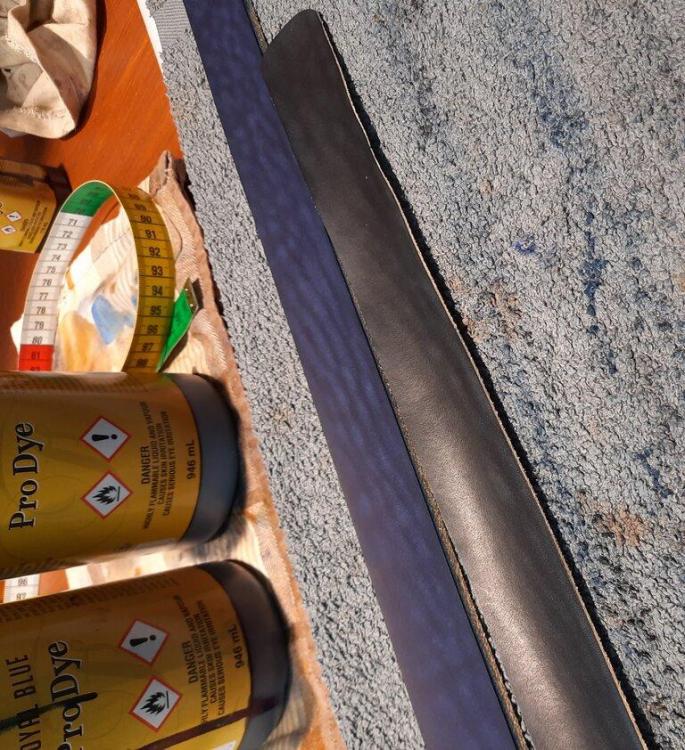

Should have updated this thread last year. Found a leather supplier in Italy I use for the odd item request. They stock a stunning green that matched the customer's tractor rather well, I reckon. Used Tiger yellow thread. Regardless whether I like it or not, the customer did. -

Good idea. I'll give it a wee go. Cheers!

-

Right then, Hand-sewing in zips. This really does get under my skin. I do them, but it brings me no pleasure. The problem surrounds the gluing in. I have tried contact glue as well as PVA. Neither of these adhere to the zip material. Ok, a wee bit. But I found the zip moves, which creates an non-straight zip. I have been using a double sided tape for the past couple of years. This does work well keeping the zip in place; however, the adhesive is all over my awl and needles. Urgh! Now I have to wipe the residue from the tape off my awl and needles about every five holes. The residue and tape also do not allow the awl or needles to move smoothly through the leather. There has to be a better method. Some type of adhesive that will keep the bleedin zip still and won't smear adhesive all over the tools. Ideas? Cheers!

-

In Germany, we refer to the round knife as a Halbmond Messer (Half-moon knife) and the head knife as a Viertelmond Messer or quarter-moon knife. For what it's worth, I agree with gmace99 and pabloz. Names are important when referring to tools. Want a hammer? What type? Cobbler's hammer, claw hammer, tack hammer, dead-blow hammer, maul, sledgehammer... etc. Giving anything the wrong name is a sign of ignorance. ... bird's head you dumbass. Brilliant!

-

Searching for an odd machine oil. Assistance.

HondoMan replied to HondoMan's topic in Leather Sewing Machines

This is the nearest thus far. Cheers! -

Searching for an odd machine oil. Assistance.

HondoMan replied to HondoMan's topic in Leather Sewing Machines

If you don't understand the numbers, then why bother with an answer lad? SAE 30 motor oil has a viscosity of 271mm2/s at 20C. Defo not the correct oil. Motor oils are utterly different from sewing machine oils or any other. An equivalent to sewing machine oil is mineral oil. I would no more put motor oil in a sewing machine than I would sewing machine oil in a car. -

Right then, we recently purchased a Pfaff 335 H3 sewing machine. This is a massive learning curve for us who sew by hand, but we are making progress. The topic of oil rose it's head during the learning phase. The machine handbook, albeit is 40 year old, states, "Only use oil with a viscosity of 41,4mm2/s at 20° C and a density of 0,84kg/dm3". We have tried to find oil with this viscosity but are not having luck. As we are in Germany, we asked a German forum - no joy. This machine needs oil often , so we are hoping to find something quickly. Thank you all in advance. Cheers!

-

Right then, never thought such a request would happen here, but seems it has. A regular customer of mine has bought an old John Deere tractor. He wants / needs a place to store a soft bound wee book. Seems there might have been one on the tractor previously, as there are two holes on the right hand rear fender. Regardless, he was not after anything stunning, but when he brought the tractor round the shop so I could do measurements, I mentioned doing it in John Deere green with yellow stitching. Aye, he was sold! I've been on experimenting to get the proper green, but cannae get there. I've been mixing Pro Dye green with yellow and with spirits to find the green, but no even close. A entirely different shade of green. Have any of you lot (especially Americans due to the amount of John Deere users in the USA) a mix ratio for the stunning green colour? Looking forward to the responses. Cheers!

-

To revive a 5 years old topic.... What would the job or title of the craftsman who made knife sheaths? Can't seem to find that wee piece of info. Pouchemaker? Girdler? Glover? Loriner? Saddler? Most like no to all. I've often wondered who, in the 12th-16th Centuries, made things like knife sheaths and scabbards, arm cuffs, and the odd things the above didn't make. Ideas or thoughts?

-

Something's off, and I cannot figure out what exactly.

HondoMan replied to HondoMan's topic in How Do I Do That?

Seems I need to add more to this. When I'm about to begin cutting, I cut away the unusable edge with a straight edge. The straight edges are not light and have a good weight. So, I'm already working with a straight edge of leather. If you're unfamiliar with a rule stop, it's basically a wee block of wood on a slide rule with a tightening screw. Aye, it's made to fit the rule. By no means fiddly. Set the stop to the desired length. Pushed against the edge of the leather and with the scratch awl, mark the leather. It's understood that leather natural and sometimes have wrinkles. I use old cast iron heavy irons to keep the leather flat or clamped down. All answers I've milled about in my head. What is being overlooked folks, is that it is always...again always the middle mark. The marks to the left and right are always spot on. -

Something's off, and I cannot figure out what exactly.

HondoMan replied to HondoMan's topic in How Do I Do That?

All rules in the shop are straight. I checked them when initially bought. I learned that a donkey's age ago. I don't think it's the table or how it's laid atop. Aye, the 3cm example was poor. For 3cm I will use the strap cutter unless I'm working with 1mm thick leather. But still occurs when I'm cutting 30cm leather. This is merely an odd matter I'm trying to get my head around. It's not causing major issues, just gets on my arse. -

Right then, this involves cutting leather. Yawn.... a wee bit of background. I have two rule stops in the shop. One is 60cm long and the other is 30cm. Both work well. When I set the stop, I check it against another rule to ensure it's set properly. I also have two straight edges. One is 100cm and the other 45cm. Equally solid tools and are incredibly straight. Had all these tools for a number of years. These lead to a rather odd problem. Regardless of the leather used, this seems to occur often and oddly I haven't noticed it until a number of months ago. Let's say I need to cut a strap 3cm wide. I'll use either rule stop, set it, check it and mark the leather with a scratch awl in three places. Left side, right side and the middle. The marks are neither deep nor long. I then set one of the straight edges down, line up the wee tick marks and the middle tick mark sits 2-3mm above the straight edge. Again, regardless if I'm using 4mm vegtan, bridle, harness, or 2mm pull-up. Any of you lovely lot have ideas? Anyone else encounter this issue? Cheers!

-

Might I ask what you paid for the splitter? Seems I have the opportunity to buy one as well from Denmark. I don't have a price yet, but it would be helpful to compare. The one on offer has been renovated, but from the photo I've seen, only the mechanical parts. Cheers!

-

I think, perhaps, I have a solution. I've been purchasing wet-dry paper from a guitar shop for my awls. These are between 500 and 12000 grit. Seems they sell various lengths! I have a bench grinder with a sanding drum on which I can attach various grit paper. I just ordered some for the drum, so I'll see how I get on. Cheers!

-

Right then, I recently upgraded my strap end punches. Blanchard. While I do like Blanchard tools and own quite a few, these were expensive and have taken time to order. Dull, would be an overstatement. I doubt the punches would cut through wet dough! I made the mistake of asking a mate who owns a knife making business to see if they would be able to put an edge on one of the rounded punches. The edge of that punch, while sharp(er), is jagged and rubbish. I have looked under 'Sharpen it' and scoured the Internet for a video. Nothing. How does one sharpen a rounded punch? Along the edge or pulling? Twisting or turning along the edge? I don't wish to destroy the edge of these as they were no on the cheap. Cheers!

-

To drive the matter home with the manufacturer, I had placed some wee washers to the right of the blade on the screws, which pushes the blade away from the measure and is now near spot-on. Shouldn't need to do that, though. Took photos and sent to the maker. They only now understand the issue. FFS.... They've contacted the engraver who mills the measure to correct that part. A corrected part will be posted after QA ensures it's correct. FFS...a tool maker should well understand the need for simple maths ensuring a measure is correct. In the meantime, jerry-rigging a new 400 Euro tool will simply have to do.

-

Right then, a question for the hive mind. I am leaving out the maker's brand / name for a reason. I am, however, interested what you lot think on this. The measure part of the gauge is offset by 2.5mm. The blade is 1.8mm thick. Let's say 2mm to make this simple. With a properly sharpened bevel, the edge of the knife would be centered to 1mm. Therefore the offset would be 1mm. Due to a 2.5mm offset of the measure, each time I use the plough gauge, I need to calculate an additional 1.5mm. Am I making sence? I'm never owned a plough gauge. I've always used the pull gauges. This seems odd to me or am I missing something. Thanks in advance and looking forward to the replies and opinions. Cheers!

-

Something is off with this leather...?

HondoMan replied to HondoMan's topic in Leatherwork Conversation

After dying it a total of three times, with 24 hours between, that marbling is near on gone. In the sun one can see it, albeit only a wee bit. I agree that it is unique to have the marbling and near on impossible to create, it would be too much bother to have it on offer. Perhaps the next butt doesn't have the effect and a belt or bag was order for such. Problem solved and learned something. -

Something is off with this leather...?

HondoMan replied to HondoMan's topic in Leatherwork Conversation

I was away yesterday, so unable to respond. To be honest, a colleague and good mate in Austria died and I was attending his funeral. His tooling was fantastic. Be that as it may, before I left, I dyed the leather one more time and let it sit for 24 hours. This morning I took a wee peek and it appears better. That marbling has lessened. I'll do it one more time and see how it fares. To answer some of the questions above: Aye, I have bought butt from this tannery before - many times. Never an issue in the past. As I stated, I did a blue belt about a fortnight ago and there was no issue. I would expect marbling from belly, but I never use belly - haven't since a donkey's age. This leather comes from Italy. I buy either from Italy or England. We do have a tannery here in Germany, but I stopped buying from them about a year or so ago. As far as being perhaps a less expensive leather, I pay roughly 200€ for a double butt. I wouldn't call that on the cheap. I believe the end result will have a very light amount of marbling, but not overly noticeable. I do appreciate the comments and info you lot have offered. Enjoy your weekend. Cheers! -

Something is off with this leather...?

HondoMan replied to HondoMan's topic in Leatherwork Conversation

I shake all liquids before use. That's not the issue. As one can see, the black did it as well, as you mentioned. I can't sell the belt this way, unless I can sort out the marbling. I'll cut another piece off, dye it and see what can be done to even the colour out. If not, I need to contact the tannery. The info on the fats in the leather possibly causing the marbling is helpful. Cheers! -

Right then, ordered some vegtan butt, which arrived this morning. It appears spot on and I've never had an issue with this tannery before. I cut off two strips for a belt in the making and dyed both. I immediately noticed an odd colouring and marbling. I just completed a dark blue belt about two weeks ago without issue using a different leather. It near on appears purple and this marbling effect... I did a test piece of the blue and it looks as it should. I need to contact the tannery, obviously. This marbling effect... is that from the tannage or the bull itself? The fact that dark blue (Pro Dye) is leaving this a slight purple, it makes me wonder on the tannage. I am unsure what caused this, hence asking here. Cheers!

-

Odd shaped tool....toolroll...ideas...?

HondoMan replied to HondoMan's topic in Patterns and Templates

The ideas are brilliant, you lot. Regardless the outcome, I'll post a few wee photos here. Due to current orders, it will be around August, I feel. -

Odd shaped tool....toolroll...ideas...?

HondoMan replied to HondoMan's topic in Patterns and Templates

Aye, git the jist.... boot nooo. Had a wee craic with the owner. We're gooin with what ah sed, boot with wee 'parachutes' on each end to aye deck tha noon threaded part. To clarify that, the threaded ends will lay next to each other in the 'pen sheath' with the rope tie ends out - five per side. Then two round pieces of leather covering the non-threaded ends. These will be secured in a parachute fashion to each other. Lastly, there will be a carry strap. Robert is your father's brother! -

Odd shaped tool....toolroll...ideas...?

HondoMan replied to HondoMan's topic in Patterns and Templates

@toxo, aye I agree. This is a non-starter. I ran a belt idea by the customer, initially, but he was against it. He wants to be able to pack the screws in a rucksack. I came up with an idea this morning and it will be similar to yours, albeit different. To a degree it will be roll-able. Laying each next to each other (threaded part) on a 'belt' and the thread part covered much like a pen sheath. The unthreaded section will be exposed. Five on one side and five on the other. A wee piece of leather through one of the holes - stitched to the belt on one end and possible a popper on the other attached to the sheath for the threaded part. This should allow it to 'roll'. Could also add a buckle and strap to the opposite ends when laid flat so it could be worn over the shoulder, just as convenience. Thanks for the input and your idea. Cheers! -

Fiebing did make white and grey dye once, but no more. To counter it, I've ordered white and grey from the tannery. Even from a tannery, can be daunting to find. As a home recipe, perhaps this might be helpful: Don't know if it works, but this lad seems to think so. Will take quite a bit of time.