All Activity

- Past hour

-

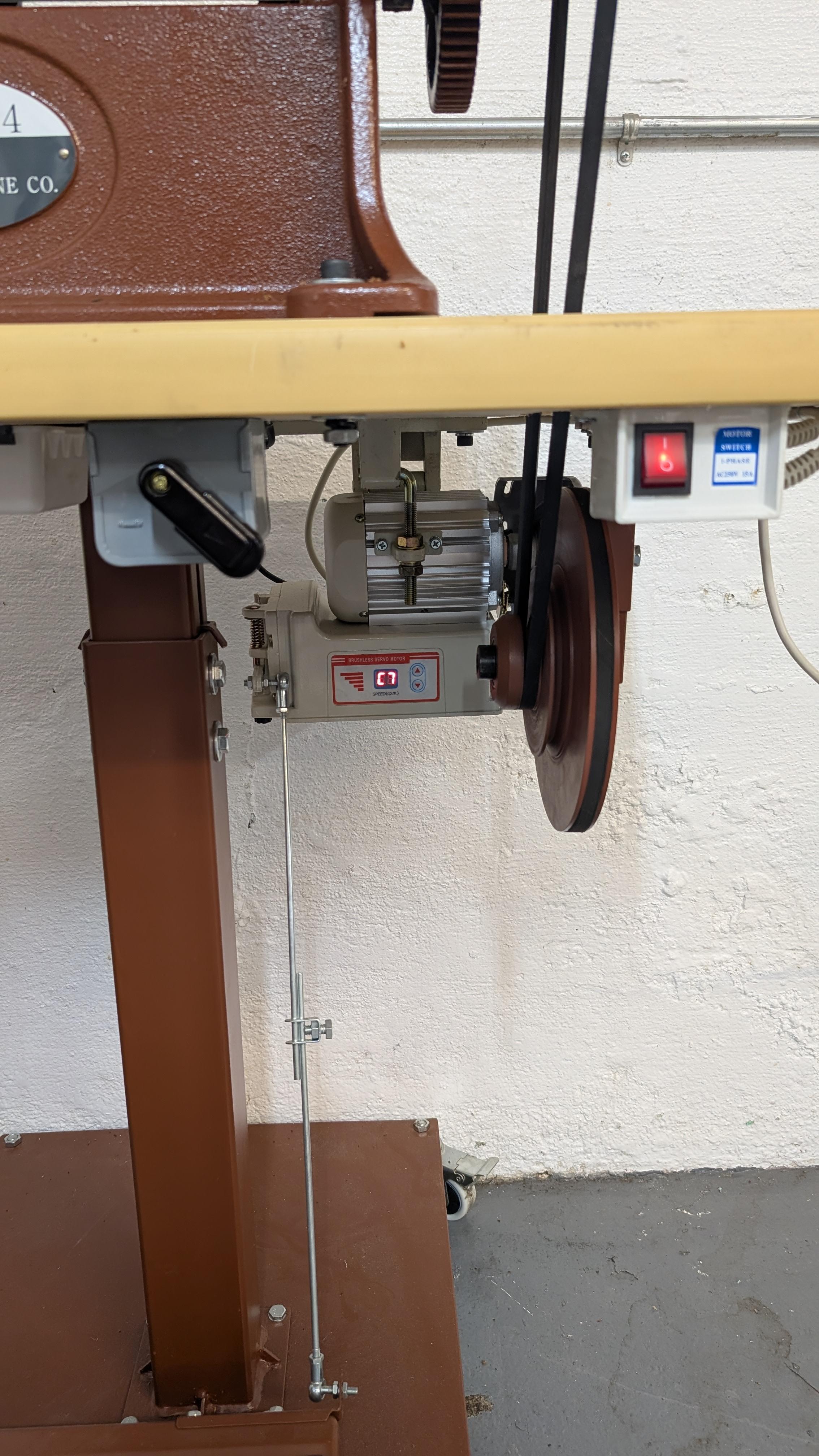

Have you tried unpluging the servo motor cord from the wall outlet. Some electronic items even through you have the power switch in the "OFF" position they are still drawing power and are basically in a "Sleep Mode". I would unplug and wait a few minutes just to make sure it has fully powered down and cleared it's memory. On my LS-341 clone which has a brushless servo motor and electronic control when I throw the power switch to the "OFF" position the electronic display stays light for about a minute before going blank. So there is a power draw. I would contact both the store and Artisan to clarify your warranty. Having a damaged cable could have or is causing a short which in turn could have caused an error or worst case fried the controller. If you damaged the wiring chances are you are going to be on the hook for a new cable and possibly a controller. If it does turn out to be the controller unit it maybe cheaper just to replace the complete motor setup for about $150 to $200 for 6 coil motor or $300 for a 12 coil motor or a brushed servo motor for about $175. The trouble you are having tracing the source of the problem highlights the difference between a brushed servo motor with no fancy electronics and a brushless servo motor with a electronic controller box. As you can tell I am not a fan of the brushless servo motors. I like my machines to be as simple as possible. Sewing machine, speed reducer (on some), servo motor, drive belt(s) and a go pedal. The two machines with brushless servo motors have the needle positioning disconnected. kgg

- Today

-

How to get this stitch length mechanism freed up? In this first photo of the main shaft, we have the timing cog on the right, the feed shaft cap in the middle, and the stitch length mechanism on the left. The large hole in the middle of the stitch length mechanism is for a set screw which I have removed. The smaller hole (upper right) of the stitch length mechanism is where I have removed the lock screw. so that the adjustment can actually be made. Then I rotate the handwheel some, and now we see a different set screw (lower left, already loosened) and the big adjustment screw next to it. The adjustment screw can move about 200 degrees from left to right before it binds. I've soaked the adjustment screw and the hole where the lock screw goes with marvel mystery oil, and even squirted some between the adjustment mechanism and the feed shaft cap. I've tapped on the adjustment screw with a hammer (using a metal screwdriver as a go-between). I've tapped the feed shaft with a hammer. Still nothing budging. Is there anything else I should try (or shouldn't try) to get this to move?

-

Best source for clicker dies?

Cumberland Highpower replied to wizard of tragacanth's topic in Leather Tools

Most of mine are from International in GA. I always got the best prices and good quality from them. I've heard some say they had problems with International. For myself, I've never had any issue. BUT I'm always very meticulous with the patterns and made notes for the die maker, that could be why? They'd be good for low cost simpler dies. Weaver makes excellent dies. If you're looking for the best workmanship on a steel rule die, they're where you want to go. Downside with Weaver is that they're x2 the price of everyone else. Did I say x2? Maybe I meant x3! -

How about some photos? We love photos 🤩

-

Best source for clicker dies?

bruce johnson replied to wizard of tragacanth's topic in Leather Tools

Personal experience - Texas Custom Dies - some years ago - quite fast, reasonable cost compared to other die makers that were on the leather worker radar screen at the time, and they followed up to make sure I was happy. Those were the only new dies I have ordered that I can think of. Realistically there are several more die makers that have been in business for a while, but now marketing more to leatherworkers. Milwaukee Steel Rule Dies, Ohio Clicker Dies, and others. I'd think between these and the ones mentioned, you'll find somebody you are happy with. I get a fair bit of used dies and really can't say anyone consistently makes a "bad die". Some that come from the industrial or production companies are pretty beat up but that is understandable. 4 ton press - Weaver Mighty Wonder is good. I have had a few through here. I have used a 20 ton shop press with plates, bench top 12 ton shop press with plates (Weaver) with the hydraulic jack replaced with an air over hydraulic jack, Weaver 4 ton Mighty Wonder, Weaver 8 ton Mighty Wonder that was parked here for a few days, Lucris M3, Import 2 post table top, WUTA 4 post table top. That is what I can think of off the top of my head. Least expensive and realistically good for non-production work is a shop press with plates. Right now we have the benchtop shop press for heavy leather and larger dies and a WUTA 4 post for smaller work. My wife really likes them both and between them she can do everything she needs. -

Yeah but if your cat shoots somebody.... the law is gonna want to hold you responsible 😉

-

I tried to walk like an Egyptian... and now I need to see a Cairo practor!

-

I have been working on a 211G155, I finished setting all the timing of the hook but the cover plate wont close. The plate hits the top of the bobbin. What am i doing wrong?

-

That makes sense. I guess I'll call it the "Apparently Singer 144 Winger" or "Singer 144 Without-the-family-tree"

-

anilerdem joined the community

-

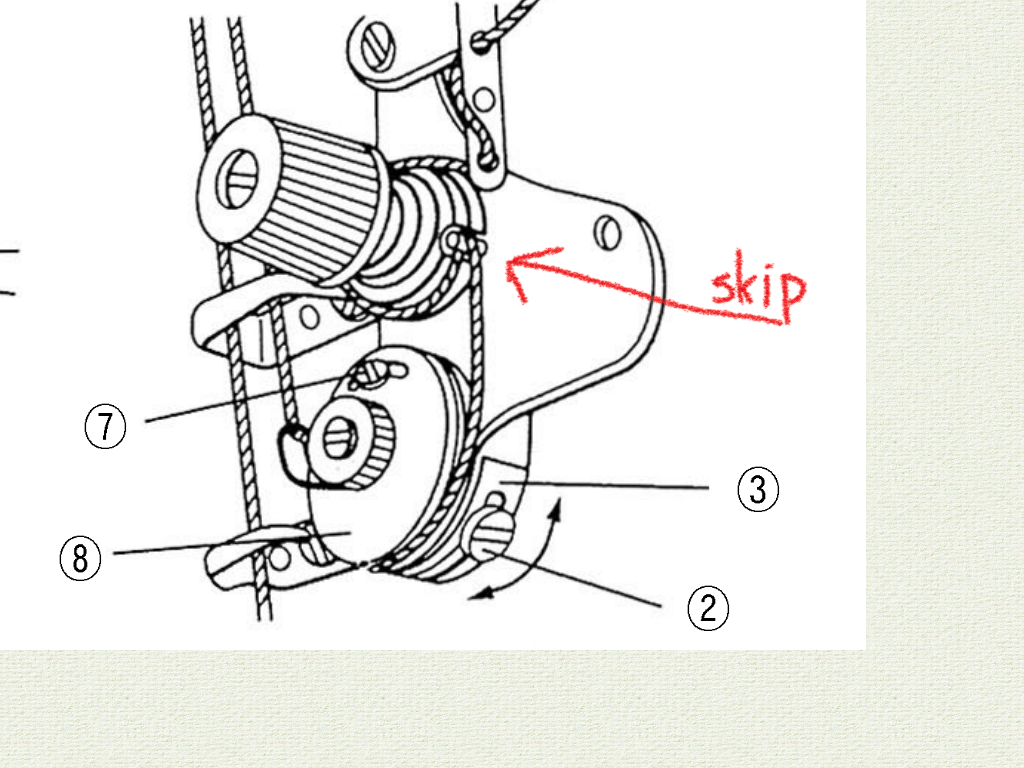

Make sure you're going counterclockwise around the thread tensioner. (one of the drawings in the manual makes it look like you go clockwise) One thing that the manual does not show but that is actually important is that the thread needs to go between the tension discs, not around them. The other thing I would change is I would skip going around the post (see attached photo with arrow) that prevents the tension discs from spinning. (Unless you're looking for ways to increase the maximum amount of tension you can get.) If you'd like to send a photo showing how you've got yours threaded, we can let you know if it looks right. The components are quite similar across LOTS of machines. Also, is it making good stitches?

-

fishinmex joined the community

-

Best source for clicker dies?

wizard of tragacanth replied to wizard of tragacanth's topic in Leather Tools

Thanks dikman. Yes, I did see the ad... and now I am seeing one for Tippmann. However, I am looking for personal experiences and recommendations. Ads do not give me that. Ads do not tell me if the products are reasonably priced or if they provide good customer service. Just looking for more info. -

Nice looking stuff, I like the pocket sheath. I made one myself, it's not shaped the same but does the same work., I also carry a small tin of cotton ball /Vaseline mix and a short striker made from a hacksaw blade with my ferro rod it will start a fire in seconds wet or dry.

-

Yeah, servo motors and their controllers are the Mysterious Black Box of sewing machines. They're all just different enough that most don't dare mix n match components and the manufacturers give us just enough information to operate them. I'm surprised the electronic tinkerer crowd hasn't started dissecting these things. I've seen them being retrofitted to lathes and drill presses.

-

very nice work my friend.

-

Hi all, Have had this Cobra Class 14 in the shop for a couple years now, had served me well, but now just taking up space I don't have. My loss. Looking for $2800, retails currently for over $3600. Everything works great, good clean blade, reversible motor. Located in Rhode Island. Have never shipped anything this size, would prefer pick up if possible.

-

I've used that method myself to get even spacing of my stitching holes. Just used an ordinary needle and then followed up with an awl for saddle-stitching (used an old Singer hand-cranked 201).

-

Been thinking on this You have a sewing machine? put a 'leather' needle in, put leather under needle and turn machine manually, without thread. That will punch your holes

-

Thank you for your help. Unfortunately I am stuck. I cannot reset to factory because it goes straight to Er 4 and does not let me do anything. I checked tye connections and the pedal: everything seems fine. I have not opened the controller yet but I am not sure what I would be looking for either. it is surprising how little info I can find about this controller. I’d think they must have sold a few of these. When I purchased I was not overly impressed by the interaction with the store people. They had a machine in the back of the store they wanted to sell me but it was very dusty and I asked if they had a new one. They told me ti go back the next day and I am pretty sure they just got the dust off that one and pretended they put a new head on. The whole thing felt wrong but I thought that these are pretty strong machines so I should not have any problem: I did not even consider the electronic parts. I hope they will be able to help me out on Monday but I wonder if they just sold me a lemon. Anyhow. Thank you for your help.

-

Montanadave joined the community

-

Is this still for sale?

-

Everything looked fine earlier but I will look better when i get home. The unit gives me the error even if nothing is plugged in. On a side note, i did damage the cable that goes from the unit to the pedal, it took off some insulation. I’ll check it. I hope tat’s the problem. And I’ll open the pedal too. do you have the same machine?