PAMuzzle

Members-

Posts

122 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by PAMuzzle

-

Thanks guys. I think I will build a wood post on the floor and use granite and top with a couple layers of thick leather. I have a 2 lb hammer that I will try. If that doesn’t work, I’ll go to Lowe’s for a 8 lb steel sledge…what could it hurt? LOL

-

I just bought an Osborne 1-3/4” oblong punch. This punch was sharpened before being sent to me. What weight mallet should I be using to cut thru 2 layers 6-7 oz leather? What would be best base? I’ve read people use a tree stump or 6x6 or larger posts on floor. Also, people use a plastic cutting board on marble. I have a 10x10x2” thick end grain Teak wood cutting board, would that work on top of a post? Looking for input before I wear out my arm or destroy this fairly expensive tool. Thanks.

-

I wanted to make some belts for a show. I wanted to offer single and double stitched belts. Is there any way to stitch a belt blank and then cut and punch holes for someone without making a bunch of premade lengths like in stores? I've been running it thru my mind but not real sure if it can be done. Any help/ideas would be appreciated

-

Help with Mauser HSc holster

PAMuzzle replied to PAMuzzle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Not out if wood, but cardboard. Stitch lines too close so tore them out. I used a piece of leather that was 1-2 oz thicker than another mockup from the same hide. Customer’s son is coming into area next weekend. May get to try it in a new mockup that fits. -

Rocky, no I have not done any finishing of edges or tapping the threads. I just started using/testing a Cobra center toe presser foot that is open in the front (much easier to see where the needle is) and it has a groover foot on the bottom to press the thread into the leather.

-

Jeff…Thanks…will keep thickness in mind. here is back of holster recommendation for sweat panel size/location? Belt slot is too small. I cut it quick and didn’t measure it. I am going to increase to 1-3/4” and make the panel 3/8” longer to give more room for longer slot and double stitch around it. I had trouble with machine as I was stitching and had to pull threads. I fixed the problem and restitched, so a bit messy.

-

COS… Dia needle…It is my first attempt at pattern…it is a OWB holster…it is a test …belt slot not cut. Also thinking of making reinforcement band wider to cover more of gun … maybe 1”? Chris…I agree, that’s why I asked…needle is marked #25 and thread is #277 Gordond…it is Dia needle. Have not ordered L needles yet. Thanks

-

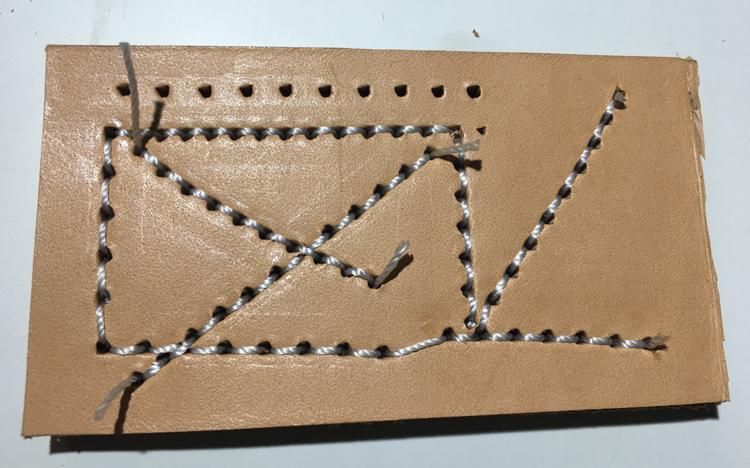

So I tried sewing a holster. Hermann Oak veg tan 8/9 oz. #277 top and bottom #25 needle, Cowboy CB 4500. how do the holes look? Too big or just right? If you want to critique go ahead but let me know how the needle holes look. This was designing and sewing practice so edges and such have not been finished. Thanks.

-

Help with Mauser HSc holster

PAMuzzle replied to PAMuzzle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

And the holster is a surprise to the gun owner from his dad. Picture of pistol is from the internet (Google images). But I will check PPK avenger style, a WWII type holster is listed for HSc and PPK. may have to get with his dad to make the mock-up. -

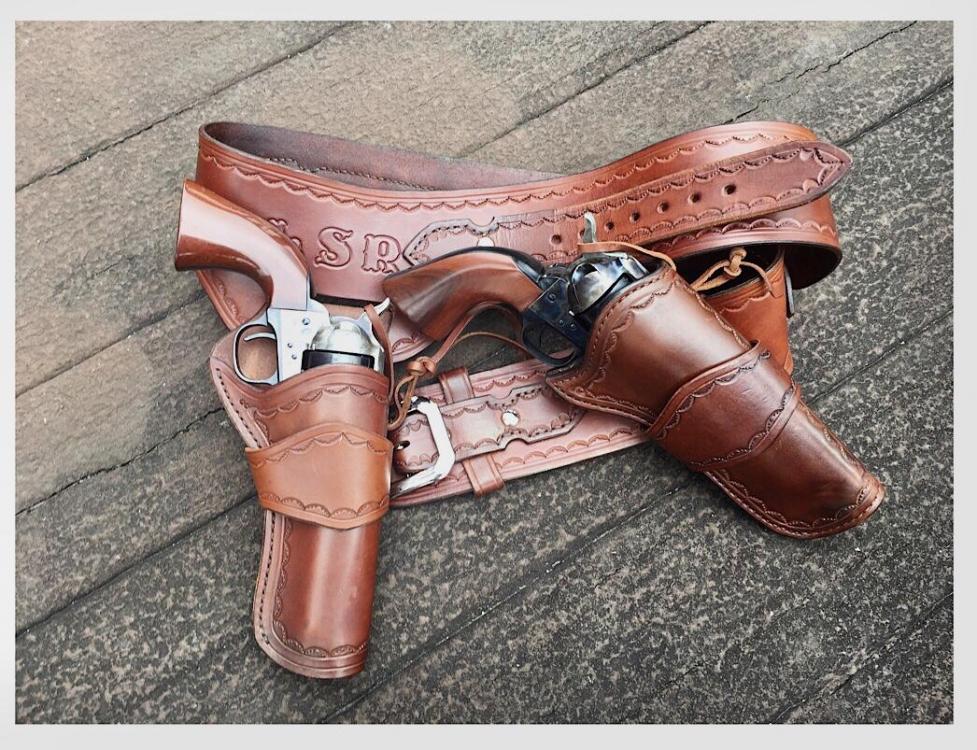

My first Buscadero

PAMuzzle replied to PAMuzzle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Appreciate it guys. Thanks -

Glad to hear!!! Now on to practice, practice, practice…etc.

-

My first Buscadero

PAMuzzle replied to PAMuzzle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yeah, the dye went from mottled light to med brown to almost black. I cut the back off and made a new belt loop and sewed it on the back. -

Help with Mauser HSc holster

PAMuzzle replied to PAMuzzle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Good idea. I will try that. Thanks -

I just finished this for a friend at a gun club. Started out as a single gun rig, but the holster, a mexican loop type, had a bad dye job. I told him and showed him a picture of it. I had another “El Dorado” style I made for myself. He said he really liked that style and asked “ Could you change it to that style?” OK!… then he added “can you make the other holster into a crossdtaw? I’ll buy that one too, it looks nice”!!

-

sorry you are in the situation. Happened to me for a much smaller package going by USPS/FedEx. i bought a sewing machine also. I am 60 miles from the supplier. Picked mine up like Dwight. Didn’t want to pay for shipping since I was so close, much less wait for it to arrive.

-

Ok thanks Wiz. I will order some tomorrow…wish they were available locally.

-

Wiz, no. It was a 794 DIA needle. But it looked like it may have a sharp nick on it. I replaced it with a new 794 #25 DIA, 277 top and bottom... New trial pics below. 6 SPI. Maybe drop down to a 24 or 23 needle?

-

Thanks for the replies. Wiz…I am using the needle that was set up in it when I bought it new. New package of 794 was included. I will try a new needle. Looked ok when I sewed thru flesh hidden by the roughness I guess.

-

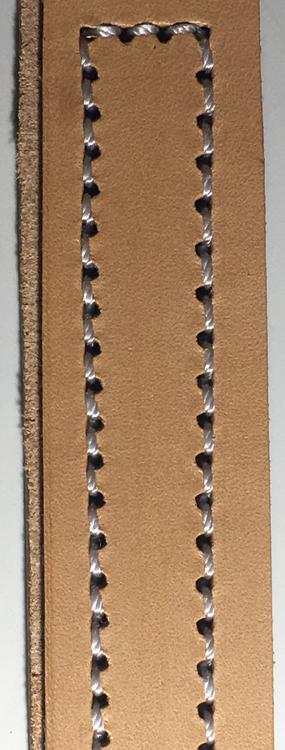

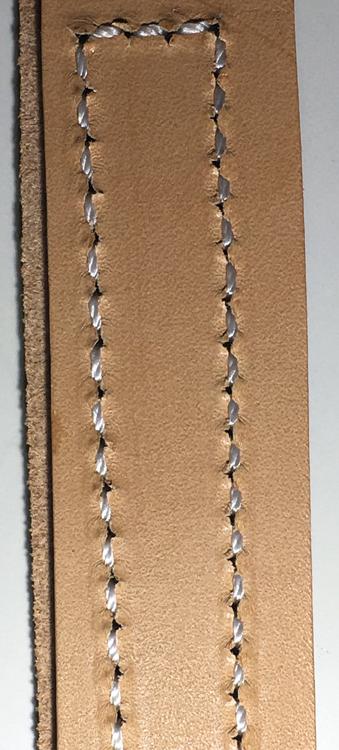

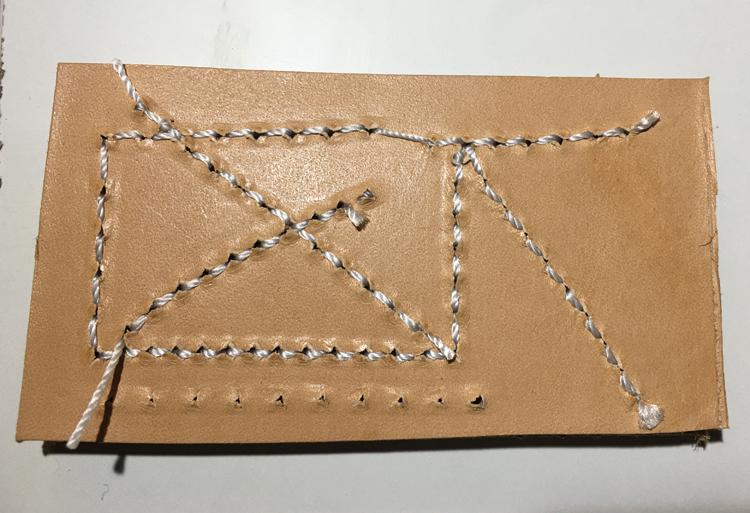

So I'm still practicing and I tried sewing 2 pieces of 7 oz leather back to back with grain side out on both pieces. The first picture is the top thread and the second is the bottom thread. #277 in both with #25 needle. How do they look to you folks that are familiar with this machine? The top and bottom empty holes were done without thread so you can see the holes. The lower right diagonal stitching on bottom stitch piece was pressed with a glass burnisher.

-

Thanks guys. I coated the western gunbelt with 3 coats of Resolene. Seems to keep dye transfer from happening. I coated holsters with 2 coats Resolene and still got rub off. Am going to coat with 4 coats on each

-

Thanks to all for your help. I may just be able to sew for client’s work soon.

-

thanks Dwight. Do you use nylon or Polyester?