Michiel

Members-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Michiel

-

-

Tension assembly is not the same holes are at different distance but it was not verry dificult to install an pfaff assembly on my adler (it works but you can see its not original) regards, michiel

-

That is why on an zigzag machine the hook is orientated the way it is (on the backside) : it needs to catch the topthread in both needle positions (left and right)

-

The hook catches both threads on the top side you see two rows of an straight stitch But on the under side you get something that looks like an strange zigzag

-

Attachment or something that will make an overlapping seam?

Michiel replied to VYO's topic in Leather Sewing Machines

Also available with triple transport -

Attachment or something that will make an overlapping seam?

Michiel replied to VYO's topic in Leather Sewing Machines

-

Rusty Adler 67-73 t w/ ac motor, do or don't?

Michiel replied to Badem's topic in Leather Sewing Machines

Badem, i have sent you an pm (in dutch) The 167 has an larger bobin -

Does anybody know what the bed size a pfaff 145 has ? want to know if it will fit in an existing table i have..... thanks in advance regards, michiel

-

Just changed my adler 220 from system. 7x23 to system 328 so i can buy leather needles for is (they are almost the same length)

-

Rusty Adler 67-73 t w/ ac motor, do or don't?

Michiel replied to Badem's topic in Leather Sewing Machines

just keeping an eye -

Rusty Adler 67-73 t w/ ac motor, do or don't?

Michiel replied to Badem's topic in Leather Sewing Machines

Acording the advertiser its a 63 (not 73) than it should be bottum and needle feed. all the adlers i bought (that old) were not dificult to get sewing verry well. this machine is for sale for some months now because he was asking to much (in my opinion) (if i were you i would sent him an email and offer 100 euro) regards michiel -

Last week i made a verry simple bag (a projectbag for my wife) and wanted some folded leather around it (to keep them open) i dohave some hemmers but they were nof big enough i did try to fold the leather with a steam iron and that did work out verry well in this case the leather was nof verry thick, i did use steam but did not make the leather complete wett and after it had the right form a waited about 15 minutes and than use sewed it (without glue) i donot know if this works with al kinds of leather but in this case it worked (i am not verry experienced with leatherwork)

-

I'm getting a birdsnest on the backstitch only

Michiel replied to christine1ca's topic in Leather Sewing Machines

Check the timing of your machine (if you never did that: take a look on other posts and watch what happens in your machine....) -

-

If you mount it that way you will be able to turn your machine backwards (which is good) but you have to change the rotation direction of the servomotor (just for the record, i am sure you already know) i did the same for one of my flatbeds. here is the quick device i made for the footpedal:

-

-

Orderd new decals here last year https://www.singerdecals.com/

-

Hello Arz, did you see this discussion last days: i have the same machine myself and normaly run v92 because of the small bobbins Think 138 will do did you see the specifications on the leaflett ? http://sew24.blogspot.com/p/downloads.html

-

Singer 111w list of subclasses & sales brochure

Michiel replied to Constabulary's topic in Leather Sewing Machines

In the aviation manuals they explain some adjustments on the 111w155 http://navyaviation.tpub.com/10330/css/Timing-The-111-W-155-Machine-10330_53-53.htm -

Thank you! i also found an servicemanual since the last post about this machine on this forum the adler website did put some more manuals on their dowload page Its too big to upload but here is the link https://www.duerkopp-adler.com/export/sites/duerkoppadler/commons/download/public/220/S_220.pdf

-

Its is almost the same as the singer 144w, so yes its dsigned more for canvas than leather but its strong, has triple feed and takes needles 200 so it will do till i find something else

-

Wen you push the left pedal the machine goes in reverse and wen you push it further it takes the other pedal also so you can sew in reverse with only pushing one pedal

-

Last weekend went camping in germany with my oldest son and brought home an (new to me) adler 220 (was watching it for months so it ended as an bargain) its working but i can't wait to clean and service it etc.... all my machines are in good working order and i use them (sometimes) but i am afraid i ended up to be also an vintage industrial sewingmachine adict (the good news is that i donot need to store them at home i know its not an heavy leather stitcher but want to use it also for leather so i think i will change the needle system it now is 7x23 but there are no leather needles for it (as far as i am aware) needle system 328 is just 0,8 mm shorter so i think that would not be a probelm (i changed my adler 166 the other way from 328 to 7x23)

-

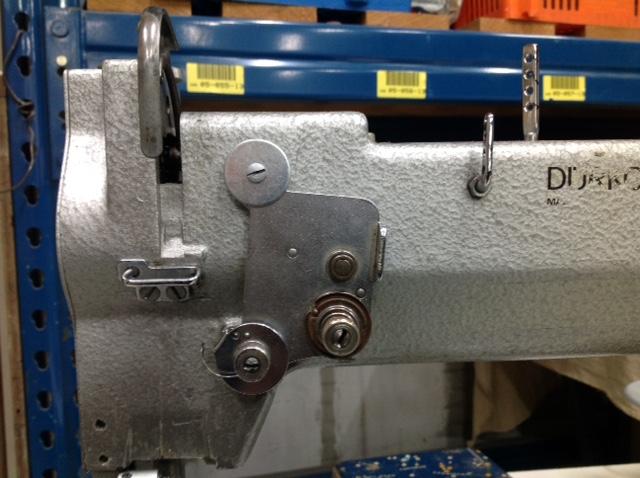

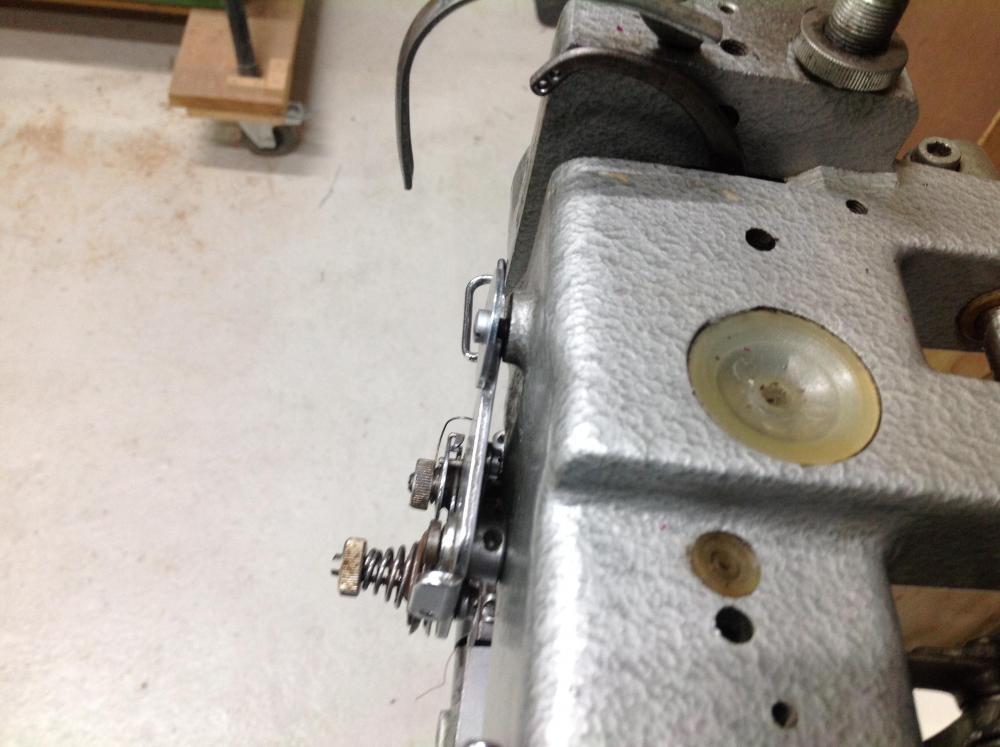

Just my impression: see the photo of the tensionunit It looks like the tread is not between the two plates where the spring is but behind them. i do not know this machine but to me it looks like it should be between them? but its early in the morning here and i might be totally wrong...(if others say its threaded ok ignore this)