Michiel

Members-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Michiel

-

I am working on an sewing machine were all the nickel corroded away from the neelde plate etc. i would like to nickel plate it again i can buy a set to do it myself: https://www.frost.co.uk/brilliant-nickel-plating-modules.html are there members who did nickel plate parts? difficult? Results? They also sell a set for "cold blackening" i orderd that anyway to try on some other parts https://www.frost.co.uk/frost-metal-blacking-solutions.html regards, michiel

-

Did you try the "user manual" for the adler 68 ? (From the second link) it is called user manual but it contains all lot of service information which you normaly find in a service manual (timing , adjusting feeddogs , hook etc) i just used it this evening for my adler postbed (put a new hook in it and had to shift the post to get the distance between the needle and the hook right) regards, michiel

-

And Here is the link to all the old adler manuals http://sew24.blogspot.nl/p/downloads.html

-

Its called manual but its more than that....

-

That's a nice trick, i learn something every day on this forum, thank you so much for al your posts! (4332 says your profile)

-

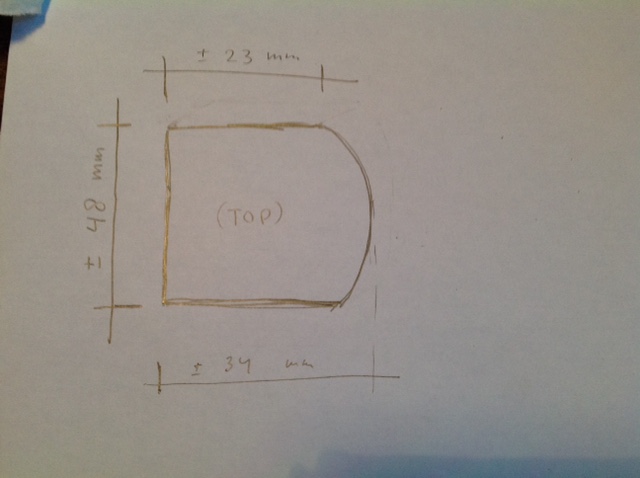

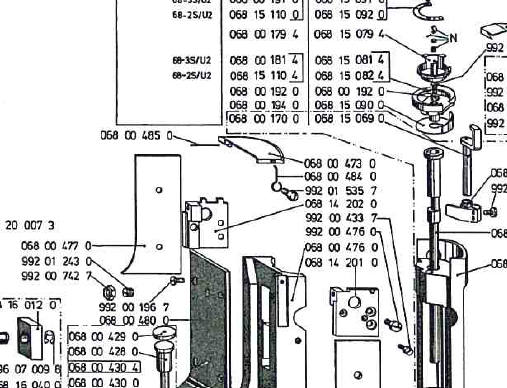

So i "found" an adler 68. doesnot need it really but it would fit in one of my adler tables and its nice to try to get it working after some cleaning it turns light, the timing seems to be alright too. some parts of the hook assembly are missing but that is the same as the adler 67 so i will be able to buy one (new or used) the cap wich protects the hook is more a challenge...(part 068 00 473 0) i will have to make one myself unless someone has an "parts machine" and is willing to sell that part. annyone ? I live in europe but have realatives is the usa so have an postadres in the states too. its an adler 68 2S U2 the cap is "shorter than the one wich is from the 68 2s ... i am aware its a wild guess but who knows.... regards, michiel

-

They seem to have an pfaff 195 (user) manuall: http://www.sewingmanuals.com/Sewing_Machine_Manuals/Pfaff_Industrial.htm (but did not try to buy one myself) regards, michiel

-

Adler 166 for sale. verry hard to find sewing machine for medium to heavy materials with 9 mm zigzag. tried to find one for years and finaly ended with two. selling the newest one which is serviced by a dealer in januari and in good working order. asking price 1800,- sewing machine is in amsterdam netherlands please sent me a pm for more photo's regards, michiel

-

I have two sewing machines i do not use verry often so they share one table (they have the same bedsize) i discovered that in my case the motor is heavy enough to produce the right moment to keep the belt on tension. (so its verry easy switching machines) it works because of the angle of the motor (realated to the v belt) maybe it works for you to (depending f the position of the connection between the table and the motor and the lenght of the V belt. since this works so well i try to have all my machines from the same " family" (adler in my case)

-

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

Yesterday i cleaned the outside of the machine (still not sure wther i keep it this way or put some new paint on it) its now ready to use. this post is to say thank you to this forum What a great place on te internet is this! kind regards, michiel -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

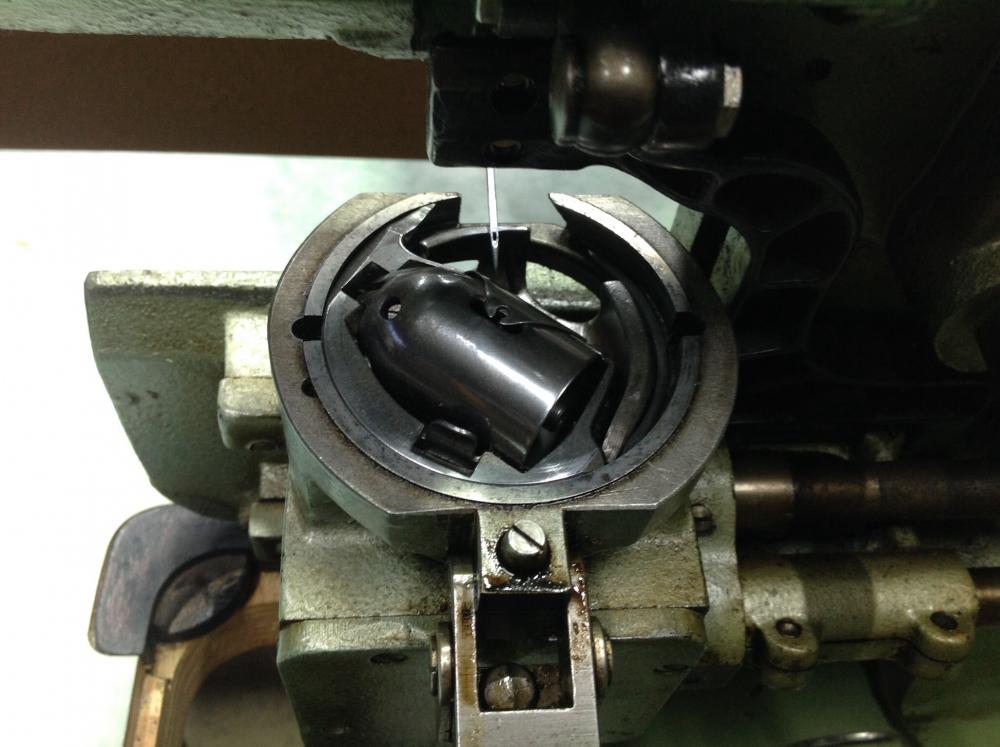

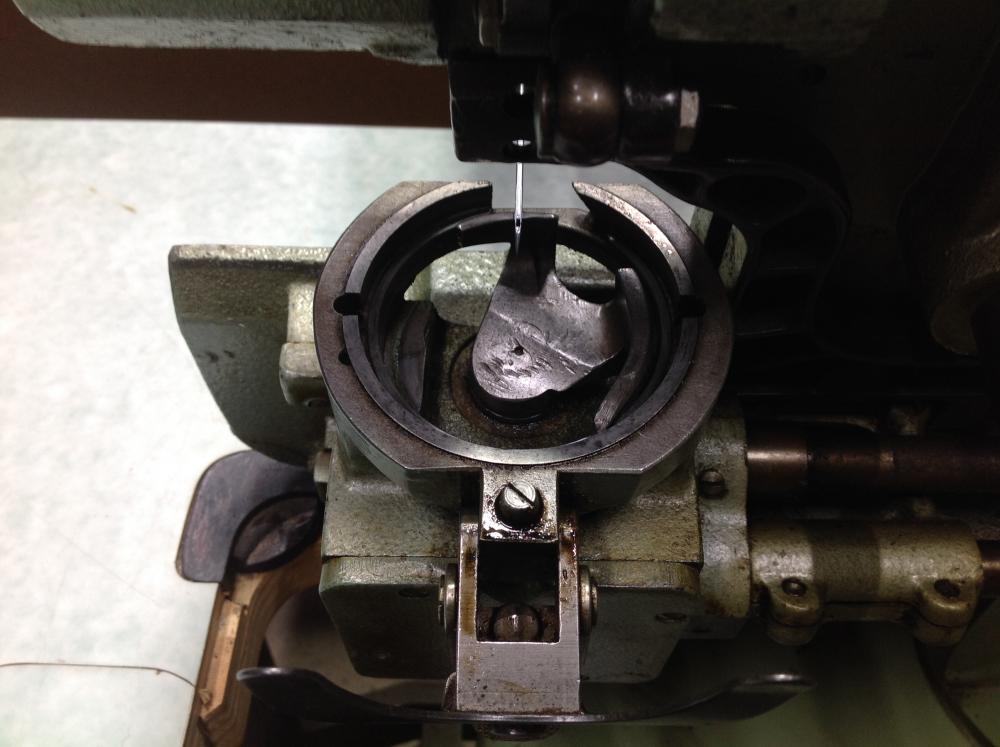

On the 2 adler 166 's i could look into the moment of inversion of the driver (in the race) is different from the 366 service manual. and because of that i think the driver should travel further to the left if i would follow the rule in the 366 manual.... on the foto you see the position of the hook on the moment of inversion of the driver (the "most to the left moment " of the hook) on this point i did not follow the 366 manual but the other machine.... the machine is sewing very well now so its more curiosity than a problem which should be solved -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

Are all the settings also the same? i used the service manual from the 366 since i did not find one for the 166. is there someone with an service manual for the adler 166? -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

Thanks, for your reply's. just Curiosity: does de race in the 366 als use thread, and are the race rings for extra? as far as i can see in the parts manual when they designd the 166 they thought it was enough to hold the race "on the thread "(sorry my english is not as good as i would like ) but on the 366 everything seems to be a little bit stronger... -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

In the adler 166 parts manual there are no race rings, but it seems my race (is it called so? ) to have the same part numbre (or is the six a five ?, hard to see on my copy -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

After giving it an other look i discoverd yesterday that my race (part 64 oo 205 0 on the expoloided vieuw) has thread on the outside so by turning it 360 degrees it moved to the needle. now the needle is in the middle of the neelde plate and the hook needle clearance is ok. this was the last adjustment i needed so now it sews like new. i changed the needlesystem to 7x23 bevause it has an longer scarf (and i already had a lot of needles in that system from an other 166) Because of of the stitchwide of 9mm or 10 mm it helps. -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

-

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

Thanks verry much Uwe and Constabulary, the needles are 328 (but always good to recheck) turning the needle bar did the trick the needle is now in the middle of the needle plate hole as i already expected (in some way) i now know why someone (maybe) put the machine the way it was: i now need to move the hook to the needle and need shims to fill the gap. i will see if i can find them or make them (and if not i can turn the neelde bar back again and try to move the needle plate) the machine is sewing but with its widest zigzag (9 mm) it skips sometimes a stitch on the left. i think it is more than the distance hook needle but start with that... thanks again your help is much appriciated ! -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

thank you too! i use the needles which came with te machine (and where the machine is timed to) and i am almost sure they are the 328 system, but i will check them as soon i am at my workshop. -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

that's an interesting idea. thank you i will investigate... -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

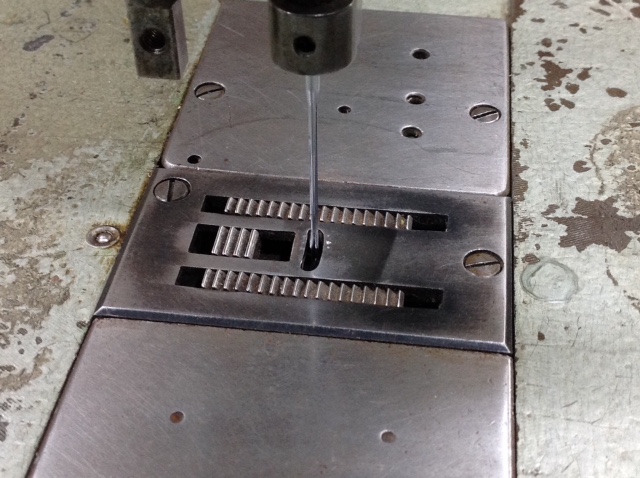

Thanks, here are some more foto's i would like to hear how this is done with other older machines (with single feed), can you adjust the needle bar or do you move the needle plate (or is it not possible at all) ps the needle looks big but it is a normal size for this machine (i think this picture is with a 160 needle) it is clear you cannot shift the needle plate (in the original design, i can make it shift) but i really cannot find an eccentric bearing to turn. -

Adjusting needle rocker to needle hole

Michiel replied to Michiel's topic in Leather Sewing Machines

Is there a way to upload more foto's (without starting another topic)? thanks anyway and apologies for my english...