Michiel

Members-

Posts

230 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Michiel

-

Or maybe the moderator can post it for me…

-

Do you have the service manual (manual for mechanics)? what i should do is follow all the steps as described in the manual (in the right order) i do have one but its to big to post for me (if you sent me a pm i can try to sent it) kind regards, michiel

-

Help with thread wrapping around bobbin case.

Michiel replied to cynthiab's topic in Leather Sewing Machines

I have seen twice a machine with a slightly bend upper axis Because of the load of the timing belt it sometimes resulted in the hook turning a little backwards when the machine stopped. (and than happend what you describe) this did not happen till the old motor (with break) was replaced by a servo motor. the first time it took me some time to figure out wat was going on…… -

Well done!

-

Hi Andre, Are you aware that you also have to replace the take-up lever? (You need a bigger one) regards, michiel

-

College sewing is also a good source if you donot find them in your neighbourhood https://www.college-sewing.co.uk/parts-by-machine/durkopp-adler-parts/durkopp-adler-67-sewing-machine-parts?p=2

-

I have one but its to big to post for me sent me a dm or may be a moderator can post it here

-

With this type of tensioner, the idea is to make two (or one and a half) turns. The idea is that the wheel turns with it but experiences resistance from the spring being tightened. The advantage over the other system is that it is less sensitive to variations in thread thickness. The pre-tensioner is to keep the wire tight around the disc so that the disc turns with it.

-

Seiko STW-8B needle bar rock mechanism

Michiel replied to Joanah08's topic in Leather Sewing Machines

Hello joanah, This play is very common in old machines. Usually it is due to play in different joints (which add up). If you have the impression that there is one joint that has more play than the rest you might indeed consider addressing that one (but usually the play is in several places). It is also a question of whether only the part you want to replace is worn, or also the shaft it rotates on. (Often one of the two parts is of a softer material, but how that is here I don't know). I bought a lathe and milling machine to possibly fit new parts but haven't gotten around to it myself yet -

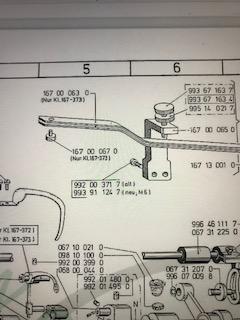

Adler 167-273HU worth restoring or parts only

Michiel replied to SingerDad's topic in Leather Sewing Machines

-

Adler 167-273HU worth restoring or parts only

Michiel replied to SingerDad's topic in Leather Sewing Machines

https://www.college-sewing.co.uk/167000670-bushing-durkopp-genuine.html -

Adler 167-273HU worth restoring or parts only

Michiel replied to SingerDad's topic in Leather Sewing Machines

Presser foot https://www.khsew.com/index.php?route=product/product&path=243&product_id=277 -

Adler 167-273HU worth restoring or parts only

Michiel replied to SingerDad's topic in Leather Sewing Machines

Did you find a parts manual? https://www.college-sewing.co.uk/parts-books/durkopp-adler-parts-books.html de presser foot is probably not in it but you will find it online In my experience these are good machines Myself i would consider to-change it to a one needle version ( but its less work to install an extra tension unit and a presser foot) -

I think its a good buy. even if you have to replace the belt. i once bought one in the same condition (i think) replaced the belt, did all the adjustments by the book and have a great machine. (but i think: do not fix it when it’s not broken) kind regards Michiel

-

Nice work, After i made my cams i figured out that by making them a little larger i could make my stitch with also wider. i bought a wider feed dog needle plate and foot from global (which fitted my older bernina) and was able to enlarge my stitch with From small to much wider

-

Pros And Cons: Cylinder Vs Post Vs Flat Bed

Michiel replied to MartyS's topic in Leather Sewing Machines

Thinking about it: when you use thick leather a cilinder arm is great and there are not much advantages with a post bed. But for thin stuff a post bed is more versatile in my opinion. I think that’s why most members here are for cilinder arms (and they are right) It depends on the material and the design of your projects -

Pros And Cons: Cylinder Vs Post Vs Flat Bed

Michiel replied to MartyS's topic in Leather Sewing Machines

A postbed is great for top stitching bags I have cilinder arm and post bed machines , but when making bag’s I always use my postbed and hardly a cilinderarm -

I tried to 3- print them worked but i was not 100 % satisfied the Bernina favourite (household machine) shares the same hook and has the same cams inside I bought one for the hook and finally pulled the cams out: they are the same as the old bernina 217 cams the global has an other size cambox and cams i believe

-

Nice machine! i looked last week for someone: college sewing sells extra wide feed dogs, needle plate and foot for this machine (just in case you want an extra wide zig zag and you do not already have them)

-

With triple feed and needle feed machines very often the side “play” from the needlebar can be removed very easy see the picture the part my screwdriver is on should move a little bit to the needlebar assembly the screws are on the backside do not make it too tight ! (A litle bit of play is better for the machine)

-

You will need a smaller pulley on your motor to slow down your machine….(in the title you mentioned a large one)

-

New Roller foot conversion for juki 1341 etc

Michiel replied to localcraftsman's topic in Leather Sewing Machines

When you remove the inner foot of a triple feed machine you wil have a needle feed machine. You will need an other type of outer foot (or roller foot as is in this kit) but to work good you need also an other set of feed dogs and needle plate its not clear for me if the sent you only the roller foot or also the other parts -

I usually use a small nail for that which I cut to size

-

I would look for a service manual and follow al the steps to set it up in the right order (so not try only to solve one problem but go trough the manual step by step) by doing that you will and up with a well adjusted machine working like it was when it left the factory https://www.duerkopp-adler.com/fileadmin/dag/Media/Downloads/269/S_269.pdf

-

Is this similar to the brother LZ-B652? (The early sailrite) That is a very nice zig zag machine With most zig zag machines the hook is too early at the left sticht and late at the right stitch the hook of this machine goes a little bit faster when making the right stitch and slower on the left one (you can see the mechanisme at work on the underside of the machine) its very helpful with this 12 mm stich it doesnot have the walking foot but i know this machine and the new original sailrite: the vintage brother has much more quality