All Activity

- Past hour

-

Just got a Consew 255RB. It needs an oil pan.

Constabulary replied to Stagesmith's topic in Leather Sewing Machines

is there an oil pump on the underside or are there hanging wicks into the pan that suck up oil (I don´t think so)? So if not it is a manual oiling machine (basically). I think the hooks run in an oil bath but is is a closed system. I think you can use random oil drip pans. But maybe you can post pictures from the underside of the machine. - Today

-

Just got a Consew 255RB. It needs an oil pan.

Stagesmith replied to Stagesmith's topic in Leather Sewing Machines

The Consew part number is #15080. I can find a few listings for it but nobody seems to actually have one. it is a full pan not a drip tray. The 206RB is just a tray, but the 255RB is more like a gas engine oil pan. -

I have shipped a patcher from Germany to the US in a custom build crate but that was just the head w/o stand and it is A LOT OF work cause you have to do a lot of internal bracing so that the machine cannot move round in the crate. BTW shipping the DIY wooden stand makes no sense. Not worth it IMO. Other that that look for a double or triple wall cardboard box large enough for the machine + 2" - 3" space to all sides of the machine and fill the space with cut so size Styrofoam boards and bits. Do not use bubble foil or Styrofoam chips. The machine needs to sit very tight in the box. To save on the box size (shipping size) I´d remove the arm lever (just two pins that go out from rear to front) the hand wheel, front wheel hub and wax pot. Maybe the from tension and lock screw too (better safe than sorry). I have shipped machines with UPS to the other side of the pond and they all arrived intact but I have some experience in shipping & packing up heavy things.

-

Just got a Consew 255RB. It needs an oil pan.

Constabulary replied to Stagesmith's topic in Leather Sewing Machines

I think it uses just a "plain" drip pan and a a drip can with oil reservoir, right? I guess the one for the Singer 211 should work but I´d check with a consew dealer they may have one or can order the correct one. See pictures here: https://consew.com/products/consew-model-255rb-3 Or check the parts list and google the parts number and machine model -

I just got a Consew 255RB and I'm trying to get it set up, but it uses an internal oil system that requires an oil pan to catch the run off. I can't find one for this machine, but since everything is a copy of a Singer I'm wondering if there is another pan that would work. I'm seeing lots of Juki pans on eBay. I have a metal fab shop and could make one from scratch, but it's going to take a while to fabricate that shape. Also the real ones have the pass thru for the knee lifter. Any help would be appreciated

-

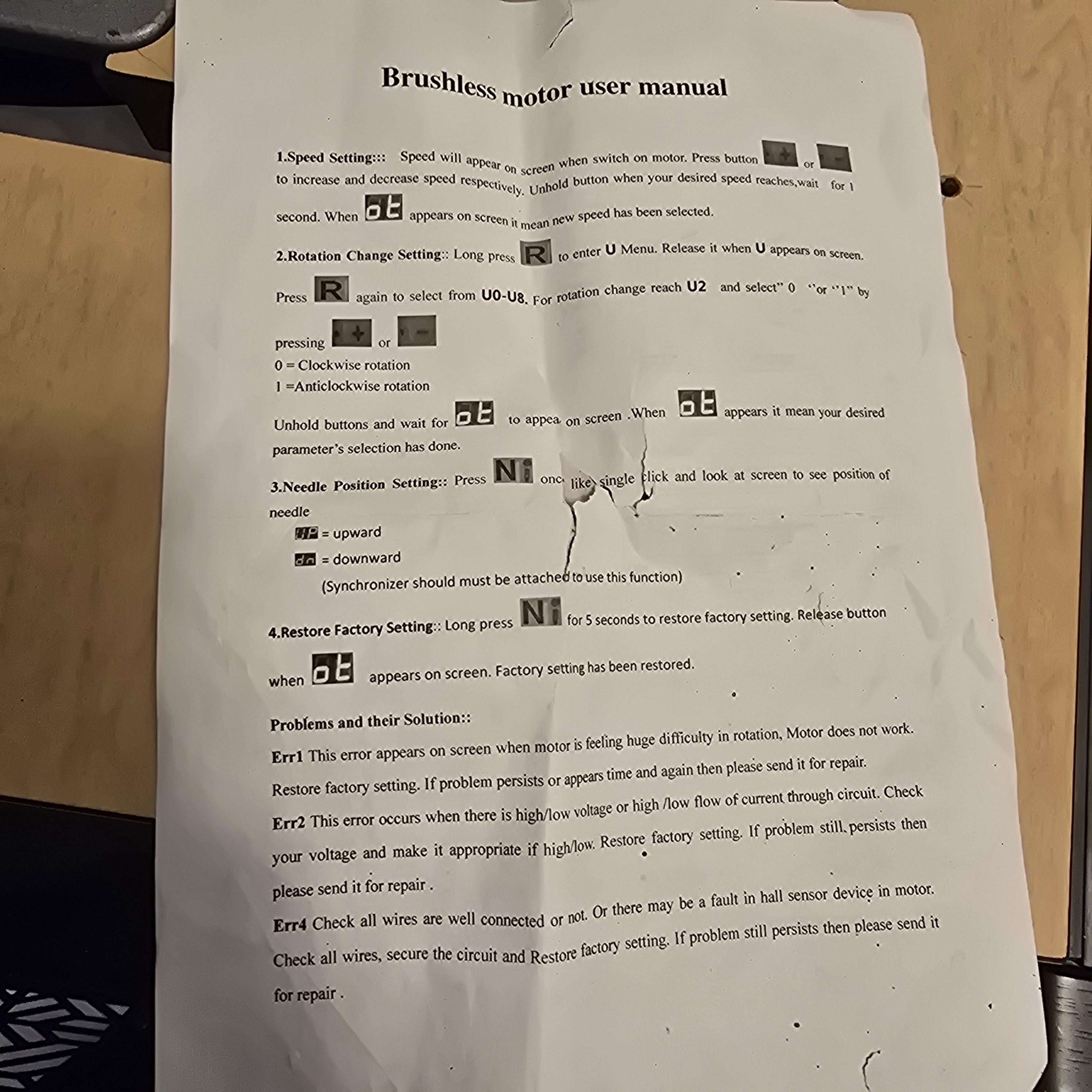

Wowza. Even better deal 😀 Here are my notes from my "consew" digital servo controller. Based on my notes, I'm assuming the minimum speed is not adjustable, so my memory is probably wrong there. Default settings: U0: 45 | (Maximum "maximum" speed that can be obtained by using the arrow keys by end user) U2: 1 | (Reverse) U3: 12 | (No discernable difference, though the PDF calls this the "location parameter") U4: 0 | (Delay between pressing full throttle to when it instantly goes to full throttle.) (Note this is not the "slow start" I would prefer) U5: 8 | (No discernable difference) U6: 5 | (No discernable difference) U7: 0 | (Not adjustable) U8: 0 | (Not adjustable) From PDF that used to live here: https://www.consew.com/Files/112347/InstructionManuals/CSM1000.pdf CSM1000 Dual Display Controller Operating Instructions 1) The Speed Setting; UO Press R; Display UO, Press M to adjust; Display the number 5 to 70; {5 represents a minimum speed of 500 rpm, 70 represents the maximum speed of 7000 rpm}. Example 1: You need 3500 rev/min Press R: Display UO; Press M to adjust; Digital display 35; Press L to save. Example 2: You need 500 rev/min Press R: Display UO; Press M to adjust; Digital display 5; Press L to save. 2) Upper and lower needle position set; U1 Press R; Display U1; Press M to adjust; Display number 0 to 1; {0 for the next stop pin; 1 for the stop pin}; Press R to save 3) Reversing settings; U2 Press R; Display U2; Press M to adjust; Display number 0 to 1; {0 clockwise; 1 is the reversed}, Press R to save. 4) Location parameter setting; U3 Press R; Display U3; Press M to adjust; Display the number 8 to 20; (The smaller the number, the more slowly, but the positioning is more accurate; The bigger the number, the faster the location, the more not allowed), Press R to save. 5) Slow start setting U4 Press R; Display U4; Press M to adjust; Display the number 0 to 9; Press R to save 6) Other display instructions: {1}When the motor stall failure occurs, when it display E1, the motor does not work, press the R key to recovery; Many times, it is recommended to reduce the load or contact your dealer. {2}When the stream or under voltage fault occurred, when the motor display E2, the motor does not work, press R key to recovery, many times, it is recommended to reduce the load or contact your dealer. {3}When the motor has the Hall signal error, it display E4, check the motor and controller plus connection is intact, press R key to recovery many times, if not, please contact your dealer. 7) Restore factory settings: In the U mode, press the M button for 3 seconds or more. The set parameters are reset to the factory default state. ®

-

It has a chain to a knee lift, pretty cool. I attached the single document that came with the servo. I'll look into the pulley, thanks!

-

The guy I bought this from seemed to think it had reverse, but I was pretty sure these didn't have that. He works as an upholsterer but hasn't used the machine in a while, so I wonder about that. I'm happy to do the poor man's reverse for now, as my projects are not my main income and are sporadic at best. Half the joy of this machine for me is the machine itself and《tinkering》:)

-

Thank you!

-

Glad you got a machine. Now you are going to have to learn the "poor mans reverse". Three stitches forward, turn the material 180 degrees, sew three stitches, turn the material back 180 degrees and do your seam. Rinse and repeat at the end of your seam. This method will lock your seam at the beginning and at the end. kgg

-

I moved your post to leather sewing machines. I think the guys here will have more experience shipping and transporting sewing machines safely.

- Yesterday

-

Fortuna Leather Splitter not turning on.

Morgan311 replied to Morgan311's topic in Leather Machinery

Thank you Bruce! -

Lovely, unusual items! Do you have these available on Etsy too? I have seen something similar there. They are in my list of things to purchase and make, the trains and the dog.

-

Yep, a slippery slope that leads into a rabbit hole!

-

Congratulations! Can we get a good photo of the back of the machine? Specifically I'm looking for what attachment points the machine head has for a knee lift / foot lift. Having a knee or foot lift is quite convenient...worth putting in the effort to source/install one. I used to have a motor controller that said "by consew" like that. It had a minimum speed of 200rpm. If you haven't already, I suggest finding a manual for the motor controller and making sure the minimum speed is indeed set for 200. (Factory default is probably higher than that) Also, if you don't have a 45mm pulley yet, they are easy to come by, for example here: https://www.amazon.com/KKUANG-Industrial-Aluminium-Electric-Clutches/dp/B0DLGNBZFQ It will slow down your minimum speed at the hand wheel, and increase the torque at the hand wheel.

-

You did good, got a real bargain there. They are good solid machines and it should serve you well.

-

Fortuna Leather Splitter not turning on.

bruce johnson replied to Morgan311's topic in Leather Machinery

My first call would be to Campbell-Randall. They are on here as a member but you will get faster results calling them. -

I’ve found a singer 29k171 that is an offer I can’t pass up in Connecticut where I’m visiting. I live in AZ does anyone have any ideas on how I can get this monster back home with me for the most reasonable cost? Thanks!

-

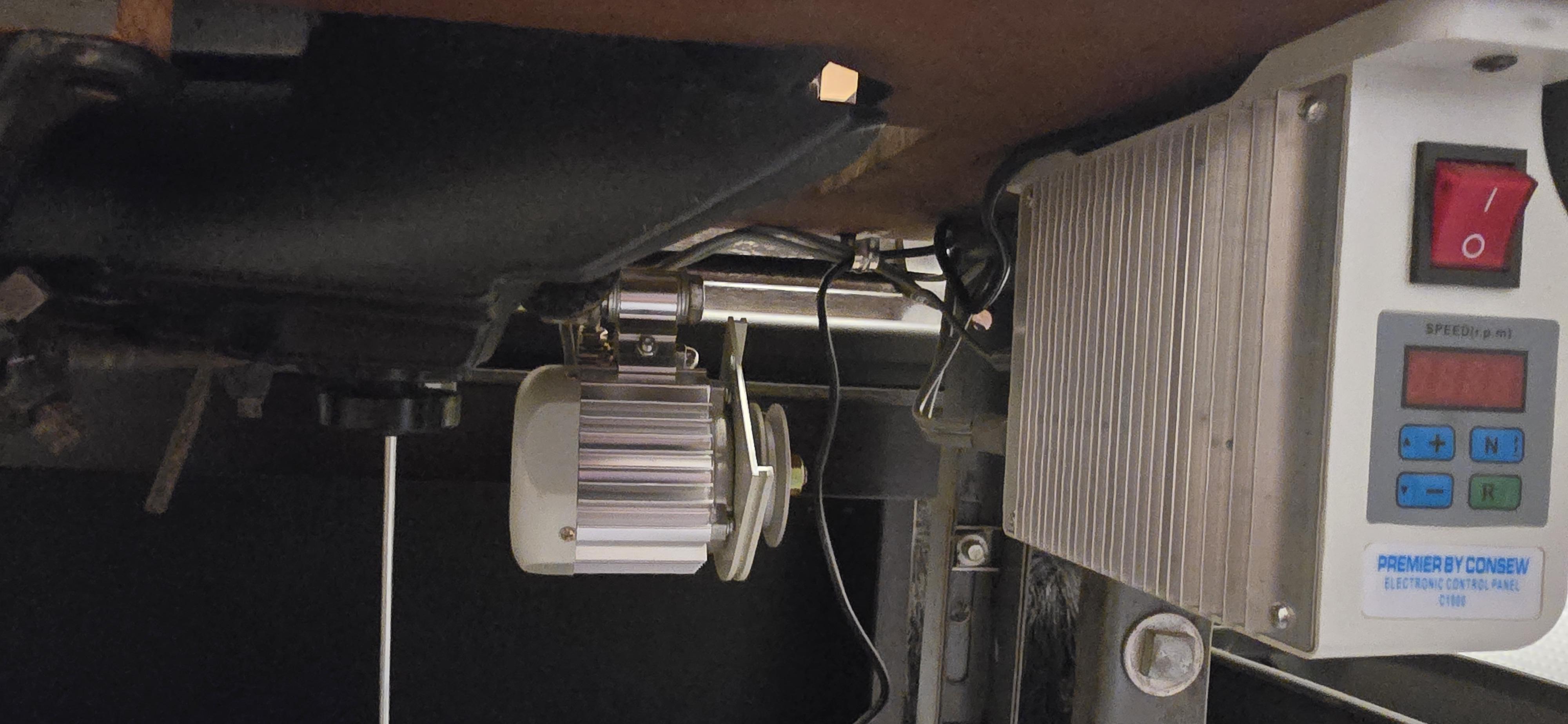

I just wanted to thank everyone that responded to my other post looking for help picking a machine. Without your advice, I might have ended up with a much more expensive machine and disappointment. Instead, I spent $200 and a several hours cleaning and swapping out the motor on this beautiful Singer 211g165. I got the servo for free from a friend that had it lying around collecting dust, so I got a great deal on that! Anyway, allow me to show off DeVille #9 (the factory it once lived in, and the number on the table). If anyone has stories to tell of theirs, helpful info and links, etc. please share!

-

Hello from Ukraine – Leather Pattern Designer

Scoutmom replied to Olena TS's topic in Member Gallery

welcome and nice items -

Canter Cart joined the community

-

Beautiful work with some unique style. well done.

-

Morgan311 joined the community

-

Hello Today my skiver decided to literally scream at me and shut off. She still gets power but will not turn on. I don’t have a manual and it’s such an old machine I can’t find much info online. Has anyone had this issue? I appreciate any help you can give me. It’s a Fortuna HIGH PRECISION BAND KNIFE SPLITTING MACHINE Thank you Morgan

-

Hello from Ukraine – Leather Pattern Designer

FrankHester replied to Olena TS's topic in Member Gallery

Great work! Welcome! -

What fun stuff! I love all of it.

-

Railed sig 1911 bbq rig

Stetson912 replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the kind words. I'm gonna have to look for a set of maple grips now haha.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)