All Activity

- Past hour

-

Wet it with warm water taking care not to go all the way to the hardware and stretch between hands . That will likely get what you need for extra length .

- Today

-

Hello, First post with a question . I was given the bracelet in the photo by my grandsons and it is engraved so I'd really like to wear it. The problem is, it's the largest on ethis company makes and its quite snug on my wrist. Does anyone have any tips on stretching the woven leather so it fits? Alternatively, changing the clasp in some way to make the whole thing longer? Any help appreciated. Thanks

-

trooper1954 joined the community

-

Bought a beautiful Singer 29K-70 with treadle base

Samalan replied to Mr. Jay's topic in Leather Sewing Machines

Beautiful machine, have fun with that, looks like it's in great shape. -

Wonderful bow tie and a great cause to get behind!

-

Nice work! That's your first purse? Really well done.

-

larry1096 started following Removing molding marks?

-

History of Bowties very nice looking bow tie

-

Renia Colle de Cologne vs Syntic Total a Superfix

Yukonrookie replied to Yukonrookie's topic in How Do I Do That?

Yup definitely- 21 replies

-

- contact cement

- glues

-

(and 1 more)

Tagged with:

-

FrankHester started following Problem with leather splitter/skiving machines

-

Hello, I've been working on improving my tooling to get more detail, crisper lines and all the things I admire from the pro's. One thing I can't overcome yet, is getting rid of the marks that come from molding the leather. I watched a video by Jason Ingles showing his boning technique, and then a photo of the finished holster-it looks like the leather has never been touched? No burnishing, and a perfect 'grain' surface like unworked leather. (I'm attaching a photo-note that's Jason Ingle's work, and posted to Instagram, so I believe it's ok to share it?) Any idea how that final finish is obtained (or regained?) after tooling the leather? I'm finding it thoroughly impossible at this point. Thanks for any help- Larry

-

Adler 68NT Seized - Any assistance/advice gladly welcomed

nejcek74 replied to Ian B's topic in Leather Sewing Machines

you can also check the adler 68 parts list: https://www.college-sewing.co.uk/amfile/file/download/file/3091/category/498/ -

Problem with leather splitter/skiving machines

Hildebrand replied to Coloradoguy's topic in How Do I Do That?

Great explanation Dwight, your picture made me take a second look, I thought I was looking at my bench. Minus the grease I have that same splitter and that same plastic mat on my bench. Like they say great minds think alike. Todd -

drtap26 joined the community

-

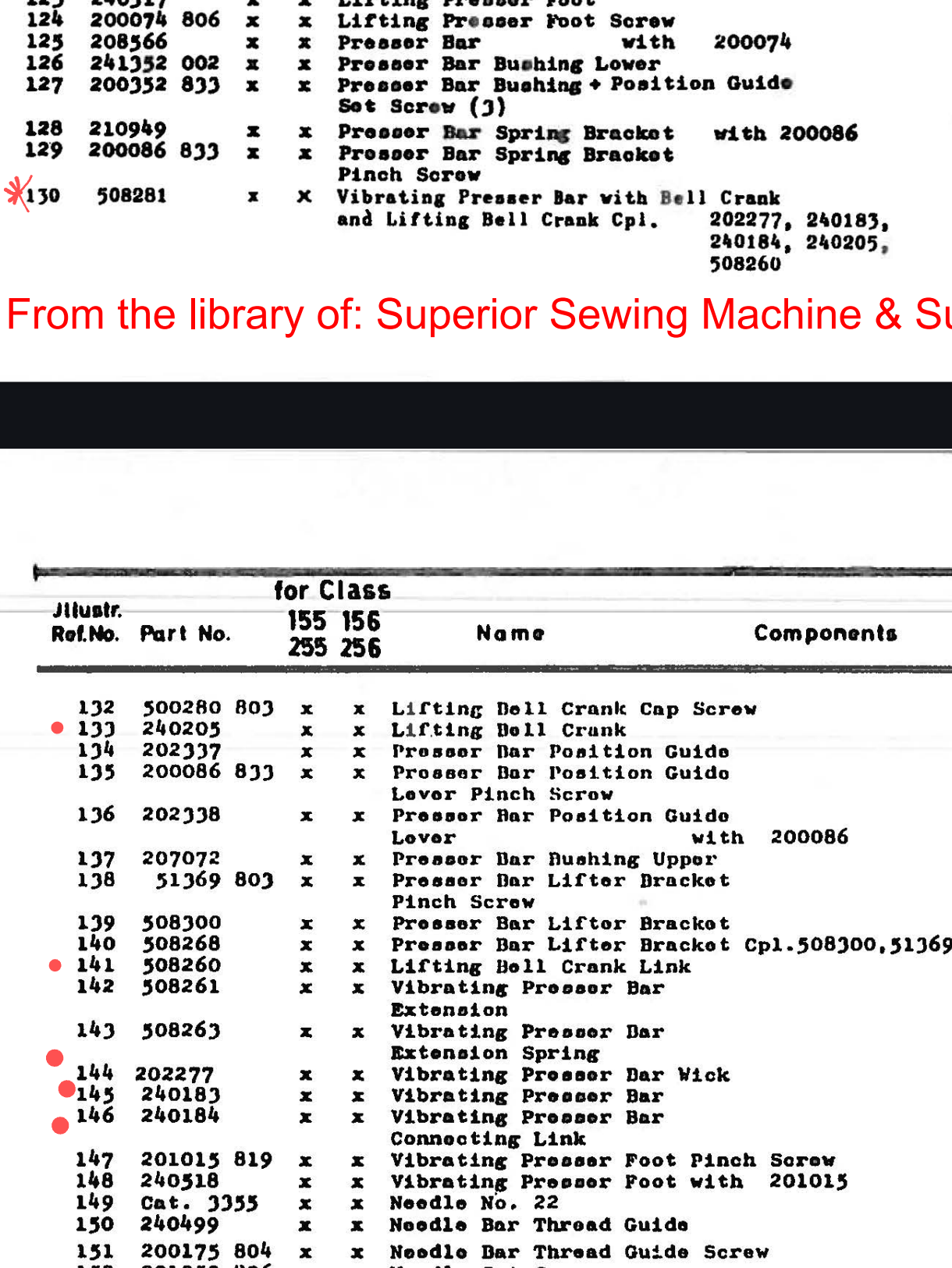

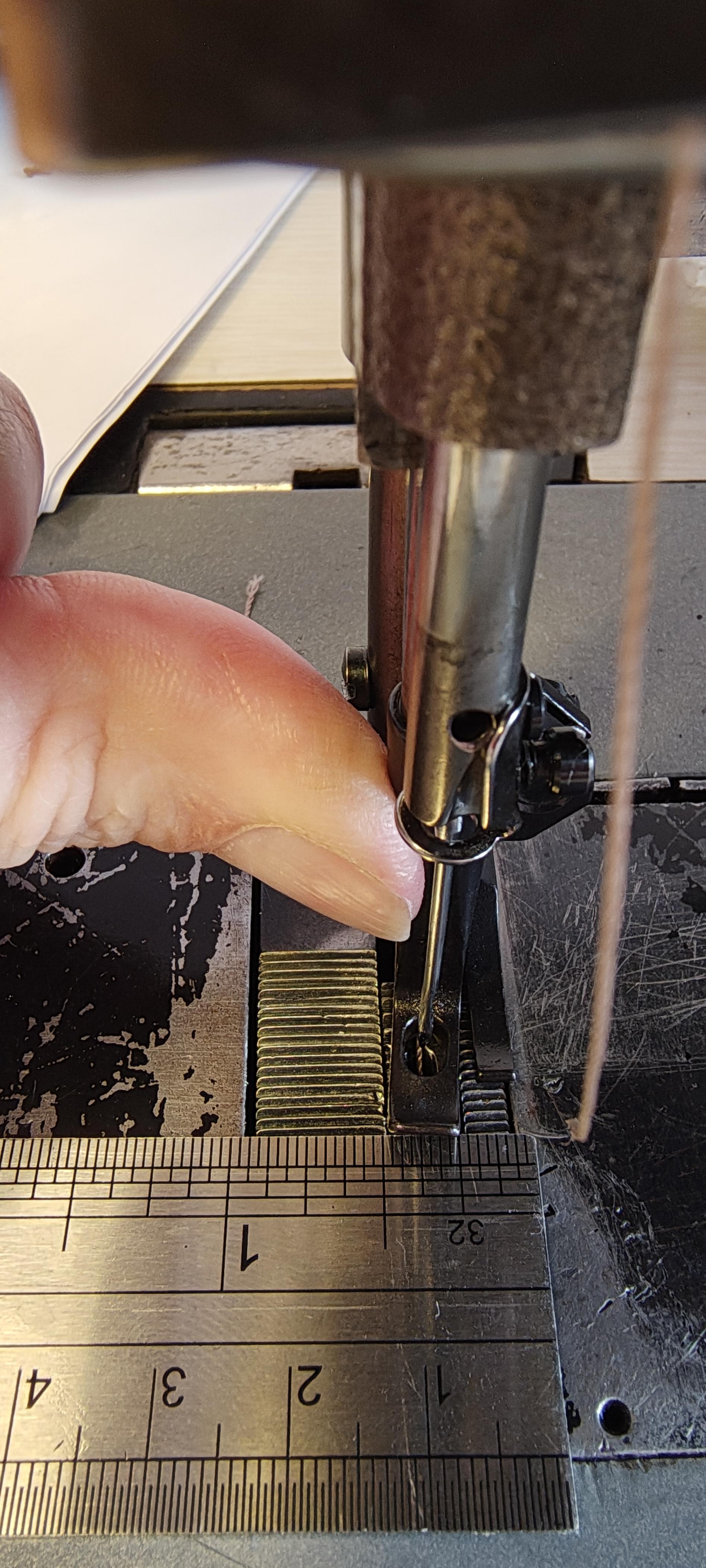

Hi guys. This is my 1st post. I'm from the UK. I mostly sew outdoor gear in heavy codura or somilar. (I'm not a Thread Insertion Technician). This forum seems to be the closest rewarding sewing machines. I'm looking for advise on parts required (&source), or internal adjustments to be made to taken out play on the inner walking fit. When it is under compression it can shift sideways or rotate axialy. A 1mm (maybe 1/32") sideways . (Pictured below), This is with about with with several layer of canvas and or webbing.. is this machine repairable? Possible worn parts included... singer211G256 508281. vibrating presser bar with bell crank, (visible wear). 508295 Needle bar rock frame. Hopefully not needed The bushing linkage on the presser bar are also worn. Which is more accessible. Hence the rotation. The oil felt on the rocket bar frame has mostly disintegrated which may have caused excess wear. I have approached a few suppliers and have BD told it's discontinued (no suprise) and not available. Pictured (sorry I can't manage the picture order) worn oil felt presser bar play no load presser bar play under compression presser bar linkage no load presser bar linkage compression Also parts diagram & description Picture 1? worn rocker frame oil pad parts_serv.pdf parts_serv.pdfp211g_155.pdf211g_155.pdfparts_serv.pdf Singer 211G155, 211G156 Service ManualA4.pdf

-

Bought a beautiful Singer 29K-70 with treadle base

Mulesaw replied to Mr. Jay's topic in Leather Sewing Machines

@Mr. Jay Welcome to the forum. Congratulations on your find, those are great sewing machines. It looks like it is in a very fine state. I have a similar model (can't remember from the top of my head the number of it), but also one with the shorter arm like yours. When you get to the cleaning/oiling job, please remember to grease/oil the pivot bearings for the foot plate and for the main shaft with the flywheel. Since they are under the table it is very easy to forget those 🙂 Brgds Jonas -

Digit started following Adler 68NT Seized - Any assistance/advice gladly welcomed

-

Adler 68NT Seized - Any assistance/advice gladly welcomed

Digit replied to Ian B's topic in Leather Sewing Machines

Could it be that the whole blue-green-red assembly is only held in place with the blue bolt? From what I understand from your explanation there should only be vertical motion, not lateral; so one bolt at one end of the assembly could be sufficient to hold everything in place. It's slotted at least, so you could try to loosen it and see if you can wiggle that assembly about. -

FrankHester started following Wax dipped leather punching mat.

-

Adler 68NT Seized - Any assistance/advice gladly welcomed

CowboyBob replied to Ian B's topic in Leather Sewing Machines

Just get some oil on the parts & it will free up on it's own! -

Ian B started following Adler 68NT Seized - Any assistance/advice gladly welcomed

-

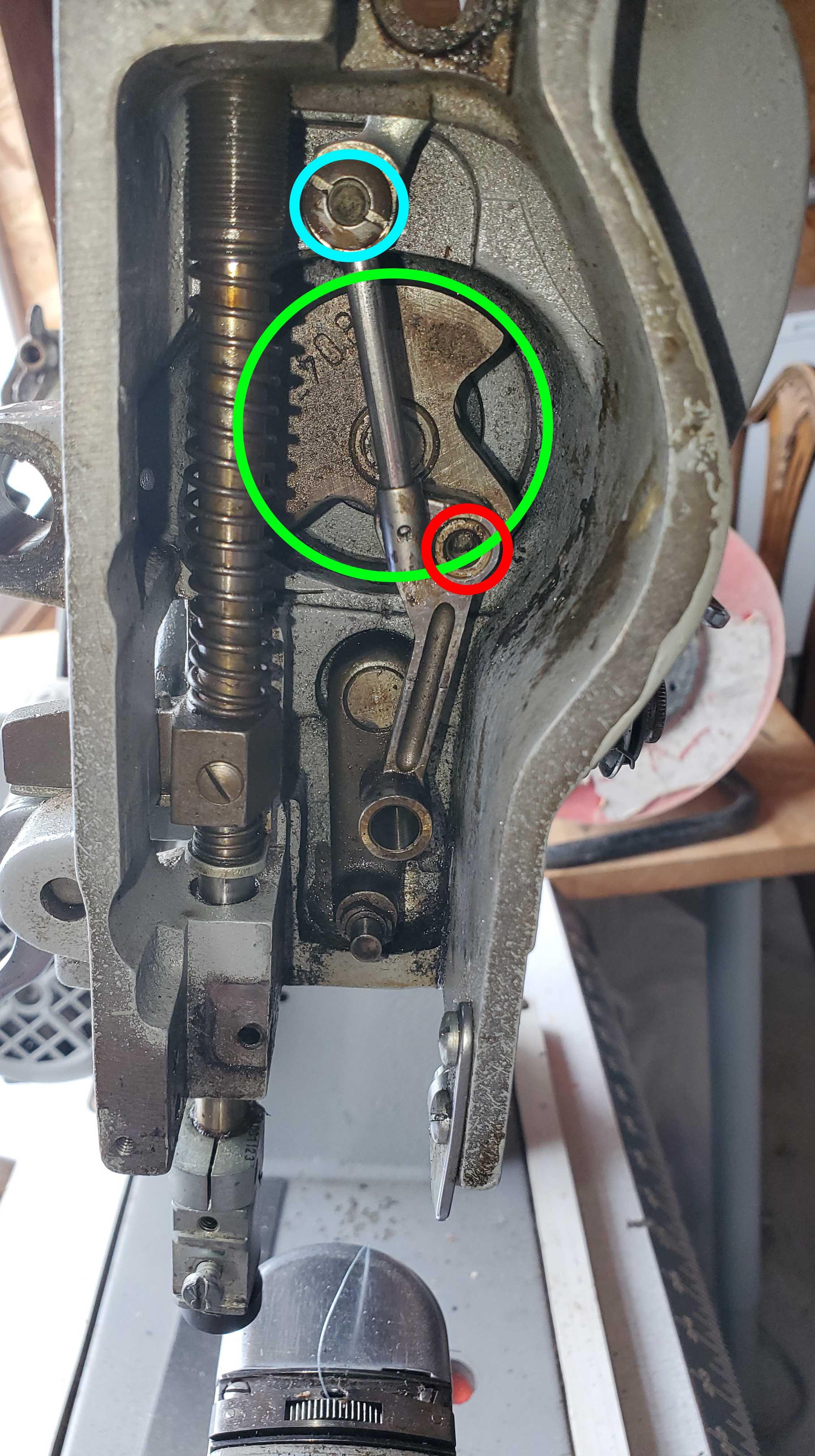

Hi, I'm brand new to this web forum and am looking for your help, I'm hoping that you might help resolve the issue I've created with my old Adler 68NT sewing machine. I bought the machine second hand around 15 years ago whilst studying footwear design here in the UK. I only used it a couple of times to make prototypes for the course. Since then it has been moved around and primary stored in one garage after another. Last week I began a project where I had need of it. I wanted to use a specific colour thread on my bobbin, so removed the needle and went about spooling up a bobbin. During this process the machine abruptly stopped working and I saw a small plume of smoke from the head of the machine (my apologies for not knowing he correct terms for the parts of the machine, the smoke came from the top of the enclosed area that contains the needle-shuttle and cam mechanism). The smoke was not from an electrical component, so I assume it was from burning lubricant. My admission, in all the years of owning the machine I have never oiled the machine. I've taken the head part of the machine apart as far as can (as per attached photo 1). When I rotate the "hand-wheel" the main cam rotates (highlighted in green in photo 2), the upper pivot rotates (highlighted in cyan in photo 2), the lower pivot does not rotate (highlighted in red in photo 2), as a consequence the connecting rod that connects the rotational motion to the vertical needle shuttle (highlighted in red in photo 3) has no angular rotation and thus hits the internal sides of the machine-head. I presume this is the part that has got hot through lack of lubricant and has seized up. I think I understand the issue (feel free to correct me), however, I cannot see how I can remove this part (or sub assembly) to try to free this pivot-joint up. Please can I ask for your advice and experience as to how to repair my machine? Kindest regards, Ian

-

B.A.G joined the community

-

Yesterday I joined the Ghent edition of the Distinguished Gentleman's Ride and for the occasion I wanted to dress up a bit, so the day before a made myself a bow tie. Red sheepskin for the bow and black cow for the collar, both chrome tan. Edges skived and folded over and the collar received an edge stitching all around. Closure with two black 9mm s-type snaps.

-

Bought a beautiful Singer 29K-70 with treadle base

Mr. Jay replied to Mr. Jay's topic in Leather Sewing Machines

-

Bought a beautiful Singer 29K-70 with treadle base

Mr. Jay replied to Mr. Jay's topic in Leather Sewing Machines

I look forward to sharing knowledge and interests on this site. -

Clear shoe polish? Honestly, looks fine to me though. My products tend to not look like high-end designer goods though. I don't spend a lot of time trying to not use the bug bites, scuffs and scratches that are on the hide, or the errant scratches that make it onto my piece even though I try very hard to be careful with it. I know that I'm going to use the heck out of it anyhow.

-

Mr. Jay joined the community

-

When stuck on ideas of what to make, sometimes I just watch people around me and try to figure out if there is something that they're doing, that would be better with something I might be able to make. Wife had a great idea recently and didn't even realize that what she said gave me the idea. Sometimes these ideas start out as gifts for other people I know. When I just get in a slump making new things, or new skills, because I'm worried that it might be slightly messed up when I'm done ... I just try to not focus on perfection, but realize that it is all a process, and that perfection is a direction, not a destination. Also, if leather is just making me frown, I try to focus on learning something else for a while, like wood, or metalworking or something. They all wind up being related, getting better at wood or metal likely makes you a more well-rounded craftsperson anyhow.