eblanche

Members-

Posts

33 -

Joined

-

Last visited

Profile Information

-

Location

New Hampshire, USA

-

Interests

lightweight outdoor gear

LW Info

-

Interested in learning about

sewing and the machines involved

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

2,143 profile views

eblanche's Achievements

Member (2/4)

-

Hi John, I also make backpacks and use a 246. To start, for perspective, I paid ~$2500 for my machine with table, servo w/ needle positioner, and a couple other items towards the beginning of 2025. This was with a local guy. These are not too common, Unft. I did not pay for shipping but the fella who found the machine for me in PA did replace a few parts including the hook with Genuine Juki parts. This was a newer style 246, not the older style as is the one you are currently looking at. I can confirm it can easily handle 14 needle and v46 thread. With the fabric you tend to use, you will have no problems even with just two layers but IMO two layers of ~150-210d is about the min I think it could easily handle unless you spend the BIG BUCKS for the extra small needle hole JUKI feed dogs. The 246, when not setup as synchronized binder, uses an elliptical style feed dog (NOT just back and forth) but more an oval shape. As synchronized binder it is simple back and forth motion of the feed dog. I believe the 1341 has the advantage of using a "four-motion" rectangular feed dog for slightly better control of bottom fabric though the needle cycle. On the 246, if you wanted to switch between regular sewing and synchronized binder, it is only a matter of 10min to swap all parts. If you use non-genuine juki parts, the swap is very much a reasonable cost. The pictured 246-6 is missing an item or two at first glance and top cover of cylinder arm appears misaligned or bent upwards compared to the throat plate. Both parts are easily replaced. As mentioned, the pfaff 335 is similar but both the pfaff and the juki have many different sub classes of those 335/244/245/246 models. Last year, Gary at Forsewing had a number of used 245/246's. Nothing listed on his site right now but might be worth inquiring with him. LA based but it was only $300 for freight at the time of quote.

-

Review of Jianglong 341 after 4 months

eblanche replied to friquant's topic in Leather Sewing Machines

Well then, talk about a precise and usable reply! I'll see what that looks like, Sounds pretty solid. -

Review of Jianglong 341 after 4 months

eblanche replied to friquant's topic in Leather Sewing Machines

Okay great, thanks for the info! I know these are more just to hold your product rather than a table to lean on, but can you comment on the stability of the table when installed? Can you put a reasonable amount of weight on top (~2+lbs) without the table wobbling or tilting? I actually purchased and returned a different table top as I was not satisfied with the stability, I think due to the stock/standard install method. -

Review of Jianglong 341 after 4 months

eblanche replied to friquant's topic in Leather Sewing Machines

Hey Folks, I am currently in contact with a rep from JL about their acrylic/alum. table top attachment. I am looking for a table for my juki 246 rather than 341/1341 style but I wanted to ask about the overall quality of the table and the pieces, as well as the clearance to the cylinder arm and throat plates. This style looks to be somewhat common although I have not seen an acrylic version elsewhere. @friquant @Smiche @toxo Do either of you have any feedback for the table top attachment from JiangLong, if you received one? Thanks, any info will be helpful and appreciated! FYI, They are asking for $65 for the table as a separate purchase. Shipping to the the USA approx. the same cost, $65. Depending on duty/tariff, this may or may not be reasonable. I am still awaiting clarification if they handle those costs for US customers. (ugh prob not lol). -

What issues are you having with the machine?

-

Bobbin thread tension and thread color

eblanche replied to Gymnast's topic in Leather Sewing Machines

Would you kindly inquire with Amann about your results, if you have a contact? Curious if they may have a response on this, whether it be normal or unnormal. Thank you for providing these results! -

I've gone through this recently with raw edge 90* binders and it wasn't long before I realized the above to be all correct and very important. Also, practice (PRACTICE? we talkin' bout PRACTICE!?!) how you are feeding the material into the binder. I went through a lot of tape, material, and time before I figured things out. I worked with a few different over the counter binders and ended up modifying my binding foot, throat plate, AND binder brackets to get my desired results. Now it works every time on smaller radius curves. This is with a synchronized Juki 246 cylinder arm.

-

I have been using the basic "sewing machine" set from Chapman Mfg. Good stuff but I do not have much experience with other quality tools. The small hand ratchet, and thumb spinner have made themselves very useful; especially with feed dogs and throat plates. All the other posters are correct though, it is important to match the sizes and having a non-tapered head also helps. https://chapmanmfg.com/pages/bits-that-dont-screw-up

-

Okay thanks! this is Amann strongbond v69. Not exactly inexpensive but willing to try others. Does the video work for anyone else?

-

Thanks KGG, I should also mention: A. I have adjusted second thread guide in different positions. I'll reposition to original as per Manuel. B. When threading the tension assembly to NOT go up and over the pin, the thread often becomes disengaged from the top tension discs, releasing tension altogether. Maybe there are multiple issues...? I used the pin as suggested in a video for a different type of machine using the same type tension assembly. Materials: yes dually noted! This machine specs suggest lighter thread/needle can be used. Idk if that directly relates to the exact types of materials. I know of many using the 1541 and similar compound machines for the same materials. Of course, this is a dsc246 and not necessarily similar enough. Noted they have thin material feed dogs available with I assume smaller needle hole. I am not currently aware any available smaller hole presser feet? When I put a similar fabric with more stiffness under the needle it does help but does not solve. And yes it does very fine with thicker assemblies. I will look into 2 c and d. I do infact use a needle feed machine as well, and it does fine with this two layers of fabric, but not totally ideal for the rest of this sewing line involving thicker parts further down the line of sewing. This 246 is primarily for binding but I'm looking to see if I can expand it's usefulness btw horizontal to elliptical feed conversion takes only 5-10 min if anyone wants to know haha Edit: does the thread twist coming off the spool look normal? Thanks a lot!

-

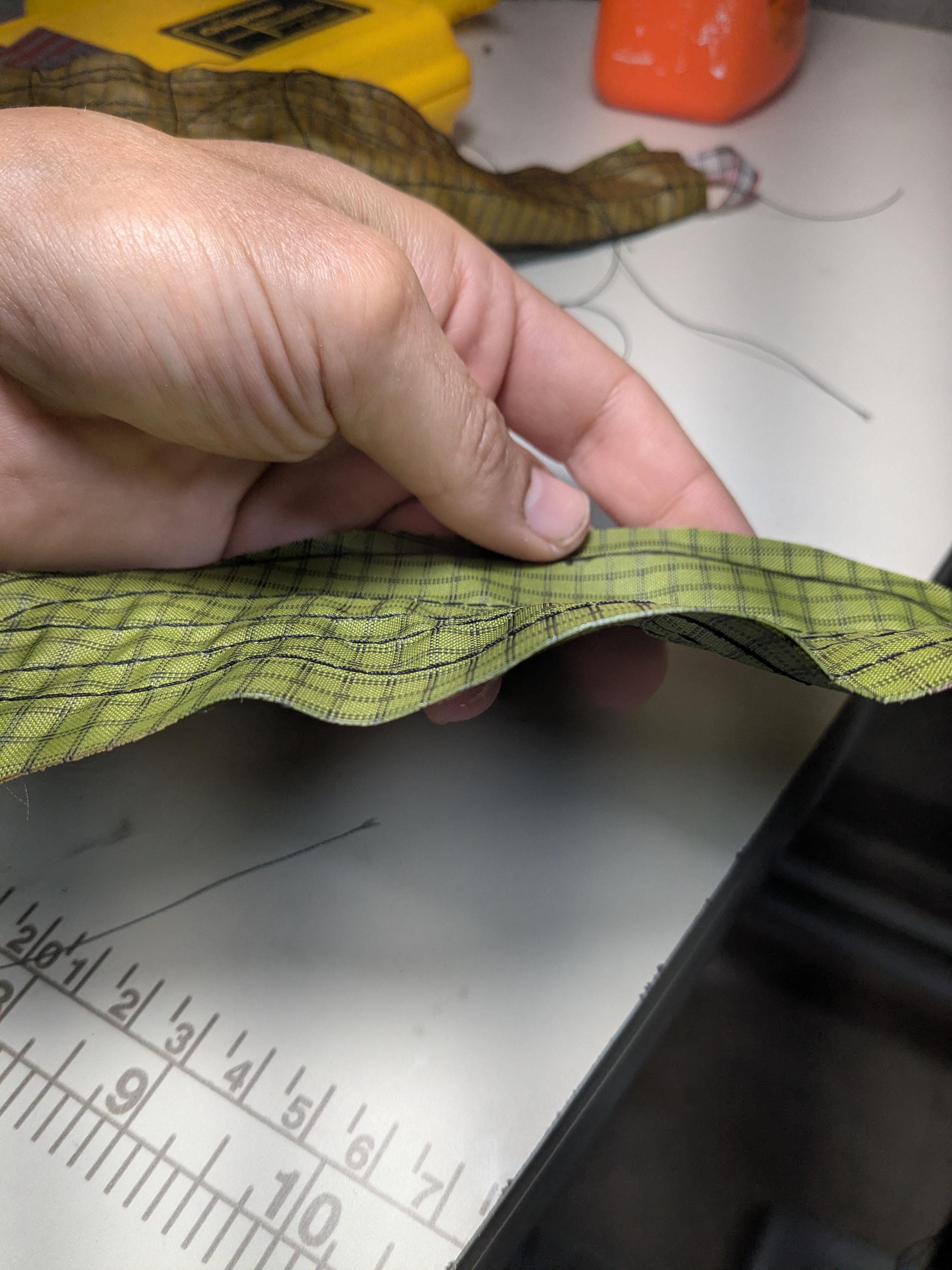

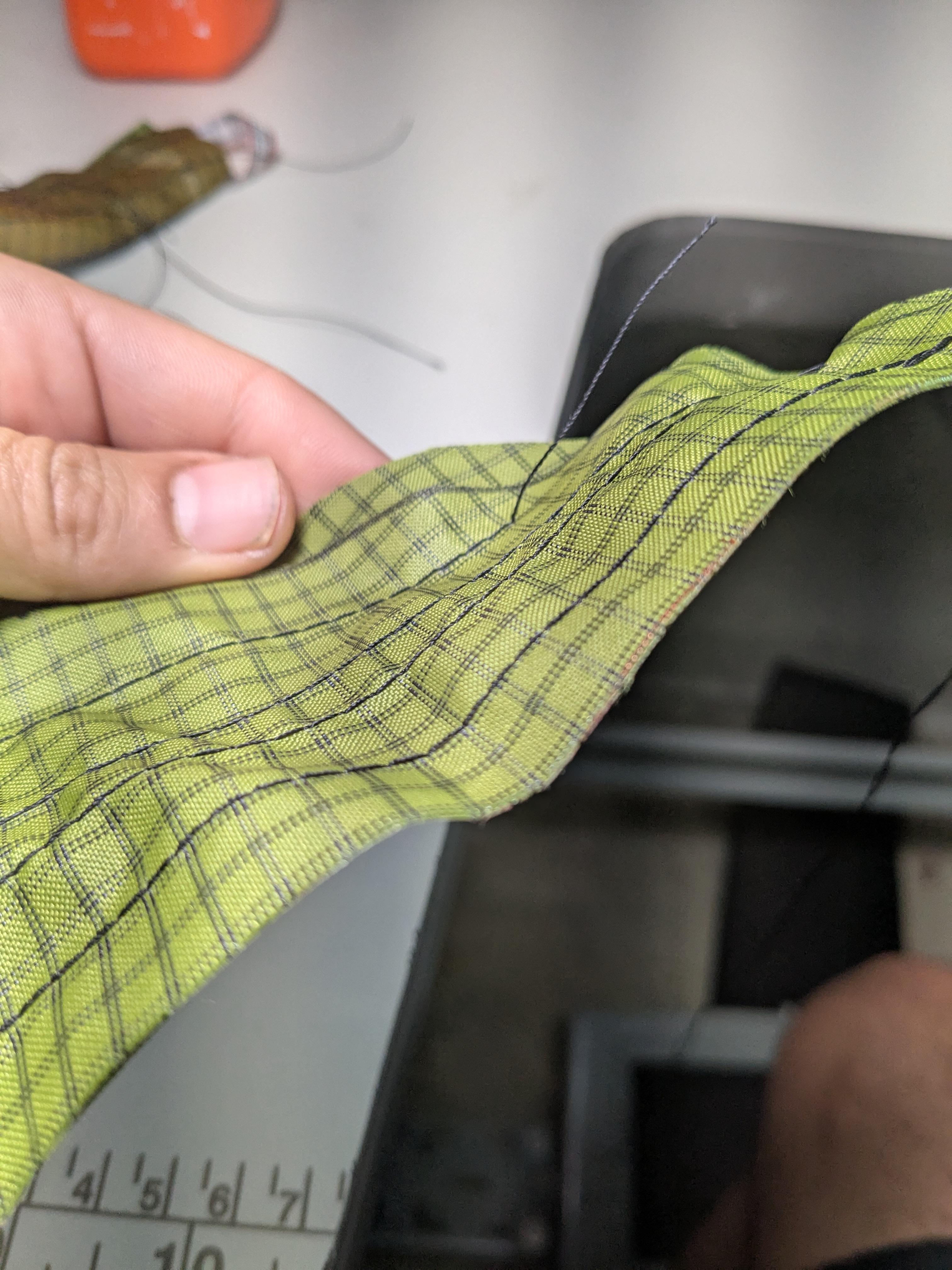

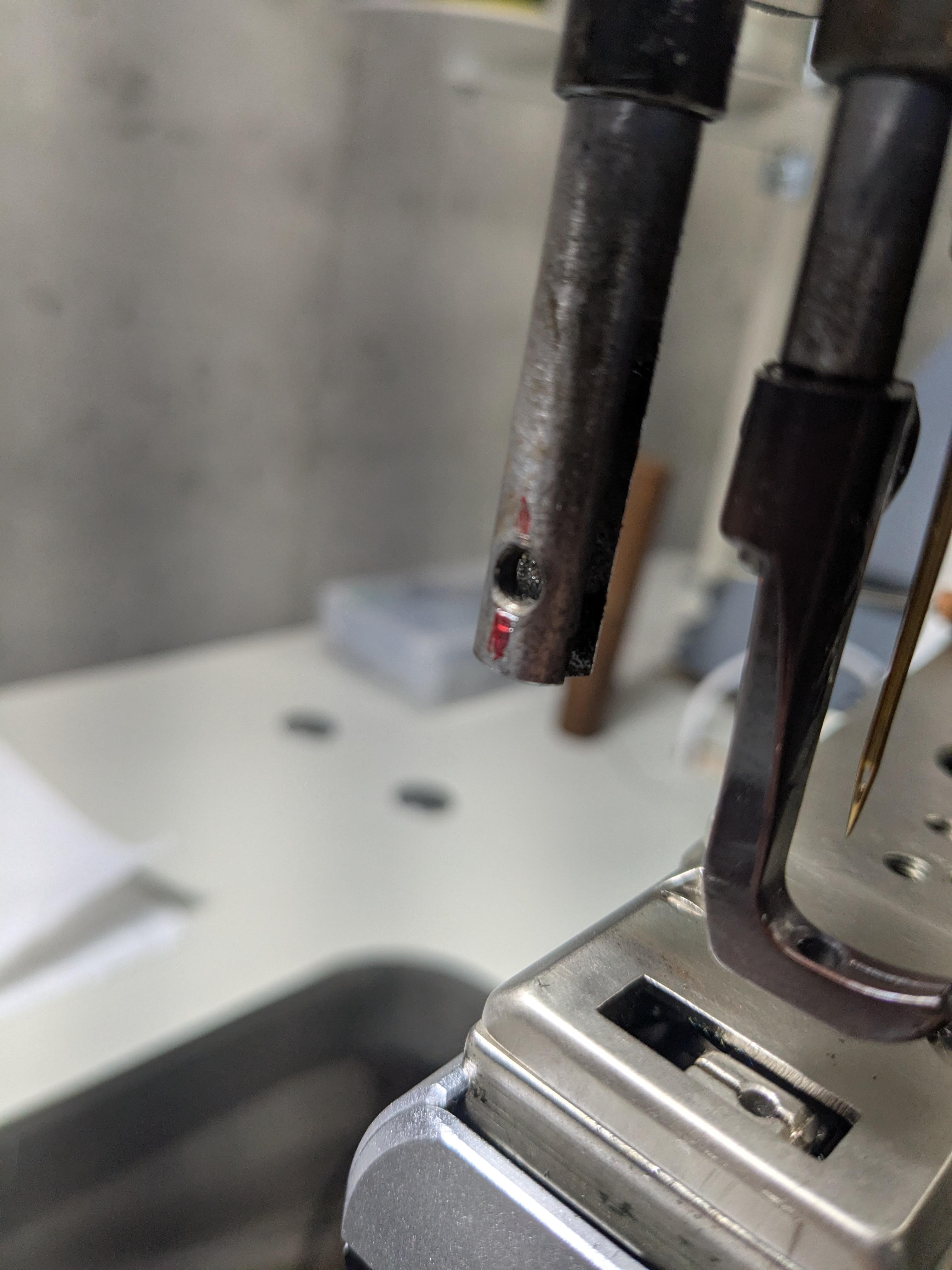

Hey Folks, I am having some troubles with a recently acquired machine. Juki dsc-246 using v69 bonded nylon, size 16-18 fabric R point needles and sewing two+ layers of 210d nylon. As you can see from the photos, I am getting some nasty puckering in the fabric leading to very unsightly seams! The fabric started out as two perfectly flat layers and now features waves. This is my first compound feed and cylinder machine so i first thought I was maybe causing the issues incorrectly FEEDING the fabric (I am doing some flat work here without a flatbed attachment). Now, I am not so sure that I am the cause of these puckers. The machine does sew heavier/thicker including binding work quite well. Things I have attempted to adjust: Thread tensions (bobbin tension here is almost non-existent in an attempt to alleviate the issue. Walking foot/inside presser foot pressure: adjustment do not seam to help? but with little pressures, my material slips around underneath with feet sitting on the throat plate Smaller Needle size Smaller thread: v46 I found a similar thread here which discusses a the same problem but with different materials: I am looking for guidance on what steps I should take next or to maybe start over. More adjusting needed? Still thread tension or an issue with the walking feet/feeding. What am I overlooking? The above thread discussed possibly worn out components being a factor. (Ugh hopefully not, this machine does appear to have been well used...) Which ones would maybe cause this? Thanks everyone!

-

Replacement feed dogs for my Artisan 246. Suggestions?

eblanche replied to Piko's topic in Leather Sewing Machines

Hi Piko, I buy all my needles from https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=ndl-135X16 the thread exchange. I buy my thread from wawak... I have attached an image of the supplied feed dogs which came with my 246 from a previous photo. I can get you a closeup with dimensions tomorrow or the following day, but the P/N is visible in the second picture (please excuse the mess, converting from 'standard' to horizontal feed, for binding). 21135009 appears to be the model the CKPSMS version you purchased is based off of from the description. -

Replacement feed dogs for my Artisan 246. Suggestions?

eblanche replied to Piko's topic in Leather Sewing Machines

I dl'd them despite the risk. They seem very similar size hole. New one has a slot...not really sure what the difference in use is?? I think I posted that Juki still sells the $200+ thin material feed dogs with smaller feed dog hole but I'm not sure that is what you need. I also have a 246 so I am taking notice. IMO, changing to that feed dog will not have any difference in the hole size of the material. The needle makes the hole, so maybe using larger thread to fill the hole. *Sorry i do not remember the original message board thread so something like this may have already been mentioned. -

Recent Relics Design on Etsy has some nice looking options that work for the ls-341. I do not have first hand experience though. https://www.etsy.com/listing/1628261312/folded-edge-cylinder-arm-table-read-the?ref=shop_home_feat_2&bes=1&sts=1&logging_key=df14ac46157a5699adef0f95481e19144bc0bbad%3A1628261312