All Activity

- Past hour

-

@noahjoshu We need the location/shipping info with this one, too. Looks like you're listing a few ads. If I notice any more lacking the above, I won't tag them, just be aware all ads need that info. Thanks for listing this stuff here.

-

@noahjoshu We need a location and shipping info to be in compliance with the Marketplace rules. Thanks!

-

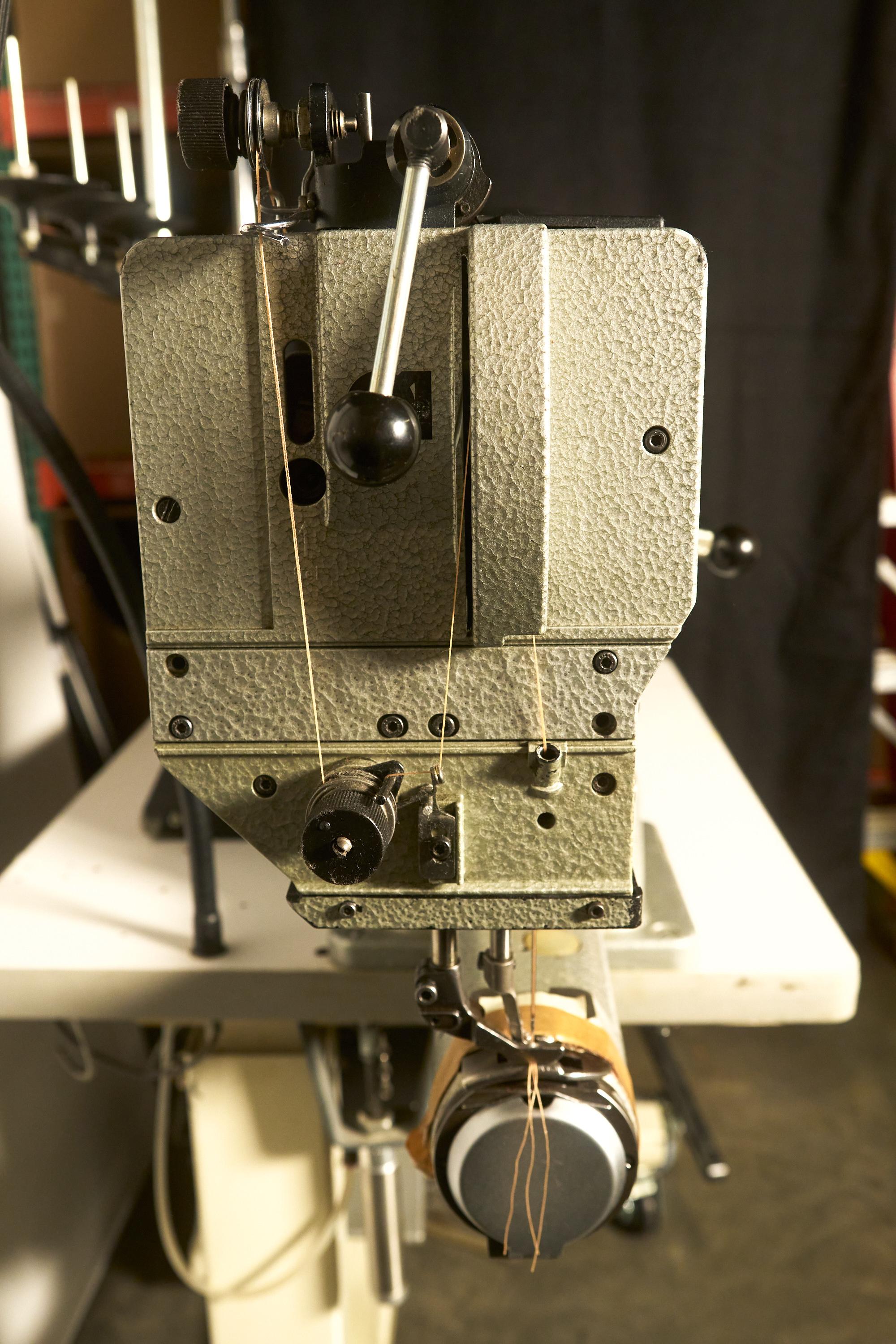

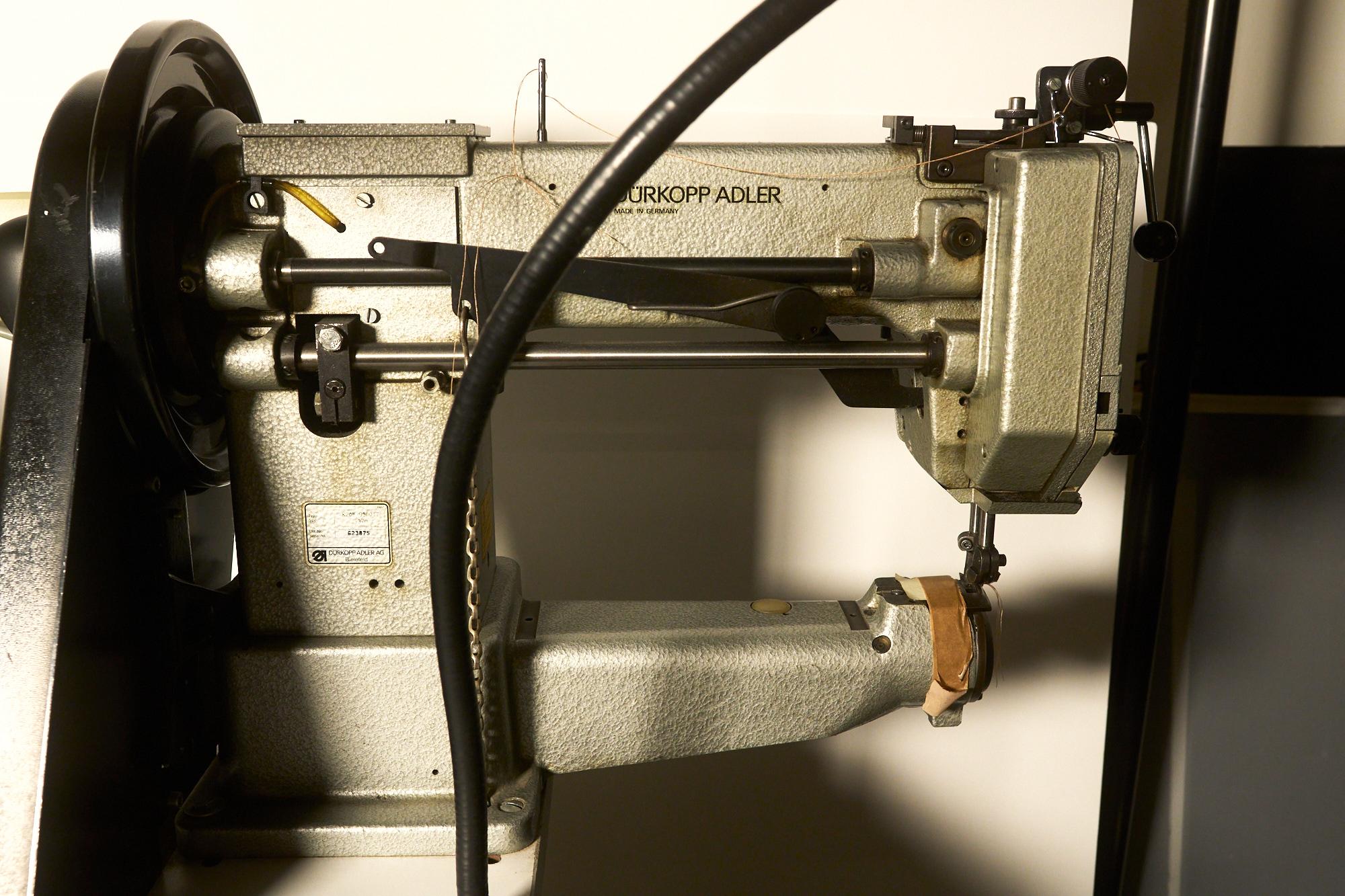

Single Needle small cylinder bed walking foot machine. This is both for binding and sewing leather in tight corners such as wallets, bags and upholstery. Comes with a Efka needle position motor and Kessler sit stand legs with power. Motor and machine made in Germany. Legs in the USA. 220v single. $2200\

- Today

-

1-3/4” wide 95% cotton, 5% nylon, olive drab, treated with mildew resistant. NOS 1969 - 50 yards per roll. $40 per roll, minimum 20 rolls. These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

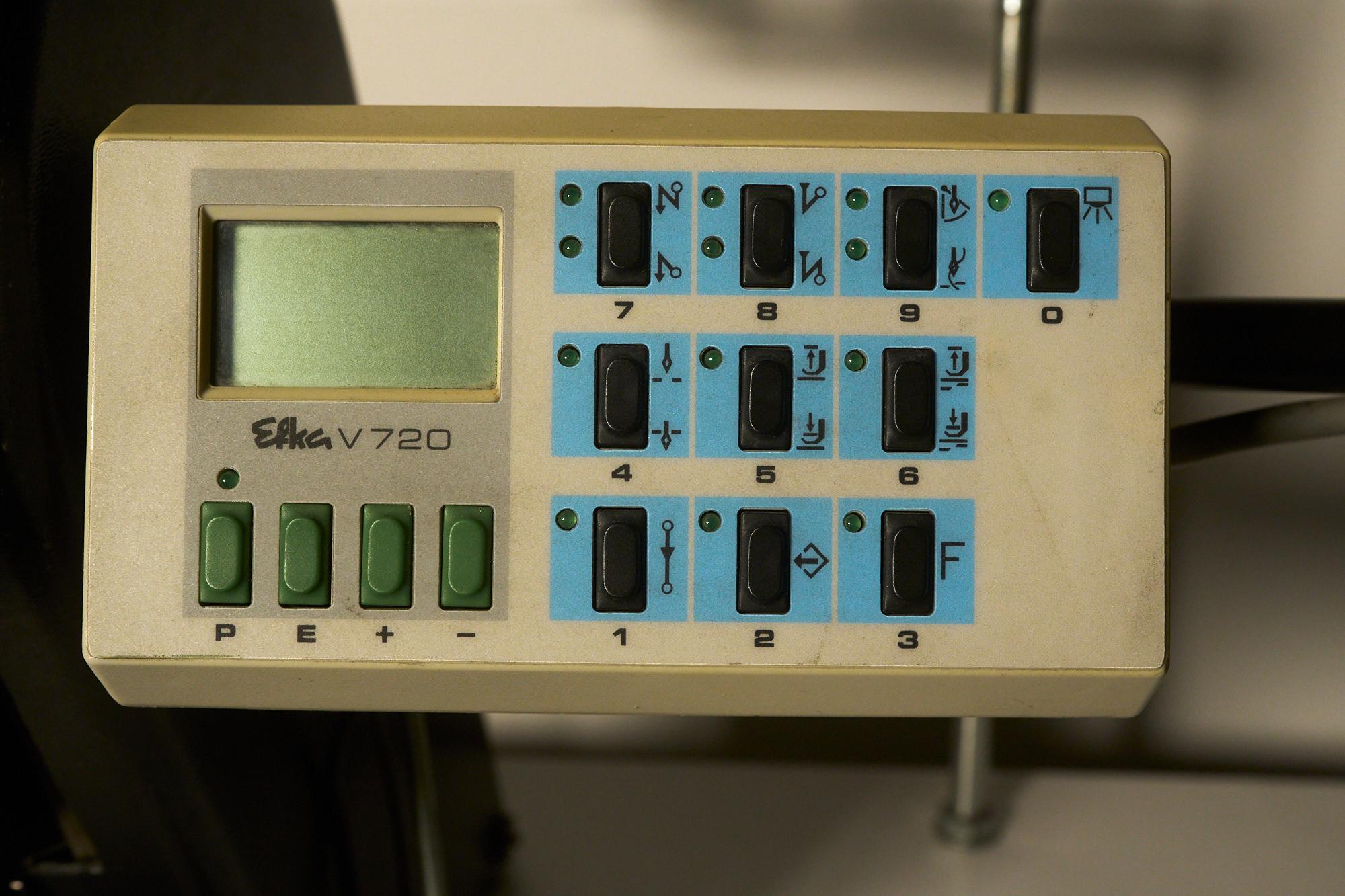

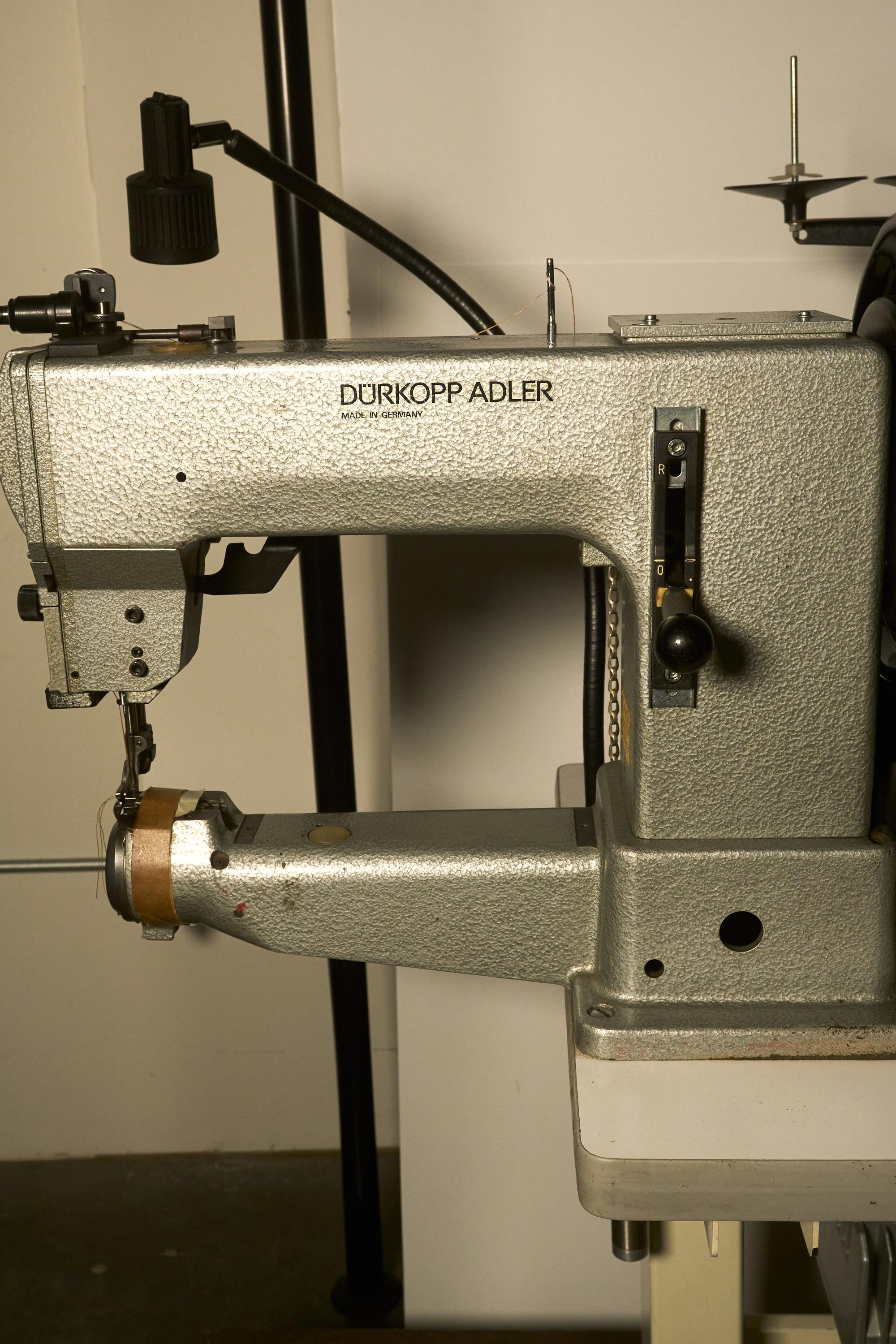

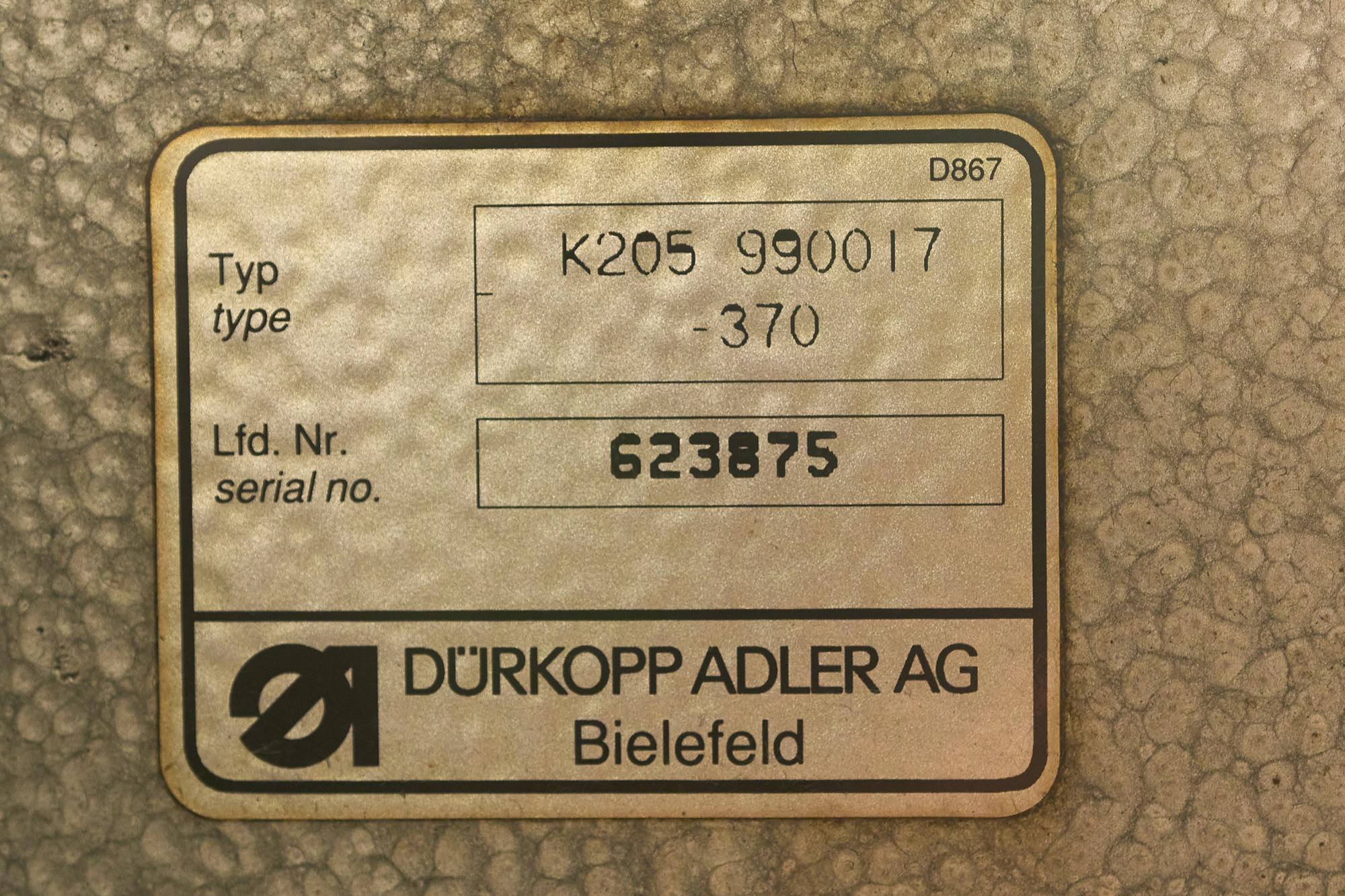

Adler 205 made in Germany New needle bar, all parts in excellent working condition, ready to sew Efka needle position motor with pneumatic foot lift - made in Germany Efka control panel Kessler motorized sit stand table 3 phase 220 $4500 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

- Yesterday

-

Im in Texas. I did manage to get the manufacture to add a 50mm pulley to Amazon. So I have one on the way.

-

This is a medium to lightweight Rossley kick press that has been outfitted to attach solid brass arches to various materials. It comes with the brass arch and the brass post rivet that holds it in place. Great machine that can be adapted to other uses. $400 complete with arches.

-

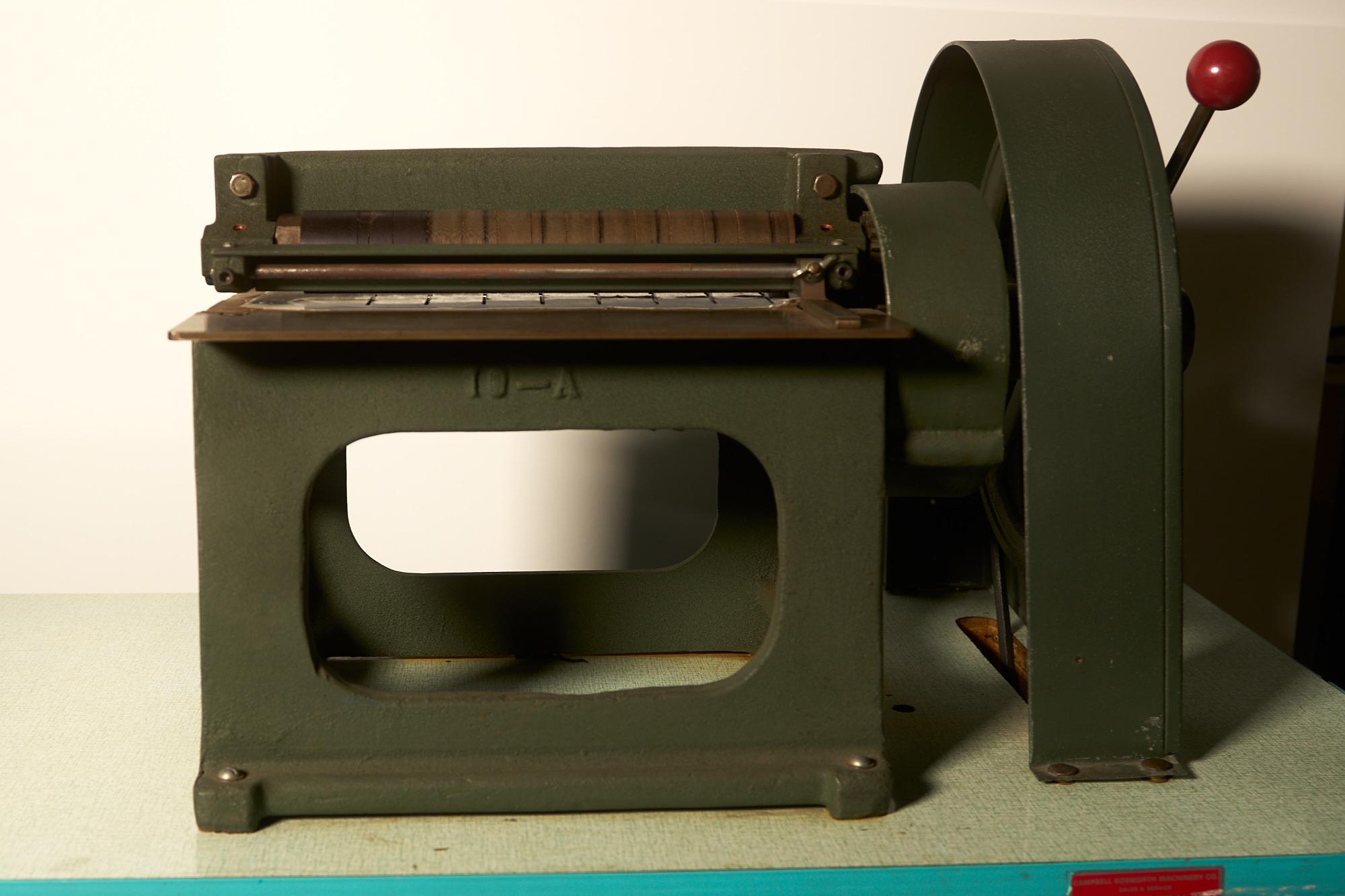

This is a strap combiner, made to fold leather strap of different gauges together. Can be set on a table and motorized, or used by hand. $100 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

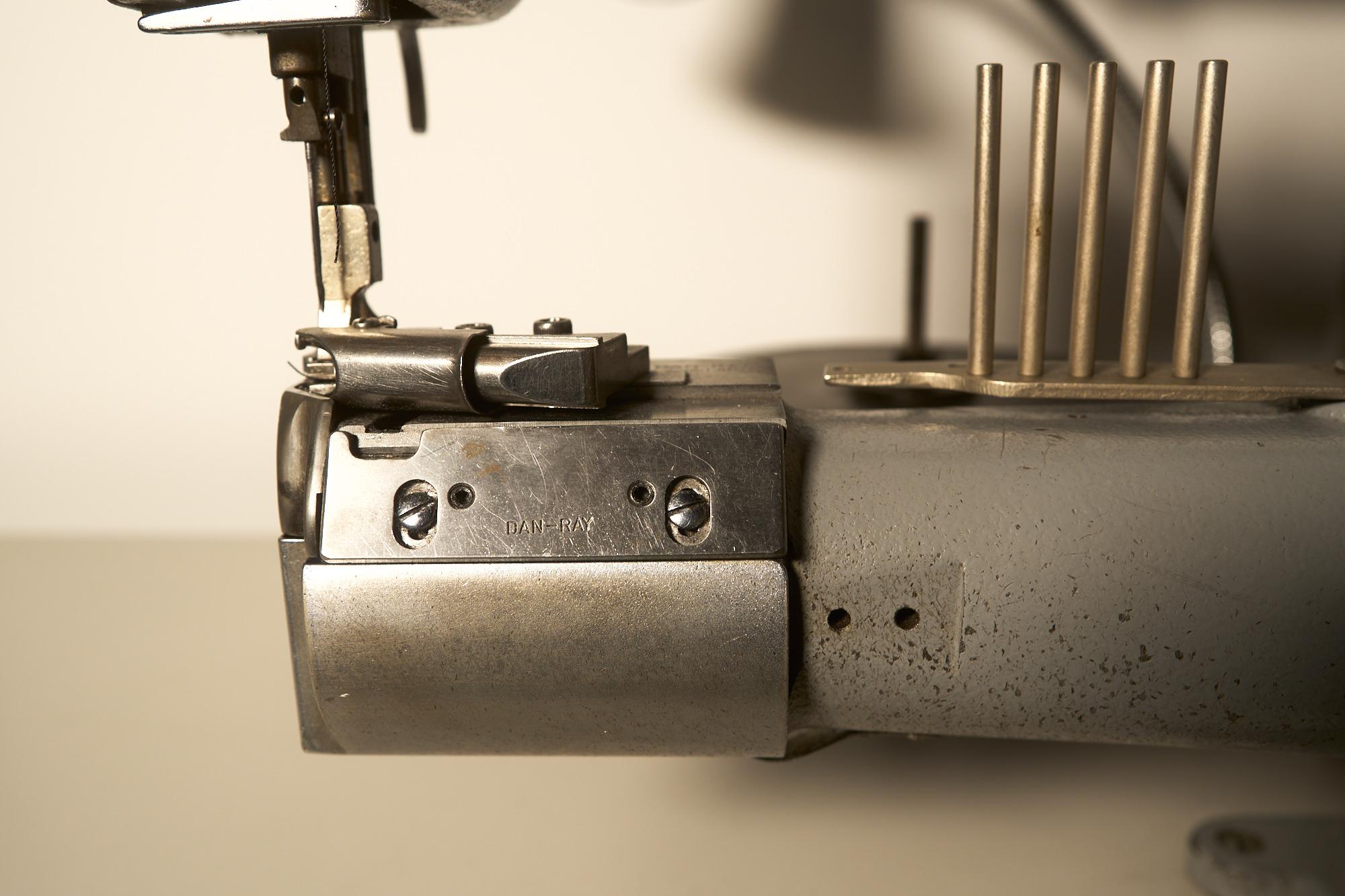

Leather strip cutter or belt / strap cutter. cuts leather into different widths. Comes with knifes and a bunch of spacer - THE WIDTHS COORDINATE WITHT THE DAN RAY LEATHER BINDER I AM ALSO LISTING FOR SALE. so you will have a 1" binding and a another width. 220v 3 phase (can change motor easily) $1000 These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

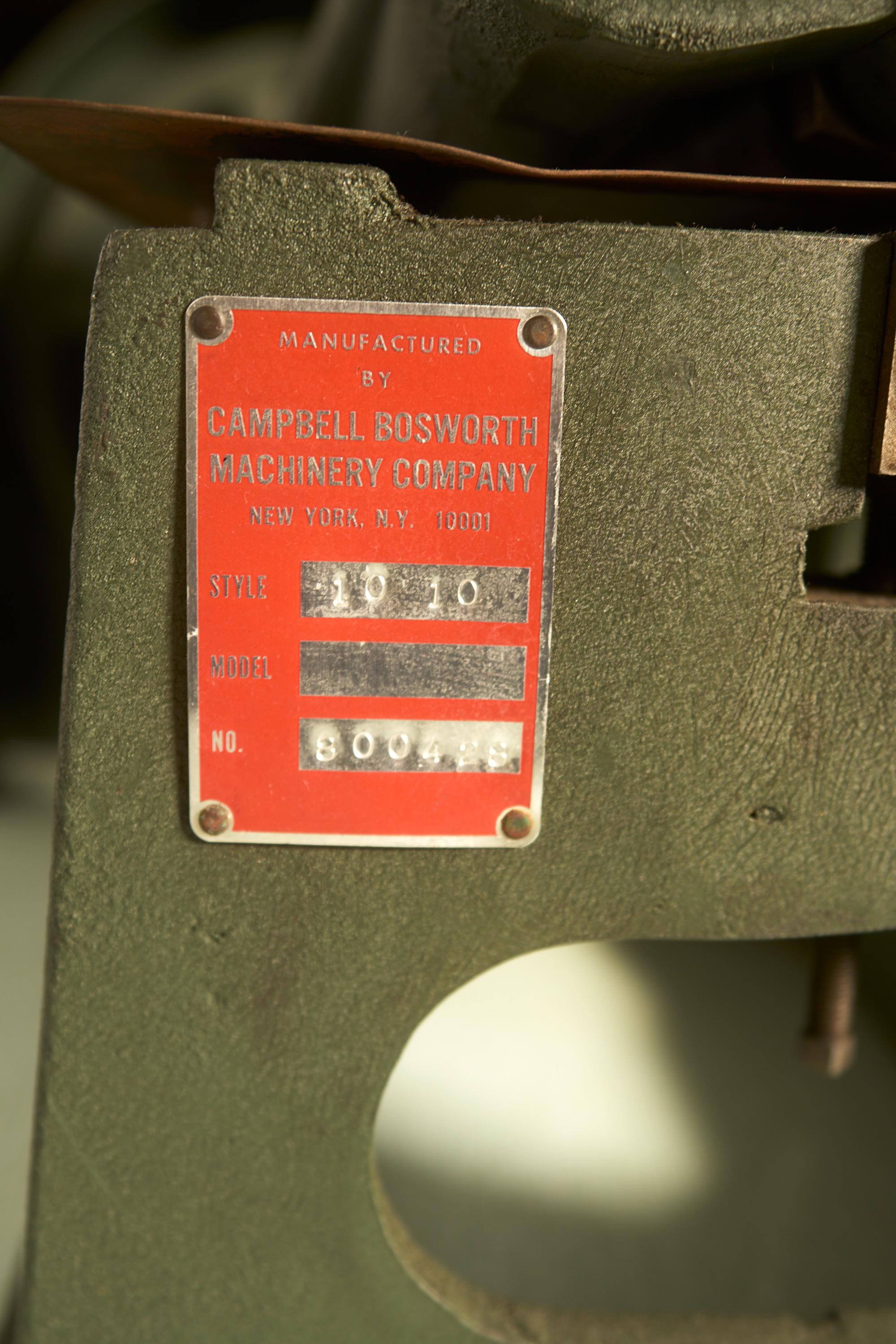

Dan Ray leather binder/edger. This is a custom setup machine for leather binding such as done on Coach bags in the 1980-90's. Needle position Efka motor. Made in Germany: $1800 (you will need the Campbell Bosworth 10 10 leather cutter that I am also selling to go with this machine) These machines are all part of a small business downsizing. They are located in San Francisco. All priority will be given to pickups. I will crate and ship only as a last resort. Alternativly you can have a local crate person pick this up and handle all the crating and shipping. This will be a bit expensive in SF, but these machines are rare. Please take a look at the other listings.

-

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)

Desert bighorn holster is finished

DoubleKCustomLeathercraft replied to DoubleKCustomLeathercraft's topic in Show Off!!

Thanks chuck. I'm happy, the client is even happier. It's a win- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

-

I would tackle this problem with a munltimeter...

-

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Wizcrafts replied to Yoshi888's topic in Leather Sewing Machines

That part is known as the "latch opener." It should be set to pull back on the bobbin case as the thread goes around it, then let go after the thread knot is pulled up past the notch in the throat plate. There is a small amount of wiggle room in that cutout for the little tab on the bobbin case/shuttle to move forward and backward. Pulling it back at the right moment frees the thread to go up without hindrance. It should not be set to pull back hard against its stopped position. Leave a tiny amount of clearance at the pulled back position so you don't break anything or wear out the pulled parts. -

Desert bighorn holster is finished

chuck123wapati replied to DoubleKCustomLeathercraft's topic in Show Off!!

that came out really nice!!- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with:

-

Man, that must suck having the knowledge right there and not being able to get to it. With your natural talent, your work could get much more refined easily.. Keep up the good work!!

-

Thank you for your response.

-

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

AlZilla replied to Yoshi888's topic in Leather Sewing Machines

I can't get that video to run this morning but it sounds like you're talking about what I would call the "case opener". A finger that contacts the bobbin case at exactly the right time and pulls it counterclockwise (in my machines) to be sure the needle thread clears when exiting the tab area under the needle plate The tab keeps the bobbin case from spinning around. If the machine is sewing, it can't be too far off. If the opener was holding full pressure all the time, the thread would hang up on the side where it enters the tab area. That said, it should have some float - I could see it accelerating wear on some parts if it's under even slight pressure 100% of the time. On my machines, the case opener finger itself has a slot on the end, where it screws down. I think there's even a spec to set the clearance. I know that doesn't tell you exactly what to do on your specific machine, but the concept is the same. Unless you're not talking about a case opener. If not, ignore everything I just typed... 😃 -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Also not sure it is completely the right term but it's whats referenced in the manual. It is the part on the bottom left of the video that holds back the thread after the hook released it across the bobbin. To my understanding it should be kept there a bit longer so it does not get entangled with the bobbin mechanism. But currently it basically releases the thread instantly after it passes above the bobbin case. -

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

-

I would try spraying it with Febreze, then if that didn't work, maybe a cold or slightly warm tumble in the dryer with a dryer sheet or two.

-

Help with square corners on wet molded pouch

Dwight replied to bigsig11010's topic in How Do I Do That?

I use two different ways to make boxes . . . the first you see as two pieces of wood . . . the leather is placed between the pieces . . . about 4/5 oz . . . WET LEATHER . . . and it is then placed in a vice . . . it takes about 10 minutes for it to partially dry and take the shape. That will hold a single stack 45ACP mag relatively loosely . . . which is the desired effect. The second way is the leather cell phone case. The bottom 2/3 of an inch or so is solid leather . . . cut out . . . and glued together . . . the inside width of the cell phone case. Once that is made . . . it is taken to a small belt sander that makes all the edges flat and level . . . then it's fastened with contact cement. I wore it for a number of years . . . my new one is made the same way . . . May God bless, Dwight -

Chicoinn joined the community

-

Thank you! I was down in Arthur last weekend and wanted to stop in but time was a factor. We were picking up a nice John Deere wooden wheel farm wagon east of him about 25 miles and were in a hurry. I'll be heading down to that area in a few weeks and will make it a point to stop in. He's kept my Landis Nr.1 in parts, shuttle, needles and knobs.

-

Thank you, got both of them in boxes somewhere from the move. Thank you, google can be a friend. Started on a Buck 119 sheath to go with the Bowie.

-

Desert bighorn holster is finished

Dee Fieret replied to DoubleKCustomLeathercraft's topic in Show Off!!

Hey Y town! My old stomping grounds were Youngstown, Boardman, Poland and Columbiana. I'm new to leather working and interested in learning leather tooling. Any advice on direction?- 15 replies

-

- desert bighorn

- holster

-

(and 1 more)

Tagged with: