All Activity

- Past hour

-

Swiss Saddler Clam Drawings

ClaimedVacancy replied to ClaimedVacancy's topic in Leatherwork Conversation

Update: Template has been cut out. Now to cut pieces of birch ply, glue, shape and trim, drill and fixture together. Hopefully everything beds well, but i expect some geometry to be out a bit. Im expecting to use some beryllium bushings for the pivot points such as the right arm and foot lever. That way i can get muchhhh greater life out of the working holes. Ill need to create the friction lock trip. Ill be making that out of mild steel. Flat stock and just bent at the appropriate areas for the piece on lever. The guide rail ill have to create a mount for that but its straight forward.- 6 replies

-

- swiss leather tools

- swiss army leather

-

(and 2 more)

Tagged with:

-

I don't see a holster anywhere on that system?

-

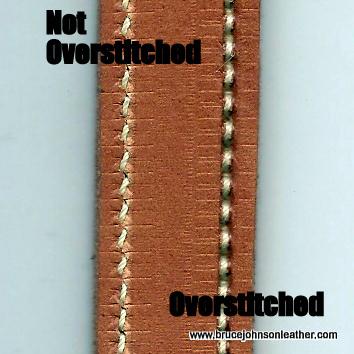

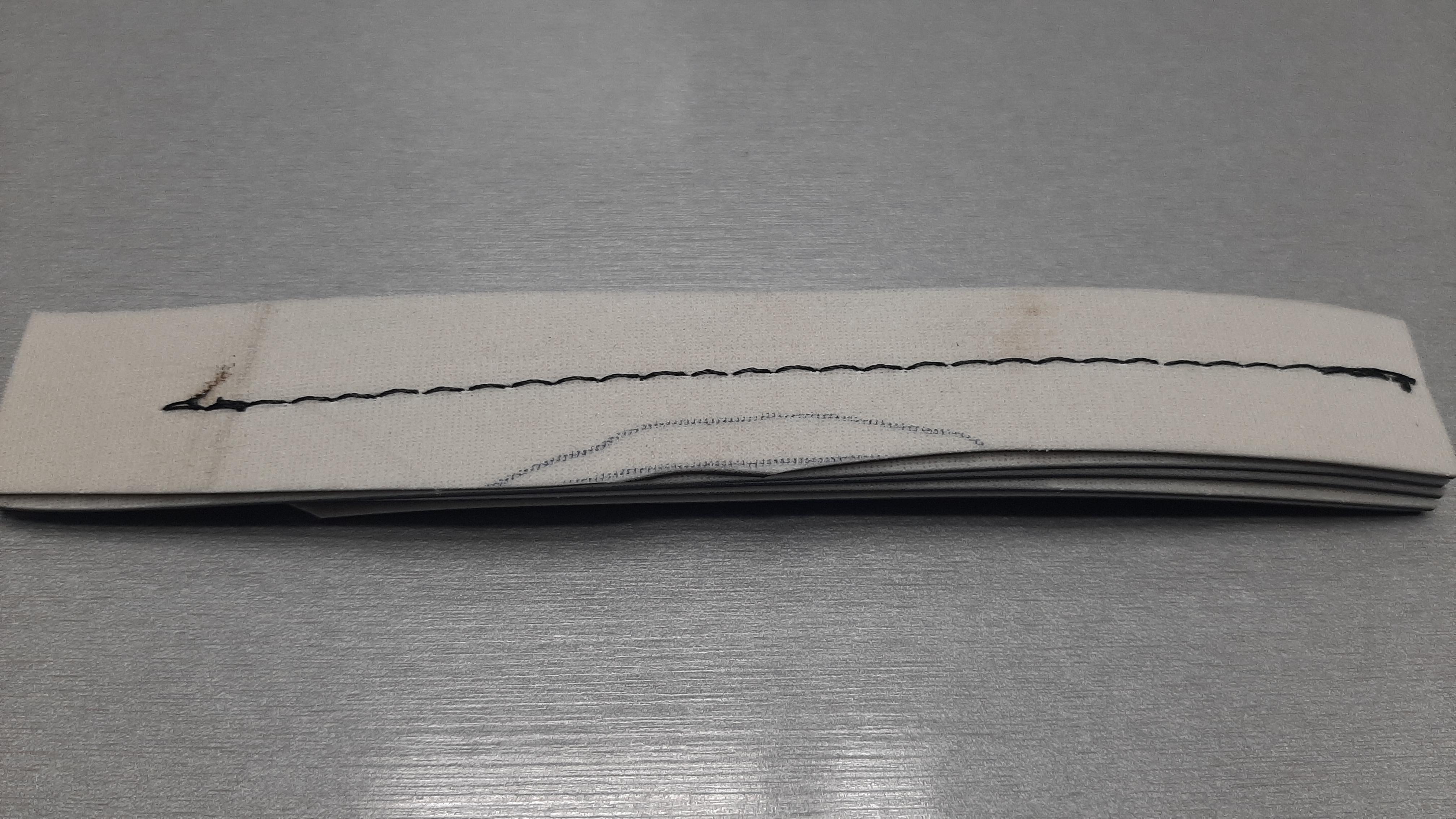

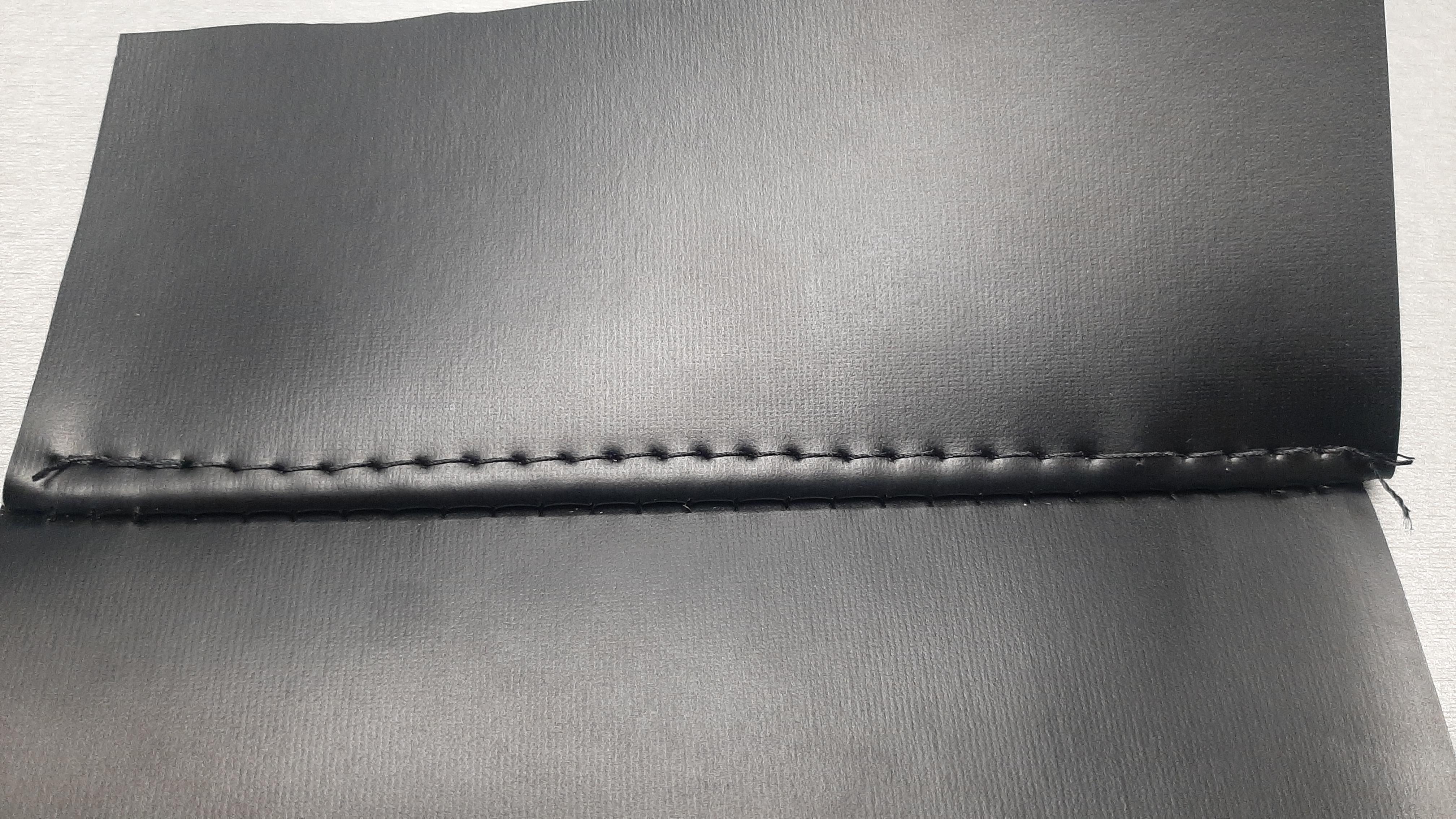

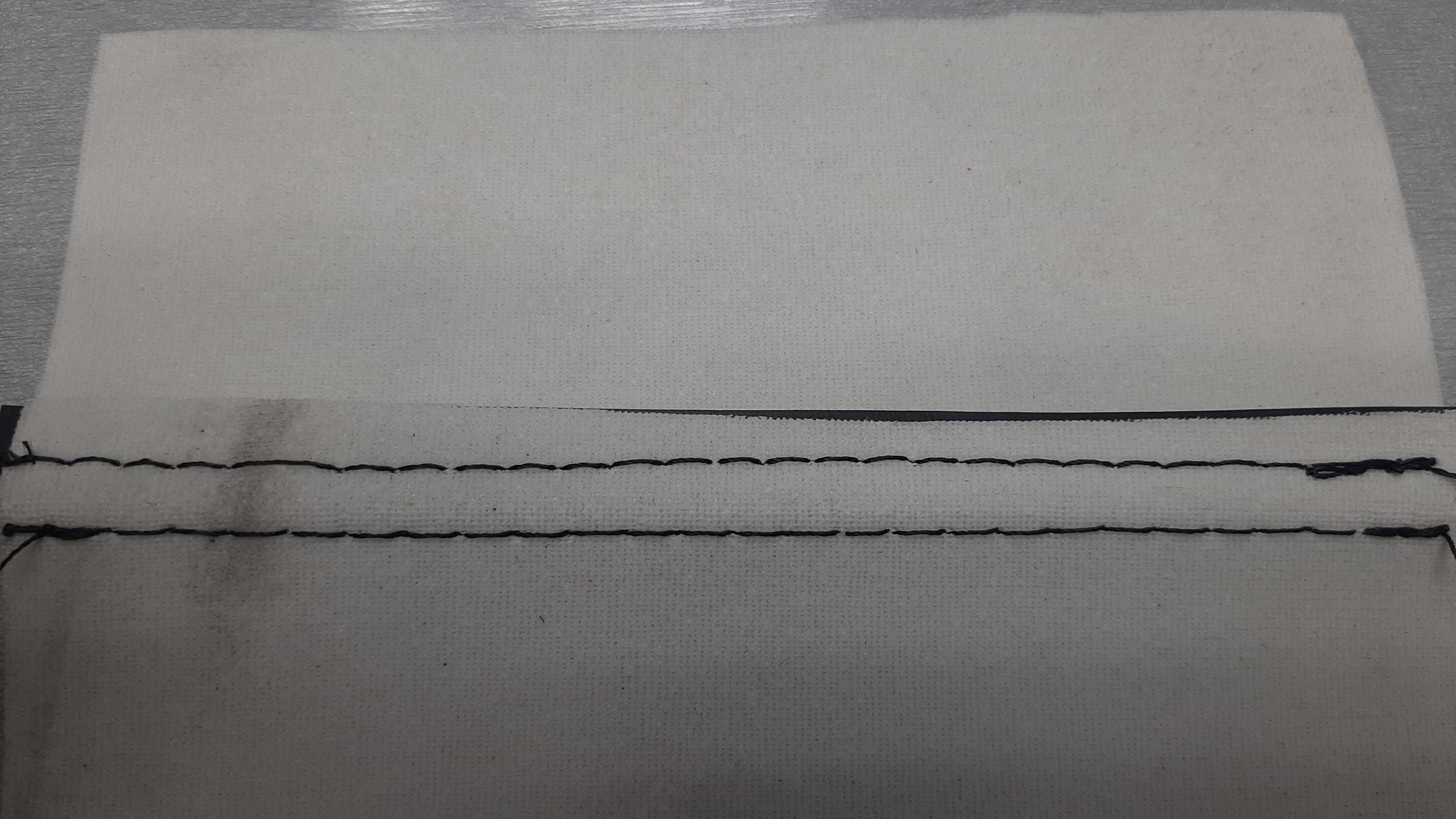

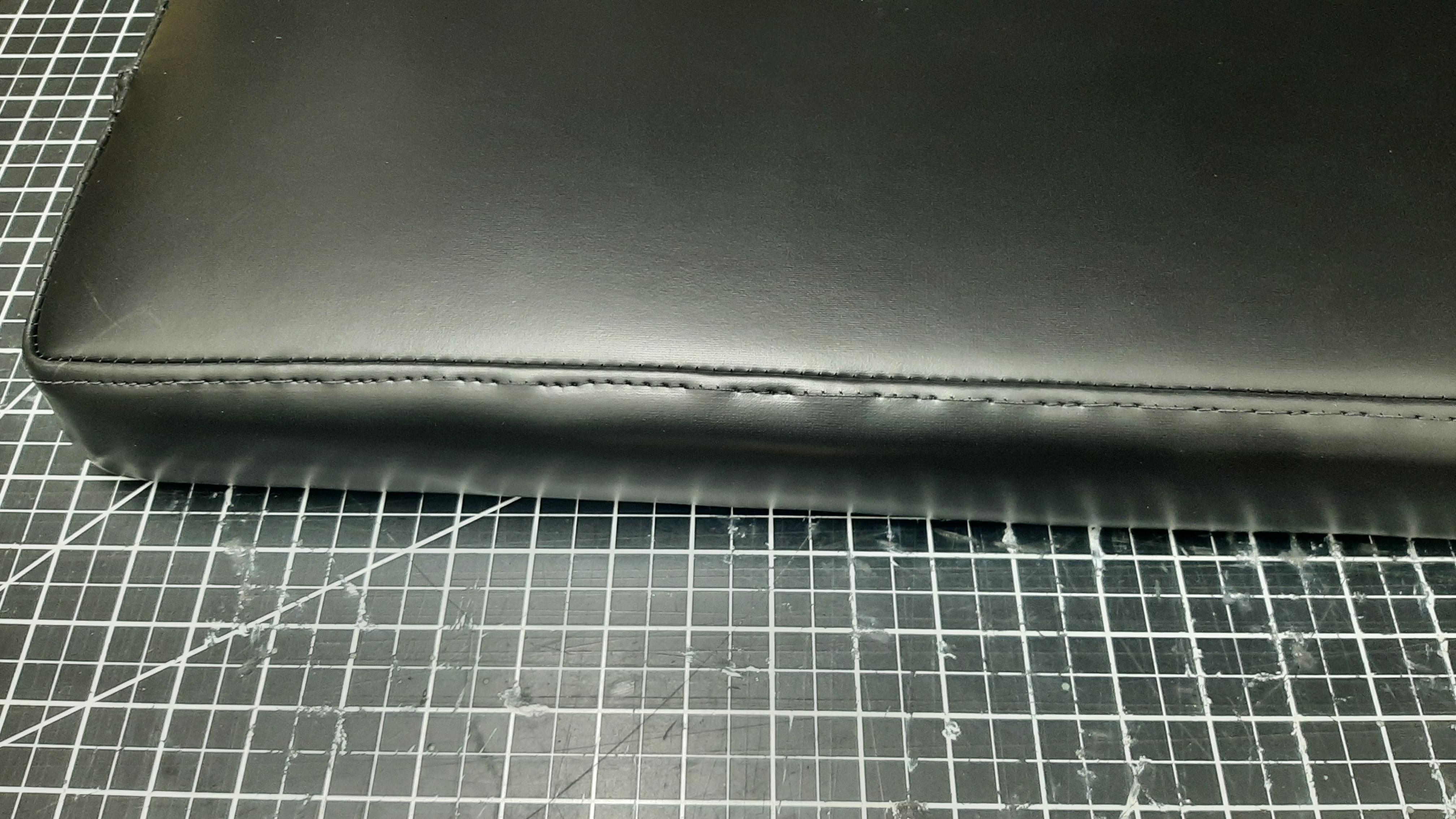

Yes, but only in the sense of the older hook and awl machines. They have an awl that prepunches the hole followed by an needle that carries the thread. They can pull a tighter stitch by nature and a cleaner looking bottom stitch. I know that is not your question but it is my answer. As far as the closed needle machines I don't think that one particular machine will shine above the others once you get to decent machines. The variables of thread size overall, one size smaller thread in bobbin vs same thread top and bottom, needle size, type of needle (straight vs slanted), stitch length, leather thickness and consistency, chrome tan will pull in tighter than veg tan, bottom feed dog, tension top and bottom, and probably more all affect the appearance of the bottom stitch more than the model and mechanics of the machine. We have three closed eye machines - Ferdco 1245, Ferdco 2000, Cobra 26, and have had others. I can make one look better than the others if the others aren't set up optimally. I can make them all look the same too with the changes above. What does improve the bottom stitch on all of the closed eye needle machines? Overstitching. Roll the bottom side stitch line with the appropriate size overstitcher. It sets the stitches, rounds the stitches between holes, and gets as close as you can get to the top side appearance. It is the 2 minute time difference that makes a big appearance difference. This example I did on the fly several years ago. I purposely put an old needle back in the machine to get some "blowout", probably 207 thread, 9 or 10 SPI, same size thread top and bottom. hard leather, heavy presser foot pressure. I think it looked pretty rugged right out of the machine. The right side looked the same as the left in the picture but was then rolled with an overstitcher. All it needs after that is the presser feet marks rubbed out to be pretty nice appearing stitching.

- Today

-

Ok, congratulations are in order for missing some stitches. Especially that last photo of the prototype cushion! 🌠 An informative exercise would be to put something like that cushion seam back under the machine so we can see some skipped stitches as they form. Then tilt the machine head back so you can see the underside of the machine. Get a good light or a flashlight, and reading glasses if they help. Then turn the handwheel by hand to make slow stitches, but watch what's happening from underneath. Pay attention to what it looks like when it actually makes a stitch, and to what happens when it skips. Let us know what you see! (More to come)

-

I'm not familiar with the tension release on the Consew 225 specifically. Feel free to post pictures of the thread tensioner and the cavity in the machine head where it sits. On the Juki DDL-8700 clone I worked on, the tension release was adjustable by how far into the machine you inserted the whole tensioner before you tightened the lock screw.

-

Unknown Chinese servo motor controller manual needed

friquant replied to Einherj's topic in Leather Sewing Machines

Yes in another manual I've seen it explicitly called "Break-in". I've updated the doc to say "Break-in" -

first pancake holster

MarlinDave replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

One of my favorite holsters is a roughout because I cut it backwards. -

Using neatsfoot oil

Mungo replied to Mungo's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Thanks for the replies! -

RFRLEATHER joined the community

-

Sorry for the delayed response... My needle is a brand new 135x17 size 20 69# Nylon thread for bobbin and top Material is 1/16" thick. So, 3/16 for the two pieces and a top stitch. The first two photos are of five pieces of material sewn at once 5/16" with no skipped stitches. Top and bottom The third and fourth photo is of a top stitch with only missing once. Top and bottom The fifth photo is of an example of tons of missed stitches with the same setup.

-

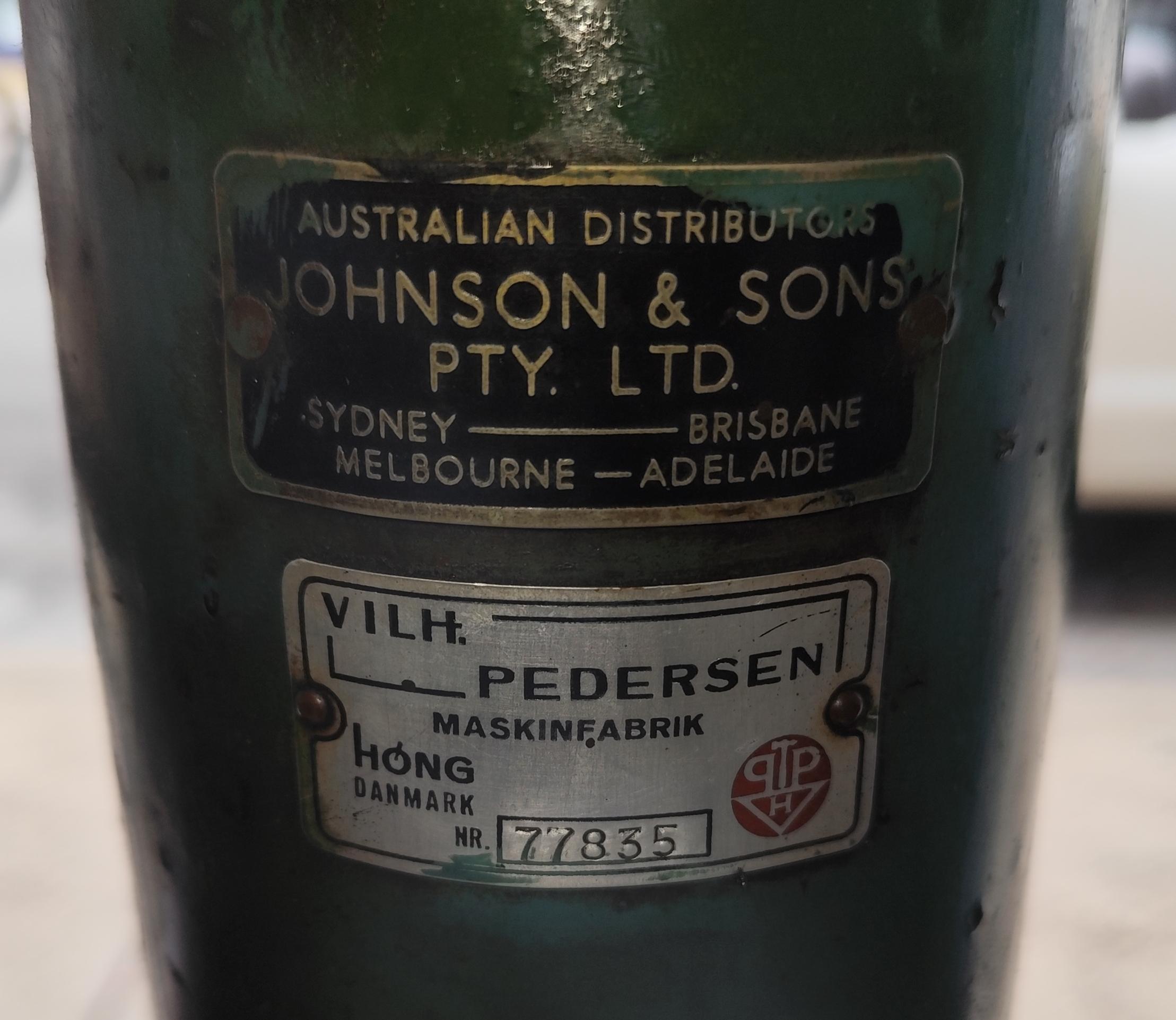

We have a Vilh Pedersen chain insole stitcher. We use it as bought 3 or 4 years ago. I would love to know if I can change the stitch length from about 6mm to 12 to 15mm. I would also love an operating manual if they exit. Thanks Matthew

- Yesterday

-

first pancake holster

AlZilla replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Could you just make a rough out version? I can't visualize if it's just an inside out mirror. Or finish it and sell it off. Some lefty GP100 owner will be happy. -

I replaced the thread tensioner on my Consew 225. Now the mechanism that releases the tension when the presser foot is up does not have enough travel to work. Do I need to bend the 3 cornered plate in behind, put in a longer rod through the machine, or is there an adjustment? No mention in the Navy manual.

-

Really depends on who you’re working with. There are people out there who will pay premium money but only if they get premium quality. If I can improve the product’s looks with a machine that I am willing to buy, why not. My experience in this thing we do is that the little things matter. Enough little things can make a big difference in appearance

-

first pancake holster

MarlinDave replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I am left handed and mostly make for myself. So hard to turn it around in my head. -

Thank you for your impute but really all I am asking is if someone has this machine send a picture my way. I know the alternatives, but really isn’t what I am looking for. Thank you anyway.

-

Unknown Chinese servo motor controller manual needed

AlZilla replied to Einherj's topic in Leather Sewing Machines

I recall seeing that P-10 type setting somewhere. I think it was some kind of break in or run in thing. Seems like it would run intermittently like that until you shut it off. I think ... -

Yeah, I thought that's how it looked. If the smaller pockets popped off, he could adapt it job to job. Of course, the upside to one unit is he'll never wonder where the hell that little pouch went to ... 😬

-

first pancake holster

dikman replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You're not the first one to make that mistake and you won't be the last!! I've come close to doing it.... -

I doubt if any of the machines generally used for things like notebooks will be much different in how the reverse side stitching looks as they all operate the same. If you want the best looking stitches and the reverse-side is a concern then hand-stitching is the best option.

-

Quite a remarkable job! Just looking at it I can visualise the amount of work that went into it! One thing, though, the circular piece on the back where the four straps come into it looks like you've sewn across the straps. I made a pair of suspenders from leather and stitched across the yoke at the back and eventually the straps tore through at the stitching.

-

Rbarrie joined the community

-

I've got a 40-ton, 240 Volt (3 phase) clicker press that has been used in a leather shop. It works great. Located in Seattle. We have a forklift on site to help load.

-

Very nice. A lot of thought and hard work went into making these.

-

Has anyone noticed the attractiveness of the bottom stitches to be machine-dependent?

-

Unknown Chinese servo motor controller manual needed

friquant replied to Einherj's topic in Leather Sewing Machines

You did your homework, showing us what the ranges and defaults are for each parameter. At a quick glance that menu looks like the "Stitchman" -

Yes, the Cobra does come with a reducer which does allow for slower sewing and greater punching power due to the increased torque provided by the speed reduce. The cost for a 3:1 speed reducer, at least in Canada, is about $100 CAD. I have never owned any of the Cobra equipment but from my experience I had for a very short period of time a Consew RB206-5 that I hoped to replace my Juki DU-1181N with as it was supposed to be similar to the Juki DNU-1541S. It wasn't good enough to replace the Juki 1181N so I sold the Consew. Bottom Line, do an honest test using a sample of your stuff on both machines. You may have to send a sample to a vendor. I could not find a weight for the head of the Cobra 18 listed so you may want to call them keeping in mind the Juki DNU head alone weights 80.46 lbs (36.5 kg). kgg