-

Posts

88 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by scrapyarddog

-

Not horribly necessary unless you don’t start the skive at the edge of the leather but even when I do that, I don’t need that round edge. A gouge or groover plus angling the blade when necessary will normally do the trick.

-

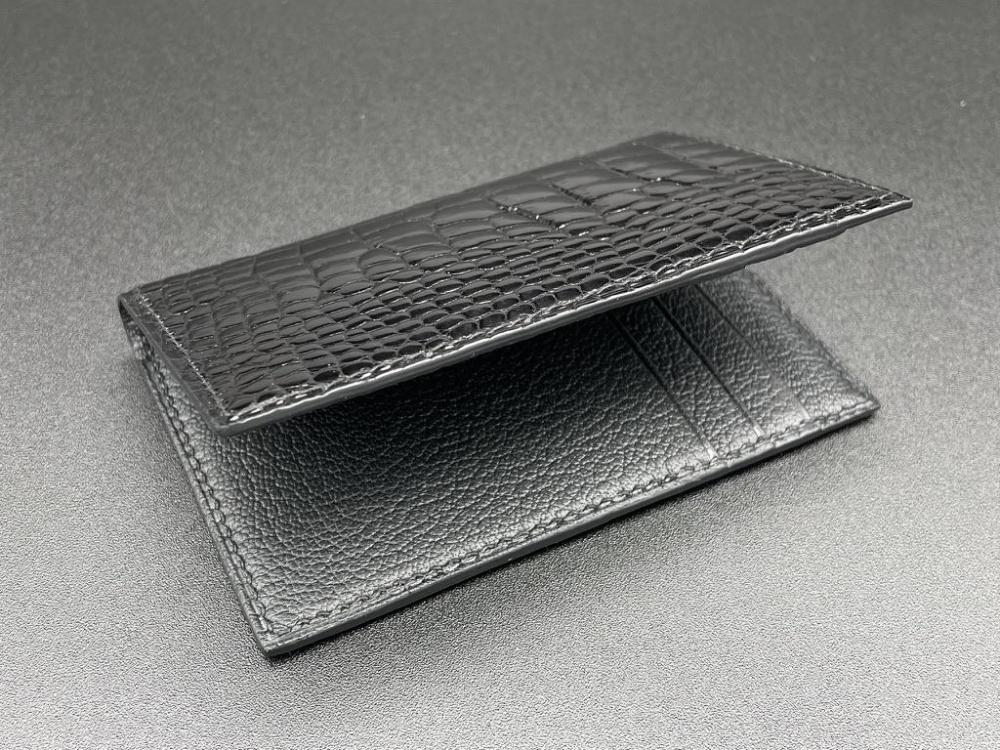

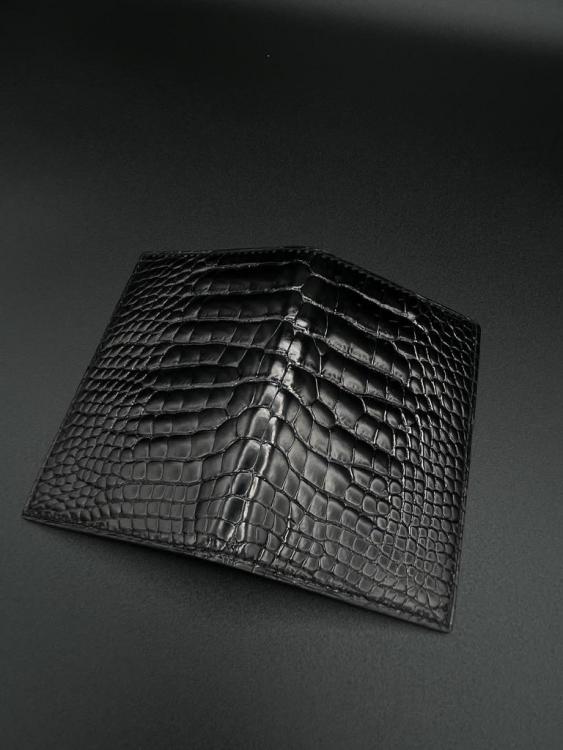

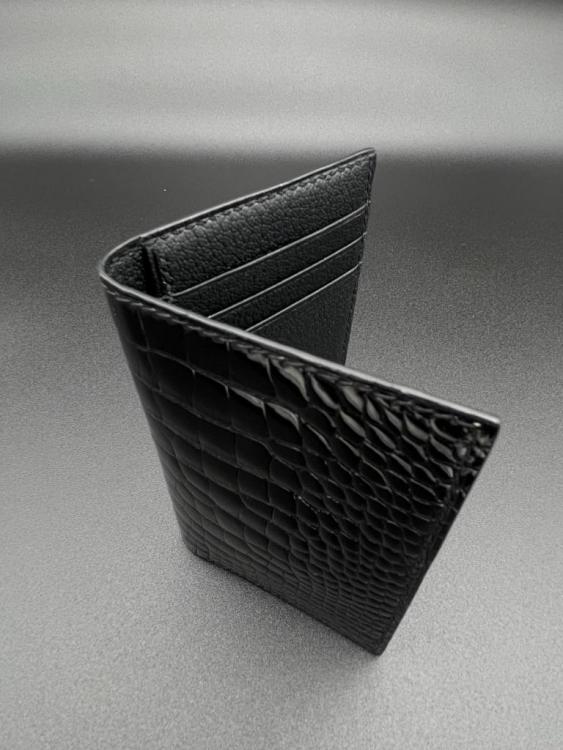

Hey thanks, the extra small works well for this type of card wallets, and I actually made an offer to buy 50 skins but they won't give me a discount unless it's 75 skins. WELL, I don't know about the buyer, but if it were me, I might intentionally whip it out whenever I go to Burger King's drive throughs. Plan on making a burgundy for myself and maybe I'll do just that when... I pump gas. If you don't mind a few minor blemishes, I think grade 2/3 are perfect for the job. Unfortunately, no, but don't tell the ID thieves. The gator is 2 oz or so, the inside is Alran Sully at 2 oz as well. Instead of gluing the gator and the goat lining completely, I only glued the edges about 3 mm in. Gator isn't flat so if you glue them completely, you'll see the pattern of the scales from the inside. I personally don't like that. Also, when you only glue the edges, the whole piece is a lot softer and you'll have less resistance or stress opening or closing the wallet. Classic luxury is low key. And I'm a tad colorblind so destined to fail with daring color matches.

- 19 replies

-

- fil au chinois thread

- wallet

-

(and 2 more)

Tagged with:

-

- 19 replies

-

- fil au chinois thread

- wallet

-

(and 2 more)

Tagged with:

-

Alligators giving me headaches... scales peeling off.

scrapyarddog replied to scrapyarddog's topic in How Do I Do That?

Thanks, I actually just placed an order for some lizard skin with them. Will definitely ask for their opinion. I'm sooooo disappointed with the tannery I bought these hides from. They were marketed as 1/2 and 2/3, but for example the one piece that's graded 1/2 has 2-4 scales slipping/lifting at almost every segment in the tail area. Another one graded 1/2 has at least 1 scale slipping at EVERY segment. There's no way these are 1/2 grades... Or maybe I'm just being ignorant. Thanks... lesson of the day... don't believe in sales and don't oder anything when you wake up 5 am in the morning... -

Finally bought my first 3 pieces of small alligator hides and immediately I'm puzzled by this revelation: if you fold the hides a certain way, the tip of some scales peel off a bit. It's probably not serious enough that it would endanger the integrity of the hides but it's enough to make me worry they would snag and eventually become unsightly. Does anyone have any suggestions? Did I just happen to have received some subpar pieces?

-

Same experience though not via eBay. My takeaway was I needed to hone my skills more before pushing out a product, but along the way I still sold products that I was comfortable with to cover cost. I also offered to make free products for ppl who bought my subpar products earlier. When they see the difference, they go WOW. It’s really hard to rework a bad reputation and win back disgruntled clients. It’s easier to maintain an operation with good and consistent QC. Not saying your straps are subpar, but I think you’ll see some resistance. Check out some higher end production contents, pay for some courses even, it’ll be good investment.

-

No, what I mean is round knives have limited applications for most hobbyist, and it honestly isn't the safest or easiest tool.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

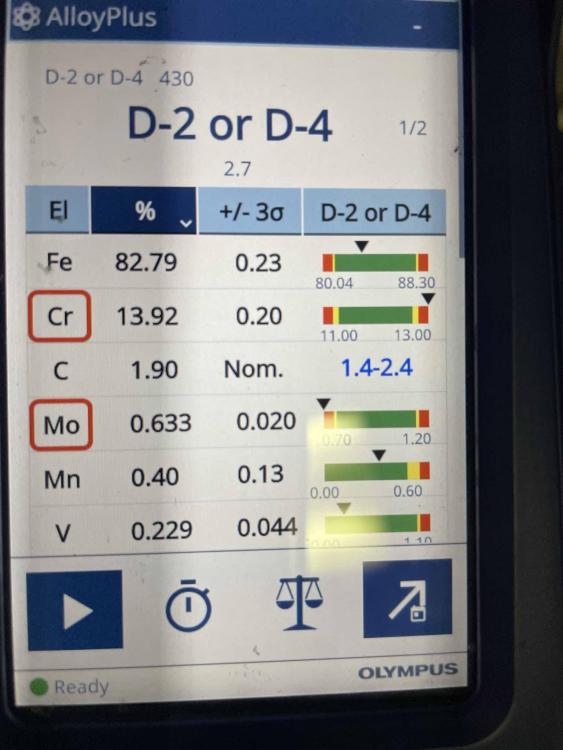

I don’t think the Tandy version is 62. It bends and flexes differently from some D2 I have that are at 60-62, and doesn’t hold an edge as well. Not a scientifically tested assessment but it’s somewhat obvious. A hobbyist using a round knife…? Hmmm… honestly, I rarely use a round knife and I spent a few hours a day on leather.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

Hmmm… D2 is not shabby by any means but is probably not on the same tier as M390 or the like. However, I think you are right about the hardening or lack of on the Tandy is probably a good reason why it underperforms. My experience with other blades made of D2, while just ok, isn’t this underwhelming. I was thinking it might be 400 stainless but it wasn’t that abysmal.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

It’s pretty easy to wrap. Just skive a round piece of Sully 1-1.25 oz, over cut a little, and wrap the rivet up like a dumpling. Don’t skive too thin or else it’ll tear easy. There are some easier ways to do it but I don’t make that many that efficiency has become a concern. It does not burnish well from my experience.

-

Oh, WELL, she can have one but your wallet's gonna be in deep pain. Sully is pretty damn awesome. Easy to skive as well. An angel to work with. OH feces... Totally forgot. Only the maker knows... where the screw ups are. Ahahaha! I wrapped the rivet with leather and use its bulk to hold it at the belt. Will probably use a hidden snap button or hook in the future.

-

Tandy using M390?? Hmmm... I’ll shoot it with a spectrum analyzer tmrw and see. I’d be surprised if they use SS 201.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

As I don’t make blades or know how to heat treat, I can’t comment on that. All I can say is I do see differences in Tandy’s head knife, high carbon paring knife from Talas, CPM 154, S30V, D2, 20CV (LW), M390, certain “HSS”, and blue paper steel used by Okada. And if someone wants to get a reasonably good knife without knife making skills, there are good options out there. For sure, the treatment done by individual makers and blade geometry adopted make a difference, but if I had to choose, 20CV and M390. For crazy sharpness (but also a tad brittle), blue paper steel.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

True, but I think it’s hard to deny that some steel provide better balance between hardness and toughness, and some steel just aren’t that great at maintaining an edge. Unless we are here saying that no matter the chemistry, all steel can perform the same.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

I'm sure some masters have no problem using it, but I'd rather spend it bit more money to get something with higher HRC and toughness. If you can get one made of M390 or 20CV, you'll see a difference in edge retention.

- 54 replies

-

- al stohlman

- round knife

-

(and 1 more)

Tagged with:

-

For wallets, I prefer 0.6 mm to 0.8 mm. For t-slots, I fold the leather over to line it or fold the top and line it with nylon where it's not visible to reduce bulk. If it's an all leather construction, I would skive all edges of the t-slot before I fold, and when I make double turn edge wallets, the "wings" of the t-slots are further skived to 0.2 mm by hand. When I make wallets, I like to overlap the t-slots for about 9 mm then turn them to prevent accidentally exposing the edges so they have to be skived really really thin. Ripping a little is fine since most areas that might rip will be hidden from view. 0.6 mm is perfectly fine and from my experience, Alran at 0.4 mm is just way too thin and would require some backing with fabric.

-

Real simple, cut out a 4 cm diameter circle with 7-8 oz tooling leather, place it on top of the base strap, skive a goat hide to 2 oz, glue, cover, mold. You could use a heated iron to improve definition. The turned edges are skived to 1 oz or less but I wouldn’t recommend that for the raised part bc it could rip. I didn’t case the goat.

-

Thanks, I thought it turned out better than expected. Originally, I was going to use a brass oval shaped turn lock, but the particular lock has about 4 mm between the top and back plate and I didn't feel like adding that much weight to the flap. Then, I remembered Philip Jury's watch case that had a raised oval design, but it was easier for me to cut a circle with my tools. It's basically a double turned edge since I added a thinner piece at the bottom to cover the turned edges. That's a great question. Thee hold downs are 2 pieces. Check the photo attached. If you burnish the edges or use edge paint instead of turning them, it's definitely possible to make that in 1 piece. But in order to turn this, after you turn parts to the loop and part to the main body of the hold down, you would have the awkward opening at the corner. I could cover it up with some paint but the idea was to expose no edges. Now, if I used a curve instead of a right angle, I would be able to turn it with a less extreme stretch rate, but when the tab flips upward, the turned edge will be expose. To avoid that, I'd probably use 2 pieces of skived leather, one to cover the larger part, and one to cover the loop in an upside down manner. There would be a faint joint line or overlapping but it probably wouldn't be very noticeable. Problem was... the friend wanted it FAST. I usually require a 3 month advance notice, and my friend, who supposedly has a MA in engineering, gave me 2 weeks. With other products to make at the same time, he frigging broke me.

-

I didn't expect it to turn out this good to be honest. It just worked. I think the thread is Fil au Chinois 632 Rouge #128. For the button, I cut a round piece of 3 oz tooling leather with a round punch, glued it to the rapid rivet, then skived a piece of goat hide to 1 oz at the center and 0.5 oz at the outside, placed the rivet at the center and wrapped the outside back onto the side and underside of the rivet. You really don't need to add the 3 oz tooling leather, but I needed the bulk. See photo for a similar button. Thank you! Well, I hope his wife likes it (and orders more... I know what she can spend on bags).