-

Posts

347 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JJN

-

Double Row Hook and Awl Post Stitching Machine for Shoes

JJN replied to JJN's topic in Leather Sewing Machines

I am guessing it only has one of the two sets of hook and awl installed in this photo. -

softpaws2, I'm glad that manual had the information you were looking for. It is also good that you know the importance of proper lubrication with your new machine. I have a Juki 1341 that I like very much. I am still looking for a binder for this machine to bind the inside seams of bags. I'll post on here once I get it resolved. I would like to see some of the items you sew on your machine when you get it all sorted out.

-

@softpaws2, Were you able to download the manual I posted? Did it give you the information you were looking for?

-

Take a look at pages 12 and 13. http://imisp.net/sewing/juki-ls-1341-instruction-manual.pdf

-

@George1520, thanks for that link. It looks like that is a similar design machine but quite a bit smaller. The cutting board on this model C is 18" x 36" and the machine stands over 6 feet tall. The upper beam is 13" x 20". I don't have any official specs on my press but I've been told it is anywhere from 10 to 15 tons pressure. I'll have my clicker running in a couple weeks and I will post again. I don't have any experience with the double clicking problem.

-

I believe MattS is correct. That is not a potentiometer. It is a rotary switch with an array of capacitors. Capacitors allow the flow of electricity for a limited time depending their value usually measured in microfarads ( μF ). It looks like the range of movement of the clicker plate is regulated by how long the current flows. The switch may be working properly. The short stroke may be caused by the speed that the hydraulics are moving. Possibly getting the oil changed and the mechanism cleaned and lubricated could solve the problem. The capacitors in that switch look like they are 'potted' in epoxy. Difficult to repair. You should be able to use a multi-meter that has a capacitance measurement mode to check the condition of each capacitor by measuring between the contacts and comparing to the values printed on each capacitor.

-

I have a manual for a different model (USM Hytronic Cutting Machine Model C) but it looks very similar. You might find some useful info in here. It is 23MB so I cannot upload it here. I put it on dropbox, just follow the link. https://www.dropbox.com/s/9mhb7vq5wnf0d9r/HCM-C-Parts-Service.pdf?dl=0

-

On Consew, I believe the first 2 digits of the serial number is the year built. My 206RB is 1991. My 206RB-1 is 1993. That machine was a great find. Replace the grease in the upper and lower gear covers before you use it. That old waxy grease can harden like glue.

-

I Just Bought a Patcher. Can Anyone Identify it?

JJN replied to JJN's topic in Leather Sewing Machines

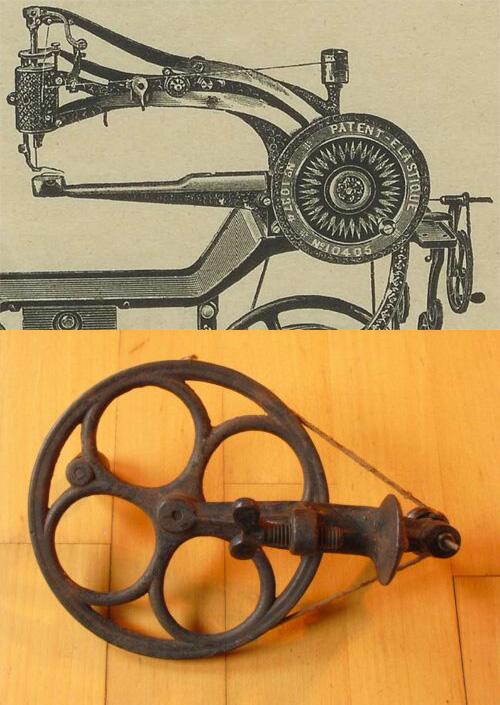

I used an image from a German language Claes manual for the patent elastic to see what the original bobbin winder should look like. I found the one shown in the photo below in the Netherlands on Ebay and bought it. I think it is the correct one. I am looking forward to getting it and adding it to the machine. It was listed as an antique Watchmakers Lathe which is totally incorrect. I have owned many watchmakers lathes and this is not one. -

I Just Bought a Patcher. Can Anyone Identify it?

JJN replied to JJN's topic in Leather Sewing Machines

@shoepatcher, Glenn, No I did not get your email about the clicker. where did you send it? I will send you a LW message with my contact info. Thanks! John -

I Just Bought a Patcher. Can Anyone Identify it?

JJN replied to JJN's topic in Leather Sewing Machines

The bobbin measures 0.615" diameter, 0.255" wide with a 0.110" hole. Any idea where to find more? The needle has a 2mm shank and measures 1.796" or 45.6mm in length. There is no scarf, just a long groove on one side and a short groove around the eyelet on the other side. I think this may be a system 81 needle but have not been able to confirm that. Can anyone verify this and provide a source? -

I Just Bought a Patcher. Can Anyone Identify it?

JJN replied to JJN's topic in Leather Sewing Machines

-

I Just Bought a Patcher. Can Anyone Identify it?

JJN replied to JJN's topic in Leather Sewing Machines

I picked up the machine yesterday. My first impression is it is smaller than I thought it would be. I had to load it and run so I didn't really look at it until today. It is still dirty but I wiped it off a little and oiled the obvious pivot points. I made a couple tension adjustments and threw a scrap piece of leather under it and it made a nice stitch. I am surprised and happy. Super smooth and quite. Here are some updated photos. -

I Just Bought a Patcher. Can Anyone Identify it?

JJN replied to JJN's topic in Leather Sewing Machines

@Egits, that is a great resource. I will be spending some there researching. Thanks for posting it. I see you live in Ohio. I was born in Parma and grew up in Seven Hills. -

I bought this "Patent Elastic" patcher sewing machine today. I will pick it up on Monday. Its a full day of driving. These are the only photos I have until I pick it up. The photos are not very good, but it looks like it is not a rust bucket and still has a lot of the original paint. It is always a good sign when an older machine still has thread in it. I am told it sewed fine the last time it was used several years ago. From what I have read on here about these patchers, there were a few different brands that had the Patent Elastic name on them. Can anyone tell me more about this machine? Maker, bobbin size, needle system, maximum thickness & thread and value? Thanks

-

@ljk, I'm sending my phone number in a message to help with sending.

-

Glenn, I definitely will add a two-hand lockout mechanism on this thing before I put it into use. I like my hands and fingers. Thanks for looking. John

-

We cleaned, oiled and removed the rust from the table last weekend. It is looking pretty good. It really changed color once we got all the crud off of it. I am rewiring the motor starter and switch next. I was offered the larger main pulley/flywheel and will pick it up later this week. I will probably switch it with the smaller one currently on the machine. @shoepatcher, any chance you found the service manual for this thing yet? Here is a current photo of the machine cleaned up and with all the parts put back on.

-

Looking for cylinder arm for leatherbag making. Necchi 840-100

JJN replied to luxuryluke's topic in Leather Sewing Machines

@luxuryluke, I've been lurking looking at that machine since a couple hours after it was posted. I've been wanting to get a dedicated binding machine. I live in southern Oregon and was seriously considering pulling the trigger on that machine and driving up to get it. It is a beautiful machine! My only concern was getting parts, but since you confirmed it can use Pfaff parts, it is a good choice. I'm very glad you are getting it. That is a great price too. I can't wait to see some posts of how it works out for you. -

I just got it moved to the shop last week. I'm checking out the wiring. The motor is a Baldor 3hp 220 single phase. The shop has 220 3 phase. I will use legs 1 and 2 of the 3 phase to run the motor at 208 volts. The machine itself needs a few days of cleaning. It has 2 oil ports with spring caps on each side of the vertical casting and 2 open oil ports on the center column. I am still looking for a service manual to properly clean, adjust and lubricate but I will start with some lilly white to get it going. The machine turns over by hand although it is quite an effort to turn the flywheel. The upper arm cycles properly. I need to resurface the Hydrosolid cutting board to level out the wear in the middle, and finally order some clicker dies. I am very stoked about getting this machine. I got it as a trade for a Noveske rifle barrel, which the rifle shop generously donated and a $30 trailer rental to move it to my friends shop. It looks like it will run as it is. I will post some updates as I go. I am still looking for the service manual.

-

@JKHelms, I like your direct approach to the problem. I also want to use genuine Juki 441 feet for fabric projects, so I would like all my presser foot options to be interchangeable without having to reset presser bars each time I switch feet. I would ask for photos of your modified feet but don't want the ridicule of being called a bubba or a redneck. LOL Thanks for your help. John Noveske

-

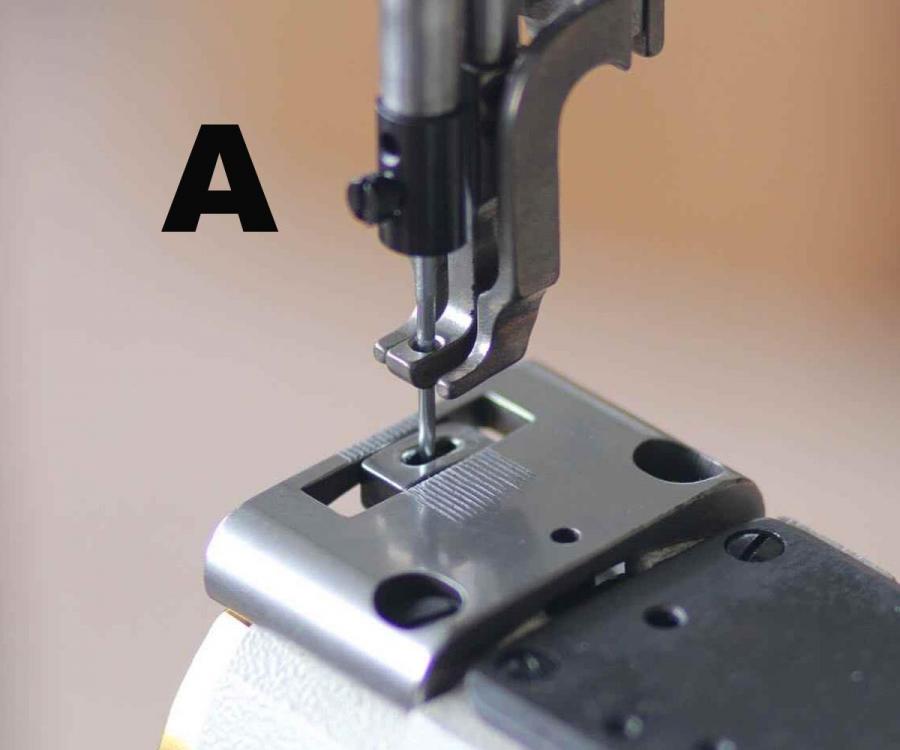

I purchased a Ferdco/Juki Pro-2000 last December (actual Juki 441 base machine). I needed to order missing parts and have just recently received them. I have cleaned up the machine and replaced the missing main tension assembly and bobbin winding tire and put a servo motor on it. It has cleaned up to look like new and I am very pleased. This machine came with only a slotted needle plate and left toe presser foot. You can see what I have in the photo marked 'B'. The feet are not the style I see on the Cowboy and Cobra dealers sites. I figured these must be Ferdco exclusive. I bought a set of feet, center and double toe, in the style shown in photo 'A' with some toothed and smooth feed dogs and throat plates. I haven't tried to put them on yet. Now I discovered some feet in the style-B that appear to match my original Ferdco feet, in the NickOSew catalog. I talked to the mechanic at NickOSew and he didn't know if their style-B feet are the same as my Ferdco feet. He did say that switching from their style 'B' to style 'A' will require resetting my outer presser bar and balancing the foot lift because the style-A feet are about 1/4" taller than style-B. I have a few questions. Does anyone know of any advantages or disadvantages with either style of feet? Does one style work better with a slotted plate or with a feed dog? Can anyone confirm the height difference of the feet? Is there a tutorial anywhere for adjusting the presser foot height for this class of machine. Sorry for all the questions. Thanks in advance for any answers. John

-

Sailrite Fabricator Sewing Machine.

JJN replied to ComputerDoctor's topic in Leather Sewing Machines

My first real machine was a 1541S that I bought new from Gregg. (based on recommendations from this forum) The sale and shipping was easy and without a hitch. I love that machine and it has performed flawlessly. I have two 206RB's that I picked up since then that I like very much, but they don't compare to the Juki. I don't think you can go wrong with a Juki 1541S as long as your needs don't go beyond 138 thread and material thicker that 3/8". -

Recommendation - Jack Jk-561A-1 Servo Motor

JJN replied to Constabulary's topic in Leather Sewing Machines

The problem is with the programming logic of the controller. If the speed reducer causes the motor to turn too many revolutions without getting either a needle up or needle down signal from the encoder on the sewing machine, it gives up thinking that an error occurred. The number of revolutions of the motor that controller will allow without a position signal varies from one servo motor to the next.