Search the Community

Showing results for tags 'flatbed'.

-

$1400/OBO. Like Brand NEW!! Less than 5 hours. Located in NW Ohio. Willing to ship price determined at time of sale COBRA Class 18 Needle Feed Walking Foot Machine is sturdy enough to handle leather and fabric up to 20 oz. (depending on material) FEATURES: Sews up to 20 oz. (depending on material) Compound Needle Feed (Triple Feed) Walking Foot Big Bobbin (M style) Uses thread sizes from 69 to 207 Safety Clutch for hook protection Digital D.C. Servo Motor Heavy Duty Speed Reducer Flat Bed stand with locking casters LED light Thread stand and bobbin winder

-

Pfaff 545-H4-6/01 in excellent condition. $900 This is a triple feed medium weight leather sewing machine. This machine was built in Western Germany. It's capable of sewing up to size 138 threads, and through 3/8" of leather. The machine has been cleaned, adjusted and serviced. It works perfectly. maximum stitch is approximately 8mm, minimum stitch is less than 1mm. Reverse stitch matches the forward stitch. Internals are clean and oiled. Shipping across the USA is available upon request. The machine can be inspected and tested at: Solar Leather Machines 2837 Galleria Drive Arlington Tx 76011 817-422-9151

-

Hello all, I have been looking at post bed machines for sewing shoe uppers and boots and was wondering if there are any products available for converting a post bed machine to a flatbed for doing boot tops also. Do any companies already make something like this, or does anyone have experience or photos/diagrams they'd be willing to share here of table converters they have made? Thanks -Also I am pretty decided on the Cobra 5110 for the machine I want, http://www.leatherma...log.php?item=25 -Cobra has a "work platform" for their class 3 and 4 machines. This is pretty much the idea I'm going for, but I want it on a post bed rather than then cylinder arm. http://www.leatherma...log.php?item=44

-

After months of reading hundreds of forum topics and opinion articles, I'm finally breaking down and just asking outright. I'm looking for the "perfect" machine to be able to handle the types of handbags I make. At the moment, I do most of my construction with rivets and a non-walking foot Juki (terrible, I know) to skirt around forking out so much money for a proper machine, but the time has come. About my bags: I work primarily with 3-4 and 5-6 oz chrome and veg tanned leather. My current bag designs are simple and primarily rivet based (photos below), but I'm expanding to a line of bucket bags and backpacks that my poor tired flatbed has simply refused to sew. I would have to make drastic adjustments to the pattern that will chop up my minimalist design. A few months ago, I sold my cylinder arm Juki LS-321 (needle fed) because, aside from the needle feed mechanism not liking my seam overlaps, for the life of me - I could not get the thing to stitch straight unless I stitched as slowly as possible and held the leather tight from both the front and back. I have 6 years of rather intensive sewing experience on a flatbed, and tried to work with the LS-321 beast for a year so I don't think it was a learning curve issue, but I might be wrong. Now, my question is this: Is it possible to stitch handbags with a flatbed, or is it best to get a cylinder arm and a good flatbed platform for it? Further, what make and model do you recommend that is between $1-2k (preferably on the lower end) and has a good resource base of attachments that make production easier? I know this question has been asked a thousand times, but all of the topics I've read have had some caveat or compared craigslist ads they had found.

- 17 replies

-

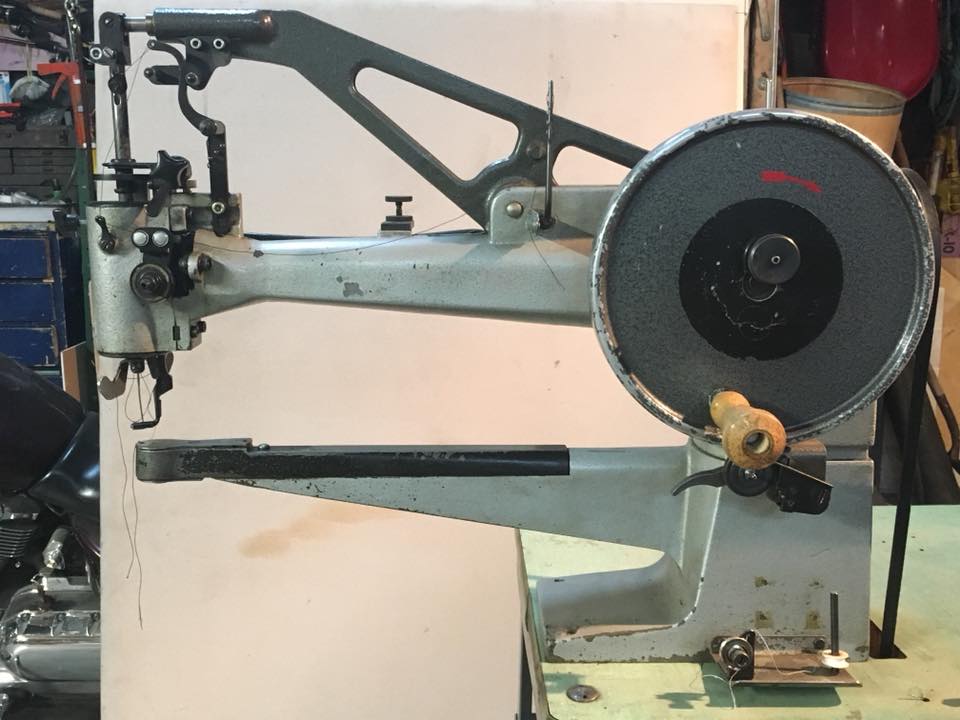

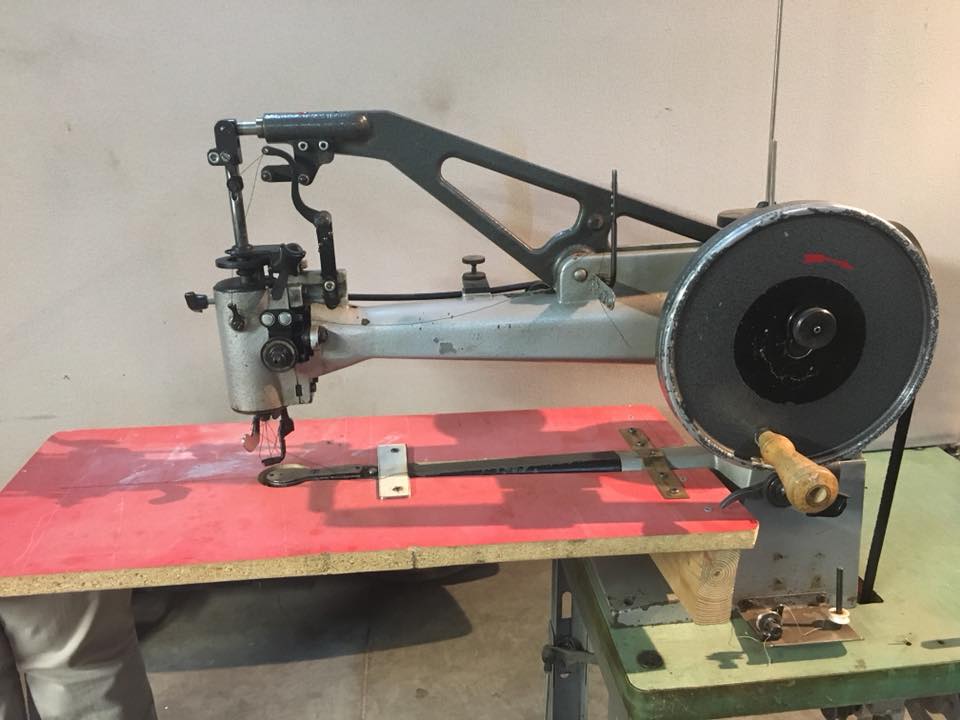

Excellent running condition with a flat bed table attachment. Extra bobbins, extra needles, selling for $3,800. Please contact Don Monroe, Email monroeleather@gmail.com or you can call 509-481-8787

-

- clase

- shoe patch

-

(and 6 more)

Tagged with:

-

Hello all! I'm having a little trouble making a decision... I'm buying my first walking foot machine and I'm not sure whether I should go with what I'm used to which is a flatbed machine like the Juki 1541s or if I should get the Techsew 2700 Pro which seems to have more capabilities? I mostly make garments but I would like to expand into accessories like purses. So it would seem like the cylinder bed would be great for that and with the table attachment it comes with it seems like a two for one. However, I've never used a cylinder machine and the height seems awkward. Can anybody attest or disagree with this? With the flatbed attachment does the fabric feed as easily as it would through a regular flatbed machine? I was dead set on getting the techsew today since they are having a sale for the holiday but now I'm feeling a little confused and a little nervous about buying something online that I wasn't able to try out... especially with that price tag. I've tried the Juki 1541S and it seems great but I don't want to outgrow it if I decide to make more accessories. Oh, and I'll mostly be working with garment weight leathers like lambskin and plonge... but a heavier cowhide to make purses with. Any comments, thoughts, or answers to my questions will be greatly appreciated!! Thanks in advance

- 11 replies

-

- cylinder machine

- compound feed

-

(and 2 more)

Tagged with:

-

This is my first post, so here it goes. I am hoping to get some advice on buying the correct machine for my needs. I only have experience with flatbed machines and I've never used a cylinder arm machine before. So some advice would be great. The type of products I have been making include laptop bags, tablet sleeves, wallets, duffel bags and some handbags. I am looking to start manufacturing a variety of products and a lot more handbags. From what I gather most people who stitch handbags use cylinder arm machines. Now my question is; would a cylinder arm be able to do what a flatbed machine can do? Are cylinder arm machines as powerful as flatbed machines? Any advice would be great! FYI, I have been running a leather manufacturing business for someone else, and I am starting my own business now, that is why I need to purchase the correct machine.

-

This is not my idea, I saw this specific implementation on Donna Nobilo's machine. It is very similar to the way flatbed tables attach to Pearson No.6 machines, and similar to the way flatbeds attach to 29k patchers. Donna runs Ethos Leather in New Zealand and is a member on these forums. It is so much better than the (IMO ridiculous) way the tables come from the Chinese factories with four bolts at the back of the flatbed to attach it to the machine table I don't know why they don't ship the tables built like this already. It takes less than a minute to attach, and requires only two bolts. It's pretty stable with just one but it is slightly more secure with two. You need two M8 machine screws. I'm using cap head allen screws and an M5 allen key. If you used an M8 wing screw that would make the lower attachment easier, I just don't happen to have one. The m8 screws don't appear to be a perfect match for the threads tapped into the machine head, but they do work. I don't know what the thread standard in the holes in the machine is, but at least some of the other bolts in 441s are metric as well. The table attaches using brackets made of bent aluminium strip. This stuff is 50mm wide and is a standard stock item at big box hardware stores. The rear strap of the bracket sits across the rectangular cutout in the arm The front strap of the bracket wraps under the shuttle race Add the machine screws and you're done This cost me less than $10 to do, and about half an hour to make. The only vaguely difficult bit was measuring up the bends. Here's a video showing how easily it goes on and off. https://youtu.be/u8zhPB5c5iA