All Activity

- Past hour

-

Yes and I red that the Consew is actually a clone of the singer 153w102.

-

Thank you AlZilla

-

thank you I will! That is awesome specially when it comes down to the price. Thanks Glenn

- Today

-

How to assemble 96k sewing machine thumb screw

friquant replied to depodarcom's topic in Leather Sewing Machines

Can you post photos and/or videos? I don't have a machine like this for comparison. Perhaps by seeing the actual parts someone will be able to suggest how to put them back together. -

I thought it was just the outline shape of the shield as well but the image he sent as an example the top of the shield is "puckered" not really sure how else to articulate it...I'll try and upload the pictures he sent me....

-

Thank you, sorry if this was the wrong forum

-

Thanks for all the tips, folks. I appreciate it. I'm used to just dealing with work boots and combat boots. Those just needed a couple coats of mink oil over a week or so, then polish as necessary. This is the first item I need to even consider where dye should fit into the mix and will anything I do before or after might drastically change the outcome.

-

Work belt with a story

BlackDragon replied to KillDevilBill's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

@Northmount Great catch! When I worked at Toyota in KY I have to wear that type of belt for that exact reason. The ones we used had two prongs. -

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

Work belt with a story

Northmount replied to KillDevilBill's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Do a search for mechanics belt. It doesn't have any exposed metal parts the can damage fenders, etc. while working, leaning against the car to reach what you are working on. Some people also refer to them for use by people that are allergic to metal as the hook is not exposed, not against skin. -

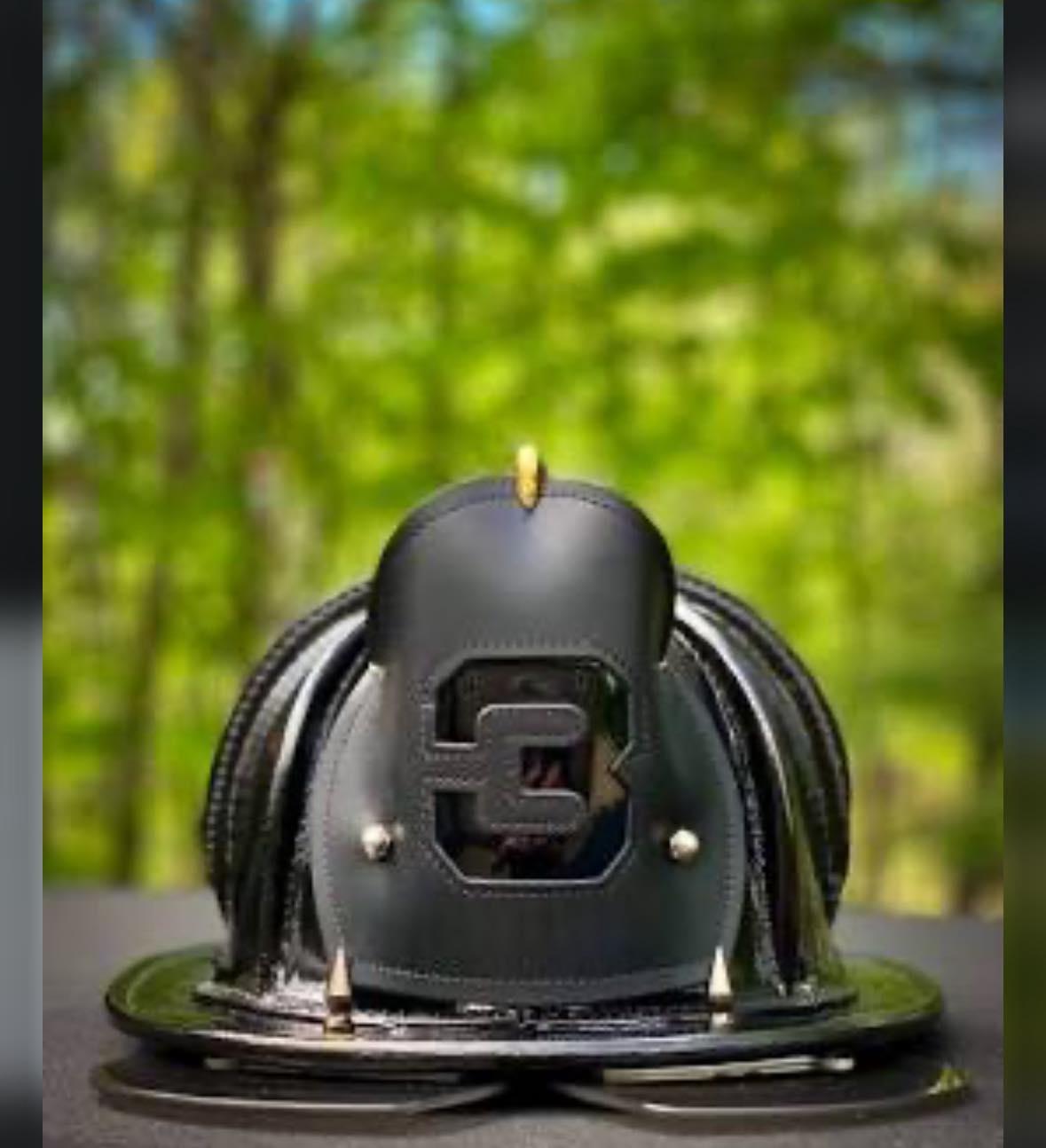

I looked around a bit and "Boston" seems to be the shape of the shield. I saw "Metro", "LA", "New York".

-

I moved your post to Patterns and Templates. Of all the different forums, this seems to be the best fit.

-

Quick note on airbrushing with ANY type of oil. Use a respirator because oils, when atomized, can cause lung issues. When I dye it's oil, dye, buff, finish. I oil with neatsfoot oil and let it sit until the oil is absorbed. How long it sits depends on the thickness of the leather. This allows the dye to spread evenly when applied. I then dye and let it sit for a day so the dye has time to spread evenly. I then buff any excess dye off. I then add my finish, usually Resolene diluted with water 50/50 or a wax.

-

Thank you very much!! That's the way I usually do it, had no idea about prefixing a search with image. I learn something every day! Lol

-

Work belt with a story

BlackDragon replied to KillDevilBill's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

That's not a work belt, it's a display belt. Beautifully done! When I first started making serious belts I made my brother-in-law a belt, it was one of my gun carry belts, but he wouldn't wear it unless he was going out somewhere nice. I told him to just wear it while he worked because I wanted it to be tested in the field. He has an excavating business so he's literary in the trenches all day. I finally just made him a second one and put some scratches in it so it didn't look as nice. lol -

Another tip on searches. Most search engines have tabs under the search field. The first one is usually "All" this is the default tab, the second is usually "Images". Click on that an it'll show you the image search.

-

Hi, I recently bought two cans oil advertised as pure neatsfoot oil. However, I have worked with neatsfoot oil from other brands before and this one seems different in multiple ways. I had used starwax neatsfoot oil, wich was odorless, and stayed liquid even at about 10 degrees celcius, and saphir brand, wich had a bit of a smell but not a suspicious one and remained liquid too. The oil I just bought is supposedly from a brand called P.Paulin, and not only does it have a very strong rancid smell, it does not stay liquid under Id say 20 degrees celcius. It is also cloudy while the other brands were transparent. is this normal? is it just a different neatsfoot oil? or is it neatsfoot oil mixed with a great deal of tallow and such greases? I dare not use it on any piece of leather, or even to lube machinery because of this horrid stench. did I get scammed? or did I just observe non-industrial neatsfoot oil for the first time?

-

@shoepatcher Thanks Glenn. Was the 1877 Singer new and unique design known as the UFA?

-

There is a shop in Kansas City MO - Fitzwater Leather. He is an active duty firefighter and does leatherwork. He focuses on shields and has made tons of them around the country. Reach out to him. He would be happy to help, if he has what you need.

-

Work belt with a story

PastorBob replied to KillDevilBill's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nicely done. I had the same phenomenon occur when I made a belt for my dad. He only wears it for special occasions. That is sharp. Hope he wears it more than just on Sundays. -

camryn joined the community

-

One of my first projects was a new belt for our mechanic at work. He asked me to make him a new work belt when I first got into this hobby. He's also an avid hunter, so I came up with this. He absolutely loved it but the "problem" is he won't wear it to work because he claims it's too fancy. It became his hunting/Sunday dress belt. Fast forward over a year, Miller still needs a new work belt, and we both forgot all about it. I guess that old worn out one wasn't so worn out! As a surprise, I just finished up a "less fancy" belt for him to wear to work. I tried a new dye technique I read about, make a new belt look old.

-

SpaceMemeCowboy joined the community

-

Dummy gun

KillDevilBill replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Dwight! I've become pay-a-zon dependant and forgot about eBay. I just ordered one. 👍🏿 -

Hand-cast solid Brass Buckles from a small foundry

Origibelts replied to Origibelts's topic in Suppliers

@Dwight Hi Dwight, Yes sir, I could definitely work from a pattern like that. If you sent me a plastic cutout of the buckle you had in mind, I could use it to build the mold and cast it in brass. Western-style buckles are a bit bigger and often carry more detail, but that’s all part of the fun. I’d just want to know how heavy-duty you’d like it, and whether you prefer a polished finish or to let the brass age naturally. Sending over a physical template should be simple — a flat plastic piece in a padded envelope can usually be mailed to Kenya for around $20 or so. Once I see the pattern or a picture of the buckle you have in mind, I’ll be able to give you a clear idea of cost and the best way to approach it. If you’d prefer to share details more directly, feel free to message me here or reach me through my site at origibelts.com Thanks for the idea — projects like this are what keep the foundry interesting. May God bless, John G. Origibelts – near Nairobi, Kenya