-

Posts

46 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by KeithHideWorks

-

Cowboy CB-818 Belt, Lace & Fringe Cutting Machine

KeithHideWorks replied to KeithHideWorks's topic in Old/Sold

Sorry about that, I must have missed it. Its $1800 -

have for sale a Like new CB-818 that comes with extra blades. This has only been used to cut a few hides to test. The machine is setup and tuned to produce.These machines are not for sale very often and retail for $2100 + $250 in freight. This may be the only machine of this type you see for sale in years. Highly sought after in the leather working industry. Located in Vancouver, WA.... right across the river from Portland. I have other tools in the used section for sale as well. Thanks, Nick

-

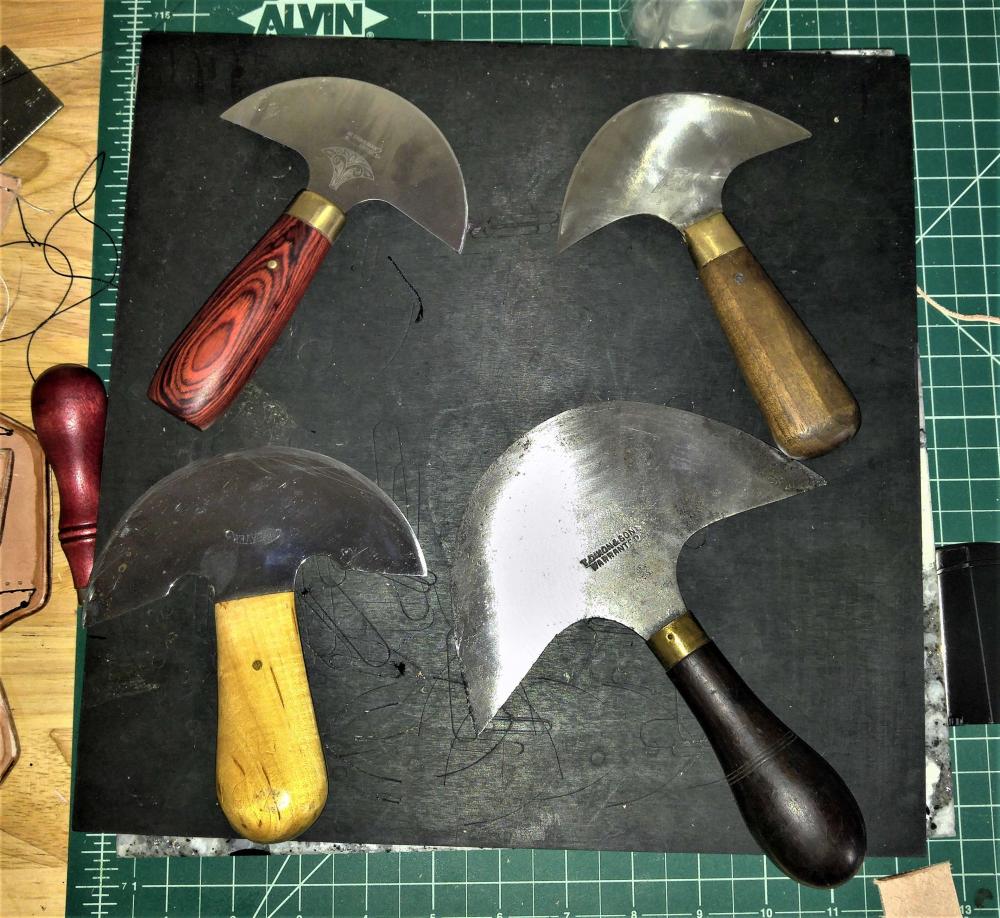

I have for sale some high end leather working tools and machines.CB806 Manual Leather splitter skiver $250http://www.solar-leather.com/cutting-machines-1/Hand-Operated Bluegrass "EZ Edge" Strap Edger $350https://www.weaverleathersupply.com/catalog/item-detail/65-6053/economy-hand-operated/pr_29255/cp_/shop-now/machinery/equipment/strap-edgersHeritage® Dye Box II $500https://www.weaverleathersupply.com/catalog/item-detail/65-6015/heritage-dye-box-ii/pr_9029/cp_/shop-now/machinery/equipment/dye-boxDixon Plough Gauge with original Blade and new Custom Terry Knipschield Blade $350Dixon Round Knife $100Weaver Limited Edition Round Knife $100W. Rose Round knife (missing ferrule) $75Tandy Oval Leather Punch Set $75Leather Number Stamp Kit $20 Located in Vancouver, WA. Prices don't include shipping. Willing to make a deal if you buy the whole lot. Thanks, Nick

-

Cowboy 4500, 818 Cutter, Edger, Paintbox,ect

KeithHideWorks replied to KeithHideWorks's topic in Old/Sold

Sewing Machine & Burnisher are sold. -

Cowboy 4500, 818 Cutter, Edger, Paintbox,ect

KeithHideWorks replied to KeithHideWorks's topic in Old/Sold

Bump and Yes -

I am getting out of leatherworking and looking to sell my machinery and tools. I am located in Vancouver, WA. Cowboy 4500 Deluxe Leather swing arm Sewing machine Package $2300http://www.solar-leather.com/cowboy-cb4500/Cowboy CB818 Leather Belt Cutter $1900http://www.solar-leather.com/cb-818-belt-fringe-cutter/CB806 Manual Leather splitter skiver $250http://www.solar-leather.com/cutting-machines-1/Hand-Operated Bluegrass "EZ Edge" Strap Edger $400https://www.weaverleathersupply.com/catalog/item-detail/65-6053/economy-hand-operated/pr_29255/cp_/shop-now/machinery/equipment/strap-edgersHeritage® Dye Box II $500https://www.weaverleathersupply.com/catalog/item-detail/65-6015/heritage-dye-box-ii/pr_9029/cp_/shop-now/machinery/equipment/dye-boxCustom Edge Burnisher $400This uses a high quality Copper electric motor, stand, switch and cocobolo burnishing attachment. You can also add a devise to the other side.I am willing to sell everything as a package or part out. Please keep in mind these are all like new and if bought new, have considerable freight cost.I also have a ton of other leatherworking tools, punches, knives , leather,ect if interested. Going to part it out on here or Ebay most likely. Here is CL post with pictures: https://portland.craigslist.org/clk/bfs/d/vancouver-leather-working-machines-for/6808743091.htmlThanks,Nick

-

Ill take them per my message.

-

Hand Clicker Press now available at Diamond Awl Workshop

KeithHideWorks replied to diamondawl's topic in Old/Sold

How is it any different then the chinessium units littered all over ebay? -

I may have one for sale as well. Bought it from a shop who used it for a large batch, really good condition.

-

Pick up one of the Douglas groover while you are at it, absolute best stitching groover on the market.

-

Yea i just with douglas had a real website where we could order all the tool. Its 2017, get with the times. Actually, lots of toolmakers are in the same boat.

-

Douglas, King and Watt all make great edgers. I don't think you could do bad with any of them. Older Osbornes and the like also do a great job.

-

Hands down the best tool I have bought in a while. I have tried cheap tandy to osborne to some older designs. Someone mentioned to just bite the bullet and buy the Douglas Tool and be done with it. I was at the Pendleton Leather show and Bob Douglas happened to be there selling tools. The tool is not cheap ($80 or so I think it was) but is very well designed and made. Its hard to explain but its the only tool i can actually make a strait stick grove with. The cheaper ones always tended to walk and were very sensitive to how much pressure you use and around corners. This little beast cuts with ease and I end up with something that is actually pleasing to the eye. You can even take an old tool handle and put the edger into that for more control. Just wanted to share my experience and see if anyone else uses it too. Thanks,

-

Do you mind explaining why the inline foot would cause you to lose throat? Looking at running that with a 4500 and not sure I understand. Thanks,

-

Pmed as well

-

I was able to crank it down hard enough to get it to stay. May end up being servicable in the end. Going to drop the Dixon blade and gomph off to my sharpening guy...he is an artist!. The 4 head knives I got back were profiled and are RAZOR sharp.....packaged nicely with a few band aids thrown in for good measure. These things glide through my leather. Can't beat it for $5 per knife. If anyone needs sharpening done, I can't recommend this guy enough. He does a lot of business and sharpens for some of premier knife makers/collectors in the nation. Hell of a nice guy to boot. I was worried about the horror stories you hear from guys ruining the heat treating. This dude's theory is you should always be able to kiss the knife. If you are getting heat, you are doing it wrong and need to change speeds, media, angle, ect. http://www.patronsaintofknives.com

-

Not worried about sharpening. This guy is local, fantastic, quick and cheap: http://www.patronsaintofknives.com Just spent the last 2 days soaking the Plough Gauge in Evaporust (http://www.harborfreight.com/1-gallon-evapo-rust-rust-remover-96431.html) and hand sanding down the corrosion and pitting. Got it dried, lubed and put back together and It's broken. The Lever with a bolt in it seems to be bent, and will not cinch down tight enough on the bar to lock it in. Anyone know a source for old dixon parts? You can kind of see the bend in the original auction photos: http://www.ebay.com/itm/FANTASTIC-ANTIQUE-SADDLERS-LEATHER-TOOL-J-DIXON-1884-RARE-/152438384467?_trksid=p2047675.l2557&ssPageName=STRK%3AMEBIDX%3AIT&nma=true&si=431LnNvKDIm6Xao3D8F3JnoRk30%3D&orig_cvip=true&rt=nc

-

Got back from vacation and these showed up. Gomph head knife in pretty good condition (Edge is terrible, dropping it off for sharpening today): Any recommendations for cleaning rust off an old dixon plough gauge?

-

So a little background. I have been having a hell of a time cutting out patterns and have tried just about everything I could think of. Stanley knife, Xacto, carpet knife, and the cheap tandy head knife I picked up for $20 on black friday. Now most of this is due to being new to leatherworking and just not knowing what the hell I'm doing. One thing I have learned quickly is quality leatherworking tools are not only expensive, but tend to hold their value. With that being said, I don't mind trying something out, knowing I can unload it if It doesn't work out. Getting frustrated with the tandy head knife, spending tons of time with oil stones and a strop, trying to get a good edge....I was just getting pissed off. I would get 2-3 inches of great cuts, then a hell of a time (Cutting 8/9oz stiff HO hides). So reading on here, it sounds like A. The tandy knives are junk steel and won't hold an edge. B. They are not profiled correctly and C. they break easily due to their thinness. So I started looking around for some new knifes and with some serious impuse buys and auction hysteria, ended up with some new tools. First I ended up with a smaller Weaver round knife. It looks like an older model and can't be found on their website anymore. It says weaver on one side, Limited Edition on the other side inside of what looks like a state I can't make out. The handle is 2 pieces with a full tang, and tapers starting thin closer to the head and getting wider towards the bottom. I paid $75 for this knife + a 2 Lb Al Stoman Maul. Next, I found a Sharpleigh Diamond Edge Knife on Ebay. It is in really good condition, and I paid $68 or so. Lastly, as I was searching for a Plough Gauge on ebay on the UK side (ended up getting a Dixon plough for less than $200) I found a T Dixon round knife for sale and ended up winning that as well. I think it was about $57 with the exchange rate. All of them need a good sharpening and the Dixon could be re profiled as there are chips in the edge and some very light pitting. Plan is to take them to a local Knife guru who has a very reputable business sharpening and rehabbing knives. I really hope these better quality knives, once sharpened will solve my issue of cutting out crappy patterns that look like dogshit once they are beveled/burnished from being uneven. If you had to keep 2 knives, which ones would you choose? Any info on these knives would be greatly appreciated as well. Thanks,

-

Must have that motor..............Any idea when they will be available for sale?

-

Yea these are shit. I bought a whole set and they are worthless. Thank god I used prime and was only out $20. First off, Dremels sucks for burnishing. They just dont have the power unless you buy the super powered one, at for the cost you can build a pro burnisher. Second, None of these are quality wood. They would catch pieces of debris, flake off and gouge my edges. Buy a real burnisher like the one from Pro Burnishers, made of smooth as goose shit cocobolo. http://www.proedgeburnishers.com/index.html I bought a cheap used electric motor, a WEN grinder stand from amazon and a $50 Motor Burnisher (http://www.proedgeburnishers.com/motor-burnishers.html) and it is WAY WAY WAY better than using a dremel. Much quicker, smoother and better edges. The wood is concentric and strait. You could do the same with a drill press.

-

Plough Gauge/Knife - Anyone seen this one?

KeithHideWorks replied to KeithHideWorks's topic in Leather Tools

How about this one? http://paffrath-remscheid.de/index.php/onlinekatalog/product/3083-166-oesen-und-scheiben-typ-oval http://paffrath-remscheid.de/index.php/onlinekatalog/product/3092-183-ersatzmesser-für-riemenschneidmaschine? Anyone know where to order them? Is there a Pro/Con of the various Plough Gauges (Dixon, Blanchard, Barnsley,ect?) Are the newer Blanchard really that good? Would really love to know more about this type of tool before I make a purchase decision. -

Does HO mark them A and B on the flesh side? They all were marked from the factory with the HO stamp and the sqft, but the actual grades were like a blue pen on the corner. I am wondering if they had pre-sorted them? $6.5 was the TR2 price/deal. I have spent over a grand there the last couple months. I think the A/B were around 9-10/ft.

- 18 replies

-

- ho

- hermann oak

-

(and 1 more)

Tagged with:

-

Just bought a HO 8/9oz TR side from a local vendor. Looked at their A and B's, and was NOT impressed. They were right out of shipping wrapper so I assume they were not pre-sorted, But those hides looked like ass. The TR I bought was much nicer than most of the A and B's. It was $6.5sq around 23 ft. So not a bad price considering. I'm nervous making a big order from them now. O'h, and i destroyed half the bend by using a shitty tandy wood strap cutter. It was measured and tightened down hard, and still drifted over cutting 10 strips. Started at 1.25" and ended at 1.75ish...... Plough gauge, here I come. Might have to try W&C Backs next time. HO was not impressive at all. Even their Brindle they had was pretty shitty.

- 18 replies

-

- ho

- hermann oak

-

(and 1 more)

Tagged with: