All Activity

- Past hour

-

Do you have a manual? Here is one I found on manualslib: pfaff-491-471-manual.pdf Page 11-33 shows how to adjust the pressure of the roller presser. You may also want to check the height of the feed wheel, that's on page 11-18.

-

Thanks, I’m still working on it, I think there’s also a tension issue.

- Today

-

Ok so I timed it accordingly to the 2mm specified for the 345. I was able to slide the bobbin base a bit forward to that the hook is closer to the needle. Good news is that I’m starting to get something that looks like stitches but there’s still entanglement. Here’s a video to the issues I’m having at the moment. IMG_9295.mov

-

Singer 211 U166A walking foot problem

AlZilla replied to NowhereMan01's topic in Leather Sewing Machines

If what @CowboyBob told us about the 111W machines holds true, at this point of the needle stroke (all the way down) the point of the hook should be on an imaginary line between the center of the bobbin and the needle plate screw closest to the operator. This one is late or early, depending. In case the viewer can't tell, the point of this hook is right next to the bobbin latch on the opposite side. -

That's the only thing I'm envious of in the US,the space. Must be great. Thanks for the cool on the hat.

-

I have published a complete guide, it is more complete than my OP: https://birchees.ca/how-to-make-salmon-leather-updated-method/

-

oh yeah, the Dixon club bar on a Saturday night would test your endurance for sure lol. It's very cool I love the look, color, and excellent work but probably not something you could wear here without some feedback.

-

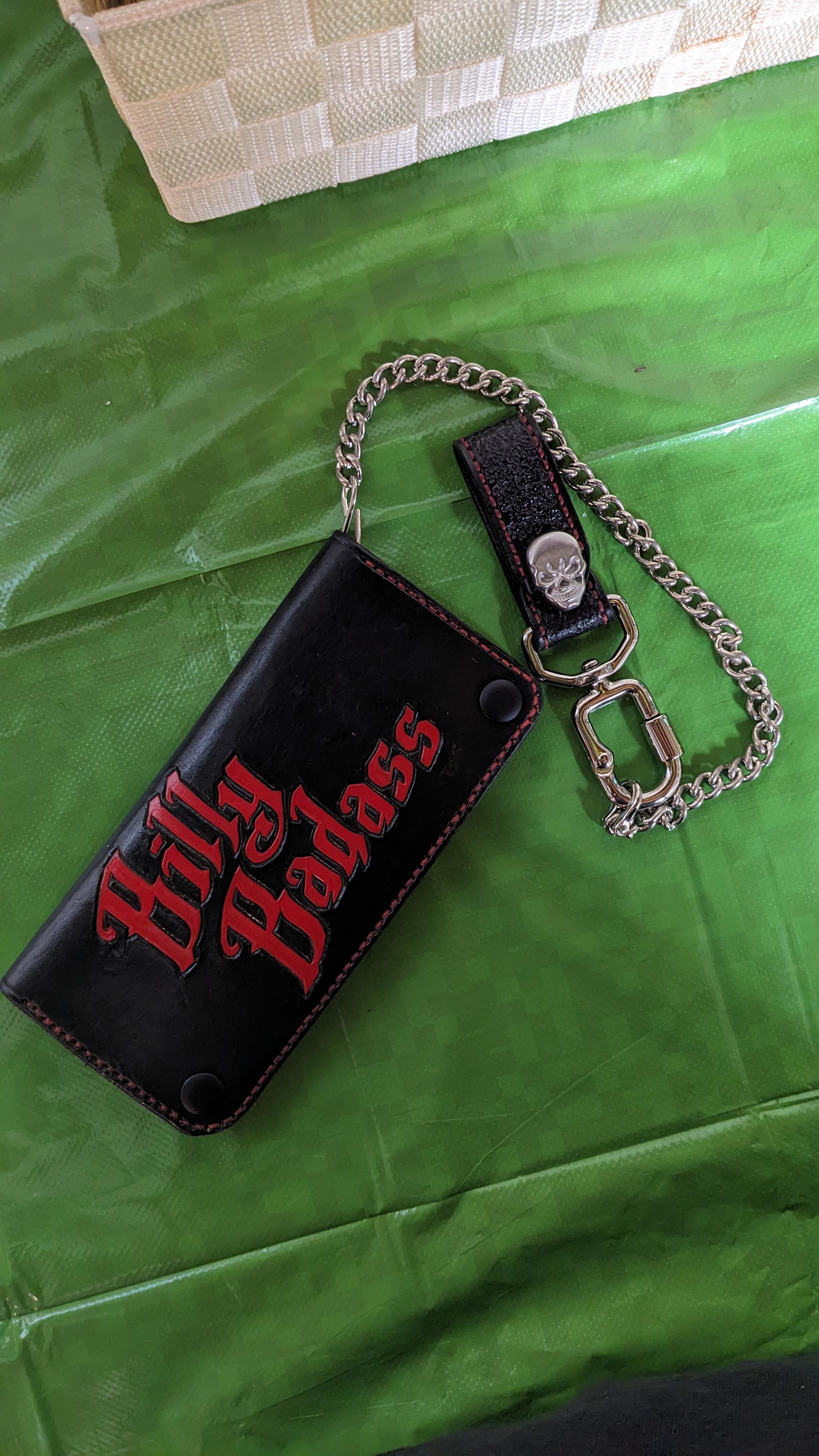

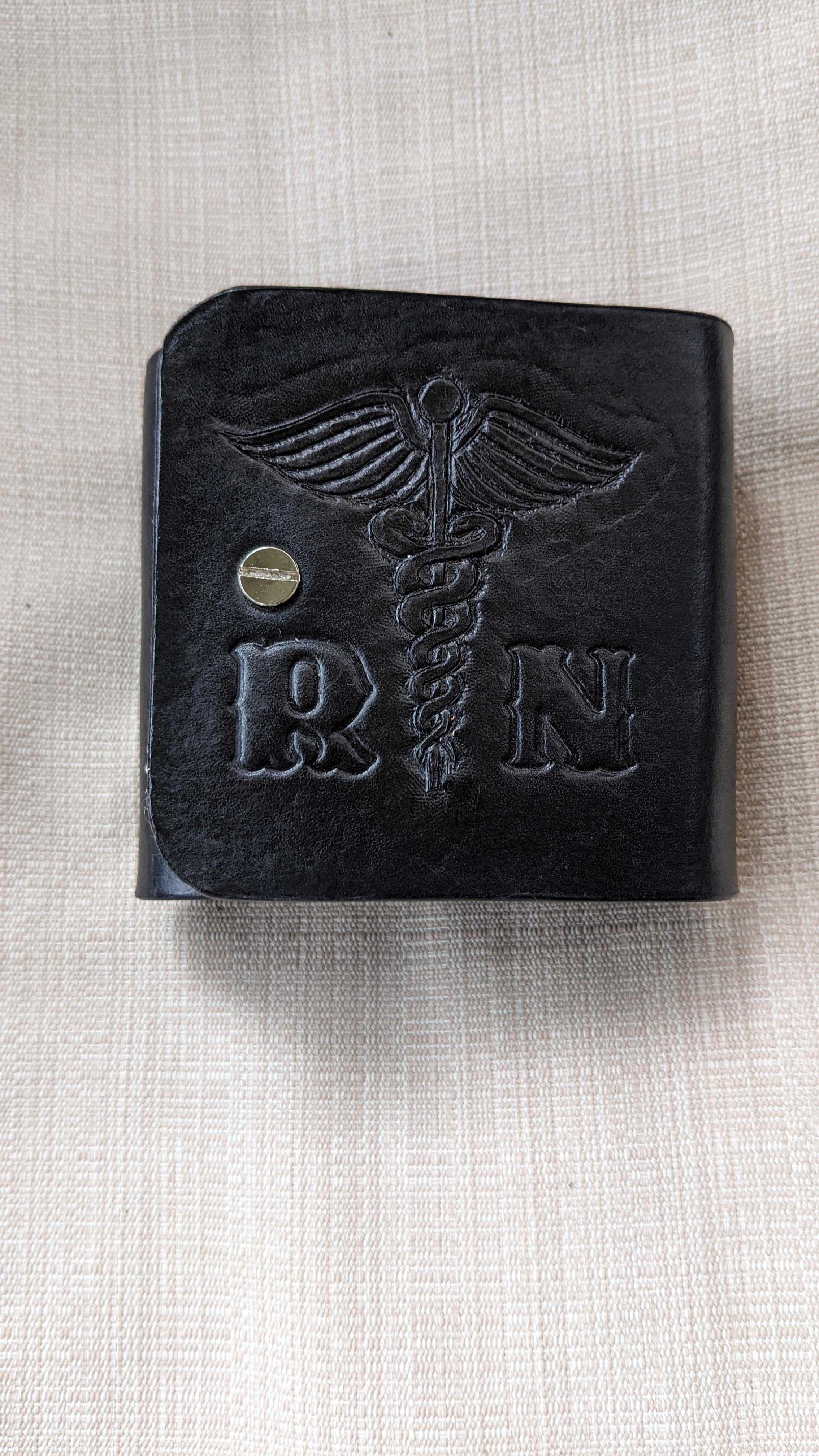

Some nicely creative stuff going on there. Welcome aboard!

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Its a suburban lol Its my nickname for this thing I drive out in the boonies (offroad). There is still plenty of nowhere out here to get lost, stuck, or broke down in. 6" lift, 37"deep lug tires, 10,000 lb winch gets me through the shit and back home. i would look great driving her to elk camp with that red hat of yours, which is really cool btw, but i doubt i would make it out of the Dixon Bar safe with it on LOL. -

Thank you! That's a huge help. I do have liquid wax running through the wax pot and I'm also waxing the thread on the bobbin. I might try putting a bit of silicone on the awl itself. See if that helps. But I'll definetly try switching around the needle and awl sizes to see if that helps. And tightening down the presser foot too. Thank you!

-

I applaud your skills Chuck but I do wish you guys would talk English. Wots a burb?

-

Don't order your rabbit food from Amazon, it's a scam. The other day I put in an order and almost as soon as I got it, they sent me an email wanting my feedback.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

just the right size for two !! Dang that looks good. All ive been cooking is mud lol, but that is kinda fun too. I've been wrenchin on the Burb, getting it ready for the hunt and winter. It was missing and running like crap so i decided to give her a tune-up. The plugs were pretty worn so i replaced them but he darn distributor cap i dont think was ever replaced lol. The rotor button was completely worn down and the terminals had big gobs of carbon burnt to them. So i figured it solved the problem, it ran better but still was not right so i rebuilt the throttle body next and found a vacuum port completely plugged with mud and someone had tried to set the idle by drilling out the idle screw, which is factory sealed, that throws off the ECM which controls air gas mix and was the biggest problem with the way she ran and the hardest to find as that shouldnt happen. Adjusted that back to the original reset the downshift cable which was also set to short and not allowing full throtle or proper shifting. I also threw on a new muffler, when i cut it off i found the one on it was to small it had just been shoved inside the exhaust pipe and welded on 2 1/2" muffler on a 3" exhaust so it had too much back pressure. Damn thing runs like new now. My son bought this thing used then traded it to us It was running well then, or so i thought, so i just drove it for a few years lol. Now for the hard stuff, My daughter gave us another burb, same year so I'm switching out the radiator supports, then fixing the other burb for my son to drive as well as having an unlifted unmodded truck for the road and town driving. The days are getting short and the mornings brisk It won't be long until snow flies here. Take care my friend!! Chuck -

AlexTzevji joined the community

-

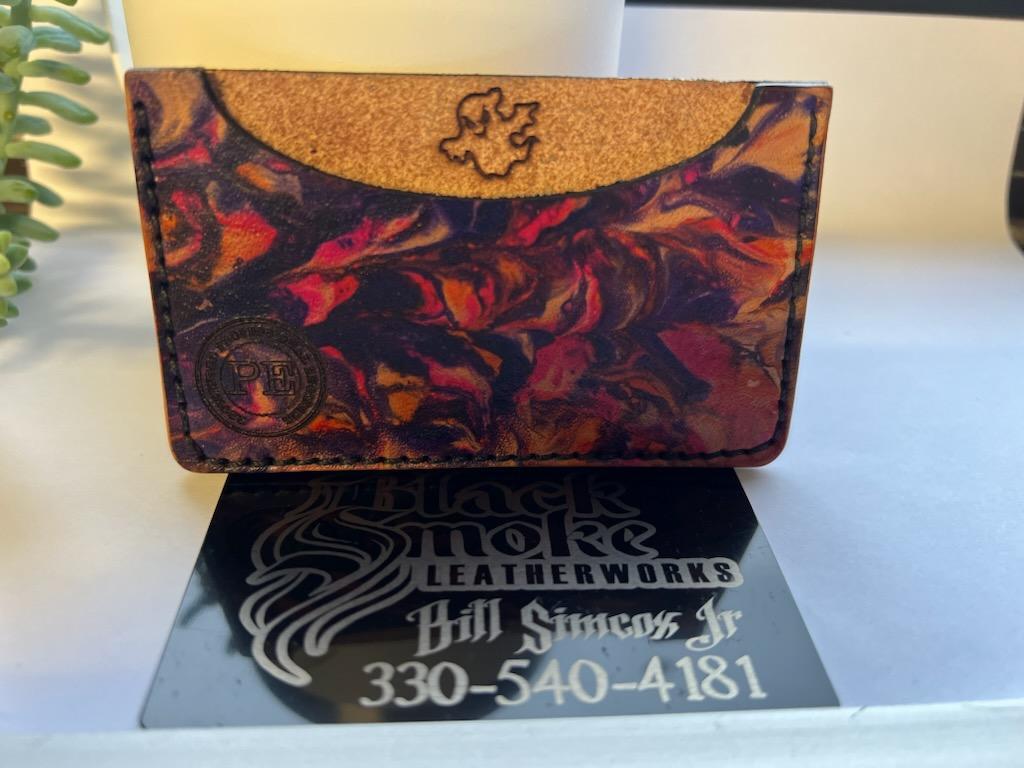

Welcome, nice looking products on your website. Brgds Jonas

-

Welcome to the forum, Really nice looking tooling! Brgds Jonas

-

This was a female spaded English Bulldog about 60lbs. There seems to be more of the Bull "dogge" type dogs like the American and Olde English around then the English Bulldog. What appears to be creeping in is the unpredictability similar to Cocker madness and Springer rage. kgg

-

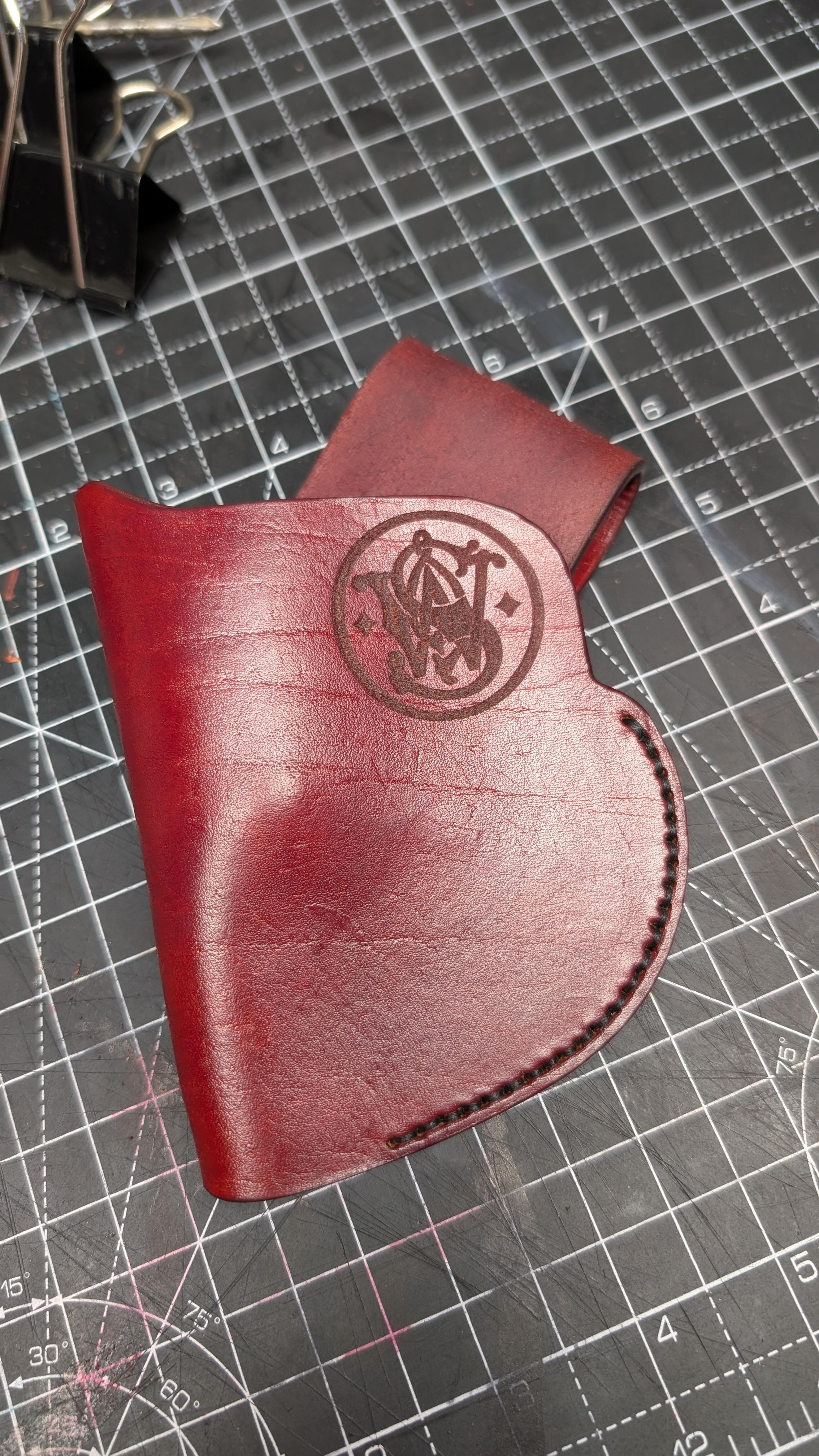

I'm a retired firefighter/Chief. New job is driving a truck for a construction company. I built a center console for my work truck a few years ago. My buddy saw it and challenged me to make a sheath for his custom knife, and so my leatherwork started. I try to keep my projects "old school" traditional styling with carving/tooling as much as possible. Collars, belts, sheaths, holsters and one-off custom pieces seem to be my specialty. Thanks for having me here! IMG_20250130_065640.heic

-

Welcome neighbour! Website looking good. Lots of friends here.

-

This is cool! I really like how you blended the dye with red/black. Black cord was the right choice.

-

Origibelts joined the community

-

@speedybri This sounds like a case of the leather is too dry and dense. Is it the awl or the needle that is getting stuck and lifting the stack of leather? If it's the awl, you may need to oil the leather to soften it a little. Or, run the thread through liquid stitching wax or silicon in the wax pot. If it's the needle, either move down one needle size or move up one awl size. And, add more foot pressure until you figure out the real problem.

-

How to increase pressure of roller on a pfaff 491? the stitch length is inconsistent.. hoping more pressure will help the material move better while stitching, and keep the stitches even

-

Hello everyone, first timer here. And I suppose a relatively new comer to the world of leather making. I started about 3 years ago as a creative outlet to keep me sane whilst doing my usual day job... I'm hoping that eventually I can turn my leatherwork into my day job. Not that it will be any less hard work, but certainly more enjoyable. I shall be posting again soon. Thanks for having me x You can find see some of my work here www.headboneleather.com

-

Hello. I picked up a landis three a few days ago. It's running good however it keeps lifting the leather. I've tried adjusting the feeder foot pressure. I'm sewing 3 layers of 12/13oz together. Making lead harness traces. So it's pretty heavy. Does anyone know what might be causing the lifting and how to correct it? Thank you for any and all help.

-

Helps if you quote a part of the post or tag the user so they get a notification in case they don't have notifications setup correctly. @esheeran

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)