-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by ConradPark

-

Making a wallet - question about thickness

ConradPark replied to Mujician's topic in How Do I Do That?

In the end of the day, it's down to personal preference. Make do and learn, as they say. I've made and sold wallets for 20+ years and most of them are from 1.8-2mm (5-6oz) veg tan leather, all around. Now, I've found that I like to do wallets from that kind of thickness and i have a customer base that obviously like wallets that reminds them that they didn't get some crap from the pound store. At the same time there are many that would never consider to use a leather wallet unless it was paper thin, regardless of durability issues. Obviously, I'm never going to get them to like my wallets. My suggestion is that you do your wallets with the leather you have, and you will quickly find out what you like and what you want to change. That's more important than what others will tell you (unless they are potential customers), because in the end of the day, you are the one making it - and it is supposed to be fun! So don't over think it, spend more time doing things and you'll pretty soon find a balance between what you like and suits you and what others appreciate (potential customers) or not. Good luck. -

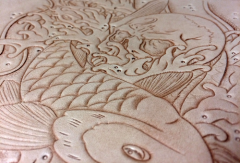

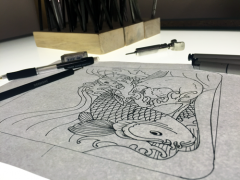

From the album: Tooled Wallets

-

From the album: Tooled Wallets

-

From the album: Tooled Wallets

-

From the album: Tooled Wallets

-

From the album: Tooled Wallets

-

From the album: Tooled Wallets

-

Nice bag, but what weight is the leather? The ones I've seen have been around 2mm but this seems thinner. May I ask where you got the leather from? Have failed to find any reseller here in Europe, and I contacted the tannery but they have currently a minimum order of 50 square meter, a bit more than I currently need. I've seen Buttero a few times but yours seem very smooth, did you burnish the surface? Also, Buttero is a veg tan leather, but on the picture of the handles the leather seems light on the edges, did you paint them instead of burnishing?

-

Been a long time since I contributed on the forum with something that I did myself. However, I had this fun custom order a while back. The last picture is from when the tooling was done, but prior to any coloring. This was a specific request order from the customer so I had little say in the choice of design and coloring, however, I did the final drawing of the design and implemented it on the wallet. Considering everything, I'm still very happy with the end result, and even more importantly, so are the customer. Tooling was done on premium 2mm natural veg tan and hand colored, stained, antiqued and finally lacquered, and the interior is a premium drum dyed, black Italian veg tan in the same thickness, besides from the card pockets that was thinned to around 1.4mm. Saddle stitched (hand stitching) with artificial Sinew thread. I have removed the makers mark and some personal markings from the pictures for the sake of the customer and also because I personally don't want to come off as to use this forum as an advertising place, there are enough people doing that already. The pictures are taken with my smartphone, as my SLR camera had an accident - so apologies for the quality of the pictures. Hope you guys like the wallet and find it inspirational.

- 3 replies

-

- trucker wallet

- long wallet

-

(and 2 more)

Tagged with:

-

"Same factory as leading luxury brands"

ConradPark replied to JanC's topic in Leatherwork Conversation

Could be almost impossible, larger brands often utilities a combination of own manufacturing (that can be both domestic and foreign) and third party manufacturing (that can also be domestic or foreign). When there is a brand that only designs and sell to low cost, it's very likely that it's manufactured in a country with low labour costs. In the case of your example, It's very likely they have their products made in Turkey as they get their leather from there and it would probably be too expensive for them to have it manufactured from the outside of EU unless they do large quantities - I doubt they do. But then again, sometimes smaller brands can be transparent if you just ask them. Smaller brands are often proud about where they produce their goods, take the whole national trend going - like made in the USA or made in UK. But for larger brands this is almost impossible. Take Apple for example. An 'American' icon brand, yet most of their products are assembled in China or Taiwan, with some components that comes from South Korea, and back to the USA again. However, I am happy using Apple products and I'm not from the USA. While I try to support local businesses (UK) out of solidarity, I personally have no problem to buy and use something that has produced in whatever country. If I like something, and think it's worth spending my money on, I'll go for it. What the made in label says, means less to me than the workmanship behind the product. -

The only way to truly get a correct answer is to actually do it. Also, there is no way to judge quality without any pictures. And how much money someone is willing to spend varies, how well you market your stuff, quality of photography, packaging etc. If it's worth your time? Dude, how do you expect other people to answer that for you? Sorry mate, but you need to just start doing your stuff, and you will be amazed how all your questions will answer them self with time as you ACTUALLY implement your ideas. Good luck, and there is nothing that beats hard work.

-

Stitching and carved belt pattern questions

ConradPark replied to PJCustomLeather's topic in How Do I Do That?

A wider belt can create several problems, like difficulty to find fitting hardware, or even to get the belt through the loops on some trousers. Instead, use a photo copier to reduce the size of the pattern 25-30%. While this affects the length as well, it still shouldn't be too much of a problem to either leave it or to 'fill' it out a few inches. -

There are machines that deboss on leather, the pattern are engraved on a metal roll that 'print' the pattern onto the leather surface under pressure. The simplest ones are hand driven and usable only on veg tan leather. The more advanced ones are fully automatic with heated rollers that are able to emboss on chrome tanned and even plastic. While it's impossible to say for sure, it is very likely that this is made with such machinery. Considering that these machines can cost several thousands of dollars and are only available from specialized trade companies (well, you can get small hand driven ones from Tandy), it would be very expensive 'cheap knock offs'. Basically this kind of manufacturing is not available for hobbyist and smaller one man businesses. It only makes sense if you have a larger manufacturing business with turnovers with minimum five figure sums every month.

-

What happened?

ConradPark replied to Ledbeter36's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is what rapid drying does to leather. It's not so much the heat as the moister content or lack of. I grew up with my parents running a shoe manufacture business, and we are talking full blown machine production capable of hundreds of pair a day. There was machines that wet formed the uppers of the shoe by pushing in a plastic or wooden last between the leather and the shoe bottom, and to hurry up the drying process the shoes were then put into giant drying 'ovens' and they where hot! However, they also had steam pumped in to keep a certain moister level to avoid the leather to shrink too fast and dry and crack. And the shoes had to air dry regardless for the end part, too cool down and to 'level' out naturally. And most of the leather used was chromed tanned (that has actually better resistance to this kind of treatment.) Basically, in my experience the quickest way to hurry up the drying at home, is to let it air dry above a warm oil/water radiator or similar and to remove it before it turns too dry and let it air dry for the final part. I always do it this way after tooling leather, to make it ready for coloring in like five to ten minutes, instead of having to wait until next day. -

Sandwiching Zippers Between 2 Layers Of Leather

ConradPark replied to gndy's topic in How Do I Do That?

It's allowed. -

Fenice leather edge paint and similar professional brands are based on synthetic polymers, so they are in a sense a plastic. Most major fashion houses and high end brands use this for their goods. The main reason is that most use chrome tanned leather and this doesn't burnish, but it's not unusual to see veg tan with painted edges too. The reasons for this is mostly down to production, as larger manufacturers rely on machinery, including 'edge paint machines' for their leather goods. Among crafters the use of painting edges often have a bad reputation and many accuse cheap brands covering up low quality leather and vinyl with paint. And while this is not entirely untrue, the fact remains that in some instances there are no alternatives, and done well - it can look amazing. And contrary to general belief, it's actually as much work if not more, to do well - compared to burnishing veg tan. For a long time these professional paints were difficult to get hold of unless you bought it wholesale (there are quite a few threads here about the subject) but Tandy did stock it for a while in 250ml (here in the UK they have unfortunately discontinued it) and in my opinion was one of the few good things they had to offer. And a quite a few smaller online shops offer these and similar brands as well, in small quantities. Like with everything else, it's not magical stuff and takes some practice to master. You do not need any electrical edge creaser, just apply thin layers ( I find it easier to use a cocktail stick and roll on the paint than to use a brush), let it dry and harden in between (at least an hour, preferably longer) sand it with fine (dry) wet sandpaper/ 600-1000 grit, apply another layer, repeat until you're satisfied (in my experience you're good if you can do it with 3 layers), let it harden for 24 hours and rub/polish it with your favorite wax formula. Also, an open bottle of paint is more or less worthless after a year to one and half, as oxygen deteriorate the binding qualities of the paint. If you apply it too thick or are restless and start sanding it too soon, you'll end up with a rubber like goo of a mess. Good Luck, and remember to practice on some scrap first.

-

Well, While I understand that it can be disappointing to see a backside like that, it's not too uncommon - even with quality hides. Anyway, I'm not here to defend or explain why a hide might look like this, rather I'll try to give some options what you can do. One thing is to cut out smaller pieces and have them being split to a thinner thickness - preferable with a band splitter. If you're unlucky to not have a workshop in your area that can offer you that service, another solution is to line your goods with a thinner leather like pigskin suede or calf. That will also have the benefit of making it look a bit more professional! The third option, which is what I always do on the backside of all split leather, is to use Tan Kote. A very underrated thing - and perfect for this. It gives the surface a 'waxy' look and glues all the fuzz down to a slick surface. The trick is to apply it correctly. I use a lint free cloth that I make a small 'ball' with. Then I pour some Tan Kote onto the 'ball' and then transfer that to the flesh/back side of the leather. Always apply in straight strokes in ONE and the same direction. As soon as the transfer of Tan Kote dries out, repeat the process. Don't overlap. Let dry at least for a couple of hours. Do another layer. Done. This have worked for me for more than 20 years and gives a backside looking nice and clean. If you plan to dye the backside, it's preferable to do that first, though. Also - always try out first on some scrap leather. Like with everything, there's no guarantee that you'll succeed the first few times. Good Luck!

-

Need tips on turning veg tan into english bridle leather

ConradPark replied to GoldArmored's topic in How Do I Do That?

-

Need tips on turning veg tan into english bridle leather

ConradPark replied to GoldArmored's topic in How Do I Do That?

The making of real English bridle leather differs from making undyed veg tan - what you call, tooling leather - thus, if you did manage (and I'm not saying it's impossible) to replicate the look by coloring and oiling it by yourself, the end product would still not be the real thing. Why would you even try to do that, it's not far from misleading customers that would trust to buy the real thing. And if you're thinking of saving money, I'm not sure you will have, after buying all the color, oil, wax and putting in the all the time and effort in trying to duplicate something tanneries have done for generations with great skill and traditions. Sorry if you feel I'm stepping on your toes here, but if you're going to sell English bridle, at least be honest to your customers and sell the real thing. Nothing wrong with doing your own coloring and oiling on natural veg tan, but make sure to be transparent about it for your customers. If I build something that would look like a Harley Davidson motorcycle from non Harley parts, it might be a great custom bike but still not a the real thing. If your intention was not to sell it as English bridle, my apologies, it just seemed like that was your intention in your post. Also, your customers will notice the difference sooner or later and that might seriously harm your reputation. -

Use spirit/alcohol based ink instead. There is a graffiti brand called molotov that is great, permanent, uv resistant and cheap. You can buy it as pen (black is perfect for the edges), spray (takes some skill to learn how to use well) or refill bottle (perfect for using with a pad or airbrush for large areas). In my opinion it beats any leather color brand any day. Buy the ink, not the acrylic, though. Seal with Fiebings Acrylic Resolene, even on the edges, after burnishing and coloring and waxing/polishing. In my experience, Resolene benefits from being mixed with water 50/50 and applied thinly with a couple of coats and complete curing/drying in between coats.

- 2 replies

-

- finish

- seal leather

-

(and 3 more)

Tagged with:

-

0.5 tonne press okay for stamping?

ConradPark replied to Artificial Intelligence's topic in Leatherwork Conversation

ebay uk -

Dropship offer in UK - Sell your products

ConradPark replied to jimmisavage's topic in Marketing and Advertising

Just wondering a few things, while I do think the basic idea you've got is fine, I would like to know a bit more in detail what it is that justify your 10% fee? For example, with a site like Etsy and other marketplaces, you get quite a lot of foot traffic and help for only a 3.5% fee. Also, what guarantees do you offer against cancelled orders, refunds and other problems? Do you do any marketing? If so, where? Not On The High Street (UK only) have one of the highest fees of 20%, but they do TV advertising and while they are quite picky about whom they accept, you're basically guaranteed to have a strong start from the beginning thanks to all the effort they do to their sellers. And now Amazon has their handmade section that exposes you to millions of potential customers. There are also so many web hosting sites that offer free or low cost hosting where you can build your own site AND get help with CEO to get google exposure to your own website, Big Cartel is one example of this. Of the little you have explained so far, I have a hard time to see what it is that you offer, that would make anyone to get involved and justify a 10 % fee? Maybe if you offered a couple of months free trial or something? Anyway, don't misunderstand me, I'm not trying to criticize you - I am actually a bit intrigued, but I feel there are a few missing issues that I hope you will answer publicly. After all, this is a good way for you to maybe gather some more serious interest, depending on how you answer. -

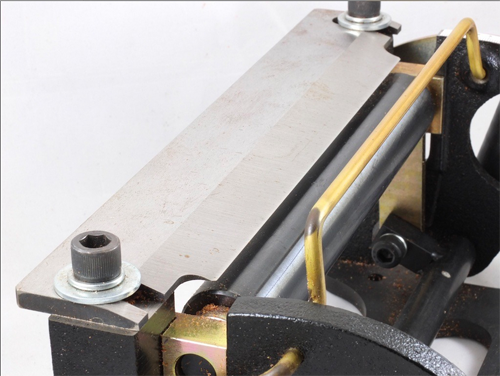

For sale is an 8-inch leather splitter, plus an extra unused spare blade, in very mint condition (pictures of actual splitter). This is a Tandy discontinued model, as they currently only have a 6-inch version to offer. I have had this as a backup splitter, however as I have never had to use it, I have now decided to sell some of my surplus equipment. This model is a clone of an Osborne 84 and have had very little use. It works very well and there are no problems or missing parts. It comes complete with a spare blade that has never been used. The paper scale you can see has arbitrary units and is simply a reference scale when splitting multiple pieces of leather to the same thickness. Price is Sterling £275 plus shipping cost (I'm based in London, UK). Paypal only. I will ship worldwide, please PM me for quote on shipping costs to your county. I will only ship with sign and tracking, due to the nature of the item. First come, first served and no offers, please. The price is a good deal, considering that the current smaller version still retails for more. Because of the different time zones, be aware that reply might be delayed. PM me if you want to buy the splitter so I can provide you with the actual shipping cost. Please see the the images below for more details and don't hesitate to ask any further questions you might have.

-

For sale is an 8-inch leather splitter, plus an extra unused spare blade, in very mint condition (pictures of actual splitter). This is a Tandy discontinued model, as they currently only have a 6-inch version to offer. I have had this as a backup splitter, however as I have never had to use it, I have now decided to sell some of my surplus equipment. This model is a clone of an Osborne 84 and have had very little use. It works very well and there are no problems or missing parts. It comes complete with a spare blade that has never been used. The paper scale you can see has arbitrary units and is simply a reference scale when splitting multiple pieces of leather to the same thickness. Price is Sterling £275 plus shipping cost (I'm based in London, UK). Paypal only. I will ship worldwide, please PM me for quote on shipping costs to your county. I will only ship with sign and tracking, due to the nature of the item. First come, first served and no offers, please. The price is a good deal, considering that the current smaller version still retails for more. Because of the different time zones, be aware that reply might be delayed. PM me if you want to buy the splitter so I can provide you with the actual shipping cost. Please see the the images below for more details and don't hesitate to ask any further questions you might have.