deboardp

Contributing Member-

Posts

189 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by deboardp

-

I don't want to use petrolatum. If rather use something that comes from things that were more recently alive. Don't ask me why, because i don't actually know.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

PS Lanolin is produced by sheep - I have forgotten exactly - by (I think) their sebaceous glands of the skin, to coat and protect their wool from the elements. The industry extracts from sheared wool in centrifuges, and bottles it - or jars it? - for use in cosmetics? I don't remember. Wikipedia probably has a description. It's called wool wax and another name starting with wool. It's used in lip balm and nursing mothers used to use it for cracked nipples during nursing months. However, there are some problems - the baby can be allergic, and a significant portion of mothers who use it develop some kind of problem. Infection? So it's probably not used as much for that, unless someone has used it without problems, hears about the problem with it, but knows she's not affected so keeps using it. I bought 6.5 pounds of it in anhydrous form. It's like a gel, I guess. It's not here yet. I bought tallow, it's not here yet. I also bought pork lard, organic, and it's not here yet, but Scott Wolf said he used some and it develop a stinky smell, so I'm not planning to use it. I'll use lanolin instead. Hope this helps.

-

It's okay to be a bumbling idiot, it's not a sin or a crime. In fact it's a bit fun. It's a natural part of life, getting old, falling apart, walking into walls, forgetting why you walked into a room - well, even younger people do that. Being able to laugh at one's self is also being humble, which is probably the greatest virtue. So when I call myself names, I'm just being virtuous. See? There's a plus side to being challenged. I can't give myself credit for being where I am. If it were up to me, I'd still be homeless. St. Xenia answered my many sincere if not fervent prayers, asking her to influence the US government, specifically the VA, to honor my service and find in my favor. She has granted my things in the past. When I worked that four years, I was getting nowhere fast in my third year, and I asked her to help me. Within one week I was booked solid for the rest of the year and all of the next year. She's known world-wide to Orthodox Christians as the saint who answers prayers concerning work. D-limonene sounds like something I could use. I had been thinking about adding some kind of subtle scent. I'll consider it. Is it readily available somewhere? Are you going to share your leather conditioner recipe on my thread? It's hardly mine, actually. It's for leather workers of planet earth. Or at least of leatherworker.net. My memory doesn't work well, so I'll say that from what I've read here and there, vegetable tanning removes everything from cow skin that could could cause it to rot when wet. The result is that all the fat (cows tend to be fat) which is embedded in the skin, is removed. So I understand (from the readings) that each craftsman has to dress his leather, or treat it with conditioners, which means to put back what the fibers need to keep them from tearing each other apart. If they are dry, they will rub, fray, and come apart. So the craftsman stuffs the leather with things to do that. I don't remember the specifics, but I think those things are fats and waxes. Maybe oils, too, I'm not sure. But tallow is simply cow fat that has been rendered, so that it won't go rancid. I think rendered means melted. There's a fellow by the name of Austin "Oz" Black who used to be a member here, under the name unicornleather. I mention him in my thread, and i think I mentioned him in ScottWolf's thread in "Dyes, Glues and such". He talks about mineral oils in that thread, but I can't tell you what he said, sorry. Anyway, I'll attach one of Oz's comments here, in which he explains how he conditions, or dresses, his leather. I thought he did it by the project, but he does mention dressing whole sides or hides and that they are still pristine 25 years later, which I thought might mean he didn't use them? Business was bad? Anyway, the way he describes how to stuff leather with fats and oils will answer your question how to do it. That's how I plan to do it, bare hands, work the grease into both sides of the warm, wet leather. He explains why warm and wet, something about opening the pores of the leather and when the water evaporates, the grease works its way deep along the fibers. The hand rubbing adds heat, which thins the grease. I think when the leather is cool the grease is thicker than when it's warm, but it still lubricates the fibers, for when they bend. Makes sense to me...leather conditioner.odt

-

I'm a disabled Vietnam combat vet, have had 2 strokes and 2 heart attacks and have heart failure so sometimes I'm a bumbling idiot. I don't know how I got involved with this thread. I'm just trying to make my own leather conditioner and somehow thought this thread was about that. Traditional English saddler's grease uses fats and waxes so i was wondering why everyone was checking out all these different oils and how they affect leather. I was just in the wrong thread. I have only about five years of experience in leather work, predominantly in making sandals, and that was in the 70's, after I left the military. I was disabled by exposure to herbicide in the Vietnam War. It started affecting me in the 2000's. I became disabled in 2004, became homeless a couple years later and was chronically homeless except for a four year period when I was able to work half time in my profession of residential remodel/ repair contracting. The VA kept denying my claims for durability compensation until the Pact Act of 2022 came into law. That law removed the obstacle to disability compensation that the government had been using to deny claims of herbicide exposure. I hadn't been able to work even part time since 2021, figured the VA would never help me, so I had the brainstorm to return to making sandals, which I had always enjoyed and with which I had some ability. Recently the VA found in my favor with my last claim and I now have enough money to pay all my bills. I started my first pair of sandals today but no longer need more income to stay off the street. I was homeless from age 59 to age 77 (this year) except for that four year period. It's really hard on an older person to be homeless. I was always a very good worker, so it was a heart breaker for me. But I will continue with the shop, just no longer with the quiet desperation. I've spent the last 15 months buying what I need on credit and designing what I call a monastic sandal, which I think has a chance to be something. Socks can be worn, there's nothing between the toes. I've also been studying professional leather techniques because my first sandals were accurate but not well finished. I used Edge Kote! And I cobbled! Quick and rough. Today i have a burnishing machine and a Cobra Class 26 and the one design (about 15 before). I'll be able to make other designs, but i want to do this one. It's fully adjustable, has gum rubber full bottom. You'll see soon. I don't care if mineral oil is good or bad. I'll use a little Norwegian cod liver oil on my veg tan leather after I stuff it with fats and wax and lanolin. It brings out the natural smell of the leather. Too bad technology hasn't come up with an olfactory app yet. I could post a link. I tried finding 100% mink oil but it's a precious commodity and everybody is using just a little bit of it and filling the bottle with fossil fuel derivatives, which may or may not hurt leather, and which cost next to nothing. I think maybe that's partly what this thread is about? I did find an alleged bottle of 100% mink fat, from Ukraine, and I thought, "Sure, they'll send it after getting my money." Haha.

-

you say the basics of conditioning are straight forward. Please, humor me, and write them down for me. I'm just not a smart as I used to be, and I'm not so sure about how smart I was then! I did some reality checking, asked my priest if I could use tallow (Scott said he had used lard and it started to stink, so I won't use lard), and the priest said use whatever is best. I should have asked him what THAT might be, haha. So I'm back to using Oz's version of saddler's grease: 50% tallow, 25% beeswax, 25% anhydrous lanolin (instead of lard). I might toss in a little macadamia nut oil so the compound is like butter rather than mortar mix. After wetting the leather with warm water I'll work that stuff into both sides of the straps with my hands, plus the topsole (top side only, by this time it will have been glued and stitched). After it all dries in my shop I'll do the cod liver oil treatment. How exciting! Tell me, Chuck, after that, are the sandals conditioned, waterproofed, or both? Haha. I just want to know what I'm doing.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

I'm near end of life, so I won't be buying a microscope to study cross-sections. I was wondering though why the experiments are centered on oils and not fats? I have heard that saddle makers use saddler's grease to condition their saddles, or maybe it's their customers who do that. Grease is like concentrated fat. It's rubbed in with bare hands to produce heat, with the leather being wet with warm water first, to facilitate the fat/wax/tallow/lanolin movement along the fibers, to keep the leather flexible. It seems like a basic principle to me, to do that. I might be in the wrong topic thread. I'm trying to find out the best leather conditioner, and as you mentioned, this one to find out if mineral oil is harmful or not. Sorry!

-

The difference between using oils as opposed to fats and waxes paste is elbow grease. The report walks through how vegetable tanned leather can be stuffed by the craftsman, and it is labor intensive, and messy. My intuition tells me stuffing fats and waxes is better than oiling, but it would require adding a stuffing concoction to the experiment and buying a microscope, to expand the effects determination.

-

leather conditioner.odtThis is an awesome and interesting experiment, and I appreciate the care everyone is putting into it. I myself want to make my own leather conditioner. I do have a bit of a bias, based primarily on a secondary source, a report by Austin Black of Wales, who was trained in the UK in saddlery trade school. The report is in a thread I started recently on the topic of DIY leather conditioners. He goes into detail how he applies his conditioner, which is something the experiment here ignores. About NFO, which it seems every contributor to this thread uses and lives, he says to avoid, and he explains why, which is that it leads to the oxidation (decay) of leather on a molecular level. Which brings me to another procedure deficiency of this experiment, which is, what are the criteria for determining the effects of the conditioners being tested? Are they simply what can be experienced with the senses of sight, smell, and touch? I did not see a concern by anyone with the effects of the conditioners on the fibers of the leather on a cellular level. My understanding from reading secondary sources and from personal experience of making multiple hundreds of pairs of leather sandals over 50 years ago is that conditioners make leather supple and more readily conformable to the human foot. I have no idea how we can test the effects of conditioners on the actual fibers of leather, unless we start using microscopes and very sharp knives to cut slide samples, before and after samples. The effects to the fibers seems quite important to me, because we want the fibers to be free to slide along side each other, at least for sandals that seems important. A flexible sandal rather than a stiff one seems more comfortable in theory. Maybe a saddle needs to be stiffer? Finally, another concern I have is that there seems to be a consensus amongst most, if not all, experiment participants that the way to condition leathers is to oil them rather than to stuff them with fats and waxes. Maybe I need more sources of information, but from the Austin Black report, the UK saddle industry has historically not used any oils at all to condition their saddles, except for cod liver oil, but then only after the leather has been thoroughly stuffed with fats and waxes from their paste conditioner. The cod liver oil is not absorbed by the leather because it is stuffed already. The cod oil treats the surface and somehow restores the smell of leather to the leather. How that works is a mystery to me. I'll attach his brief two page report here, which he posted on leatherworker.net a long time ago. I wonder if we can put the thread I started in the same sub forum as this one? What happened to all the test results? It seems folks moved on to other things after December 10... oh, the holidays...

-

I'm impetuous. I realized this evening that Eastern Orthodox monks don't eat meat, and my target demograph is monks first and Orthodox lay people second, so why am i buying lard and tallow to condition their footwear??? Sheesh. I'm an idiot, too. So, regroup. I need to reread the discussion about recipes for leather conditioner that Scott Wolf mentions above in this thread, and read the thread on this topic from September. How does one mark that? Could i have used a browser bookmark? I had just gotten to the part where someone posted links to discussions from 1940 and from 100 years ago about fats and oils to condition leather. I did read in one of those that wool wax and wool grease are ingredients, and I heard of some kind of fat or wax made from nuts. I lost many memory functions during my stroke of 2015. Be grateful if you remember things. I guess I'll be wanting a leather conditioner that 1), doesn't harm leather in any way, but rather makes it soft for contact with tender feet, and 2), doesn't stain the socks that people can where with these sandals, and 3) doesn't contain fats from animal food products. Off the cuff, there's anhydrous lanolin and there's beeswax. I'll read more and see if my aversion to using NFO and other oils is warranted and supported by actual evidence, and to find evidence of what else could join my recipe.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

Which recipes are for waterproofing, Scott?

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

What the book calls wool grease is what we call lanolin.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

I'll read it again.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

I might like to buy the book online if it's in print and if it's relevant to making sandals (and later, belts and bags).

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

I would like to look at it. I was thinking earlier this morning that if I didn't like the conditioner I'm about to make, I'll have all this organic pork lard in a jar, and I could eat it out of the jar with a spoon, like a bacon smoothie. Well, maybe not...

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

It did finally show up last night.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

That's an interesting topic thread. Why are you averse to using tallow and lard? Those two ingredients make up 3/4 of the recipe of the English Saddlers conditioner. Austin, who apparently goes by"Oz", recommends to not use oil at all, until after the leather has been stuffed with fats and waxes, and he points out that the leather doesn't absorb this oil since it is already stuffed. I know almond oil is heady stuff for the olfactory sense, but the Saddlers of old didn't use oil. They used fats and waxes, which are removed in vegetable tanning leather. They're simply replacing that stuff with their conditioner. So I think I'll try the old way first, see how it works. Leather sandals are similar to tack and saddles in that there are straps and body weight on the topsole. I'll try what has worked for centuries. I bought 50 tins to send along with each pair of sandals I make, no charge to customers.

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

I just edited my post at the top, you might want to look at it. Do you have a link to your recipe?

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

This topic was started here in 2016 click here . There was an interesting discussion, and one fellow, "unicornleather", who is Austin Black of Wales, made saddles, and he makes his own concoction, which he sells or used to sell. But I can't reach him. Basically he said he uses an ancient saddler's grease made with tallow, beeswax, lard. He recommends using lanolin, but doesn't mention it in his basic formula. Also, he doesn't include the actual recipe. He says use 50% beef fat (tallow), 25%beeswax, and 25% lard (pork fat). In an effort to add lanolin to my recipe, I've jotted down these numbers: 40% tallow, 20% beeswax, 20% lard, 20% anhydrous (no water) lanolin. Lanolin is made by sheep sebaceous glands to lubricate and protect its wool. It's a waxy, white substance, the same stuff as the white part of a white head on human skin. I've considered maybe adding something else, for aroma, but Austin "Oz" said that the final treatment of leather, after this conditioner has spent three days moving along the leather fibres, and is apparently "dry", is to rub a small amount of cod liver oil onto both sides of the leather. He said this restores the leather smell of the leather. I'll have to try it. My leather already smells like leather, but after rubbing all that grease into both sides of it, who knows WHAT it will smell like! He wrote a similar article in another journal in 2012, but I didn't save the links to either article. However, I saved his article on the computer. I'll attach it, if allowed. He posted and was a member known as unicornleather. This is his website. I couldn't get his messaging to work for me. https://www.unicornleather.co.uk/ You can read his story if you click on "about me", at the top in the blue banner. I ordered all my ingredients today, online, except for the cod liver oil. Patrick leather conditioner.odt

- 193 replies

-

- saddler recipe

- diy conditioner

- (and 4 more)

-

Veg-Tan bellies: what to do with them.

deboardp replied to DieselTech's topic in Leatherwork Conversation

I'll be using then for mid-soles, since I'll be cutting out rectangles from the midsole to create channels for straps and stanchions. The other ideas are good, too. I can use them to practice stitching, testing my glues, trying out dyeing techniques, trying out my new DIY leather conditioner based on basic ancient recipes. I'm starting a new topic on that. -

I'm making a four sole sandal, three layers are leather, glued and stitched together. The fourth layer is 1/8" gum rubber, a full sole. What's the best glue for this? In my glue drawer I have Barge, Renia Top-Fit, Renia Aquilim 315, and Intercom Ecostick 1816B. The last one listed holds great when dry but the leathers separate when wet. They can be pulled apart. The shop is in my living room so i haven't done that experiment of soaking and pulling apart with the other glues. I'm thinking the water based glues will also not hold when the leather is well soaked but that possibly the barge will hold. Anyone know? The leather will be well roughed and the rubber, too. I have a one ton manual press for some pressure on it.

- 22 replies

-

- rubber to leather

- glue

-

(and 1 more)

Tagged with:

-

View to soften veg tan straps and maintain strength

deboardp replied to deboardp's topic in How Do I Do That?

I did some more online snooping about oils and conditioners and read something from Carl Friedrik that reminded me of 50 years ago hearing the same thing, that neatsfoot oil can harm leather, while mink oil is the best oil for leather. My second stroke destroyed many of my memory functions, so I just don't remember many many things. So I bought a few bottles of mink oil online from Tandy. I've been using the neatsfoot oil on my stones to sharpen my round knives and I guess now I have a lifetime supply for that. Here's the link to what I read: what Carl said about best oil for leather -

View to soften veg tan straps and maintain strength

deboardp replied to deboardp's topic in How Do I Do That?

-

View to soften veg tan straps and maintain strength

deboardp replied to deboardp's topic in How Do I Do That?

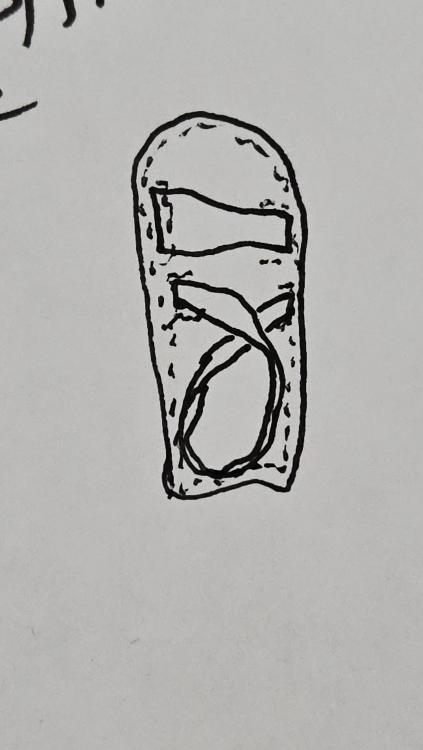

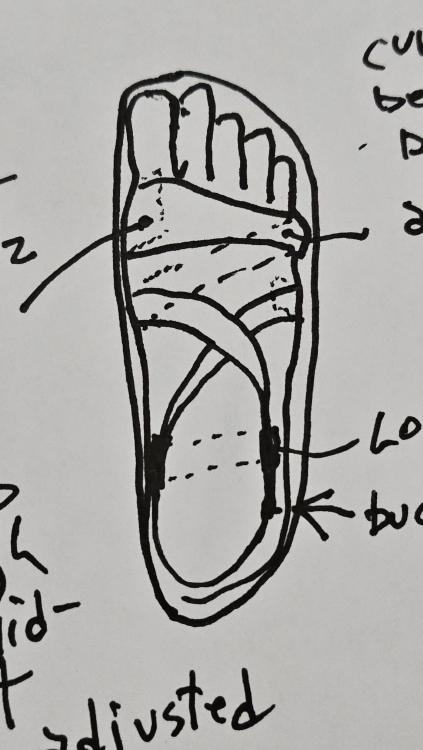

I added the deadends, with dotted lines. I also added a photo with the stitching, how it passes over the deadends and also reinforces the other straps with parallel stitches. -

View to soften veg tan straps and maintain strength

deboardp replied to deboardp's topic in How Do I Do That?

I answered this laboriously on my "smart" phone, and then lost the message when I went looking for my attachments. So now I'm on the laptop, and I edited the pic I want to send you. I use slots in the topsole, and channels (cutouts) in the midsole, to pass straps across to the other side of the sandal. In the picture, those straps are one piece of leather, separated so I can use a buckle. The wide end, at the big toe knuckle, deadends under that knuckle. I glue it to the flesh side of the top sole under the knuckle. Later I will run a doubled stitch through all three soles and the deadend, make sure it never pulls out. The dotted lines show where that front strap crosses to the other side from the little toe slot. The ankle/heel stanchions, one piece of leather, also pass across through a cutout in the midsole. The stanchions strap will be glued to the topsole, and stitched to prevent shifting. I use the midsole in order to keep the topsole flat, no humps from a strap being under it. The midsole is made of the same side of leather as the straps, the parts that are not prime strap leather. The straps fit in the cutouts, laying flat with the midsole, because they are replacing the part I cutout for them to lay in. I'm innovating with this design. My hypothesis is that two thinner layers of softish leather (7/8 ounce) will conform to the foot better than a more hardish, thicker single layer, and in my practice sandal, I noticed the the edge of the topsole curls up after I run a stitch along the sandal edge, which I like immensely. It creates a raised edge, helping to hold the foot. The bottom sole is not bend, which is too stiff. I'm using another double sole feature for the bottom sole. The two-part bottom sole will be 10 ounce shoulder, stiched together with top and midsoles, and then a 1/8" thick gum rubber bottom sole that will be glued, not stitched, to the shoulder. I wonder about the glue, and I'm going to create a new topic under the shoes and sandals forum here. I had tried a water based glue, Intercom ECOSTICK 1816B, and I liked it. I glued two scrap pieces of shoulder together and it held quite tight. A week later I wondered about it getting wet, and how it would hold up. So I soaked it in warm water, probably unfair, because rain is not usually warm, for 15 minutes, and tried to pry it apart. To my surprise, it came right apart. That's not good. I wonder if Barge or Renia Top-Fit would withstand being soaked. I have a gallon of each. I used Barge on my own personal sandals that lasted 20 years before I finally lost them, and I'm pretty sure they got wet from time to time. Do you know the answer to this question? I have a gallon of another water-based glue on the way, wish I could remember the name of it... but I think all water-based glues will share the problem of losing their bond when the leather is soaked. On the other hand, if the leather pieces are stitched or cobbled, they won't separate. The question might be moot.