Michiel

Members-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Michiel

-

Its not my machine but may be someone is intersted its an new adler 30-10 still in its original package i think 500 euros is a bargain Gerade bei #eBayKleinanzeigen gefunden. Wie findest du das? https://www.ebay-kleinanzeigen.de/s-anzeige/industrie-naehmaschine-adler/2054171307-240-3038?utm_source=copyToPasteboard&utm_campaign=socialbuttons&utm_medium=social&utm_content=app_ios

-

I can imagine when i started I bought an old (not very expensive) sewing machine to see if i could fix it before trying it on more expensive machines

-

Timing a sewing machine is no magic. i would suggest you read about it on internet and / or watch videos about it (no matter what kind of sewing machine, just to understand whats going on) than dowload a service manual for your machine and follow (all) the steps in it first time it can take some time to figure out where the screws are located but after a few times you even do not need an manual to time an unknown machine if you cannot find your service manual on internet you can sent me a dm kind regards, michiel

-

No timing marks just rotate shafts till the timing is right.

-

I have the service manual but only in german if you sent me an dm i will mail it to you nb: to replace the timing belt you do not need to take the machine apart (i changed the timingbelt of my adler 169 in about 1 hour) It is the same procedure as the adler 167 , you will find it on this forum (google adler timing belt replacement)

-

I have got a some Adler spare parts frome someone who got them a from a “adler repair guy”. most parts i can recognise but there is one thing what looks more like a special tool i has no part number or brand and it is even possible it is not sewing machine relateted but anyway: is there some one who knows what it is? (looks like you can use it to remove an bearing but i can not see were to use it) any thoughts? Regards, michiel (Scale is cm)

-

Low Profile/Buckle Foot for Adler 69

Michiel replied to nycnycdesign's topic in Leather Sewing Machines

There is a adler 69 model with only needle feed (no moving inner foot) If his machine has triple feeed the shown feet will work indeed -

Low Profile/Buckle Foot for Adler 69

Michiel replied to nycnycdesign's topic in Leather Sewing Machines

The feet for adler 69 are the same as for adler 267 but you need a machine with triple feed for this feet. You said youre machine has a “not vibrating arm” if you have the needle feed variant, this feet will not work. -

If you remove the inner feet, the outer feet wil stop oscilating. But i think you need other feed dogs and needle plate to get get it working and figure out to get the roller on the right spot….. its easier to get another machine i guess but if you like to tinker, it could be a project

-

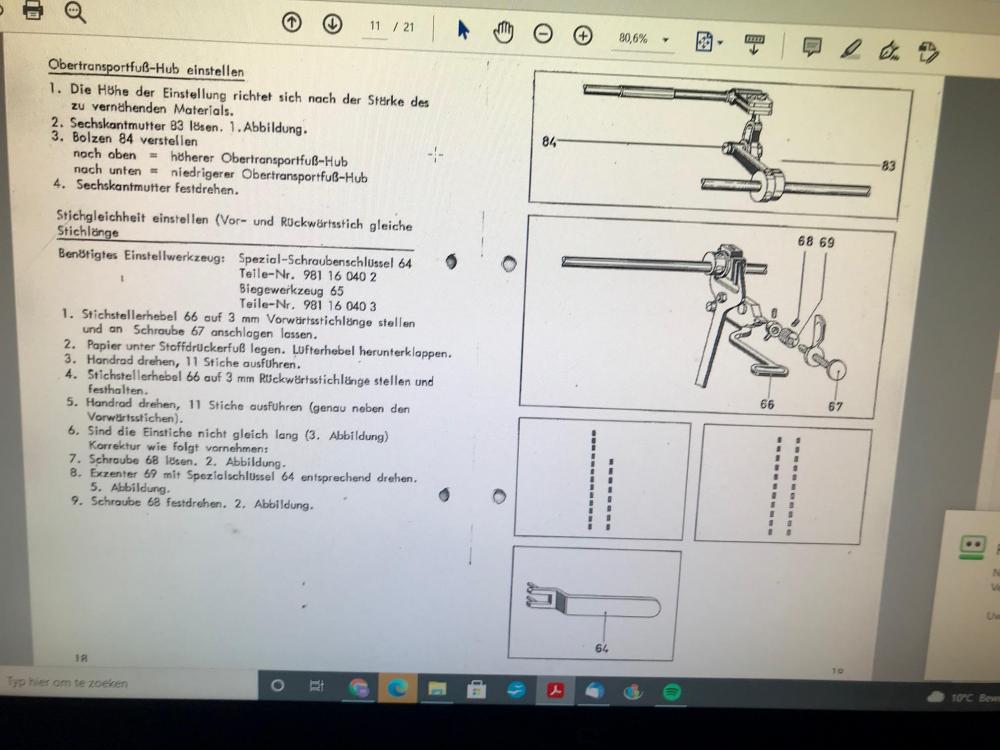

Pfaff 145 h3 reverse stitch length shorter than forward

Michiel replied to ThomasBH's topic in Leather Sewing Machines

In the service manual there is always an order in which you should do all the adjustments (and sometimes the advise doing an previous adjusment again) i think it is best to check all the adjustments in the right order before doing the adjustment which is obvious neccesary (but i have to admit i am usualy not very concerned about being revers and forward exact the same since i hardly notice small differences if i just make two or three stirches back and forward) -

Pfaff 145 h3 reverse stitch length shorter than forward

Michiel replied to ThomasBH's topic in Leather Sewing Machines

What i do is rotating the exentric just a litle bit, fix it, and than rotate the handwheel to check the feed (and repeat that a few times) most of the times i put the needle at the hook point ( the position you use on timing the hook - needle) but i think it depends on the model / make of the machine -

-

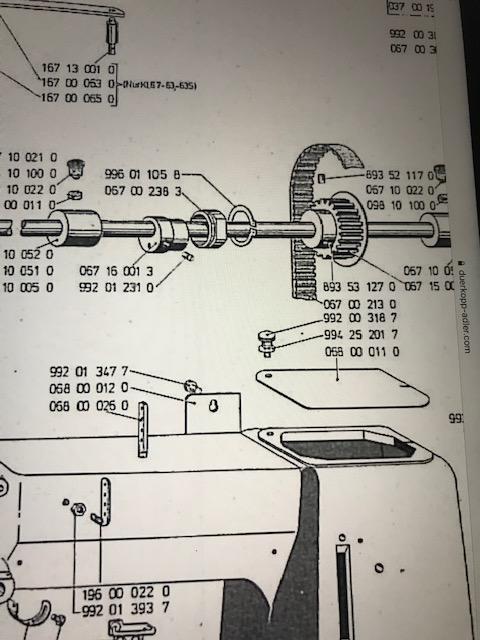

Adler 068-4272 high post bed walking foot double needle

Michiel replied to Pierick's topic in Leather Sewing Machines

And the parts manual https://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Parts_Books_Adler/68.pdf -

Adler 068-4272 high post bed walking foot double needle

Michiel replied to Pierick's topic in Leather Sewing Machines

Service manual (but only in german) https://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Manuals_Adler/Manual_Adler_68.pdf your machine is from page 44 - 47 -

question on older Adler cylinder arm machine

Michiel replied to UncleSam's topic in Leather Sewing Machines

This is the timing belt for the 169 https://www.college-sewing.co.uk/0169002130-timing-belt-adler-169-269-genuine.html -

question on older Adler cylinder arm machine

Michiel replied to UncleSam's topic in Leather Sewing Machines

Here you will find the service manual https://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Manuals_Adler/Serviceanleitung_169_DE.pdf -

question on older Adler cylinder arm machine

Michiel replied to UncleSam's topic in Leather Sewing Machines

It is an adler 169 I have the same (and had to put a new timing belt on it too) michiel -

i took a better look to your photos: your cam is better than de photos i used till now This really helps, thanks again for your efford!

- 11 replies

-

- bernina 217

- chandler 217

-

(and 2 more)

Tagged with:

-

Thank you John, this will help improving my self made cam kind regards michiel ps: for who is interested : my machine has the 6 mm stitch but i figured out with a new cam and some small adjustments it should be possible to make 12 mm with 2 or 3 step stitches (i need to replace the feed dogs, needle plate and foot but they are not so expensive since global makes them)

- 11 replies

-

- bernina 217

- chandler 217

-

(and 2 more)

Tagged with:

-

Adler 67-GK373 stitch length and reverse

Michiel replied to andru's topic in Leather Sewing Machines

Thank you this is not from the 167 service manual (but i think it was mentioned in other manuals) i do it often after hooktiming (and check the other adjustments from the manual after it) i think its not a bad idea for other brand triple transport machines too and wondered if more people do it that way… -

Adler 67-GK373 stitch length and reverse

Michiel replied to andru's topic in Leather Sewing Machines

Part 69 is excentric you can turn it by a special tool (64) or you use two nails…. -

Adler 67-GK373 stitch length and reverse

Michiel replied to andru's topic in Leather Sewing Machines

The forward and reverse handle mechanisme has an hidden way to adjust forward en reverse stitching it is only in de 169service manual but its the same on 67 167 69 etc i did only find a version in german https://www.duerkopp-adler.com/commons/download/download-text-attachments/Vintage_Manuals_Adler/Serviceanleitung_169_DE.pdf its on page 18-19 -

Adler 67-GK373 stitch length and reverse

Michiel replied to andru's topic in Leather Sewing Machines

-

Adler 67-GK373 stitch length and reverse

Michiel replied to andru's topic in Leather Sewing Machines

Hi andru, I have the same machine (more than one) i think you should adjust the excentric on the (top) mainshaft. what i usual do is put the needle an the hook in the postion that the hook just is about to pick up the thread and than move the reverse handle if the needle bar moves i adjust the excentric so that the needlebar does not move when going up and down with the revesre handle good thing is : the timing in reverse is now the same as in sewing forward the better thing is, with most of my machines the forward and reverse are more or less the same. fine tuning is possible with an excentric on the front side (but its rare you need to do that) but first of all best is to follow the service manual step by step. Did you find the service manual on internet? kind regards, michiel