ke6cvh

Members-

Posts

75 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by ke6cvh

-

Hello group, My contact here overseas offered me a Juki LU-563 that has been "overhauled" for 400 dollars on the head. With a new 750 servo motor and a new table it will raise price less than 200 dollars. Reading up on the threads I see there is a spring that can become weak. He did not tell me this problem and I asked of course how tight the machine is and was told it is very tight. I asked I think it was the third time and was then told the spring had been doubled and then someone had tack welded the pulley so that the safety clutch would be bypassed. Looking I can see the 206rb has it and already knew the 112w had it. He tried to tell me the 212w does not have it but a google search showed it does. My Singer 45k1 does not have it and I think but not 100 percent the Cowboy cb-4500 here does not have it. I remember Bob Kovar mentioned to hold the thread back at 2 o'clock or if the thread got hung on the hook it could knock the machine out of timing so I'm assuming no safety clutch on that machine. Assuming the machine is in fact tight and this is my only concern my question then is what happens when the thread gets all caught up? Will I damage the hook assembly or the machine or just knock it out of timing without the safety clutch? I need to decide by tomorrow as he already had it in his car and was driving home. He thinks I will be careful sewing and in fact that is mostly true (nobody is perfect) but if I have a sewer and that person hits a zipper with no clutch then a broken needle and/or timing knocked out or more extensive really bad damage? Advanced thanks and best regards, Mike

-

Cowboy cb341 to Juki ls341 accessory compatibility

ke6cvh replied to ke6cvh's topic in Leather Sewing Machines

Hi Bob, The reducer has just the slightest wobble to it but the belt negates that largely. We used local pillow block bushings. These are our other patcher stands in picture. China patchers taking a 7x3 needle on one and a dd214 needle on the other. Metal is soft so they are no Adler that is for certain. I'm not certain yet on the medium duty cylinder arm compound feed local or not but what I am certain of is that on a machine being used at higher speed than a patcher and seeing lots of use I'll go any day of the week with your speed reducer. I have read some posts and some of the leather workers have a trio of a cb4500, a patcher, and a medium weight cylinder arm with added bed option when needed such as a Juki or CB341. Wouldn't even be a consideration if I was in USA but I'll be able to make a decision soon enough on what is being offered locally. Gotta be real careful to balance what is available local and what is better off from USA. Best regards, Mike -

Cowboy cb341 to Juki ls341 accessory compatibility

ke6cvh replied to ke6cvh's topic in Leather Sewing Machines

Hi Bob, I'm still on the fence regarding this machine and need to know allot more about it. My thoughts on 207 top and 138 bottom is that one will get added abrasion resistance and strength on the top portion. Understand that a chain is only as strong as it's weakest link etc.....but if the stitch normally fails because of wear and tear on the top and it looks better that is all a bonus. I've used 415 before on top and lesser in the bobbin with our circa 1915 Singer 45k1 with great success using braided made in USA poly (which must feed from side of cone). I'll be in contact with the gent tomorrow. If it is not an "N" then I will likely walk from even considering it any more. Problem here is sometimes they people scratch name plates to hide sub models and remove name plates. I can ask for a picture of the needle plate if it is an easy way to identify this aspect and also the name plate? Again I'd much rather buy a Cowboy from you for many reasons. Nice tables, included speed reducer, guaranteed support and accessory compatibility, nice DC brushed servo. Problem of course is the extra money and time getting it here. By the time it's all said and done I'm adding about 1k plus in costs to get that machine here because the table, machine, motor, etc. Was 1000 percent worth it on the cb-4500 you sold me but for the extra money I could likely buy a new machine from the Juki dealer here for the medium weight compound feed cylinder work. They also have the DSC-246 available (I got mixed up that is the one for feeding V type bias folded) and likely would need to be set up for this lower feed dog to work with missing eccentric/cam lobe if that is the part they need to include. I'm thinking the smaller cylinder arm is not worth the added inconveniences. dI've not asked on the 1341 yet but know they can get that as well. If it is an "N" and they want to reduce price if the table is a hack job and they want to do a 750 watt servo I may just buy a speed reducer from you. The speed reducers I diy'd on the patchers don't hold a candle to the one you sold me. Attached is a picture of one of the diy tables with diy speed reducer for one of our three patchers using similar diy setup. Since this picture we added some custom stainless steel drawers to your pedestal on the Cowboy in the picture Best regards, Mike -

Hello group, I'd much rather buy a new cb341 but have one locally here overseas being offered to me with table and motor for 1400 USD and no shipping or taxes. I'm almost tempted but getting clarification if it is an "N" version or not. Does it really matter much between the N and the older 341? Are all the accessories on the Cowboy cb341 fit the ls341 and/or ls341n ? I have my doubts on the table and will look into all this. Likely we can make a much better table ourselves and it might be a point of reduction in price. Also, it's not going to come with a speed reducer and that is yet another possible issue. Last, I'm seeing both 138 and 207 max on the ls341. What the deal with that. Is it really problematic does the cb341 and/or ls341 sew an honest 207 in bobbin and top ? Or is it 138 in reality for limitation on the bobbin? Did see a post about one being set up for feeding tape and subsequently having issues with the feed dogs so I'll need to look into that also. Best regards, Mike

-

Hello group, I hesitated for a really long time to buy a patcher because all the negative comments I read. Now I have 4 on hand in a month's time and considering buying an antique Bradbury A1. A couple of things I've noted. I bought a "2972b" China clone which seems to be the same as a Techsew 2900 costing much more. I bought on Amazon for 899 because they delivered to my overseas location but it shipped from USA. There was a washer missing on the hand wheel but we fabricated that easy enough allowing proper dis engagement of it for bobbin winding (it would over tighten and be next to impossible to release without the washer). The different sized needle holes are actually the same size on the plate of this machine but again no big deal as I can change that. It sews like a dream and it is as close a copy as they could make with interchangeable parts generic available on internet. So then I bought the tiny low cost China patcher. They are starting to go up in quality. The bearing on it is a modern sealed bearing. Many of the parts are chromed. It has an honest 1/2 inch lift and can do that 5-6 spi at 1/2 inch thickness going through 16 layers of medium weight denim exactly 0.5 inch. It cost me 177 off Amazon. Not all are equal. So then I bought two patchers from Robin industries out of China. 165 for their four different models before shipping. Here in Philippines I paid 75 Fedex, 12 US dollars tax, 25 bank wire fee from US bank. The first was an RC32-3A. It takes a system 7x3 needle up to size nm250. I sewed v346 right out of the box and haven't tried anything thicker yet. The bobbin on this machine is giant compared to the larger of the two Singer bobbins on a 29k72. It has a built in roller guide (but there are youtube videos on how to make a sliding and simple cloth guide that clamps onto the wings rotating the universal feed). The next one is a Robin RC32-2A post bed. It had a minor issue going above v138 thread that I fixed with a little work in 1 hour and now goes up to nm250 as well but this machine takes a Singer 45k1 needle (dd214). So now to my comments on production work. That is an interesting statement to make. We have 5 dozen industrials. We try to keep pairs or more of every type. In a factory one thing is for certain there will be machines dedicated to each portion of a stitch operation in the assembly process. Do I believe these machines could be used for production purposes? Absolutely! If used in a certain stitch operation that others cannot perform which will limit them in use but at the same time allow them to do a tiny procedure others cannot perform. The bulk would be done on flat beds and cylinder arms and the tiny little portions that only they can perform would be on one of these. A classic example is my circa 1917 Singer glove stitching machine that is a post bed and a chain stitch.....I'd never use it for almost anything but then again if I was to sew fingers on light leather gloves why not? Doesn't look like an industrial and is much smaller than most domestics but it still is/was a production machine. We are currently making mad tables for all these and we will post them as they are completed. Yes, these patchers don't touch a candle to the Cowboy cb4500 Bob Kovar sold me but then again there are times they can do things the Cowboy can't do (production or non production). Best regards, Mike

-

This is an amazing thread that I appreciate very much for it' s information. I can see these tension assemblies for the Singer 111w through Consew 206RB on eBay for just under 10 US dollars. I am planning to install one of these on a cheap Chinese leather patcher (we actually have 4 different types with one of them being a clone of a Singer 29k72, one being the tiny one people many times buy, one being a heavy hitter rc32-3a taking up to nm250 and max 3.5cm thick/min essentially zero thick, one being a post bed rc32-2a with same bobbin as the large version of the 29k patchers). I see lots of people on this facebook group for patchers install aftermarket tension assemblies but they are always removing the check spring. The 29k72 clone has a leaf spring on the take up lever that is adjustable but my suspicion is that it is a crude and inferior version of a check spring. The other three low cost patchers only have a spring on the take up lever. My suspicion is that everyone who is experiencing stitches with upper loops occasionally are having one of two issues. One is the known issue of allowing the hand crank to go backwards even a tiny amount during a cycle. The other likely is a crude or completely missing check spring assembly. We are installing diy pulley reducers and 750 w BLDC motors with a total reduction of around 6:1 in speed. We want good control not so much the power available from the motor as we'll be sewing very slow on them. With the pulley reduction and servo the backwards motion is a non issue. I prefer Bob's brushed DC motors but these do have an advantage in that there is no brake pads. If I'm going slow anyways I don't think I need the brake pads anyways (and the motors were easily available with same pulley shaft as clutch motors allowing me to change to different sizes). My suspicion is that this information, coupled with the assembly same as one in Uwe's video and discussion will vastly improve quality of stitching (when properly adjusted). Best regards and many thanks for contributors on this thread, Mike

-

I have a couple Singer no 2's. One is an "Imperial" and I'm in the process of verifying the other is also. Here is a quote from the needlebar.org manual for the Singer model 2/3 user's guide. Lead oxide mixed with linseed oil? Likely I bet it works darned good just don't breathe the stuff. "For stitching patent leather and other materials which are hard and difficult or perforation, the Imperial Machines are used. They are furnished with an iron cup, to hold a drying oil. Boiled linseed oil, prepared with litharge in the manner used by painters, is the proper oil for this purpose. The effect of thus oiling the thread is, to prevent heating the needle, and to make the stitching of leather as rapid and easy as cloth sewing. The silk twist, after being oiled, rapidly dries, and is left with its surface as smooth and perfect as if no oil had been used – and the firmness of the seam is improved by it."

-

40W Chinese Laser - Engrave and Cut Leather - Discuss

ke6cvh replied to Billy Hell's topic in 3D Printers and Lasers

Hello group, regarding the comment about having a hard time getting one's head inside the case.....the real concern seems to be the laser reflecting off anything and in the video link provided how the alignment was way off. I'm shopping for a laser myself but need a larger work area so I can use it for various things besides also leather. I'll google alignment procedures done safely. The "sunglasses" provided with some of these surely are part of the solution as well as using a lowest power setting while aligning but there certainly is possibility of injury to the eyes if the wrong mistake is made. With a larger unit comes more potential for accidents as the cover is lifted. Best regards, Mike -

Will the Weaver implementation be manufactured in USA? If so, that is a huge and I mean huge marketing difference that will spread like wildfire. If made in china nobody will have interest for the most part. Just my 2 cents and also my personal power as a consumer and my ability to choose. Best regards, Mike

-

Hi Bob, You confirmed many of my suspicions. Are the newer Cowboy 29 clone patcher with 18 inch arm and heavy bobbin white or grey? I'd like to get a matching color to the cb-4500 that you sold me already. I know that sounds vain likely but they'd be installed next to one another. That cb-4500 is a great looking and working machine. We have a drop down roller guide coming and the serrated under feed dogs. We'll take it a step at a time from there. Best regards, Mike

-

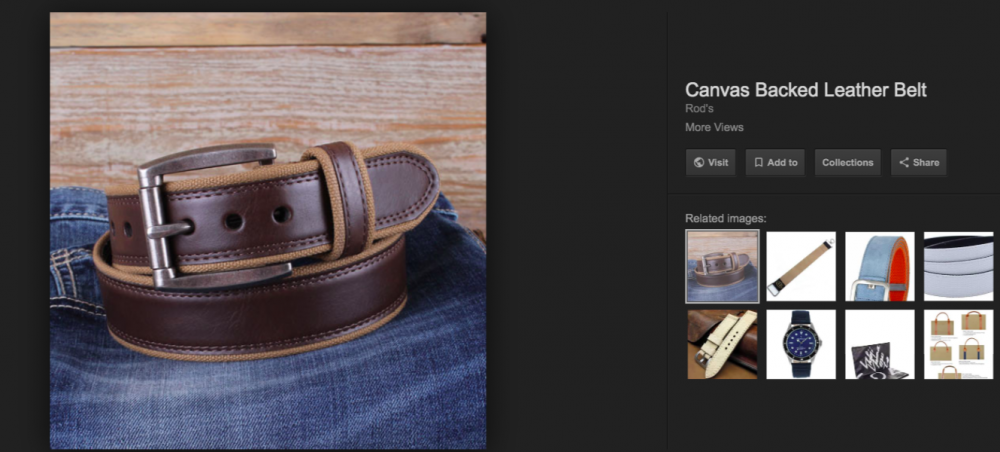

Hello group, I'm preparing for my first leather (sort of) project. We have made some packs and want to try canvas backed leather. Wiz already responded it can be done and thanks very very much Wiz for taking the time to mentor (elmer) me so far. If this was a bigger panel should I use decorative stitching to secure it better to the canvas or just sew around the edges? I'm thinking since this would be potentially the bottom and a little up the sides it'll only be necessary on the edges while giving me a cool look and added abrasion resistance. The canvas backed belts I've seen on the internet almost look like there is a small piece of cord sewn into it as it's folded over. Sounds like a really good pack strap. Here is a picture I found the belt that seems to look best. My thought is to use two layers of leather sewn together with the canvas in the middle of the pack strap and possibly folded over a cord on the inside edges of the canvas giving a layered look of leather back, canvas middle with cord inside edges, leather top all in reducing widths as sewn on. Any ideas or comments like can I wax the canvas backing after sewing it all together without damaging the leather? Best regards, Mike

-

Thanks again Wiz, Really big help. Best regards, Mike

-

Newly received Cowboy CB4500 blanket foot adjustment

ke6cvh replied to ke6cvh's topic in Leather Sewing Machines

Hi Wiz, OK got it adjusted but there is something strange going on. Sometimes when the outer presser feet toes are adjusted downwards then tightened up then they do not move and then other times they did. So I just fiddled with it until it works ok then adjusted the 5mm allen to balance the toes and inner vibrating foot. Not sure what was going on but problem solved. Now, I'm going to wait for the under feed dog with teeth. The canvas will be my main material (besides denim) until I source a local supply of leather overseas here. Trying not to waste material so testing on available scrap and can sew down to a single layer of denim with size 207 and well formed stitches after adjustment. Pretty amazing for such a heavy duty machine. After that I adjusted the spi from 4 up to around 7 or 8 stitches per inch. I might try some braided poly later but will need to rig up a sideways feed as the braided can't come off the top of the cone like twisted can. More use and testing on the machine. Thanks for the help. Best regards, Mike -

Newly received Cowboy CB4500 blanket foot adjustment

ke6cvh replied to ke6cvh's topic in Leather Sewing Machines

Thanks Wiz, That is an easy one to adjust the presser foot bar but I did not want to do it without QA'ing with someone else first. Is that UWE the only liftable roller guide available for the cb4500? It looks like a Chinese industrial lifter with an adapter that has been made for it but that is just a guess....or maybe they are making one right out of the box? I have a lifter roller foot I bought for a different machine and not installed but might give it a try. The one supplied is really good for leather but not working with canvas necessarily. Now I need to source leather here over seas. Best regards, Mike -

Hello group, I finally got the Cowboy CB-4500 and setting it up over the last couple days. Went to change the harness feet to the blanket feet. Realized there may be a serrated feed dog and sure enough called one on order. Realized there is a drop down guide and even though I got a guide I'd like to be able to install the drop down guide for work with canvas so working on that. My big problem with the machine right now (actually no problem with the machine but problem with the operator...me) is that the outer toes on the blanket feet go nowhere near making contact with the material. Saw a video by solar leather where I can take a 5mm allen wrench and adjust the balance of lift between outer toe and inner vibrating presser foot. However, I don't want to loosen anything unless it is the right one. Which piece/part will I need to loosen to allow me to drop down the outer toes on the blanket feet? This is a really nice machine. I'd like to first try sewing some canvas packs so want to get that blanket presser feet working. Advanced thanks and best regards, Mike

-

Hello group, I'm hoping to get my cb4500 on line that Bob sold me in less than 2 weeks. We had to get three crates shipped overseas and I have received 2 with the 3rd on the way so very excited with my fingers crossed from a gent who has been helping me with shipping. The head is here, most of the table, just need the motor, hand wheel and some odds and ends parts. We have a good 112w-139 compound feed also purchased from Bob and a circa 1915 45k1 bought locally. I was offered an 1800's patcher and love vintage machines but am likely going to pass as I need something I can rely on especially if I want to go up to size 138 thread and the longer 18 inch arm with the heavier bobbin. Read a post about a long arm Adler and how exceptional this machine was on a motor up to 138 used for small production runs. Ran across a company on a famous auction website called Axis. They make a long and short arm and I'm not sure about the different bobbin sizes yet. Does anyone have experience with the Cowboy long arm large bobbin or the Axis machines? Best regards, Mike Kendall

-

Hello group, Currently my heaviest machines are a circa 1913 Singer 45k1, a hand crank Frobana (honestly haven't used it yet but own one), Singer 112w-139 (thanks Bob at Toledo), and I'm currently waiting for a CB-4500 Bob sold me some time back with all the bells and whistles. We have lots of lesser machines for medium weight work. I'm an American living overseas so have to be exceptionally patient and inventive on how to get stuff here. Was studying the Pfaff 545 and that looks to be an amazing machine. Found this video linked below on youtube where a sharp gent figured out how to make a synchronized binder. He has a feed dog with a hole in it then uses a long piece of 1/8 inch maple to accomplish the rest from a pivot point on the far end of the maple. Is it possible to DIY a right angle synchronized binder for the CB-4500 or is that an already available option (I'm thinking not)? Best regards, Mike

-

Hi Bob, I'm not sure how I missed your comment on the 135x17 or maybe I forgot it and read it long ago. Will both the needle bar need to be adjusted as well as the timing? That is really good and appreciated advice. Thanks! Best regards, Mike

-

Hello group, I have been purchasing braided poly off ebay made in USA in size 415 and 277 (for the bobbin). The bobbin never has a problem. The top thread, 415, would wind up terrible so I contacted the maker. I already posted this information in a different thread not knowing that this thread was specifically about braided thread (lots of puns sorry). The solution was obvious but I needed confirmation. The cone was not designed to feed off the top. Instead one needs to make a horizontal rod and allow the spool to spin on the rod as it feeds off (similar to how the bobbin feeds the thread). Braided thread is stronger than regular. This stuff being made in USA and bonded/waxed and white/brown/tan/black colors. So now I'm waiting for some braided fishing line to arrive (although I truly love the braided poly and the mfg from USA I have long lead times getting it here overseas). So I bought some braided fishing UHMWPE line. The stuff rated at 80lbs is 0.5mm so perfect for a size 23 needle which is max for my Singer 112w-139 and the size 42 is slightly smaller than ticket 30 so perfect for the bobbin and seriously strong stuff. UHMWPE is super UV resistant and has abrasion far beyond the best Nylon plus the extra strength. So, I read people say that if the thread is too strong it will rip the material before the thread breaks. I believe in this 80lb smaller size than 207 (approximately) top and the slightly less than ticket 30 42lb (in the bobbin ) is ideal for a machine like the 112w-139 or Consew 206rb etc. And I get free shipping on it. We use commercial device that fits onto the spool pin and uses silicone lube on the thread. With the fishing line I'd use the silicone lube pot and feed it sideways off the horizontal spool like the braided poly (size 415 is rated at 95lbs ! ). We are setting up to weave on a hand loom next week (12 shaft homebrew countermarch) and I've even considered trying to make a rip stop on steroids with braided thread in the rip stop portion. It'll be interesting for a project. Best regards, Mike

-

Hello group, This is a really old thread but I want to add some information. I have used a US made braided polyester thread that is size 415 and size 277 (bobbin). I contacted the manufacturer over a technical question as I discovered an issue with it. They said they are making it in USA proudly and as long as sources for the fiber don't dry up they will source the fiber in USA. If forced they will only source overseas and still braid in USA if supply is no longer available. I put it on my thread stand and it twisted hence the reason why I contacted. With the braided stuff it is stronger than regular equivalent sized thread and is not sensitive to right/left twist requirements. However when feeding off a regular thread stand from the top it will twist up. The answer is to feed off side and let the entire spool turn as it unwinds to feed the machine. They have tan/brown/black/white waxed/bonded. Same seller below is selling gun holsters so must be using them successfully with their biz and it is obviously listed for leather work. However, something I want to try is an 8 braid (that makes it a round braid coming off a maypole braider) UHMWPE fishing line. I just ordered some rated at 80lbs and color dark grey with 0.5mm. Using Bob's chart that puts it on a size 23 needle which is capable of many of the machines that would be used for wallet leather etc. that max out at size 23 and the size 207 is 0.508mm so this will be ideal. The 42lb stuff is barely smaller in diameter than ticket 30 so would be a good candidate for the bobbin in a machine like a Singer 112w-139 compound feed sewing wallet type leather. These types of lines are much stronger than polyester or nylon and UV resistant unlike nylon with much greater abrasion resistance than even the best of nylon but the Achilles heel is very high heat temperatures. If I wanted max bang out of smaller threads on my Singer 112w-139 I believe this 8 braid fishing PE (UHMWPE) line is the way to go. Here is the link for the USA made stuff but I will try the 8 braid 80lb PE fishing line and am fairly certain it will be amazingly strong. I might try to figure out a better smaller size for bobbin as well. Best regards, MIke https://www.ebay.com/itm/Braided-Poly-Thread-Tan-Size-346-Waxed-1-4-lb-for-leather-upholstery-and-more/192776703116?hash=item2ce2630c8c:g:J24AAOSw~FJZMIK2:rk:1:pf:1 https://www.ebay.com/itm/Goture-500M-Braided-Fishing-Line-8-STRANDS-Super-Strong-Saltwater-Fishing-Line/202066283470?ssPageName=STRK%3AMEBIDX%3AIT&var=502064358039&_trksid=p2057872.m2749.l2649

-

I contacted the owner of this thread and asked them if it is made to be side fed and the response was that it feeds better that way as they put it on the spool that way. Also he said they have made holsters to allow the thread to feed off sideways. That explains my twisting problem. Too easy to make an adaptor to allow this so I think I'll do that soon enough. Best regards, Mike

-

Hello group, I have been using a braided polyester thread from J&S called "New Millennium". We are using a size 415 in the needle and size 277 in the bobbin. This stuff is made in USA and the material to make the thread is sourced in USA. A little expensive but the braided thread is supposed to not have the twisting issues as well as being stronger (the 415 is rated at 95lbs breaking). It has a unique and decorative look to it. Although a little more I find it well worth it and proud to use a thread made in USA with quality and good performance. They have both bonded and waxed as well as white, black, brown and lighter brown. Has anyone had any issues using the braided thread? I have found that I do need to straighten it out every once in a while so I'm not completely sold on the non twisting but I'm not an expert. Even though the 415 is supposed to take a size 28 needle I've found it to work quite well in a size 27. They claim braided goes through the needle better as well. Just my 2 cents if I was to go regular twisted I'd surely buy the cowboy brand from Bob at Toledo Industrial. Maybe he'll start stocking a braided as well. Best regards, Mike

-

Hello group, I just received some size 415 braided that is available in either waxed or bonded sold by J&S thread supply but I got it from a pack goat web site. From J&S it is $38.95 a pound. It is either brown/black/white/tan. I got the black and it is shiny and really sews well in a size 27 need 214x1 on a 45k1 and looks incredible. I also got size 277 but it is not as noticeably flat as the 415. I will get tan next. This stuff is USA made I'm sold on it !!!! I'm considering in investing in a compound feed machine even though I'm only doing heavy waxed canvas with the thread now I like the idea of a machine that can do it all. I'm considering a double needle shuttle hook but I think it is allot more expensive. Is that un-necessary with a drop down roller foot like on the Cowboy cb-4500 for a clean double row of stitches on a pocket? My concern is the roller guide not working right on pocket attachment and a double needle that could also work single as more appropriate....sorry to shift from the thread top to also machines after adding the thread info. Back to Amman that braided thread confuses me as the J&S is available from 207 in all the steps up to 415. This Amman site is nothing short of confusing on their smallest size which I think is about 415 (and it is round not flat) Best regards, Mike

-

Hello group, We are using a recently overhauled circa 1915 Singer 45k1 allot lately and love the machine for heavy type work with webbing, canvas, and denim. I took the low road and got a locally available 750w brushless servo as the price was just over 100 dollars in this country. It is nice enough but I've seen problems with this brand of motor wanting to chug along at the lowest speed when letting off the pedal and not stopping ever. It was a case of supply and demand...low cost and easily available. Lots of messing around got it to work properly again (motor stopping after letting off pedal) and I noted the problem went away when I messed with the needle up/down button. My assumption is that the circuit board/micro controller circuitry is confused thinking it needs a sensor input so it is hunting and waiting for the sensor to tell it to stop. This was partially confirmed by shorting two pins on sensor input connector resetting the board. So I spent under 20 US dollars (850 Philippine pesos) and got a sensor and hooked it up. Well the motor no longer gets confused with the up/down sensor button. However the heavier weight of the flywheel allows it to freewheel past the up or down position hahaha. Inertia of heavy hand wheels and needle position sensors just don't seem to be made for one another. I thought this motor had a brake on it like the ones that Bob Kovar sells but it seems to not be the case. Anyone have similar humorous but not so good experience with motor position sensors? Maker of motor is CHM and of course China mfg. for motor. Best regards, Mike