-

Posts

46 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by KeithHideWorks

-

http://www.leprevo.co.uk/photos/plough-knife.htm Has anyone used this or bought from them before? At 125 GBP, its considerably cheaper than the Blanchard at $400USD. Just ruined $200 worth of HO leather with one of those shitty strap cutters. I need something that won't slip and can cut heavier leather with ease. Been searching for a plough gauge all over, but cant find anything under $400.

-

Does Herman Oak provide a Strait cut back (Like actual strait edge) or will they cut the backs strait for the order?

- 18 replies

-

- ho

- hermann oak

-

(and 1 more)

Tagged with:

-

Edge Guide for Consew 225 (and clones)

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

Looks like a winner. Thanks! -

Edge Guide for Consew 225 (and clones)

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

So I got the Magnet it in. Lets just say its a little too powerfull for this machine. Going to look into getting a smaller one and trying that. This one is WAY WAY to powerfull and takes everything I have just to move it. I really don't want to operate the machine with this massive magnetic field that attracts everything metallic within 8inches. I am thinking a smaller, round one will work better as an index. This is a N50, 71LB magnet and is 3x.5x.5. Something with much less than half this magnet power, I'm thinking in the 25lb range would be a much better choice. Debating between: https://www.kjmagnetics.com/proddetail.asp?prod=BX884DCS&cat=173 or https://www.kjmagnetics.com/proddetail.asp?prod=DA8 -

Cool story. You are still a civilian and not even within the top 10 most dangerous career fields in the USA. LE doesn't hold a candle to the BS a service members has to go through and the sacrifice many have made. You ever work 120 hours strait with no OT? You ever been deployed to a combat zone away from your familly for 15 months? Do you work 15+ hour days , 6-7 days a week? but paid as if you worked a normal 40 hour work week (or much less) Can your boss show up to your house and demand a health and welfare inspection whenever they feel like it? Get called in on a Saturday or Sunday to take a piss test at 5AM with zero notice? Do you have to get written permission from your boss to go further than 50 miles away from your house on a weekend/days off? Have to take a Physical fitness test every 6 months along with body fat test in order to keep your job? Have to fill out a SF86/87 and go through a SSBI for a clearance and the last 7-20 years of your life ripped apart? Can you just say it, quit, and walk away without going to jail and being court marshaled and/or losing benefits every American gets by simply being born here? Please tell me more about your service durring the Gulf war. Were you actually deployed? What service and what career. I will agree that the military is overpaid for most servicemembers, its a simple supply/demand situation. For the same reason LE is vasty overpaid. When you have 2000 applicants for 8 vacancies, you are paying to much. Lastly, don't bitch that you took a low paying shitty job. Thats your choice. I make way more and work way less as a civy now in a nice climate controlled office. Maybe you should have actually used your bennies to get that masters degree instead of taking what you think is just as hard.

-

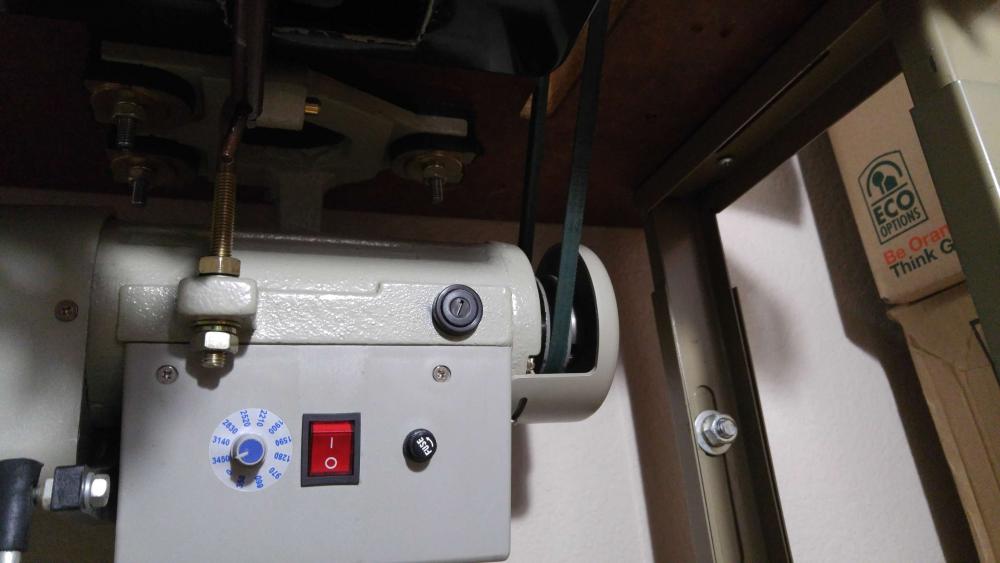

I was doing the Dremel and burnisher attachment method and it just wasn't resulting in a good edge. So this is what I ended up doing: -3/4HP Dual Shaft Electric Motor ($60 on CL) -WEN bench Grinder Stand ($35 from Amazon) -Pro Edge Motor Burnisher ($45 from Amazon) I wanted to buy the Cobra or Weaver, but couldn't justify $500+ when I could build one for less than $150. This is what I end up with and it makes glass edges with saddle soap and water. 3450 rpm and no issues. You would have to be a moron to injure yourself.

- 23 replies

-

- burnisher

- burnishingmachine

-

(and 1 more)

Tagged with:

-

Edge Guide for Consew 225 (and clones)

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

I ended up buying this after doing a bunch of magnet research. I only hope that the magnet doesn't throw off the bobbin timing or throw it out of whack. https://www.amazon.com/gp/product/B000UU6W3Y/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 -

Edge Guide for Consew 225 (and clones)

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

Also found these which might work: http://www.kjmagnetics.com/proddetail.asp?prod=BY088-N52 http://www.kjmagnetics.com/proddetail.asp?prod=BZX0X08 http://www.kjmagnetics.com/proddetail.asp?prod=B88Y0 -

Edge Guide for Consew 225 (and clones)

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

Damn man, that looks fantastic. Im trying to order them but you have to get them in person....and the stores are in Canada! 4.5 Hr drive from vancouver ,wa to vancouver,CAN After Searching this is the best I can do: https://www.amazon.com/Magswitch-MAGJIG-95-MagJig/dp/B003FWERRC/ref=pd_sim_469_1?_encoding=UTF8&psc=1&refRID=2NNMJY3WCNJNEBBPBZWY Its the only one that i am reasonably sure is small enough to clear the head of the machine. -

I use the HF bench as well. With a coupon code it came out around $107. Take your time installing it and glue all the joints with Gorilla wood glue, and it is rock solid. One of the very best things they sell for leatherworking (Other is the deablow hammers and razor knives). I have used expensive tables before and you can't build a table this good for even twice the cost. What I have realized is you quickly need more than 1 ,2 or even 3 benches. Need a whole workshop

-

I have seen these on some of the higher end machines, a bracket or plate that acts as an edge when sewing belts and the like. Does anyone make something like this for a Consew 225 class machine? I think they may be called a roller edge guide?

-

Anyone Tried this Speed Reducer?

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

I know someone was going to say something about that lol. Its actually at the lowest setting, turned all the way clockwise. I thought the same thing too, and played with each setting to see if that was the issue. Backing it counter clockwise it speeds up considerably. I think its just the cheap chinesse manufacturing in that the labels don't line up with actual settings. Thanks for the Video! I ordered the Speed reducer and it should be here friday. After I get it installed I will report back with pictures and results. Thanks again everyone for the kind words and assistance. -

Is Golinger good to deal with? Do they sell backs? I have a great leather supplier by me, just wanting to compare prices and see what the real price will be for wholesale.

-

Anyone Tried this Speed Reducer?

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

Well I can feather it slow, but it doesn't have enough torque to smoothly sew through what I need it to. The motor will bind up until enough juice is fed to it then its shoots off like a rocket. I cant get a nice slow and steady pace like I see with most of the machines online. -

Anyone Tried this Speed Reducer?

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

Thanks for the information fellas. I do have a bunch of add blockers running in my browser, but disabled them for this site. The least I could do for all the generosity the membership has shown so far. Thank you again. -

Anyone Tried this Speed Reducer?

KeithHideWorks replied to KeithHideWorks's topic in Leather Sewing Machines

The Servo in it is a Familysew FESM-550N. When I see videos of people running quality machines online (Cobra,Cowboy 441 Clones and the like), they are all nice and smooth and slow. I see that most of them come with a servo motor AND a speed reducer built into the table/kit. The pulley in the motor looks to be between 2-3 inches, hard to measure without taking guard off,ect. Its really not about the money. I plan to buy a Cowboy 4500 in the next year and really am wanting to learn and have a good backup machine down the road. Even if it turns out I need a new Servo, would the speed reducer ever be a bad idea? I am having trouble keeping my stitches inside the groves and don't know what else I can do but slow the machine down. The motor is currently at the lowest setting (350rpm) and won't move any further. Its way to fast for what I'm trying to do I think. -

After trying my hand at handstiching, I quickly realized I wanted a sewing machine to speed the process up. I started to do some research and was able to find a local Consew 225 with Table and Servo Motor for $500 locally. Nothing else was in this price ball park so it really was a good deal locally. Having never even touched a sewing machine before, the gentleman i bought it from spent an hour showing me the basics in getting it running,ect. Looked easy. I get it home that night and over the next week, cus this damn thing out because it won't work. I tried everything I could research and eventually traced it back to not threating the bobin thread correctly under the hook when it catches the upper needle thread. Anyway got that sorted out and have been running a bunch of #138 Poly Thread with Groz Beckert #22 leather needles (135x16 DPx16D). I was having trouble with getting enough foot lift with the knee lift to get my holsters made of 2 12oz veg tans lined with suede under there and eventually figured out how to adjust knee lift to get more clearence. I am still have issues with the walking foot messing up the leather on top, not sure what adjustment will fix that. I have twisted the knob ontop of the head (Looks like it compresses a spring in the walking foot, figure that is foot tension) but nothing really changes. At this point im just trying to be able to practice sewing, I can fix the adjustments later. The machine is timed dead on the money so thats not the issue (I dont think). Anywho, even with the servo motor set to lowest setting 300rpm, and feathering the foot pedal, Its way to fast. If I feather it too much, there is not enough torque and then the machine jumps when it gets enough power and is hard to control. So i thought , hey, maybe a speed reducer will help with this. It will slow it down and provide more torque on the low end to smoothly punch through the material. So as I have been researching, I found this one on ebay. This seems to require the least amount of modification to my table, while also being local (few hours away). I was wondering if anyone has used this and has any thoughts? Here are the links I have found so far. http://www.ebay.com/itm/222373125535?_trksid=p2055119.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

-

How Exactly Do You "dip" Dye Your Leather?

KeithHideWorks replied to Sixer's topic in How Do I Do That?

How and with what exactly do you dilute? Thanks! -

Getting An Even Finish Using Fiebings Dye

KeithHideWorks replied to wvcraftsman's topic in How Do I Do That?

I am getting ready to start dip dying as well. Has anyone tried the Pro Dye and Neatsfoot oil in a 50:50 ratio or similar vs denatured Alcohol? I know the ethanol is a solvent and will dry out, just wondering if this will keep the dye from dying out too much (problem with regular dye vs the Pro, Pro seems to have more oil in it). I am about to order some 2 gallon buckets with twist lids to keep this in. Don't want to waste $80 worth of dye and $30 worth of neatsfoot oil if i don't have to. This will be for holsters, belts, ect...