All Activity

- Past hour

-

The manual for this machine is very close to yours. 72w19.pdf

- Today

-

It looks to me that you've just drummed up a thread on this forum to make sales of what you already market, Right? You're asking for input on "designing" a new servo, yet debate every time someone mentions a point or suggestion contrary to what you're already marketing/selling. For example when a member suggests options for supply voltages, you just jump to market your "Kenedyne" motor as it's available in both. You should have said, that's a great idea, we'll incorporate that into the worlds best heavy servo motor that we're working on, maybe we'll make it a dual voltage, plug and play unit! If you're looking to design a servo for leatherworkers to use on heavy stitchers, follow our collective advice and be open minded. If you want to add all these features including a ridiculous "jog dial" you're not really going to get anywhere. ISM in the Republic of China already has the best servo going with all those "other" features we don't really need. The ISM SV-71 650w servo is around $300. I bought mine from College Sewing machine for 189GBP ($258). Those units are light years ahead of any of the lower cost PRC made units and not all that inferior to a Ho Hsing unit. Maybe I'm a little too skeptical, I don't know. It could be something innocent like a mistake in translation from English to Chinese, or maybe a cultural communication mismatch? The members here buy Servos for 2 reasons. 1) Better low speed control 2) Needle Positioning Those are the only major advantages they have over a clutch motor and yes, clutch motors are very much still a thing. They're nearly indestructible, basic, easy to adjust, and power machines along all day, every day. I actually like the faint hum they make, you know the machine is on. Yes, they do consume a little more power, but unless you have a shop floor with 100-+ machines running, it's not an issue. If you factor in maintenance/repair/replacement of burned units as well as electricity consumption over a 10 year span, servos could and probably do, carry a higher cost. I have 21 clutch motors operating on my shop floor, the oldest date on one is 1967, the newest is dated 1993. (Most all are made in Taiwan/ROC back when that wasn't really a great thing quality wise). I seriously doubt any brushless servo would last 30-50 years?

-

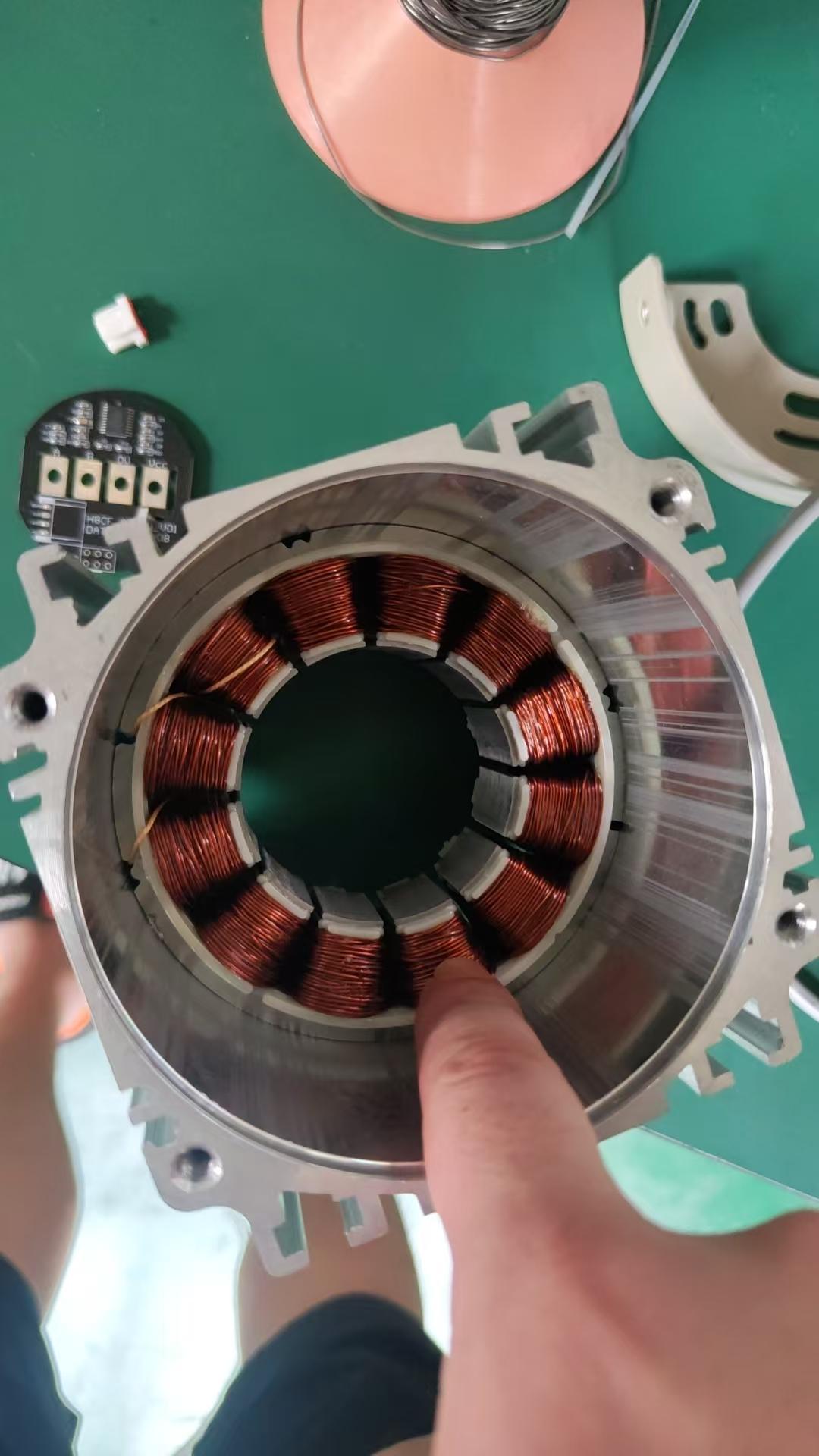

Development of best servo motor for leather sewing machine

kgg replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Like @dikman I did a similar search for servo motors and I find that I can get a Brushless for about $150 CAD or a Brushed for about $200 CAD. As I don't need or want a Brushless servo motor or any of the additional features the documentation needed for a Brushed servo motor is so basic. 5 easy steps: 1. how to install the servo motor and mechanical linkages, 2. install belt to the machine or belts if you have a speed reducer, 3. set speed by turning the speed dial, 4. plug it in to a wall outlet, 5. turn power switch on and hit the "go" pedal. If at some point a Brushed servo motor fails you typically have to replace the servo motors fuse and brushes. If a Brushless servo motor fails chances are you replace the complete servo motor setup. kgg -

The part # you are looking for is B1525-053-0A0. An original Juki part will have the needle guard while a lot of after market ones will just be the presser foot. If you contact a Juki dealer and ask for the complete presser foot assembly you will get it with the needle guard. Another alternative is to buy a Needle Finger Guard off places like Amazon. Example: ( https://www.amazon.ca/YICBOR-Sewing-Machine-Brother-Machines/dp/B08ZCF899N/ref=sr_1_17?crid=UO5IAKRG7BVO&dib=eyJ2IjoiMSJ9.2fLw6Era9Ry_EQb4ctlNR0XMnKd9cxPTyATq6kljrRUsFAsAY60K0rL24TCK1bhBM71KGBRj_bN5NkMMVaN4cKrL0Ttl1dPFMzVojOWsPo7wY9ruXUERvP51UQ9Z6Ws0-PC59GirIwKvznJSxcsbXhB2D9FV30xEjQtKF_ez23X6JfLEHT1L_DGHy5IyTM5Gud5gVQ5sQeej1YO1MFbOCaz30Vq3Omf80-yk9hkngzDM7Zv7Kht2CXjrZ-tNUZxKCzXU_reMtpUjrD4o9CfPCmsvX480rlFWypy8fpcw3Lw.v6_DjuKOKwrz96P_yooYKPm6sQqqEQ2RE5efMMrS0UU&dib_tag=se&keywords=needle+guard+for+Juki+presser+foot+for+juki+ls-341&qid=1751713038&sprefix=needle+guard+for+juki+presser+foot+for+juki+ls-341%2Caps%2C317&sr=8-17 ) kgg

-

I learnt sewing with modern servo motor with needle positioner. I am buying them in Europe from a big reseller, Strima, they are around 300 euros. They start at 100 rpm minimumspeed I think, 750 we. Thanks to needle positioner I don't miss lower speeds. I do needle up, needle down and I can go step by step when I want. And the needle is always in the right position (locked stitch or open tensioner etc) so working is easy and precise. I don't need and don't want a speed reducer under the table. A jog dial would be useful to limit upper speed which I need to do on the controller. I also miss more robust needle positioner with better and easier fixing to different types of machines. For me a middle priced servos with good documentation and support would be interesting. Efkas prices are too steep, the cheapest Chinese imports are undocumented and have often strange quirks that are difficult to solve

-

Wiz, thank you for this info. I wasn’t sure if the minor difference was an adjustment issue or just how the machine sews. As this machine was in poor condition I wasn’t sure if I could adjust backstitch to be nearly perfect. Your input helps me believe backstitch is good and and to move on to practicing sewing. I also do the “poor man’s reverse” on a Tippman Boss. I did the adjustments Friquant recommended which significantly helped. The tip to use the tape to mark when the presser foot and feed dog doesn’t move when holding the reverse lever also was greatly useful. Much Thanks to you both.

-

Thanks, to manufacturers in China, India, Indonesia and other Asian countries, we use Kinedyne HM-750L low cost motor, because they need efficiency, instead of "low speed", compare to other Chinese motor, the advantage is high durability. Yes Kinedyne HM-750SH low speed high torque servo motor is ideal for leather sewing machine. At least, the motor can greatly improve the performance of our leather sewing machine.

-

Keep your fingers out of the way & then guards are not needed.

-

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Just did some checking, your current servo is available here (Australia) for Au$500 plus shipping, generic servos start at Au$ 140 shipped. Bit of a no-brainer really, even at $200 it leaves me a lot of money for other things. -

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

Mmmm, ok, this is primarily a hobbyist forum and our needs/wants will be different to those of a large manufacturer of leather goods. WE want controllable slow speed and torque out of a servo but to a manufacturer slow speed = lost time so I doubt they would be interested. Your potential market is harness makers, saddlers and those who make goods using heavy leather but it is not exactly a huge market, in fact I would say it's a very specialised market, with probably very limited sales possibilities. The obvious market is to convince those Chinese manufacturers of leather stitching machines to use your motors with their machines but that's probably unlikely as they will be dictated by cost and the cheaper generic motors work well enough for them. You're not appealing to the hobby market as your motors are in the upper price bracket, so I'm not sure where that leaves you. To get back to your original post, so far it's not looking good for your "options", other than a good variable speed control. If your Swedish/Italian people need them then it shows that their needs are different to ours as hobbyists. So who are you going to cater for? -

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

If you consider Ho Hsing and Efka as your competitors then you've come to the wrong place to promote your servo as very few on here buy those motors (other than as used units that come with a second-hand machine). You can't compete with what most of us buy, generic Made-in-China servos off ebay (or from a dealer, selling those same generic servos). You're response came in while I was typing, you're missing my point, I can buy a generic servo and a speed reducer for less than your motor and it will achieve the same results. For me it's even cheaper because I make my own speed reducers. At one point I had a machine that could do one stitch every 3 seconds, it's not that difficult to achieve. -

Thanks for your opinion! Before making Kinedyne servo motor, we sell other brand "servo motor" for our leather sewing machine! The fail rate of board is about 7%. We spent a lot of time and money for service after sale! Cluth motor is too bad for leather sewing machines, so we produce Kinedyne 750L economical servo motor, it is durable motor with good price, but the minimum speed is 300 RPM, customers still need to buy speed reducer! Why waste money to buy speed reducer? We developped Kinedyne HM-750SH low spee, high torque servo motor. Finally we spend less money with high performance servo motor!!

-

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

When I bought my first servo I was fascinated by all the settings in the menus, over time I realised that for the most part they were irrelevant as once I had it running to suit me I didn't need to change anything again. Like KGG once I have it set to an optimum speed (for my needs), including a speed reducer as the generic servos need one, then I don't need to change anything. Your Kinedyne is apparently a superior servo compared to the array of generic servos available but the price reflects that and while I would love one as a hobbyist spending that sort of money isn't justified when the cheaper option is working fine. Plus I have more than one machine! I'm not sure which part of the market you're aiming for, the vast majority on here are hobbyists and like me can't justify the expenditure for a Kinedyne so you're unlikely to achieve much in the way of sales and if you're aiming for the commercial market you've come to the wrong place. -

Yes, digital servo motors will lose torque at low speed, and the motor will vibrate or noise when start up, because the torque is not enough. When get change, please test Kinedyne HM-750SH sero motor from Ryan or Toledo Industrial Sewing Machine, I think you will be surprised with torque and speed control. Really appreciate for your information. Can you test 10 stitches per minitue? See if smoke came from the needle! Now we use 45mm pulley, the lowest sewing speed of CowBoy CB4500 is 10 SPM. If the needle still smoke, we will try to use smaller pulley or modify the program. And when thin leather, we have speed controller that allow you to increase speed in a second. Thanks again for your informtion about the lowest speed!

-

Development of best servo motor for leather sewing machine

kgg replied to CowBoyOUTLAW's topic in Leather Sewing Machines

I totally agree. I think as a cheap old geezer the hobbyist is looking for simple operation, reliable and most importantly cost effective. I can count on one hand the number of times I have changed the speed on my servo motors. Once I find the comfortable "spot" that is where it stays. To the average hobbyist cost is always king whether it is a complete machine setup or a servo motor. Why?? Just build simple good working motors for the majority of your customer base that are cost effective. kgg -

A good place to start is by picking up a copy of Stohlman's How to Make Holsters. It has a list of all the tools you will need to get started and has several patterns you can use to try your hand at making holsters. There is wealth of knowledge available in this forum. I came here to learn from the masters when I decided to give holster making a try.

-

I 100% understand your opinion, but many modern standard arm sewing machines use JOG dial, for example Durkopp Adler 967, you can see the jog on some other computerized upholstery sewing machine. Ho Hsing i90 is an excellent servo motor for heavy duty industrial sewing machines, the price in China is over $500.00 USD, and about $400 USD in Europe, it is too higher for 205-370 Clone or 441 Clones. Clutch motor is very bad for leather sewing machine, we searched good servo motor for our CowBoy leather sewing machines for about 6 months, no affordable servo motor can work for us, that's why we start to produce servo motor. We has been selling servo motor in United States for about 2 years, all Tandy CowBoy 797 sewing machines come with Kinedyne HM-750SL servo motor. However we must keep innovation. Last October, our Italian dealer suggested the JOG Dial, we make it reality. Last month, our Sweden dealer suggested Half Stitch we made it reality....

-

On a standard size Adler 205 clone, the jog dial concept is a bit ridiculous to redundant. The handwheel is as close a reach as the jog dial when you're sitting in front of it. Adler has it on the 969 because the handwheel is a much further reach. A jog wheel on a standard machine is also a poor idea because of it's diameter. The handwheel is very large, and can afford a very fine control over the needle. The "long arm" machines you're mentioning (Such as the model below) with the extra front mechanical hand wheel are probably 1% of the heavy stitchers out there. I'd gamble most anyone with one of those is either set up with a heavy Clutch Motor, or a quality Efka or similar. I just pulled the first random long arm machine image I found with a Google search. As you can see this lower end Chinese machine looks like it's equipped with a either Ho Hsing servo or a close clone that's probably 5x the cost of a run of the mill Chinese brushless servo. I kinda doubt a $100-150 servo you're working on would be the right piece of that particular puzzle? I would maybe suggest not concentrating on that particular market? You're soliciting input from a forum of fairly competent people but It feels like you're debating the input? Is it that you've already designed the "perfect" servo and just haven't released it yet, and don't like what you read?

-

charlesfraces3884 joined the community

- Yesterday

-

Development of best servo motor for leather sewing machine

dikman replied to CowBoyOUTLAW's topic in Leather Sewing Machines

I guess it depends what market the OP is aiming for. I think it's fair to say that most don't want fancy options that they will never use, once one is set up for leather sewing it's doubtful they will fiddle around with the options in most servos - other than speed control. Yes, I know some like an NPS but once you have your machine setup for sewing leather, which generally means slow-speed, then an NPS isn't necessary. Having fiddled around with several different generic servos/speed reducers my optimum for sewing leather would be very low speed startup, lots of torque and variable speed using a knob placed near the machine. Having converted my lathe to a VFD I can use a knob to vary the speed at will, it is a much better system that anything else. And make it affordable!!!!! The OP has a "high-torque" motor currently available and it is apparently pretty good but at 2-3 times the price of generic servos I won't be buying one.