-

Posts

347 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JJN

-

Other Thread Size Specifications Listed by Juki

JJN replied to JJN's topic in Leather Sewing Machines

Thanks for that link @Wizcrafts. I may have to read it a couple more times but that is an excellent article on the subject. I have to remember the world is not all bonded nylon and polyester. I have been reading on this forum daily for the last few months and I am getting a good education about industrial sewing. Thanks to everyone for sharing their knowledge and experience. -

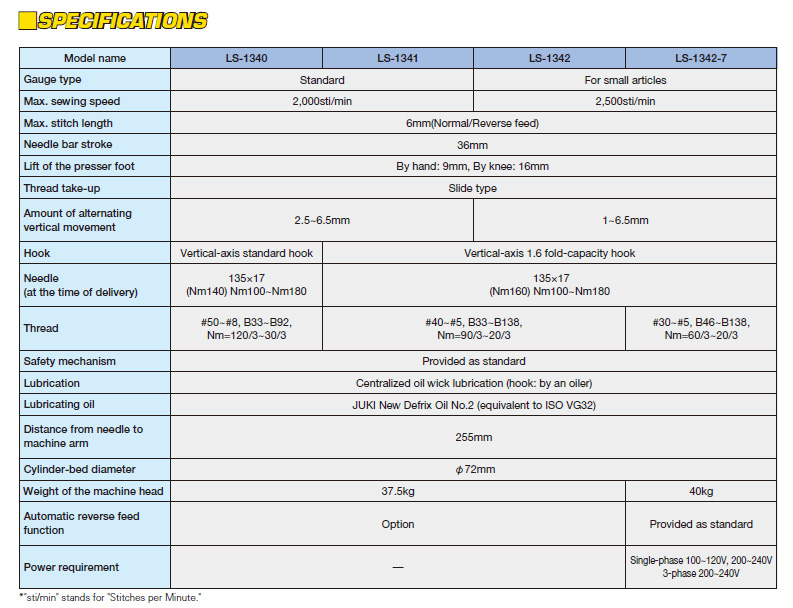

When I look at Juki sewing machine specifications for thread capabilities I see other thread size values that I cannot find any reference or comparison to. I have looked at the charts referred to here on LW but I do not see these measurements systems. #50 to #8 and Nm120/3 to Nm30/3 is equivalent to B33 to B92 and. #40 to #5 and Nm90/3 to Nm20/3 is equivalent to B33 to B138 (#50 and #40 both equal to B33) Does anyone have a full scale conversion chart of the '#' system and the 'Nm' system used by Juki?

-

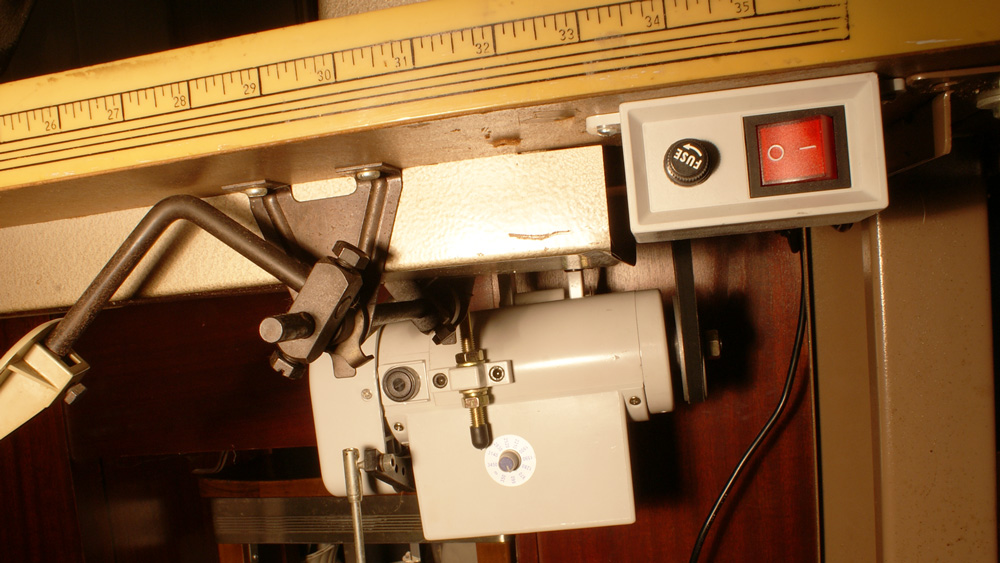

A new table without the motor will cost $200-$300 with shipping. The servo motor costs $110 - $150 delivered. If you have the room it is worth getting in my opinion.

-

It has to be a 206rb-3 or 206rb-4. the rb, rb-1 and rb-2 do not have the dial stitch length control. The 206rb-5 has the push button lock above the stitch length dial. Great find at a great price. You have to buy those deals when you see them or they will be gone.

-

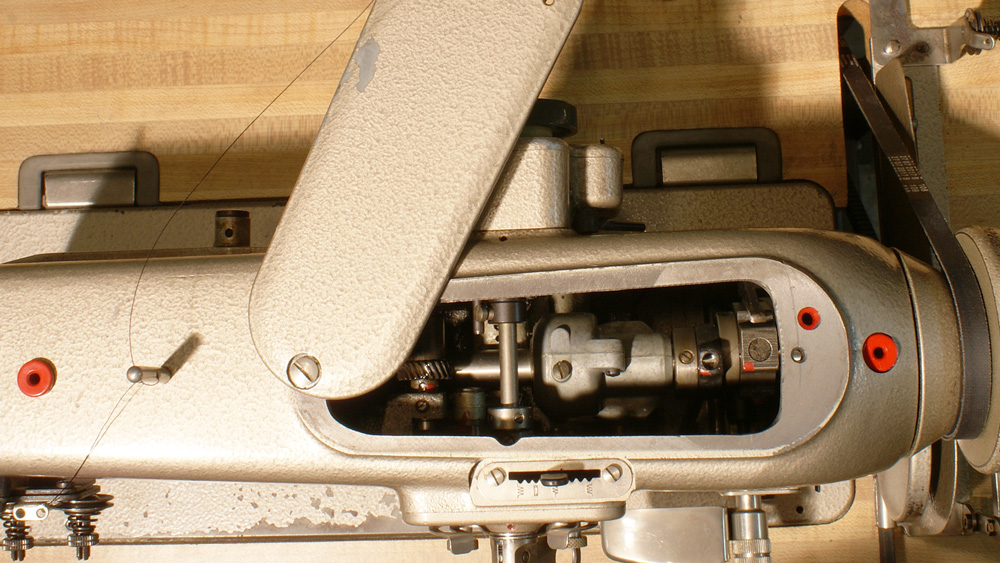

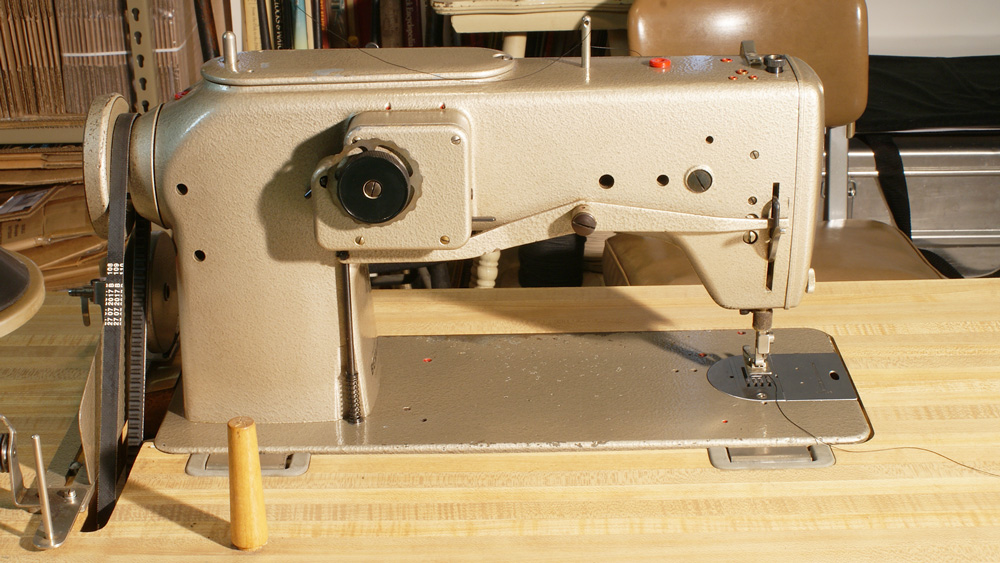

Thanks Eric and everyone else who responded. We had a successful trip and the advise offered here really helped. We drove from southern Oregon to SF Bay and got 3 machines. The 2 that were bought new and never used are the 9010 mentioned above and a LS-1341 cylinder bed which was my main reason for going. Also picked up a really nice, cosmeticly perfect 206RB-1. The 9010 was no problem to remove from the table. Just had to unplug like gottaknow said. I'll post some photos when they are running. It was a long drive, but an incredibly fantastic deal found on Craigslist.

-

DrmCA, I don't think this machine has any pneumatic hoses. I am hoping all the electrical connections to the head have connectors so all I have to do is unplug them.

-

If it is working good, that seems like a good price. I see a lot of 562's but haven't found a 563 yet. What is the table and motor like. Servo or clutch motor. Do you have any photo's?

-

I am picking up a Juki DLN-9010A-SH machine with a CP-180 control panel this weekend. It is new and unused but the seller is not a dealer. It was bought for a project that never happened about a year ago. It is about a 7 hour drive from here. I will need to remove the head from the table. I have no knowledge of how easy it is to disconnect the electronics. Any advise, tips or precautions will be much appreciated. Thanks.

-

I hope I can jump in on this thread. I am picking up a Juki LS-1341 next week and would like to know what binders are available for this machine and any experiences or recommendations folks here at LW might have about binding on this machine. I also have a Juki flatbed 1541s and can attest to @kgg comments that it is a fantastic machine and I have no regrets buying it.

-

Here is a link to CL ad for a barely used 206rb-5 for $700. I know it is not in your area, but I show it as an example that deals can be found. My experience is that good deals are gone quickly. Sometimes they are sold less than an hour and the ads are deleted. If you want to find a good machine at a good price, determine all the Craigslist locations that you are willing to drive to and check several times every day. Search separately for 'sewing machines', 'consew', 'juki' and 'industrial machine'. Not everyone puts 'sewing machine' in the titles. I have found some fantastic deals this way. https://seattle.craigslist.org/oly/tls/d/consew-206rb-5-walking-foot/6641688818.html update: here is a machine in your area, found with a search for 'consew'. https://stlouis.craigslist.org/bfs/d/rebuilt-consew-255rb-1/6608441800.html

-

Hi Eric, I found a deal on a couple of new (less than 10 hours) Juki's that are about a 7 hour drive from me. I am picking them up in a pick-up with a shell and slide out bed. I have to remove the heads to fit the tables in the truck. I figure the LU-1341 is like my DNU-1541s and no problem. The other machine is a DLN-9010A-SH with a CP-180 panel. I am not sure what I need to do to safely remove and transport the head for this machine. I have read on this forum that you know these machines well and hope you can give me some tips. It looks like a very capable machine for production work.

Thanks in advance.

John

-

Lynn, Send me a PM with your address and I will ship 6 of them to you. No charge. Thanks, John

-

I just tried a couple 16x257 needles and they fit perfectly.

-

Included with a purchase I made was a large quantity of these bronze (or brass) two needle clamps. I have no idea what machine they are for but I suspect it is an old domestic type of machine. It has a 0.25" hole to attach to the needle bar. The holes for the needle shanks are smaller than a normal domestic needle and measure 0.068", or a little over 1/16". The needle centers are 0.085" or 2mm apart. The overall height is 0.688" ant the width is 0.500". The needle holes are drilled through to where the needle bar stops. I have a ton of them. I am sure it is not for an industrial leather sewing machine, but I figured someone on here might recognize them. Any help is appreciated.

-

Aaron, The accessories go with the machine. It would be kind of crazy to separate them as it would make the machine unusable. Try ebay for the parts you are looking for. John

- 11 replies

-

- bernina 217

- chandler 217

-

(and 2 more)

Tagged with:

-

I've been using Chapman Mfg. screwdrivers for a couple years now. They are American made and top quality. Here is a suggestion. Spend about $100 and get the Master Set. You will use it for everything, guns, auto, home repairs and more. I made a list the tool bits that fit specific screw heads I turn on my sewing machines and made a custom set for each machine. You can easily order just the bits you need ($1.50 +/-) and additional ratchets.

-

Just Picked up a Pfaff 138 - Time to Get It Sorted Out

JJN replied to JJN's topic in Leather Sewing Machines

Does anyone have a source for the tension assembly for this machine? Pfaff # 91-007655-91. Or is there another assembly that will fit. Maybe other European machines from this period have compatible parts? Otherwise I have found a tension post for the 145 that says it is also for the 138. Can I just press the old broken tension post out and press the new one in? -

Just Picked up a Pfaff 138 - Time to Get It Sorted Out

JJN replied to JJN's topic in Leather Sewing Machines

@brmax, There is an inventory tag on the legs that tell me it is from Eastern Oregon Hospital and Training Center in Pendelton, Oregon. It was a psychiatric center. Probably used to repair gowns and bedding. -

Just Picked up a Pfaff 138 - Time to Get It Sorted Out

JJN posted a topic in Leather Sewing Machines

I recently got re-interested in sewing because of a machined writing pen project I did last year. I needed a pen pouch as a part of the 'packaging' of the pen. I was in a hurry and ended up getting a domestic serger and it worked out very well. I then started my education on industrial machines on this site. I learned so much. Early on I picked up a couple of class 68 tackers with a Chandler/Bernina 217 with a cam reader. I got the 217 running but knew I needed a walking foot for the bags and notebooks I wanted to make. From the advice here I bought a Juki LU-1541S from Keysew. @Gregg From Keystone Sewing was very helpful and shipped me a beautiful machine, all set up and ready to go at a great price. Thanks Gregg! I kept looking on craigslist and have since found a Consew 206RB. I have been reading on here about the Pfaff 138 and knew I would buy one if if was in nice shape and affordable. Yesterday I found this Pfaff. It was a 600 mile round trip and I got home at 2am but I am really happy with this find. The bonus is it is a 6mm ZZ, hard to find I have read. It has been stored for 5 years so I need to clean and oil. I'll post an update when it is up and running. -

FN 40 snap on holster set

JJN commented on Bolt Vanderhuge's gallery image in Our Leatherwork Galleries

-

I've been reading posts on this forum for several months now and have gained so much knowledge about industrial sewing machines. I want to thank all the contributors for taking the time to share their valuable knowledge and experience to people just getting started. I knew that sewing was in my future a few months back when I picked up 3 industrial machines about 5 months ago from Craigslist and started the journey. I didn't know much back then but bought them because I love machinery and they appeared to be a good deal. The purchase was for a Bernina 217 and two old Singer bar tackers. I followed many threads on this forum and realized what I really wanted was a walking foot machine. I changed my mind a dozen times about what machine I would get and finally ordered a new Juki DU-1541S from Greg at Keystone Sewing based on the recommendations on this board. It is expected to be delivered this coming Friday. I can't wait. Greg was super nice and helpful. I will be doing more business with him in the future. So after I ordered my new machine, a Consew 206rb in almost new condition was listed about 100 miles from here for $500. I couldn't pass it up. I am in the process of cleaning the 12 years of idleness off the machine and getting it ready for sewing. It is an awesome machine too. I have to make room so I listed my Bernina in the LW Marketplace. I plan on sewing Cordura and webbing at first, to sharpen my skills,, before I start working on leather. I am sure I will be reading more threads on here for sewing tips now that I will have some very nice machines to work with. Here are some photos of my first machines, the Bernina and the Consew. I am very glad to become a member of this forum. Thanks! John Noveske Sr.

- 1 reply

-

- introduction

- grants pass

-

(and 1 more)

Tagged with:

-

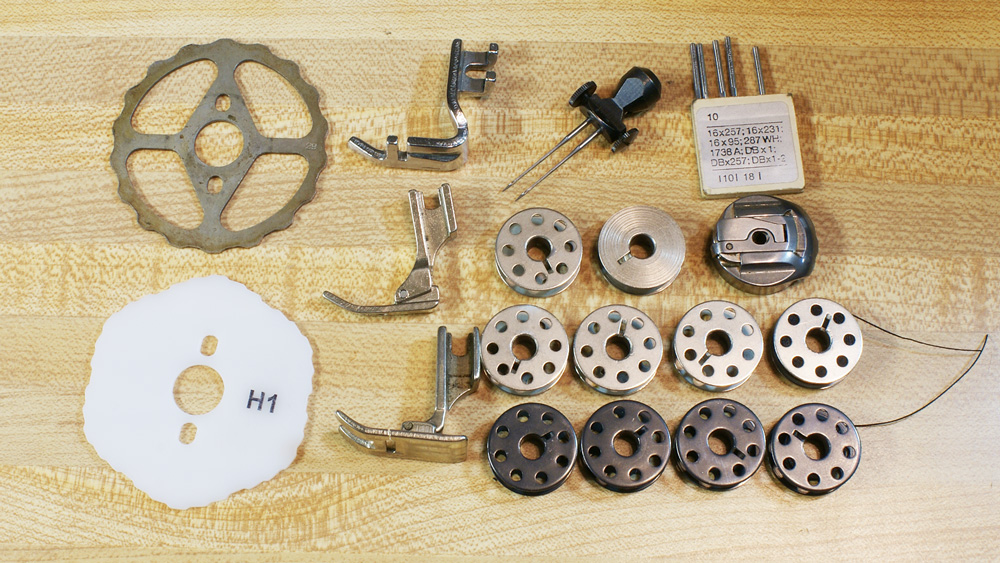

This is a Swiss made Bernina Chandler 217 industrial zig-zag sewing machine with power stand/table, motor, bobbin winder, spool stand and accessories. This machine has the optional decorative stitch cam box attachment on the back side. With the cam attachment, this machine can sew special stitches in multiple layers of heavy material. This machine comes with 2 cams, a serpentine zig-zag stitch and a 3-stitch zig-zag that is very popular with sail makers. Over 20 different cam styles are available online at AllCraft. This machine comes with three feet, ten bobbins, one bobbin case, two cams and a dual-needle holder. The machine is mounted in its original industrial power stand with a bobbin winder and spool stand. It has a newer Consew 550w servo motor powering the machine. The machine is in great working condition with very little evidence of wear. Please look at the photos provided and go the the YouTube link below to see a video I made of this machine in action. Asking $1600. Local pick up. https://youtu.be/j3XXoFs9bVk

- 11 replies

-

- bernina 217

- chandler 217

-

(and 2 more)

Tagged with: