All Activity

- Past hour

-

Damn, but I figured it was a long shot. Thanks for the feedback, guess I'll keep looking then.

-

What are some tools that changed your leatherwork?

RidgebackCustoms replied to Kenzi's topic in Leather Tools

A hard lesson. I remember when I was learning to skive (book binding). I decided the knife I had was the problem. So I saved up and bought a nice skiving knife from Chartermade. Beautiful tool. Showed up pristine and ready to work. Took it to the bench and basically had the same problems. Realized I probably just needed to practice. Nothing wrong with having great tools. I've learned a really great tool can let you focus on the skills because your problems will just be you. -

What are some tools that changed your leatherwork?

RidgebackCustoms replied to Kenzi's topic in Leather Tools

DMT Diamond stones (not the hatched pattern ones, the full width kind, metal bed). I tried water stones, sandpaper, etc. Both work, but the diamond stones let me focus on just the sharpening as I was learning. The 3/4" and 1" skiving knives from Lisa Sorrell. Those things came to my door screaming sharp, no break in or touch up required, so I could focus on learning the inlay work, not the sharpening. - Today

-

What are some tools that changed your leatherwork?

AlZilla replied to Kenzi's topic in Leather Tools

Is leatherworker.net a tool? It's been a great learning resource for me. -

NueLine joined the community

-

Besides books, especially by Al Stohlman my other things are; A Tandy Pro-Press. I use it a lot, for pressing stamps, as a clicker press, for making sewing holes with chisels Sets of sewing chisels with different spacing; 3mm, 4mm, 5mm, 6mm and my stitching pliers and lacing pliers A couple of sewing clamps; a light-weight one for taking out to places and a larger heavier one for use at home base My special stamping table Which is adaptable for various jobs

-

Singer 112W 115 Knee lifter installation

Constabulary replied to DMH's topic in Leather Sewing Machines

please post pictures of your machine from the rear and when tilt back from the underside and how you have installed the foot lifter. -

Union Special machine setup installation and modifications

nejcek74 replied to DMH's topic in Leather Sewing Machines

yes, that's right, both machines were only fixed/sitting on those rubber feet. -

BBC caught with its knickers down . . . .

fredk replied to fredk's topic in All About Us and Off Topic

Ah, but they haven't. Only the two top dogs resigned but those responsible for the wrongful editing remain in their jobs -

Looks good from here . . . May God bless, Dwight

-

What are some tools that changed your leatherwork?

chuck123wapati replied to Kenzi's topic in Leather Tools

yup all the tool answers above need special knowledge to use them and care for them correctly, and it can all be found in a book. Also, the saddler will have a different answer than the shoemaker or the guy who makes watch straps lol. What each of us envisions as leather work usually is diferent. And I'll add this forum as a great tool also.😁 You can see those who take the critiques and advice seriously improve as time goes on, while those who blow off the help or ignore helpful tips and good advice just don't improve as fast or as well. It's not the tool in the hand, it's the hand that drives the tool. A knowledgeable craftsman with mediocre tools can outperform the ignorant man with the best tools. -

I wanna thank @Dwight for recently sharing some of the knife sheaths he built. He inspired this design for some fixed blade knife sheath I made for a local knife maker. Welt on all edges. I also engraved the sheaths, as well as one of the blades and handles. I used my laser to create the template out of 1/8" acrylic. If you are interested in a template let me know.

-

That's a fantastic idea! Thank you!

-

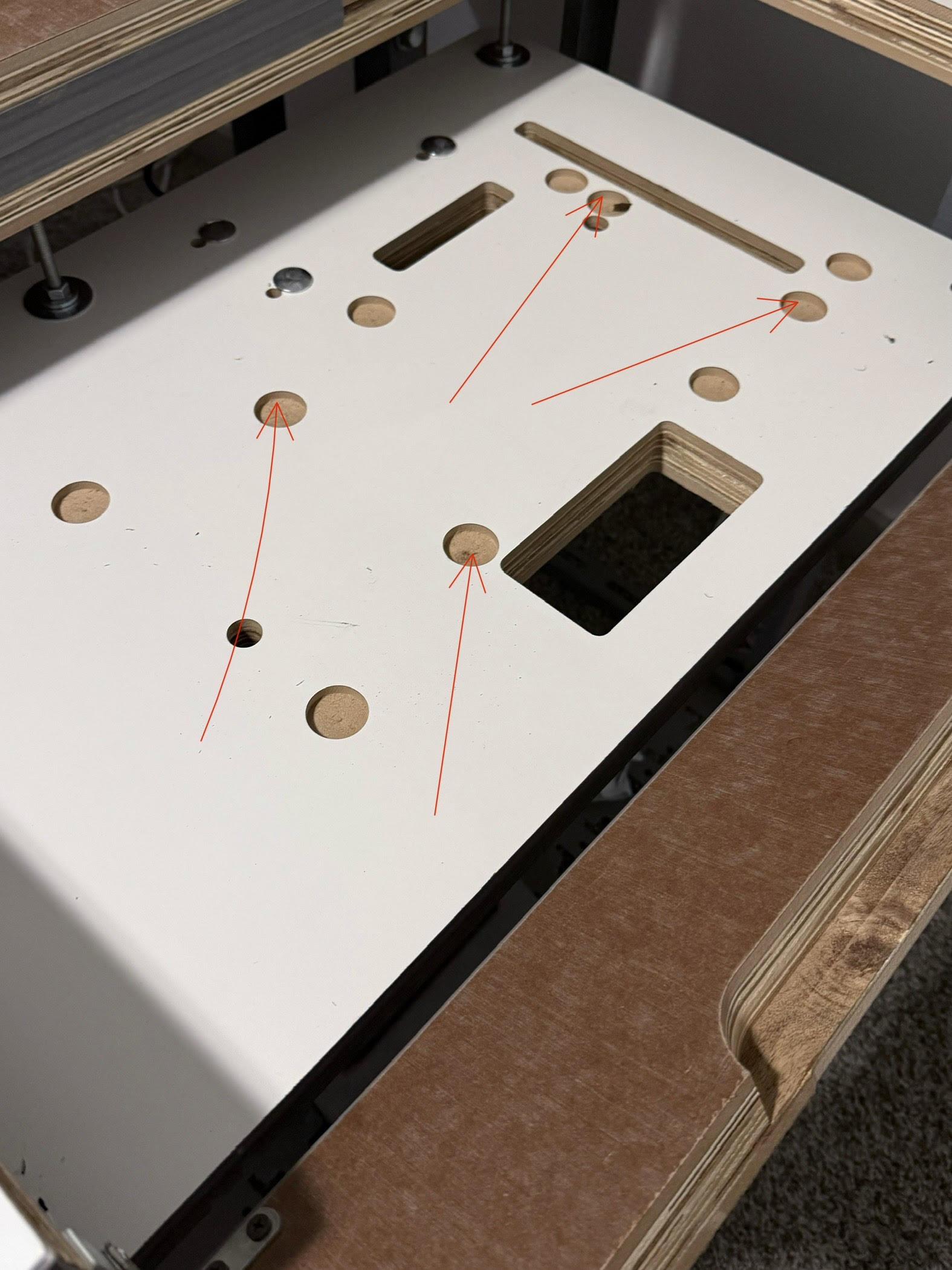

Hello, I'm looking for help with the knee lifter placement for my recently purchased Singer 112W115 double needle machine. I purchased a table top and had some difficulty finding mounts for the machine head, but finally got that resolved (I think). I installed the oil drip pan, motor and belt. I purchased a knee lift (photo attached) and lined it up with the space in the oil drip pan, but when I try to engage the knee lifter it does nothing. What am I missing or doing wrong? Where should the knee lifter make contact with the machine?

-

Mablung is right. I could shave with any of mine. I strop before using, every couple cuts during and after before putting it away.

-

Union Special machine setup installation and modifications

DMH replied to DMH's topic in Leather Sewing Machines

Thank you very much for getting back to me. @nejcek74 thank you for confirming where I need to place the machine to the table. I was told recently I should the placement in the pictures attached and that I can use the rubber insulator without any additional bolts to rest the machine head on. -

BBC caught with its knickers down . . . .

Darren8306 replied to fredk's topic in All About Us and Off Topic

Whenever something upsetting, concerning or important happens in the world, I try to remember to look at what the severely TDS affected authors publishers and presstitutes have to say. Now that the BBC has fired those guys, my options are narrowing... -

A blade can never be too sharp for skiving, but it sure as shootin' can be too dull, even if it's plenty sharp for cutting. Sharp, sharp, and sharper.

-

What are some tools that changed your leatherwork?

Mablung replied to Kenzi's topic in Leather Tools

Books are always tools, in a different sense. Intellectual tools, which are the best kind. To paraphrase another saying, the mind is the final tool. -

BBC caught with its knickers down . . . .

AlZilla replied to fredk's topic in All About Us and Off Topic

Some things never change. In 1787 Thomas Jefferson called out the British gazetteers of the day for fake news: "Wonderful is the effect of impudent and persevering lying. The British ministry have so long hired their gazetteers to repeat and model into every form lies about our being in anarchy, that the world has at length believed them, the English nation has believed them, the ministers themselves have come to believe them, and what is more wonderful, we have believed them ourselves. Yet where does this anarchy exist? Where did it ever exist, except in the single instance of Massachusets?" -

Welcome from SW Missouri! As mentioned...lots of good stuff here.

-

oh, i get it now. Of course, the maker logo on the front/face of the hub and maybe the specs of the machine age and any pertinent info around the hub.

-

Welcome! There's a wealth of knowledge among current participants and in the archived posts. A tip that I regularly use is to search the site with Google using the syntax: site leatherworker.net your key words here Look forward to seeing your work.

-

Caracoda joined the community

-

What are some tools that changed your leatherwork?

chuck123wapati replied to Kenzi's topic in Leather Tools

Books, books, and more books! Don't know if you would classify them as a tool. but the knowledge I have gained from them has enhanced my work much more than any specific tools have. -

the parts list may help you pfaff_471-474-491.pdf