-

Posts

70 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by SteveOz

-

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@Tastech Thanks for the tip Mate! -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

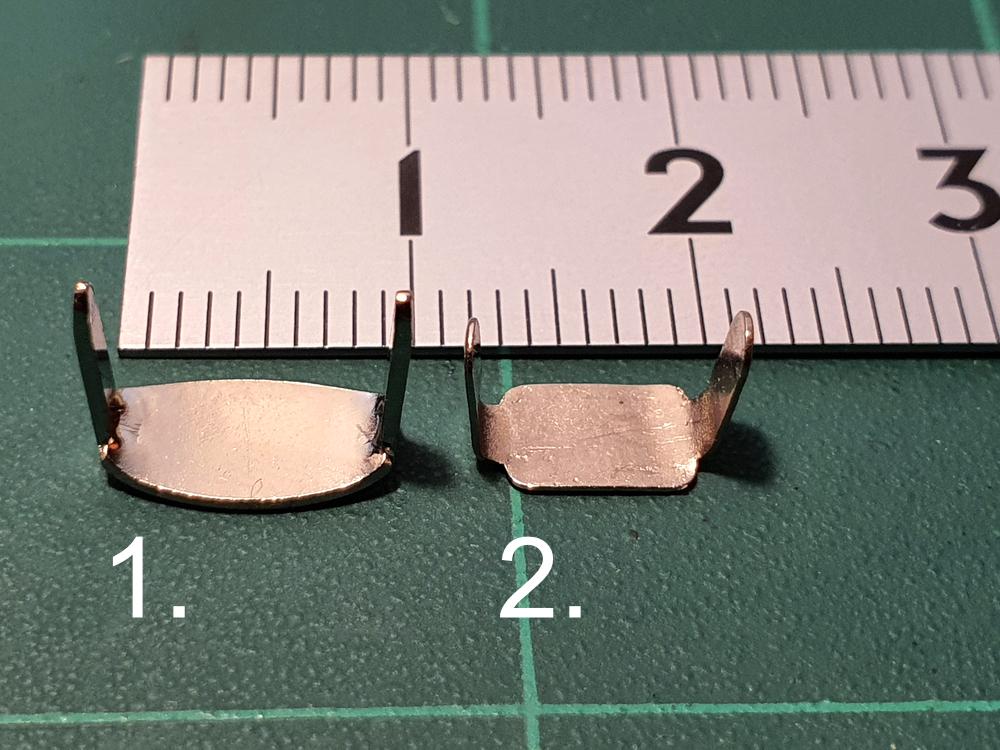

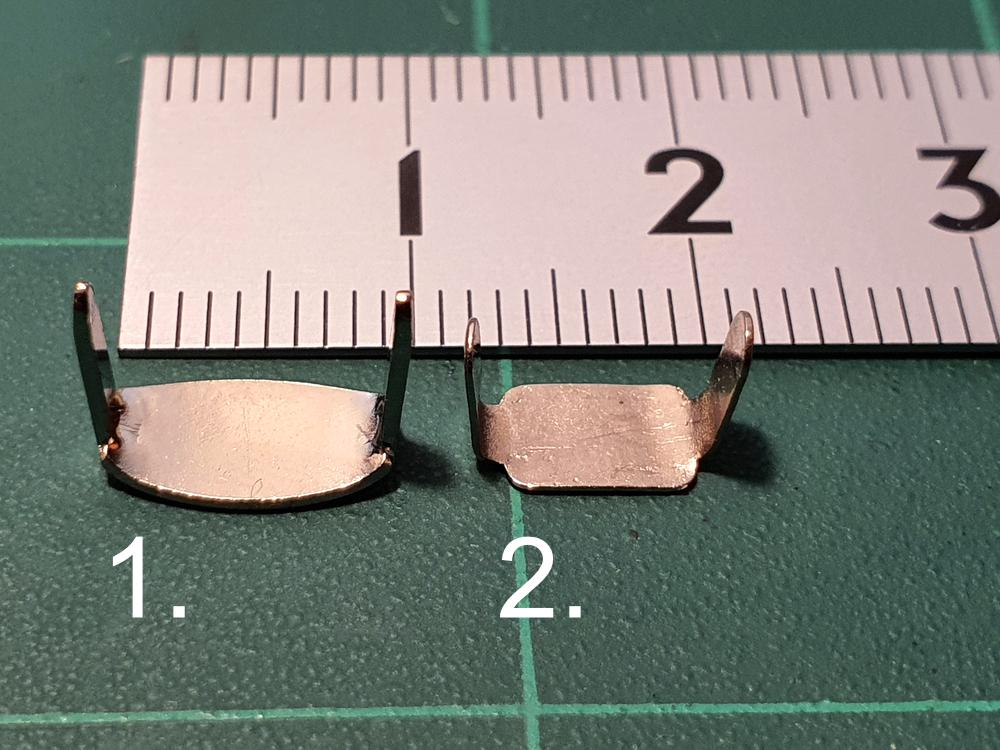

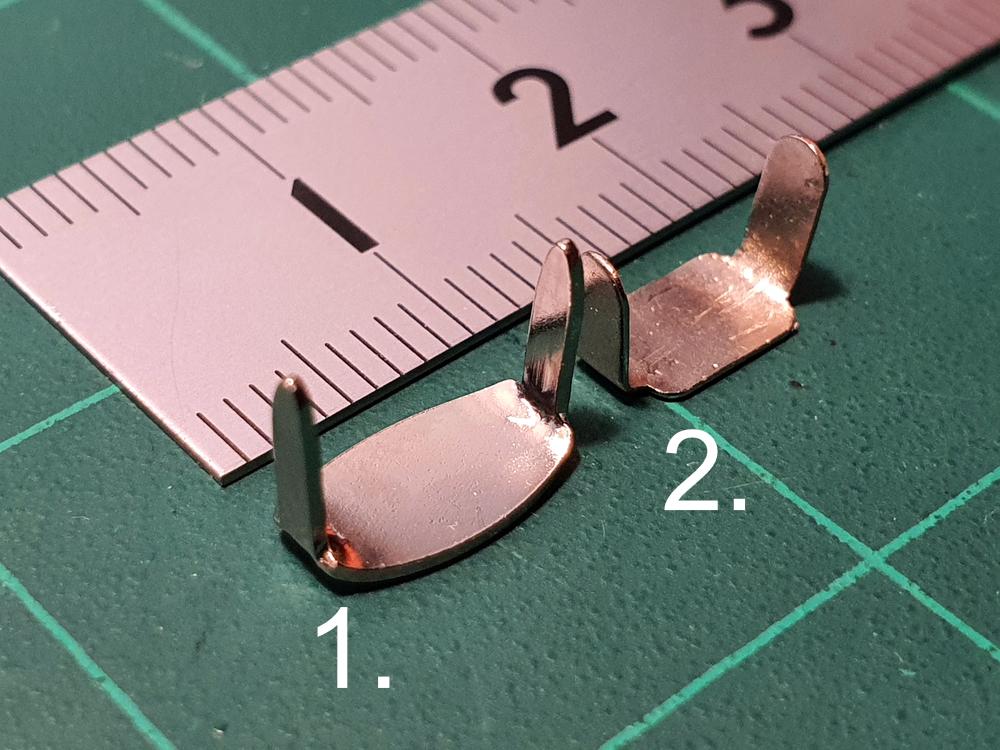

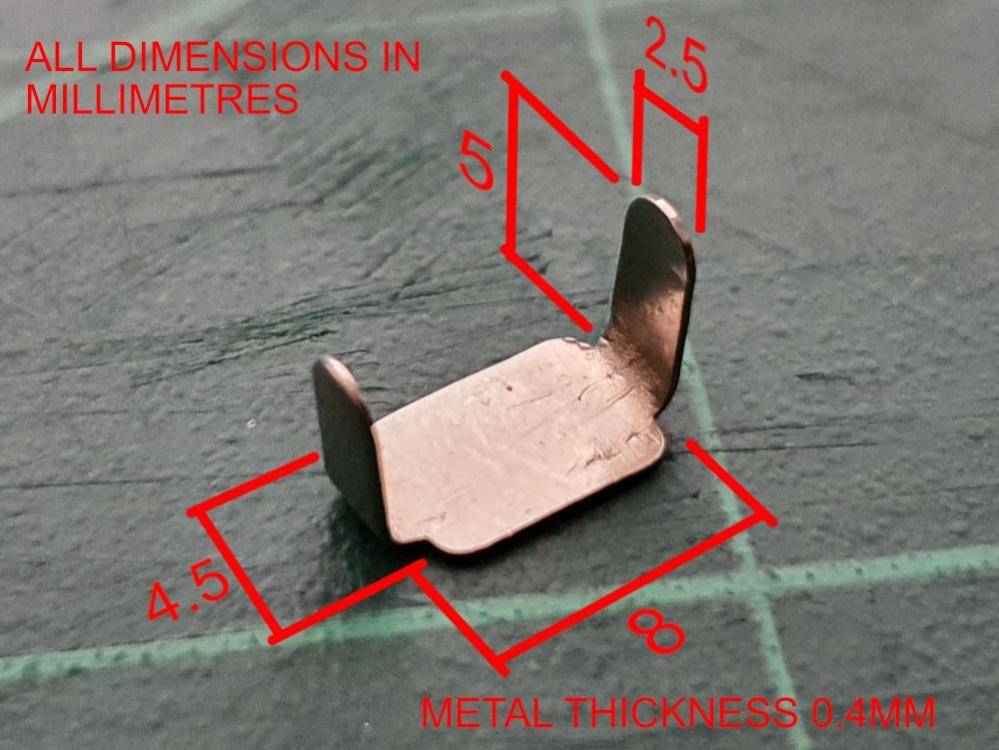

@SUP and @Wepster Thanks for your help with this and the suggestion of changing the post title too. Hopefully, I can do that... Yes, all of the measurements are metric, and it's the tiny ones (2.) that I'm looking for. -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@toxo Thanks for the link Mate. I might be lucky there! -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@SUP Thanks for your help here. But, I haven't had any luck finding these little guys (2.) out there. -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@AlZilla Hey Buddy, thanks for the link there. The clips (2.) I'm after can be folded and unfolded with a finger nail. They're for watches that don't have removeable spring bars. Number 1. is a thicker metal staple that you'd close with a small flat blade screw driver. -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@toxo Thanks Mate. I might laser cut some. I was just hoping to find an 'off the shelf' answer. -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@DieselTech Thanks Mate. -

Small metal folding tabs for open end watch straps

SteveOz replied to SteveOz's topic in Leatherwork Conversation

@Wepster Thanks for all of those links Mate. But, they're not the same thing. -

@Tastech G'day Tas, Thanks for your reply Mate. I fully understand your position here. You've put a lot of work into those machines and it really shows, I'd be reluctant too. Your comment about sellers falling into 2 categories is definitely true and made me laugh. Some sellers of new equipment can be pretty sketchy also. I don't want to buy a new Asian machine, but I may have to. They go for around $1500. I need to start about fossicking a bit I think. What I'm after, is a small splitter that will take my chrome down to the thickness that I need. I'm only talking 4.5 oz down to 3oz. I can manage to do it hair side up on my pull through splitter but it's a PITA to do so. I make watch straps out of Chromexcel, veg tan, and roo. I've attached some pics of what I do. I'm not after a project machine at this time. I just need something that works. Thankyou for the link too, that's kind of you to add that in. Do you have any pics of the things that you make? I'd sure love to see them. I'll dm you right now. Kind regards, Stevo

-

G'day there, I'm based in Melbourne Australia. And I'm on the lookout for a good used or refurbished hand cranked splitter machine. Cheers, Stevo

-

@Tastech G'day Tastech, I couldn't help but notice your beautiful work here. Do you sell reconditioned machines at all? Cheers, Stevo

-

@Frodo They look great, and are guaranteed to be heirlooms!

-

@Zippin23 I don't drive my chisels all the way through. I drive them in half way, then prick the centres through with a needle to the other side of my work. I then flip my work and drive a reverse chisel in from the other side lined up with the needle holes. You could use an awl to open the wholes from the back if you don't have reverse chisels. This gives me uniform shaped holes front and back. There's some great videos by Nigel Armitage on saddle stitching on YouTube. These are no nonsense techniques by a real expert. They helped me perfect my stitching.

-

@Zippin23 G'day Mate, Nice wallets you've made there, they should sell really well! As other people have mentioned, a press with a chuck to hold your chisels can help you straighten your stitching lines. I made a lightweight press recently from scrap. I sell watch straps and I use my diamond chisels with this little press without a problem at all. It's not my invention. I hope this helps you.

-

Light weight press for making stitching holes quickly

SteveOz replied to SteveOz's topic in Leather Sewing Machines

@AlZilla Thanks for the compliment Mate. It's doing its job very quietly. I do have an edge guide on it. I can punch holes in a tapered watch strap as the edge guide is quite small. So, if you blink, you'll definitely miss it. -

Light weight press for making stitching holes quickly

SteveOz replied to SteveOz's topic in Leather Sewing Machines

@chuck123wapati Hey Man, thanks for the compliment. It looks like a Rube Goldberg machine in a big way. But, it works surprisingly well. -

Light weight press for making stitching holes quickly

SteveOz replied to SteveOz's topic in Leather Sewing Machines

@Wepster Hey Mate, I found one locally that was made in Taiwan. It's not too bad, it was only $23.00. The brand name is 'King Diamond'. I would have preferred to buy something made locally or in the U.S., but the cost was prohibitive for those. Anyway here is a link to the King Diamond site- http://www.king-diamond.com.tw/push_pull_type_toggle_clamp_KD-302F.html King Diamond, when only the best will do. -

Light weight press for making stitching holes quickly

SteveOz replied to SteveOz's topic in Leather Sewing Machines

@dikman Thanks Mate. It has cut down the time it takes to make stitching holes greatly. And it is better than what I can do with a mallet, and stitching chisel following a marked line. -

Light weight press for making stitching holes quickly

SteveOz replied to SteveOz's topic in Leather Sewing Machines

@fredk Thanks, I readily admit that it is a funny looking thing. For the time being it does the job nicely for straight and tapered watch straps without any noise. -

Light weight press for making stitching holes quickly

SteveOz replied to SteveOz's topic in Leather Sewing Machines

Curiosity got the better of me. So, I made one of these light weight presses. It amazingly gives me a perfectly straight line of holes on both sides of my work without the noise of a mallet. I had everything in my shed except the toggle clamp. It cost me $23.00. A nice rainy day project. I'll be tinkering with my Singer next to try that out. Thanks again everyone for your kind suggestions. -

@AndrewWR That's beautiful work!

-

@Luke856 Both are very deftly done! But, my preference is for the tan example. Is the tan example the French piping?

-

@Alsopp Thanks Mate, nice to meet you!

-

That will last a life time!

- 2 replies

-

- wallet

- card wallet

-

(and 1 more)

Tagged with: