Michiel

Members-

Posts

229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Michiel

-

Turns out its an german language only version (I am sorry) But You might be able to translate it online if you sent a pm with your email adres i can sent it by email (i think i do have a service manual for the adler 167 in english, you might be able to use that as well)

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

I do have a service manual (it did help me with my 169) maybe a moderator can help me to post it because its bigger than 1.46 mb

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

Do you have a service manual? In my experience, it's best to do all the settings in the order described if you really want the machine adjusted properly Michiel

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

Wheel feed issue - problem or design limitation?

Michiel replied to ElfLeather's topic in Leather Sewing Machines

Yes, you should try to get the feed dog higher. shoul be possible from the underside of the machine -

I am not sure its in the manual but i should first follow the complete procedure in the manual. And if its not in the manual i would try to tinker a little with excentric b on photo 1 (just my two cents…) michiel

-

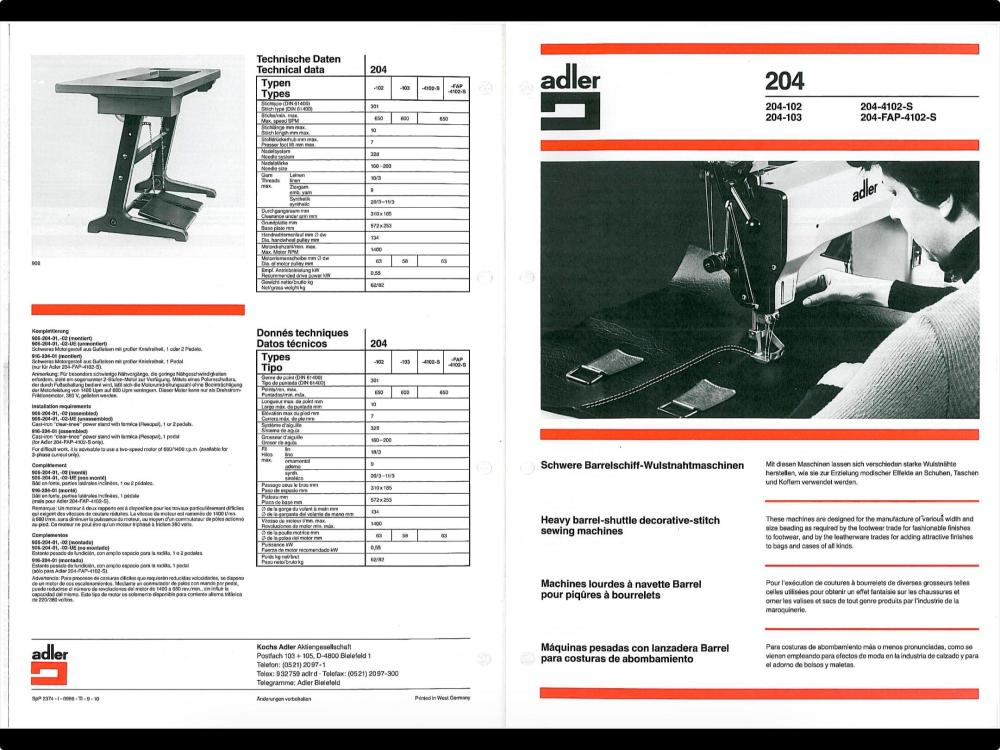

https://www.duerkopp-adler.com/fileadmin/dag/Media/Downloads/205/S_204_EN.pdf

-

Very interesting what did the set cost? en can you post a picture of your bernina? kind regards , michiel

-

These old durkopp machines are rare. if the internal timing belt fails i doubt if you will be able to find a replacement (for the more popular adler or durkopp-adler models its not difficult to find them) otherwise if its good it could take a long time before you need one. For Myself i would rather buy a zig zag machine without a timing belt for example bernina 217 / adler 1217 or a pfaff 138

-

I am willing to help with shipping But at the expense and risk of the buyer Shipping overseas preferably just the head (I can make a crate for that). If seriously interested contact me and we will see what is possible. (But try and pick up on site is of course always preferred) kind regards, Michiel

-

-

Did you try to combine two smaller shims to get the right size (or a little wider)?

-

Did you find the parts manual? Maybe its not what you are looking for, but this is what’s available for adler machines

-

Adler 205-370 feed dog and needle plate

Michiel replied to Michiel's topic in Leather Sewing Machines

Yes you are right! i first was not sure if this was a moving binder, but after looking to the video of Uwe i understood this is also a moving binder (but connected in an other way than the binderset i first looked at. All in all, I do need quite a few parts for this solution (the other option was a complete set) and I don't think I'm doing enough binding to justify the effort of conversion and total cost . i think i will start trying with a non moving binder (for most binding my adler 69 and 67 with moving binder setup will do anyway) -

Adler 205-370 feed dog and needle plate

Michiel replied to Michiel's topic in Leather Sewing Machines

Thanks, i think i will give that a try first -

Adler 205-370 feed dog and needle plate

Michiel replied to Michiel's topic in Leather Sewing Machines

I think you have a good point there. For lighter work i have dedicated binder machines to avoid that I'm going to take that into consideration -

Adler 205-370 feed dog and needle plate

Michiel replied to Michiel's topic in Leather Sewing Machines

Thank you, if its not impossible, than i think you're right. I have ordered there before and that was a good experience -

I recently bought an adler 205-370 and would like to buy a moving binder set. Kwok Hing offers one for the juki 441 but they claim it also fits the adler 205. https://www.khsew.com/index.php?route=product/product&product_id=1902 Is that possible? are feed dogs and needle plate for the juki 441 and adler 205 Exchangable? Thanks in advance Michiel

-

Yes 950 euro Thank you i will try to edit my first post….

-

ADLER 204-102 heavy duty two needle cording sewing machine recently serviced and in good condition machine is in Amsterdam, netherlands price 950 euro please sent me a pm for more information or photos

-

Or maybe the moderator can post it for me…