All Activity

- Past hour

-

Bob Park- Creating Western Floral Designs

bruce johnson replied to SulaSaddlery's topic in Suppliers

His wife recently passed away. That is likely one factor. -

would you recommend a straight, angled, or curved blade?

-

Maine thread does have a lot of wax that gets dry/flakey during storage. I store it in ziplock bags. For some projects I'll add a little cobbler's wax (mixture of pine resin and beeswax) to freshen it up. I use heavy brown wrapping paper to burnish/smooth the wax on the threads before hand sewing. The paper absorbs some of the wax and the friction melts it and evens it out. For most hand sewing I am using bonded nylon thread from my sewing machine and waxing/burnishing it before use.

-

Digit started following First purse

-

I've recently finished one of the more complex assignments at school: a purse with card holders and coin pocket. It's made from chrome tan goat leather: smooth black outer and suede red liner.

- Today

-

Hello, I am interested in purchasing a leather sewing machine for small leather goods like wallets, card holders and book covers. Most of my projects range from 5/6oz-9/12oz in thickness. I primarily use vegetable tanned leathers such as buttero and Pueblo. I am also looking for something that will not leave marks on the leather from the presser foot. Also look for something that has a clean stitch and backstitch. Any and all suggestions are welcome thank you!!!

-

The techsew sold thank you @Nanamagic

-

Hey thanks for the info. I don’t mind waiting until you get back from your travel to buy from you. Just let me know after you have checked it out.

-

Yeah I think so. Thanks anyway

-

See if you can find Hidepounder on this site. That was Bob Park's member name.

-

AlZilla started following ID RT Frazier vintage saddle

-

ID RT Frazier vintage saddle

AlZilla replied to KathrynGiardiello's topic in Saddle Identification, Restoration & Repair

Welcome to the forum! We prefer you to upload your pictures directly here. 3rd party hosted pictures disappear, making this thread useless to future users. If your time to edit your original post expires before you get back here, simply add a reply to the thread. Thanks! -

KathrynGiardiello joined the community

-

My mother swears this is valuable, given to my family in the 1990’s from someone cleaning out a home in Mystic CT. RT Frazier stamps all over it, very ornate with a high back which also includes an unusual pocket. “Patent App’d For” on both sides and “187” written under flap (no idea how or when) Possibly unrelated, there is also what looks like a degraded Air Force sticker. Perhaps nothing to do with the saddle itself. I am at a total loss for anything comparable online due the amount of detail. Anyone know how I can date or place this? Would love to see it it’s one of the catalogs.Pics of saddle

-

That's cool. I like it

-

Here are a couple knife sheaths a client order. The one with the ostrich leg inlay is for a Buck 119. It's his son's and it's a gift so I don't have the knife to work with. Not a hard knife to make a sheath for. With this one I also decided to use some of the leftover ostrich on the retension strap. He wanted the large scales to go straight across, but the length of the window was the wrong size, plus the pivot sanctum that was close enough to fitting had 2 or 3 loose scales. This is my first time working with ostrich, and I find it nice to work with. It's really thin so adding a 4/5 oz backing doesn't overkill the thickness. The bison leather is for a Randall custom knife. And, I understand 1000% why he didn't want to let that knife out is his sight. They have a 7 year waiting list if ordering directly, aren't cheap, and are hard to find. So I'm glad not to have it. It's a model 12 little bear Bowie 6" with stag handle. The blade is a hefty ¼" thick. Anyway, I decided to go neodymium magnets instead of a strap for retaining the knife so that there is nothing that can damage anything on the blade or handle. I used three 1"x⅛"x⅛" magnets I had available from some light fixtures that didn't last long, but the magnets are strong as can be. I made sure they will hold his heavy knife by testing the strength of the magnets on my wood chisels that are a bit heavier. Not only is this a first, but it's also the thickest leather I've had to stitch. With the welt, lining, spacer for magnets, weight of the bison, so on and so on..... all the layers it takes, put together and the belt loop folded over it's over ¾" at the thickest point. Amazing thing was it was not nearly as difficult to stitch as some of my holsters at ⅓ the thickness.

-

- knife sheaths

- buck knives

- (and 5 more)

-

pugetgold joined the community

- Yesterday

-

FrankHester started following Is Maine thread too waxy?

-

That's too bad. I wonder why.

-

Looks like you're covered on photos -

-

Moved your post to sewing leather.

-

You need to state if you will ship, where to, who pays. See the marketplace rules here https://leatherworker.net/forum/forum/70-announcements/

-

Yeah - and I called his shop, twice. First time I left a message, second time the call was declined.

-

Is B69 thread thick enough for use attaching bag handles?

AEBL replied to AEBL's topic in Sewing Leather

@MarlinDave, like AlZilla said, for sure, do the math ... size your stitched area for ~ 50% more weight than you figure the maximum weight it should carry (a "safety factor"). @kgg, glad you had backup! I suppose another variable is "shock loading" -

Paul M joined the community

-

I would like you to try a different leather, that i love to tool with. It's from ALD American Leather Direct. Look at their strap leather and order what they call their Golden Strap. i like it better than Herman Oak. i just got some HO from Panhandle Leather and it was horrible! The Golden Strap from ALD is beautiful and they are huge, they are the same size if not bigger than any HO i have gotten. if you get a business account the grade A side is $196! i even applied for a business account after my first order and they refunded me the difference on what it should have been per side. I heard about the side through Jim Linnell on his weekly tool time at 6pmCST on Tuesdays. i wish i was going to the Rocky Mountain Trade Show this weekend but i will just have to wait to do the one in Waco. Paul May Texan Leatherworks

-

All good advise above. The lines in the cut are a give-away that the blade is not as sharp as it needs to be. Instead of the material passing through the blade easily, it meets resistance and will try to go above or bellow the blade as it cuts. Only thing I'd add is that if there's any wear in your feed roller, such that it's out of round or has play on the spindle it turns on, the machine is likely to "eat" the material, especially when doing thinner cuts.

-

There is one on ebay https://ebay.us/m/MZBMPe There are also some Chinese for a fraction of price (24$) that could maybe work. They don't have the sliding wheel on the top. I can do it for 70$ (knee lift) + ca 45$ shipping. But you need to wait at least till Friday when I am back home from a short travel. I need to weight it and check if it is really working.

-

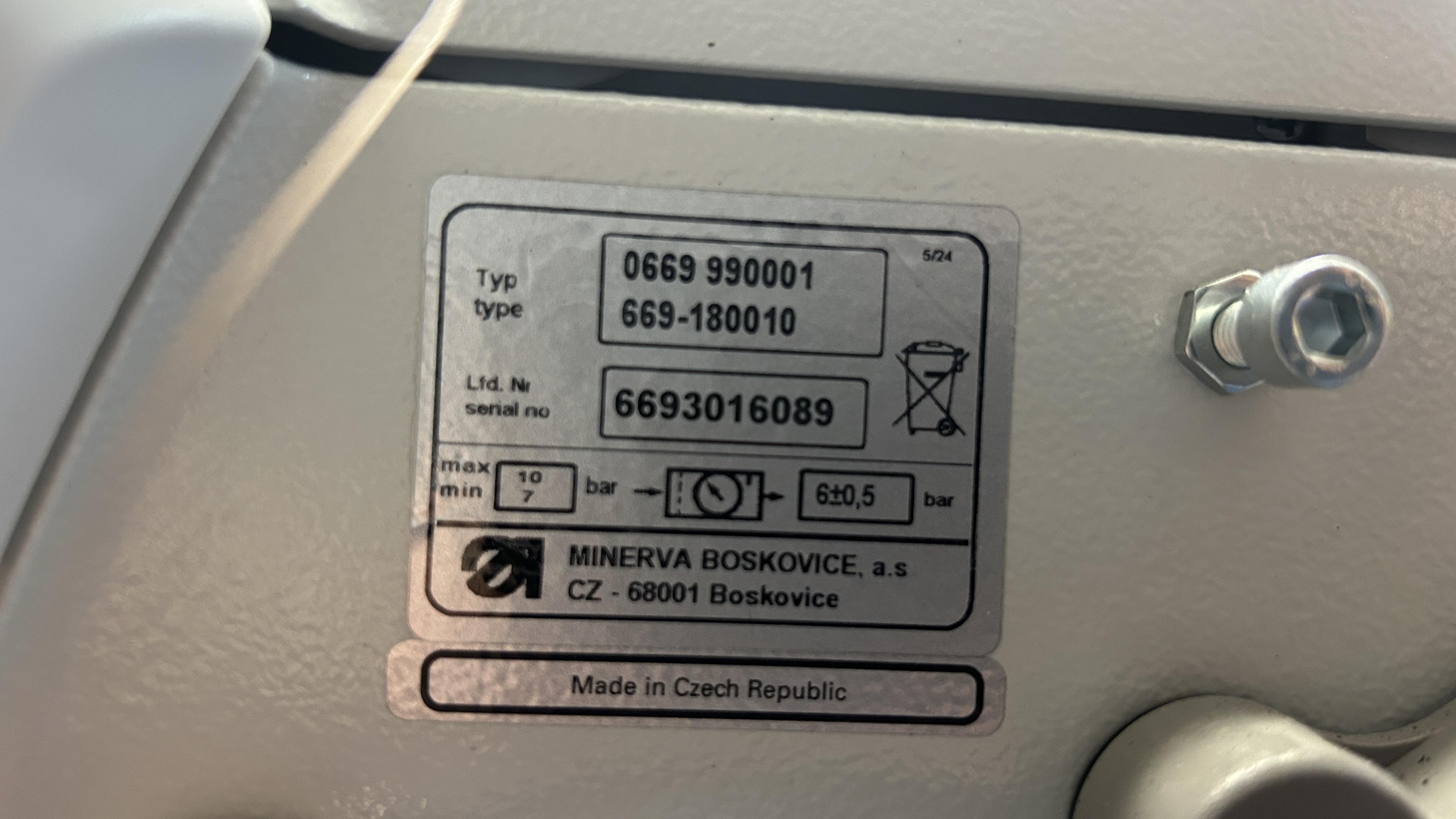

three months ago, I purchased a brand new Adler 669 cylinder arm to using my Shoe Repair shop, wrong move, I actually needed a Post bed. Selling the Adler for $3500 had only. The machine is actually still brand new, altogether I use it for about three hours. if interested, call 978-771-0949. Or contact me through this site.

-

That’s what I’m looking for. I dropped off my machine at the mechanic this morning. He told me he may be able to find one but not sure yet. If you do think of a price, please let me know.

-

Is B69 thread thick enough for use attaching bag handles?

AlZilla replied to AEBL's topic in Sewing Leather

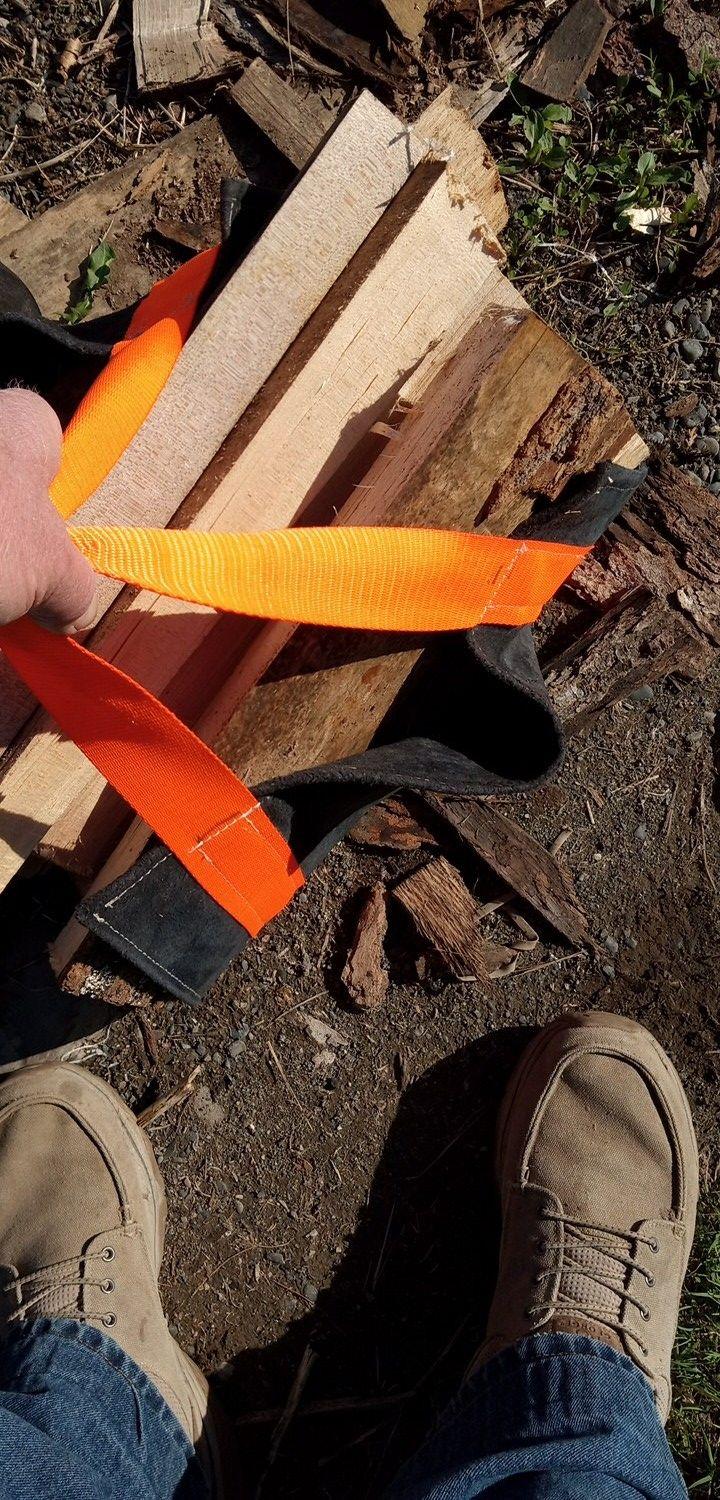

As above, do the math. An X or W pattern helps add stitches, if you need them. I made mine from pig suede. I wrapped webbing all the way around and sewed it with v138. I used maybe 1.75 inch webbing. Essentially, the webbing carries all the weight anyway.

.jpg.cb453e7a76a3acb33397941d6a40355c.jpg)

.jpg.c2e7fca66d9ae5dcd04c5dda041b60d3.jpg)

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)