-

Posts

260 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JeannieH

-

Ok thanks for the pictures. I don’t know how to draft my patterns on the computer..so I have to do everything on paper with a ruler. I’m not sure if I want to thread it down since it’s nice to be able to pull the lining out for cleaning...I guess..not sure if the processionals donut that way. I don’t have any expensive brand bags lol.

-

I’m not sure I understand. I forgot to mention I’m talking about a drop in lining. Can you explain what you mean a little more?

-

Does anyone on here have any tips for drafting the lining size for the bags? I want the lining to fit perfectly without that bunched up look..which looks low end to me. I normally do the lining pattern 1/16 inch smaller in height and take 1/16 off either side seam. But this doesn’t always work out how I want. Any suggestions?

-

Thank you! I actually already have a skiving machine. A consew one.

-

Ok I will give that a try! Thanks!

-

I attached a picture of the tape before sewn and one after seen..didn’t stretch as much nor warp the scrap as much...go figure! It stretches a little bit normally it stretches more. The videos show me pulling the tape by hand and then sewing on the scrap..not sure why it did so well..guess because I was recording and the machine wanted me to look bad lol. Once you guys give me your thoughts on what you see still..I have one more problem lol..so the bag I want to make requires me to have the top part of the binding flush with the top of the bag..exposed. When I try starting with the body and binding tape flush..when I turn the wheel the binding moves toward me and down further from the top..so I’m not sure of the correct way to start and end in this case..probably simple but my brain is fried at this point. I attached a picture of the top of the bag so it makes more sense.

-

Ok that could be an issue as well. I will take a look at it in the morning. I never adjust the bobbin tension..it’s been the same as it was when I bought it. I need to make sure I have the bobbin installed correctly too. First time having a side loading bobbin.

-

Hi. I posted a topic before about finding a binder for the synchronized cylinder arm I bought. so I have a binder installed..but my binding stretches after I sew. The opening of the attachment is 7mm...my tape is .6 mm..and the two lives of leather with the binding amount to a little over 4mm. So unless I don’t understand how they work..the attachment seems as though it should be big enough for my tape. The tape goes in easily. My scrap pieces also curve after sewing. Do I need to keep looking for another attachment or is something else the problem? The machine sees fine. I have a size 20 diamond point leather needle and the thread is serafil 20.

-

I have a synchronized/vibrating arm cylinder sewing machine I’m not using as much as I thought I would. Im located in Douglas, Ga if anyone is near my area. I would be willing to trade for a roller foot post bed machine. Machine works great! I bought a binder attachment for it but I think my leather is too thick for the binder because it stretches longer than it originally was before going through it. I don’t want to buy a custom binder right now, too expensive. Table and motor included. $1300

-

Inconsistent stitches, leather lifting, loose thread

JeannieH replied to JeannieH's topic in Leather Sewing Machines

Ok thanks guys! I thought I needed to use a round needle for inside seams and a tricky for the top stitching. I will order some tri cut. The only size I have in it is 22. Yes it appears that is so. I did change to a size 22 R and the problem stopped. I really like my modified foot because I can get my guide very close to the needle to get my top stitching close to the edge like the designer bags are. Ok I thought I needed the R for bag construction inside seams and the tri it’s for topstitching or leather over 4 ounce. I will order some and try them instead. I think I have a size 22. I will order a 19 or 20. -

Inconsistent stitches, leather lifting, loose thread

JeannieH replied to JeannieH's topic in Leather Sewing Machines

Ok I will try a bigger needle as well. Will update shortly. -

Inconsistent stitches, leather lifting, loose thread

JeannieH replied to JeannieH's topic in Leather Sewing Machines

Ok I will try to see what it does with a different center foot. But I modified that one so I could sew very close to the edge when top stitching my bags closed. If that doesn’t work I will load a better video and see slower for you guys to see. ive been sewing with this inner foot for a while. Maybe this thinner leather requires me to tweak some things. It’s like a 2-3 ounce chrome upholstery leather. I normally sew 3-5 ounce chrome tanned. -

Hi. My machine was sewing fine..minus the fact I noticed a few stitches not looking the same as the rest. Now, I’m getting inconsistent stitching. I changed the needle..rethreaded machine three times..changed bobbin..the stitching has gotten worse. im using #5 MBT thread on top and bottom..size 18 round point needle, consew 227 is the machine I’m on. No idea what to do now.

-

Ok thank you for that!

-

Ok thank you!

-

Yes it is! Ok I will try increasing the pressure. The binding pulls through easily by hand. Guess it’s different once I get sewing. Hope I don’t have to still get a custom binder!

-

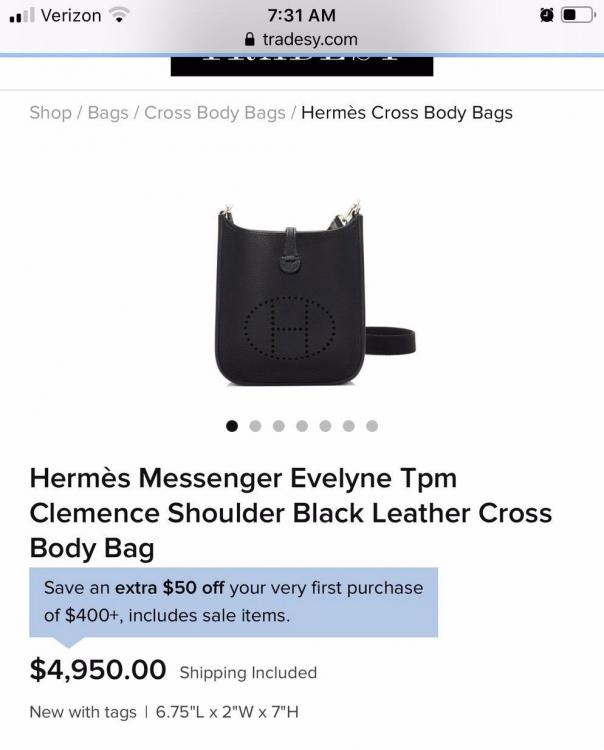

This is a long post. So here is the little bag that prompted me to want to bind things so bad and buy ama home for it lol. There’s a short story behind it. Hermes makes it and I can’t afford it! End of story lmbo! So I said I will make my own. First pic is the Hermès bag. Small bag about 7” tall. Unlined. Cost a fortune for what you get! So I used the same “Clemence” leather(actually it’s the lagun taurillon) and made it look a little different with my hand punched J for my brand name “Jaicani” and a tassle. My shape is more square and straight up and corners aren’t as rounded. It’s a quick bag for on the go since I don’t put a lot of stuff in my bags. It’s so cute and I was obsessed with it! Side note: this is how I’ve taught myself to make handbags. I look at designer bags and get their measurements off the websites. Draw it. Find videos of women unboxing them on YouTube and stare at the bags to see what info I can gather...then I go to bed and sew it in my mind (for real) so I can see what problems may come up and if I have the tools needed to make it..then I make a pattern then make the bag. this is my first attempt so I did make mistakes on the machine. For some reason the stitch length wasn’t the same as on my test pieces. It was a lot smaller. My binding did stretch... it sure if that’s normal or not. There are still some things I gotta figure out with starting and ending the binding to get it looking higher end..since at the top it needs to be painted on the ends. I did leave the threads long and hand stitched the ends so I could secure the top with overlapping the threads. But..when I awled through the layers my holes weren’t lined up on the underside...so maybe I need to go at an angle. overall I feel good about the first go and now I can try again. Please critique! Tell me what you see that needs to be done better even if it’s something I already mentioned. It’s hard to see details since it’s black though. Also, does any place make d ring holder does I can hit with a mallet? I can never cut them perfectly.

-

Wow! Close call! Lol well I put the shoes on the passenger seat but my husband did tell me I need to learn to drive with shoes on lmbo. I will take that oiling advice!

-

Oh Ok I see now. Yes I will be sure to oil more places on my consew! Ok thank you for that suggestion to run the machine at high speed before sewing. I am really loving this machine. It sews the binding with no problem other than operator error lol. I will be finished with my first trial bag on it tomorrow and will post it in the thread I started about the binding attachment. With the Zoje, I guess I need to put some shoes on (I sew shoeless lol.....I like to feel the pedal like when I drive a manual car....shoeless as well lol) and take the head off so I can put oil underneath where I think it goes. then run it on high speed to get it going. I will let you know if oiling the consew some more helps. How often should I oil the machines?

-

Just in case you misunderstood, the Zoje 2628 is the machine I was trying to figure out how to oil. My consew 227 is no problem as it has the holes marked. The other guys mentioned the Zoje seems to be a high speed binding machine and it has some sort of window that tells me how much oil is in it. My problem was that I don’t have access to it besides taking the head off(which is heavy lol). Someone also mentioned that those machines normally have to be running at a certain speed to get that oil going where it needs. So, I’m trying to figure out how I can make sure it’s oiled properly since I won’t be sewing at high speeds and will need to it manually. But, the machine only has three holes at the top left area marked red. The other visible holes have screws in them. That’s it.

-

The feed dog was fine. I hear the noise even with it out. I also oiled the bobbin case as you mention. I still feel something sounds different though. I remember how much I enjoyed running it (I like hearing sewing machines go lol) and I’m sure it sounds different. Just one of those things I guess.

-

Ok thanks for all the suggestions guys. I’m about to oil it some now and RockyAussie I will check the feed dog as well!

-

Appreciate it! Almost finished with the bag so I can get some critique on it!

-

So as far as the oiling...I should just put oil in the three holes marked red periodically? Since I won’t be sewing at high rpms like the machine is designed for?

-

Ok! I was just typing that the sound looks like it’s coming from that piece you are referring to hitting the bobbin vase notch thing..lol I don’t know the names of the parts. Ok I will stop worrying over it and move on. The machine does sound different though lol. I haven’t seen on it a lot so I was expecting it to sound like day one.