Michiel

Members-

Posts

217 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Michiel

-

Hook to Needle Distance: A Compromise

Michiel replied to friquant's topic in Leather Sewing Machines

I would try too see what’s happening when actualy sewing with tread and material (leather, canvas or what you are using) It can be hard to see, but if you can, and turn the machine by hand, you can see what is the problem if the machine forms a good loop in the thread the hook needle distance is not that important but if your thread is bad or the timing wrong you might get this. with some machines you can see it by sewing on the edge of your project and open the slide right of the needle sometimes you have to look from the underside. use a flashlight! -

help from the masters..... Is the machine fixable?

Michiel replied to MattiJoy2's topic in Leather Sewing Machines

I have seen adlers with a crack that stil worked. (For a long time) i would like to see a picture, but in generall i think: “if its not broken, don’t fix it” (if you have someone who thinks he can weld it, you might consider to buy it and start using it) -

Just a guess: Have you tried pushing the button you use to set the stitch length?

-

Did you see this recent thread? Is contains find the service manual This looks fine to me

-

According to the manual they are both for foot pressure. i think the small one is ment for fine tuning

- 3 replies

-

- sewing machine

- adler

-

(and 3 more)

Tagged with:

-

Searching for an odd machine oil. Assistance.

Michiel replied to HondoMan's topic in Leather Sewing Machines

If it is sold as sewing machine oil your machine will be fine -

I hope I am clear enough my (technical) English is not good

-

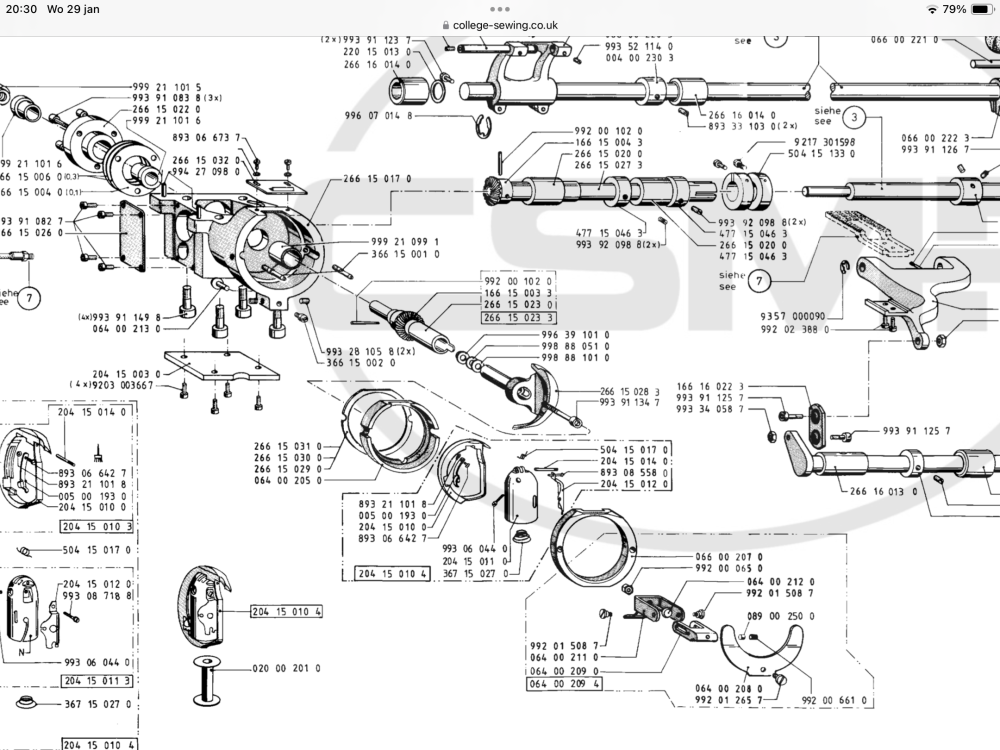

Here you find the partbooks https://www.college-sewing.co.uk/parts-books/durkopp-adler-sewing-machine-parts-books.html but i think you have a change your barrel hook race is threaded on the backside and you can make your adjustment by making turns anti clockwise

-

I might be wrong but i think i have had a 166 where one can turn the race for the barrelhook to move it front and backwards you could try that….

-

I think i had some help from the service manual for the adler 366 when I worked on my adler 166

-

Hook setup is the same as adler 205-102 adler 266 and adler 366 (Part 266 15 on this one) I think the hookdriver act as an needle guard

-

If I remember correctly, the distance is set with shims

-

Turns out its an german language only version (I am sorry) But You might be able to translate it online if you sent a pm with your email adres i can sent it by email (i think i do have a service manual for the adler 167 in english, you might be able to use that as well)

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

I do have a service manual (it did help me with my 169) maybe a moderator can help me to post it because its bigger than 1.46 mb

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

Do you have a service manual? In my experience, it's best to do all the settings in the order described if you really want the machine adjusted properly Michiel

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

Wheel feed issue - problem or design limitation?

Michiel replied to ElfLeather's topic in Leather Sewing Machines

Yes, you should try to get the feed dog higher. shoul be possible from the underside of the machine -

I am not sure its in the manual but i should first follow the complete procedure in the manual. And if its not in the manual i would try to tinker a little with excentric b on photo 1 (just my two cents…) michiel

-

https://www.duerkopp-adler.com/fileadmin/dag/Media/Downloads/205/S_204_EN.pdf

-

Very interesting what did the set cost? en can you post a picture of your bernina? kind regards , michiel

-

These old durkopp machines are rare. if the internal timing belt fails i doubt if you will be able to find a replacement (for the more popular adler or durkopp-adler models its not difficult to find them) otherwise if its good it could take a long time before you need one. For Myself i would rather buy a zig zag machine without a timing belt for example bernina 217 / adler 1217 or a pfaff 138

-

I am willing to help with shipping But at the expense and risk of the buyer Shipping overseas preferably just the head (I can make a crate for that). If seriously interested contact me and we will see what is possible. (But try and pick up on site is of course always preferred) kind regards, Michiel