Danne

Members-

Posts

772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Danne

-

This is 100% tangent. But it doesn't show it that way when I preview a print or laser cut.

-

Yes exactly. And even though I try to save text documents with instructions for settings, it's always something you forget, and you spend hours trying to remember or google to figure out how to do it (even if it's something simple, if you haven't done it in a long time, then it's easy to forget)

-

Yes, I know what you mean when using the arc function. I find this way quickest and easiest to get the same shape on my points on straps. And it's a good way to avoid that problem you talked about. I don't think this is a problem with machines, I used a laser cutting service with good reputation, and I mean they have nice fancy industrial laser cutters with servo motors. And I can also see the problem when I print it on paper. I'm not that keen on doing a reinstall of Autocad either, it's always settings you have to do, and you don't remember since it was a long time ago I installed it. Just things that should be simple like plotter calibration, I remember I struggled with that, I forgot to choose the correct calibration file somewhere and it refused to print to correct dimensions length wise lol.

-

Thank you, I think their suede splits can be suitable for me. https://www.pergamena.net/leather-shop/leather-splits Like I often use Alran sully goat, and the split from that leather would be perfect when I need to build up thickness but use reinforcement, but of course I don't want to take perfect hides and split away the grain.

-

I get what you mean, like the radii would be too large, but on this one I used two circles (see my photo) and I have recreated it and checked the geometry after trimming and everything is spot on dimension wise. I have drawn many arcs and lines in cad during my years as a lathe programmer, sometimes for more advanced projects, other times when a circle meet a line at an angle and I was to lazy for trigonometry, and never had any problems like this.

-

Thank you

-

Thank you, I forgot to look there. And they have a perfect soft calf for paddings that I have samples of. Saint Crispin baby calf. BUT of course they don't sell that product anymore But they might have other products suitable for me.

-

So I had some watch strap templates laser cut. But something is wrong with the transition between lines and arcs. And it doesn't matter how I do it. Two circles and join and trim, a line and an arc, a polyline that transition into an arc (without snapping) there is a little step at the transition between lines and arcs. And this is visible in preview also, and if I print on paper (Except with like 0.05 in lineweight, because of resolution) Most templates came out really good anyway, this was the worst part, it do look worse than it is because the protective film is a little melted, it's like a 0.2mm step. The geometry for the lines add up perfect if you look at X/Y on both the lines and arc in my included photos (Keep in mind that start and end is different depending on where I started drawing the line)

-

I will look for calf crust from D'annonay. Directly from tannery is like 100m2 moq. But the owner (Hermès) sell some products through their tannery division HCP. It's possible to find leather from the best tanneries for decent prices here if you really look for it. The downside is then I can't buy like 1sq.ft and try it. And for this purpose the price isn't that important, the important thing is that I find the correct leathers for my purpose. Btw, thank you for your kind words about my straps.

-

I'm in Europe (EU) but as long as the seller have either samples or sell in sq.ft it doesn't matter. Let's say I find a suitable firmer calf crust that I need for some type of straps, and I have done tests with a smaller piece, then I can buy a full hide or two, and it will last A LONG time. Btw, I have seen your posts, you probably have a good answer what leathers would be suitable for me. The leather I think will be hardest for me to find, is the chrome tanned calf skin with really good tear strength. Right now I use a veg tan firmer calf skin, and I'm certain it's good enough for those constructions I use it for, but from my understanding there will be chrome tanned equivalent skins that are stronger. The important part for me here is to have crust skins that are super soft but still possible to shape, and also firmer ones, so I can mix the leathers for what is suitable. I show you an example in a minute.

-

Thank you, I check the links.

-

I think it would be easier to answer if you tell us what sort of products you are doing, or plan to do. I only do small leathergoods, and let's say someone ask "Which pricking/stitching irons are the best?" And I recommend Ksblade european style irons, and you make gun holsters with thick thread, I think those who make gun holsters prefer other irons (No experience from holster making though) Any reason for "keep to made in USA" to support business in your/his country? then it make sense for me. But when it comes to quality then there are good tools produced elsewhere also. (Ps, don't take it as a rude question, just curious)

-

So as some of you guys know I make mostly watch straps as a hobby. With different construction methods, when making a durable strap in layers, sometimes I use reinforcement but need to add a middle layer or add leather to the top layer (as example if I would use a exotic leather that is around 0.5mm) then I don't need to add it for durability, since I have reinforcement, but for the thickness of the strap, and I need a soft leather. Other times I want to make a thick strap, where it make sense to reinforce the construction with leather and no synthetic reinforcement, then I need a strong leather. It's calf crust I'm looking for, or for some of these maybe kipskin. 1. A really soft calf/kip but still with a "tight" grain so it's possible to shape with a skiving knife for padding (So for example a tumbled calf, or a leather like Perlinger Odessa (shrunken calf) will not work, because it will be hard to shape it for a round padding. 2. A chrome tanned calf crust that is more firm. I use a vegetable tanned calf crust today, but I think there will be chrome tanned versions that are stronger. 3. Really soft split leather, still need good quality, veg tan or chrome tan doesn't matter (going to use where I need to add thickness to leather, but not make it that much firmer, and no need to add durability) Please read this: I appreciate all tips, but I need to know the tannery and product, because if something works for me, I need to be able to source it again somewhere, and that seller might not be around anymore, and also please don't make this thread a discussion why I need certain leather types for my constructions, as always I'm willing to discuss this if people are interested, but then pm me, and we can discuss, and if more people seems interested in that, we can discuss that in another thread. Also I know I can use microfiber (Like TecnoGI and LuigiCarnevali) for some of these things, and I have a lot of these materials in different weights and firmess. But I don't want to use them for watch straps, for these things I want leather. Thanks

-

How about this? buy the size you need and trim it so it fit your table perfect? http://www.yellotools.us/Cutting/Cutting-Mats/ And for those in EU, they are located in Germany, but also have a shop based in US Here is their website. https://www.yellotools.com/de/

-

Manufacturer's Supply Company Bell Skiver Project

Danne replied to mcguyver42's topic in Leather Machinery

I found this thread, a similar machine, a post from Nuttish further down in the thread show a machine with the same model number as yours.- 20 replies

-

- leather paring

- bell skiver

-

(and 1 more)

Tagged with:

-

I can't see how a single layer of edge paint with a nice rounded finish is possible, not with the outcome of even close to a durable edge. Sure you can use a really high viscosity edge paint and get a really nice edge, that edge you see on really chap handbags, that peel off after "a week" I have never focused on being able to get an even and as durable edge as possible with few coats (I paint with low viscosity paint and sometimes 5-6 layers with heating and sanding in between) and the leather types I have been using haven't required any primer or anything, just heating the first layer. But I do have some primers from Uniters that I tried. EP-filler and EP-full. I haven't tried the durability over time, but Uniters have a good reputation. One layer of Uniters EP-Full and one layer of Uniters EP2000 created a rounded and nice edge, without any sanding in between or anything. (Standard viscosity of EP2000, it's available in high viscosity also)

-

Watch straps templates regular and with taper

Danne replied to Danne's topic in Patterns and Templates

I guessed it would work, but thank you for confirming it. -

Thank you, This watch have quite tight clearance between spring bars and case, so I had to take that into consideration when making this strap. Leather weights - Top layer: 0.9mm + 0.2mm velodon (dimensionally stable reinforcement material) lining: 1mm Stitching - 3mm/9spi and 0.3mm synthetic thread (Meisi Xiange twist #35) I have irons in 2.7/10spi and 2.45/11spi, and most people would probably see them as more suitable for this thread weight, but I like this look. Templates - I make my own templates, print them and glue to thicker card paper. I used the same template as I use for straps with thicker padding, and it's a construction where I assemble the strap oversized and flush cut it to size, which have a quite steep learning curve, especially if not using acrylic templates. (See my photo, it's the same template I used for this strap) I did actually upload some templates yesterday. 125-75mm and 18-22, with and without taper. I guess you use letter size in Canada? I haven't tried printing it in letter size since I'm from europe. But please try and update me, it should fit, it does when I show it in letter size preview in printer settings, but not sure if the dimensions will be correct. When you have skived the edges and folded and glued them in place, you cut an oversized lining and skive the ends (two ends on the short strap, and one end on the longer, glue in place and trim excess from the top. It can be easy to "stab" your way around with a skiving knife, and then if you are going to paint your edges, you will have to sand it so it's slightly under the final dimensions in width, how much will depend on the viscosity of your edge paint, and how many layers and such. I usually sand to around -0.2/0.3mm when using Fenice or Uniters (multiple coats with heat and sanding in between) this will probably not be the same if you use a higher viscosity edge paint with primer. How I learned this - A lot of trial and error, and prototypes, and also analyzing other peoples work when people have shared photos on Instagram.

-

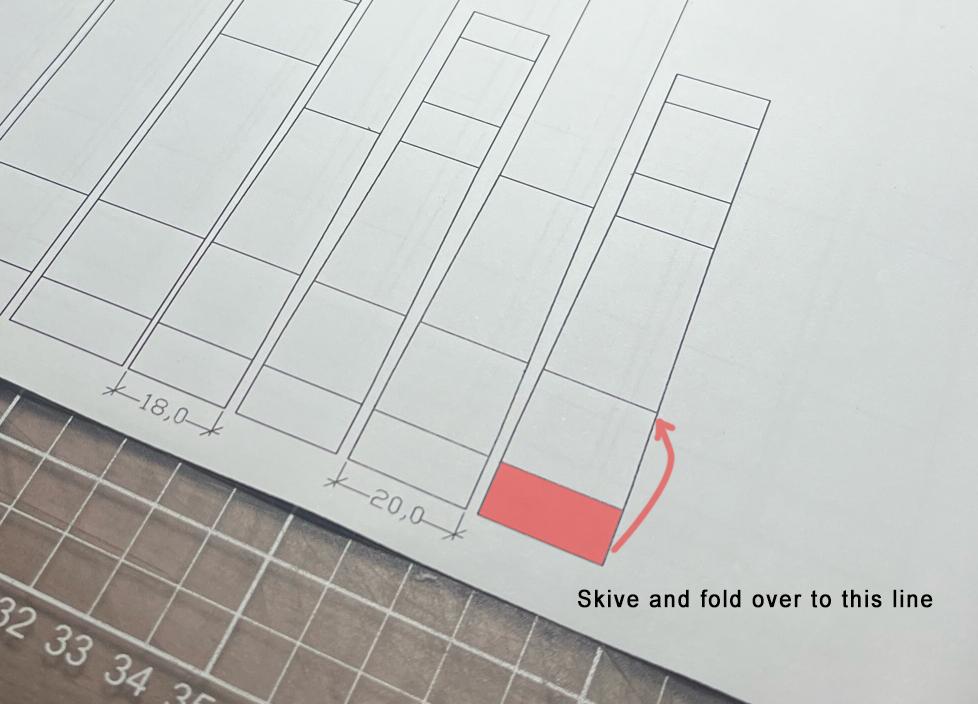

I had to modify the file a little bit so it will print in both A4 and letter size. But I can't try printing in letter size. So please someone update me if it doesn't work in letter size My instructions wasn't that good. But skive this part and fold over to the first line. For leather around 1-1.2mm thickness it will compensate for the fold so the length will be correct. straps_A4_letter.pdf

-

Thank you, I'm very happy with this model also. But I've had my eye on the new green one, super nice. https://www.certina.com/en/watch/ds-action-diver/c0328071109100

-

Yes, 17.5 cm. And yes a 40 case would probably be a little large for your wrist.

-

Yes, 40mm. I have quite small wrists but it does work for me.

-

Free card case template (beginner friendly)

Danne replied to Danne's topic in Patterns and Templates

I actually have one more, and I was about to share it, but something is off with my printer calibration in Autocad (Like you compensate for deviation in the print in feed direction, over a A4 or letter size length print, you usually have a deviation between 0.5-1mm on home and office printers (Sometimes you can be lucky though) and this affects when I save it as pdf also, since I want to test print the template, and print it without compensation for my printer. But here are the dimensions, and with the dimension in correlation with stitch lengths maybe someone can use these dimensions anyway. I mean it's not that hard to draw on paper if you have the dimension. (Of course there are those who can make awesome drawings on paper with planned stitching distance also) -

Looks awesome, I have never made a belt, and I prefer black belts, one of those in black and without that leather thing on the buckle, and I would wear that belt for the rest of my life.

-

Free card case template (beginner friendly)

Danne replied to Danne's topic in Patterns and Templates

Same philosophy as with tools. I mean give me a large space and unlimited funds, and that large space is soon filled with tools and equipment