All Activity

- Today

-

Hello, I am figuring out some if the logistics of starting a small business. My plan as of now is to sell discounted leather sheathes because I am a novice. My only concern is making a sheath pattern without having the actual knife on hand. What would you do then? Would I have to have the customer ship out their knife to get a proper sheath made? Thanks a lot for all of your input!

-

New pistol, new holster

Thadrick replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks guys. It went faster than I usually get them done but I had fun with it. I got the holster done before I even sighted the pistol in. -

New pistol, new holster

Littlef replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That’s nice, love it! -

New pistol, new holster

BigBore replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Outstanding work! - Yesterday

-

New pistol, new holster

dikman replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wow, a lot of work went into that! Nice job. -

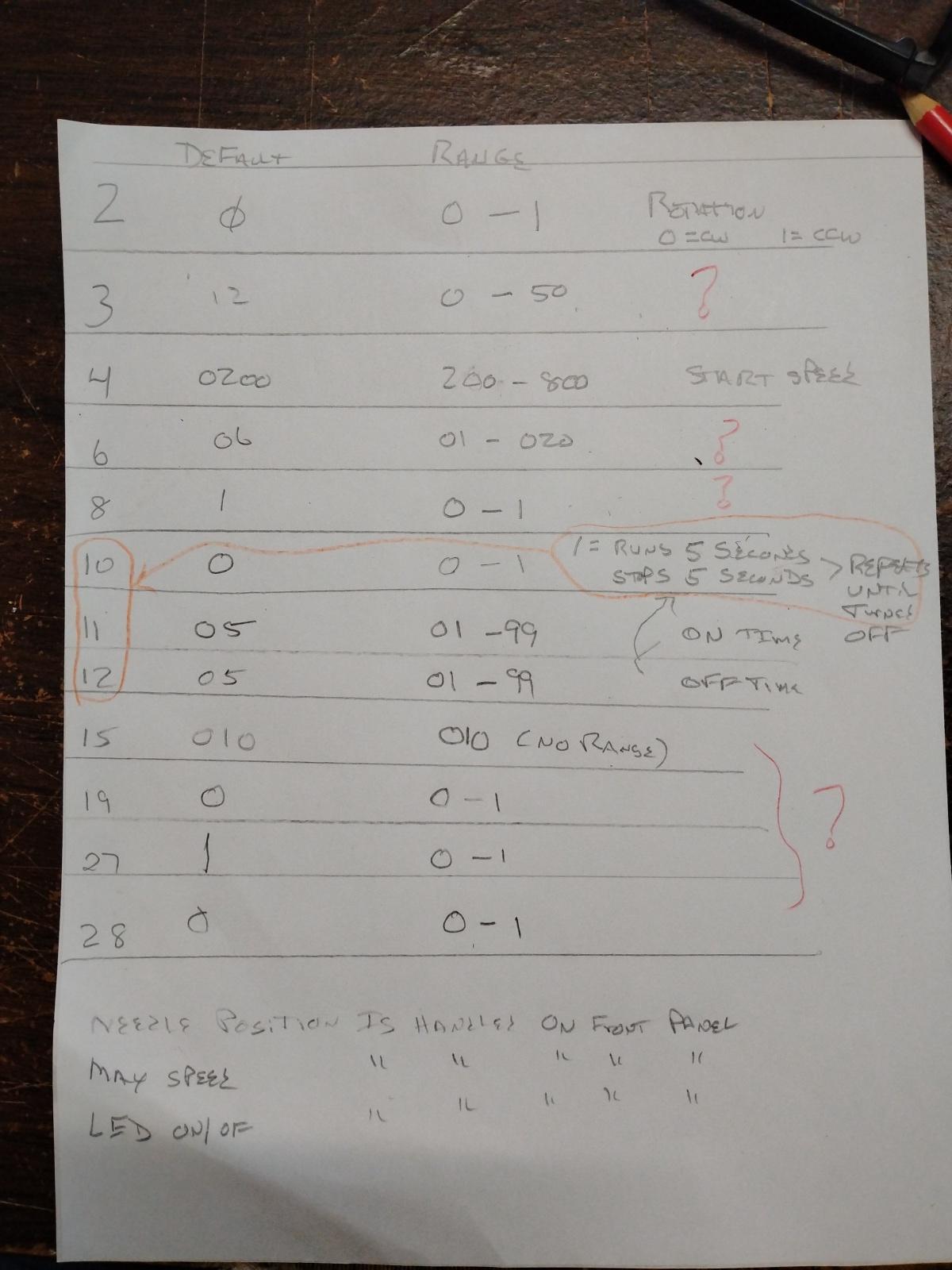

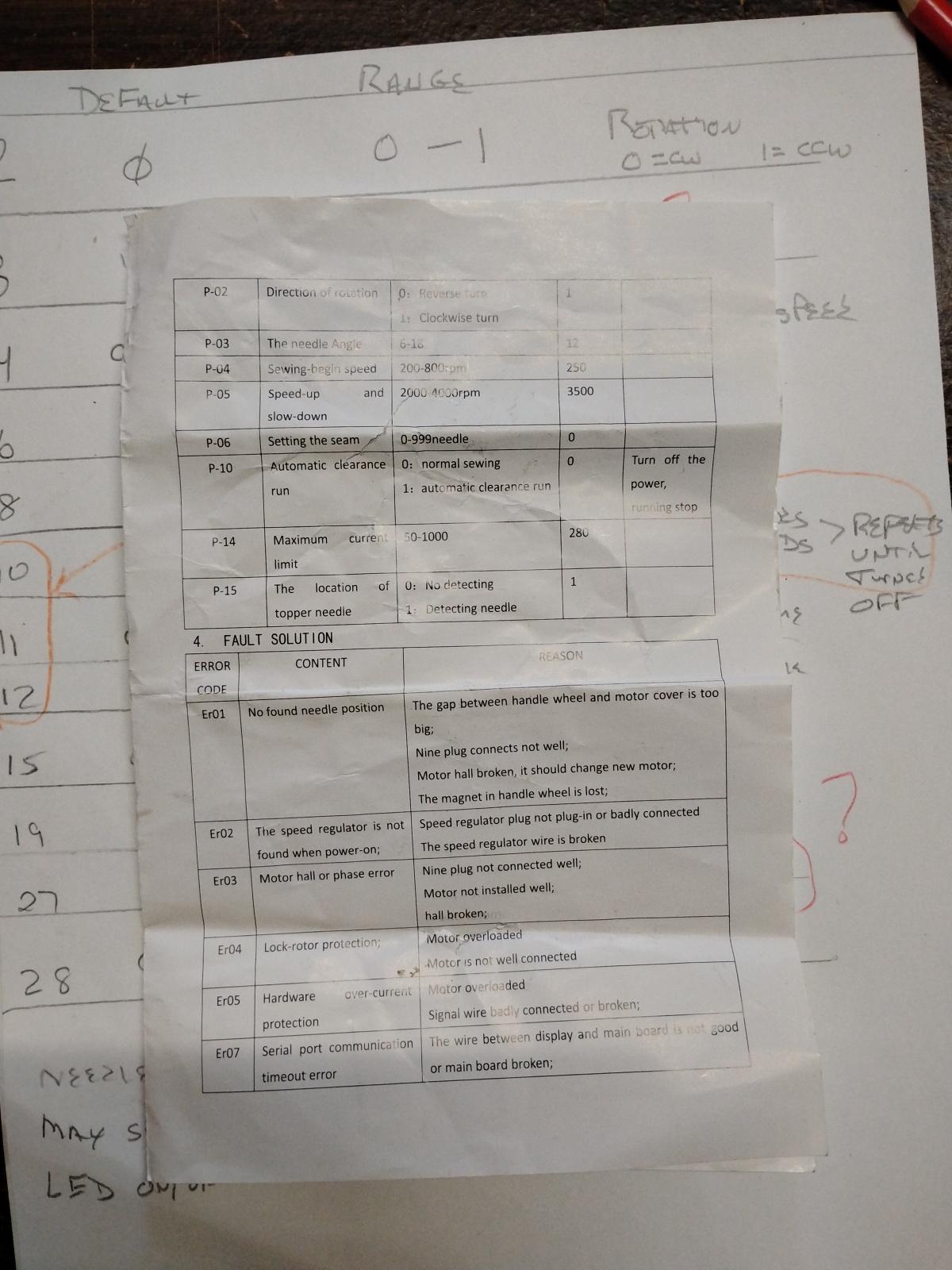

P03 is probably needle-down position (mean how far the handwheel turns from needle-up position to needle-down position) P10 is supposedly for breaking in the machine. I forget where I read that. This Stitchman Servo: The missing manual may give you ideas about some of the others.

-

It will certainly out last me! If used as intended (or possibly even abused!) I can't see any fail points on it, an unusually well made bit of Chinese gear.

-

Nicolethea2025 joined the community

-

Hi folks, I’m closing out my leather handbag studio and offering two professional-grade machines in a clean, bundled sale. Ideal for a maker looking to upgrade or expand their setup: 🪡 TechSew 2700 Industrial Sewing Machine Cylinder-arm model with removable flatbed extension. Great for leather, canvas, and bag construction. Mounted on the original table with motor and controls. Lightly used and stored indoors. 🌀 Cobra NP-4 Leather Skiving Machine Reliable edge-thinning skiver, also mounted on its original industrial table. Great for prepping strap ends and clean finishes. 🎁 Bonus supplies included: – Heavy-duty thread cones – Zippers – Pleather scraps – Various accessory pieces 🛠 Machines were in good working order before storage. They have not been serviced recently, so I’m selling them as-is. 💰 Asking $2,300 OBO for the full bundle. 📍 Located in Lancaster County, PA – local pickup only. Open to buyer-arranged freight, but I will not pack, pallet, or ship. Photos will be added this weekend, but feel free to message me with questions or for early interest. Thanks for reading, Nicole

-

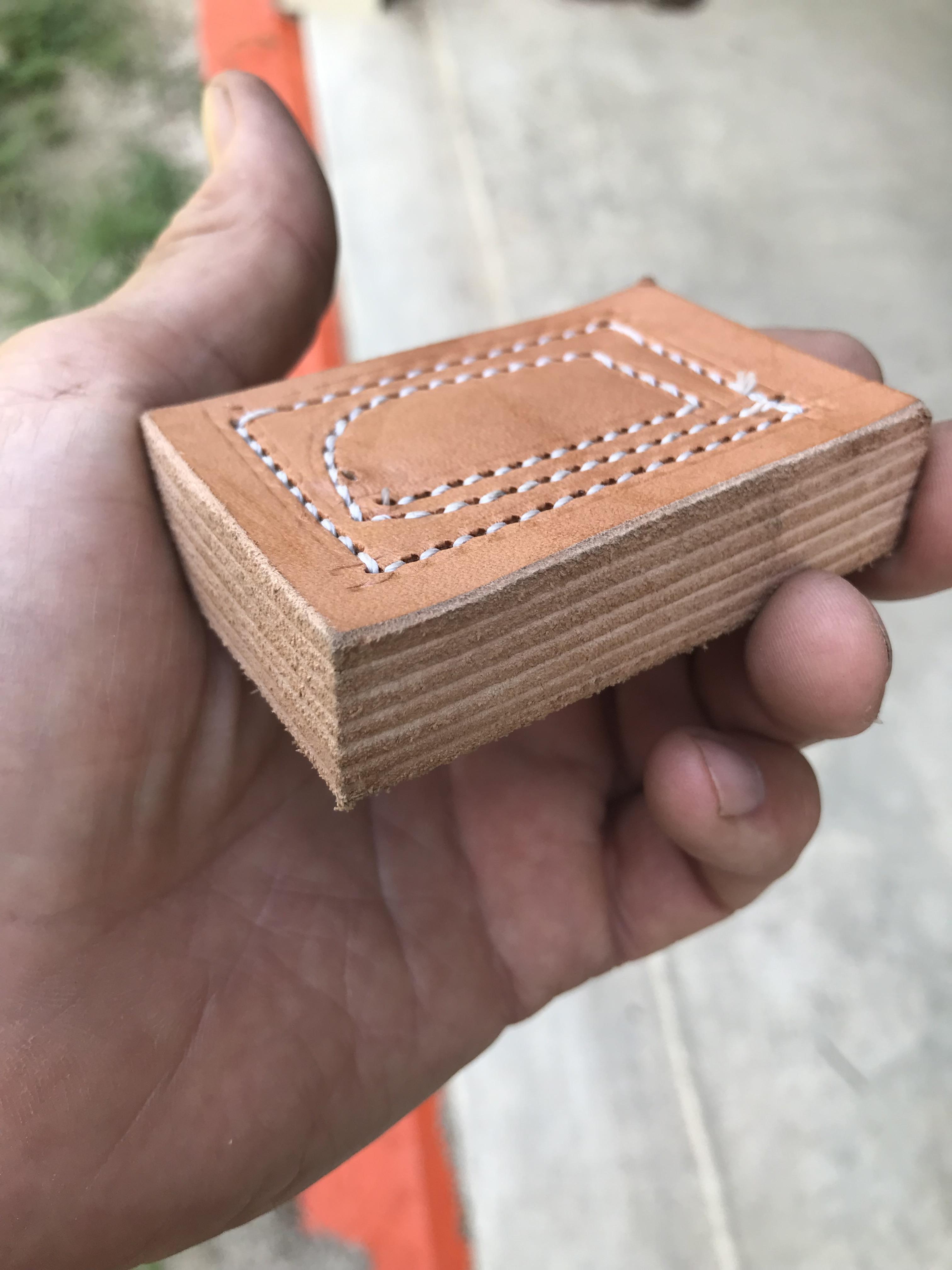

That (simple) stamping with the white stitching really pops out at you!

-

-

I got a pig in a poke used servo motor with a parameter sheet that doesn't quite match up. I went through and made the best sheet I could based on playing with the knobs. P2 and P4 are the same. The printed sheet had far fewer entrys than the control box gives me. P10 to 012 seem to be for automatic sewing of some kind. It'll run and stop the the number of seconds specified by 11 and 12, repeatedly until you cut the power. Turn the switch on, it cycles until you turn it back off. No idea of the brand. If anybody knows or cares to speculate about the mystery parameters, I'm all ears. I have enough to make it work.

-

jsndijns joined the community

-

Awesome! Thank you so much for the help!

-

I regularly sew padded straps as shown in your picture using TSC-441 clone (Cobra Class 4). I typically sew 1-2 layers of 9-10 oz bridle leather over a pad of 1/8" neoprene wrapped with 4-5 oz chrome tanned leather. The pad turns out fine with a #25 needle and #277 thread. I make English tack as well, and prefer to hand sew bridles, reins, and most repairs. I use the 441 machine mainly for halters, and it did a good job sewing new shearling on a surcingle (8-9 oz strap).

-

If it has a Singer flatbed industrial size base, any industrial sewing machine dealer can sell you a table and whatever else you need. If the base or your needs are out of the ordinary, we'll need more information. More information and a picture of the head should get you more information than you'll ever need. These guys love to type about sewing machines. I'll break this off the tail end of a 16 year old thread, Hopefully, you can fill in some blanks ...

-

They use the Schmetz 331LR needles, which at one point I think were discontinued, but looking online it appears some suppliers show inventory so maybe they started making them again? Landis #1 Needles Parts I highly doubt will be available, other than finding good used parts or making your own. If anyone were to have them, check with Eli Schlabach at Landis Machine Co. in Arthur, IL (217-543-3464). He's mainly in Landis #3 and Landis #16 machines, but he might have something.

-

Capabilities of a type 441 machine

bladegrinder replied to Valletta's topic in Leather Sewing Machines

I also have a Cowboy 4500, as to the thickness, it will do it. And as wizcrafts say you’d need to probably experiment some with needles, feet and foot pressure to get the appearance of the stitch you’re looking for. Here is a pic of a test piece I tried shortly after I got my machine, yes, it will sew thick! -

Lena Carlton joined the community

-

Moved your post to leather sewing machines. You'll get answers here.

-

rathorse joined the community

-

You didn't offend anybody I know. I often learn about people being dead after I wish them happy birthday on the book of faces!

-

Hello. I found a Landis #1 at a very good price and in considering buying it. I have gotten into a lot more heavy harness work but need to sew with natural thread, linen/cotton. My question is, how hard are the parts to find these days? Needles, awls, etc...? Thanks so much for any and all help. Brian Merrick

-

I own a Cowboy cb4500, which is a Juki 441 clone. It easily sews over 24mm thick stacks of whatever you have under the feet. It is a heavy duty sewing machine with two feet: inside alternating and outside presser feet. I would not refer to them as meant for delicate materials! The bottom appearance will vary with the presence or absence of the feed dog and its size. The stock feed dog is very wide and has a large oval hole in it. Soft stuff will be pushed down into that hole and may look dab compared to the top layer. To get around this problem, a couple of enterprising people have come up with narrower feed dogs that have smaller needle holes. I use one of these all the time. One maker is in Australia and the other is in the USA. They sell the narrow feed dog with a matching throat plate that is just wide enough to let the feed dog move freely. If you buy a 441 clone, then add the aftermarket narrow feed dog and throat plate, you will still be able to sew with #277 bonded thread, using a #200 (25) needle. The geometry of the needle matters too. you could experiment with different leather point shapes, and even a round point. Or, you might find somebody who owns such a machine in Hungary and send them some sample stacks of leather and foam to sew for you. Ask them to sew a separate line of thread with different needle point shapes. If they lack a particular shape that is available, maybe buy them a pack of 10 of those needles. The main needle shapes I've used in my 441 clone are Schmetz "S" point (inline wedge), tri-point (3 sided), diamond point (4-sided), and round point. I believe that some companies make traditional tilted wedge points, called LL or LR. They produce slanted stitches. I just don't have any of those.

-

New to me Pfaff 145 H3 BSN, set up and other questions

dwhacks replied to dwhacks's topic in Leather Sewing Machines

Well I figured out the stickiness, I think. Someone previously had over tightened the pre-load on the handwheel (I believe). Loosening the set screws and screw on the back I gave it a little tap away from the machine body and it all freed up! I readjusted it so there was no slop, tightened the set screws, and it all seems excellent. -

Hi everyone! 😊 I'm a saddler and harness maker (mostly English tack with just a little harness work), and I’m thinking about getting a Typical TW3-441D. I’ve heard it's a solid machine for saddlery, but unfortunately I don’t know anyone nearby who owns one, so I’d really appreciate some input from those with experience. My question is about its versatility. I’d need it to handle stitching through about 10mm (3/8" to 1/2") of harness leather plus a layer of soft foam (around 10mm thick) covered with thin, sensitive leather — like a thicker sheepskin nappa or a thinner calf. Do you think this machine could manage that without damaging the delicate leather on the bottom? Thanks so much in advance for any insight! 🙏

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)