-

Posts

7,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Wizcrafts

-

Regarding going bobbinless, the top thread has to pass both over and under the bobbin and shuttle. In standard operation the bobbin case/shuttle holds the entire bobbin load and only exposes the loose thread on top of the case. The top thread is picked off the eye of the needle, then fed around, and over and under the shuttle. This is how it forms a type 301 lockstitch knot. This works fine when there is a bobbin in play, but fails when the thread is fed from under the bobbin, then through and out the top. In effect, the top thread captures the bottom thread twice; on top and bottom of the shuttle. The results is a chain, not a lockstitch.

-

If one is experiencing dropped stitches, one should remove the throat plate and observe what the heck is going on with the loop. The loop might be too small, or might twist away from the approaching hook. I've had situations where a particular needle and hook timing led to too much of the loop forming on the left side of the eye of the needle. The hook that was approaching on the right had a hard time getting enough thread loop to pick off. Sometimes a smaller needle cures that problem. Other times the check spring needs to be readjusted. Still other times, the needlebar may need to be raised slightly so the forming loop clears a cutaway on the left side of the shuttle (meant to aim the loop towards the hook).

-

I recommend making every adjustment a machine is capable of to obtain the strongest loop possible. This includes trying different settings and tensions on the check spring and fine-tuning the timing of the hook. It must also take into account any unusual twist the thread might have, such as in double dyed black bonded nylon thread. With a maximized loop the needle can be just raising from pickoff time as you lift the feet and turn the material. My Union Lockstitch machine used to drive me crazy by routinely dropping the loop after picking it off the barbed needle, on hard right, but mostly left turns.

-

Help, Tension Issues Consew Sewing Machine

Wizcrafts replied to littlewing6283's topic in Leather Sewing Machines

Possibly. It depends on if the inside foot fits between the toes of you OEM outer foot. This would have to be at all heights, in action. It it fits without binding, but the alternating lift is wrong, adjust the lift via the bolt on the back of the head that feeds the crank that screws into the curved slot. The inside foot is usually timed to meet the top of the feed dog hole either at the same time as the point of the descending needle, or very slightly after. -

Help, Tension Issues Consew Sewing Machine

Wizcrafts replied to littlewing6283's topic in Leather Sewing Machines

I bought a set of presser feet like the ones the OP has. I cannot use the short left toe foot at all, unless I am starting to sew completely on the material and the material is not soft and floppy. The foot is too far back to hold down the leather and causes skipped stitches. If I try to start sewing at the leading end of a belt or strap, the outer foot doesn't even make contact with the leather and there is no feed! It is a design flaw. You can either buy a left toe foot that is long enough to reach the front of the inner foot, or buy a second double toe foot and grind off the right toe. -

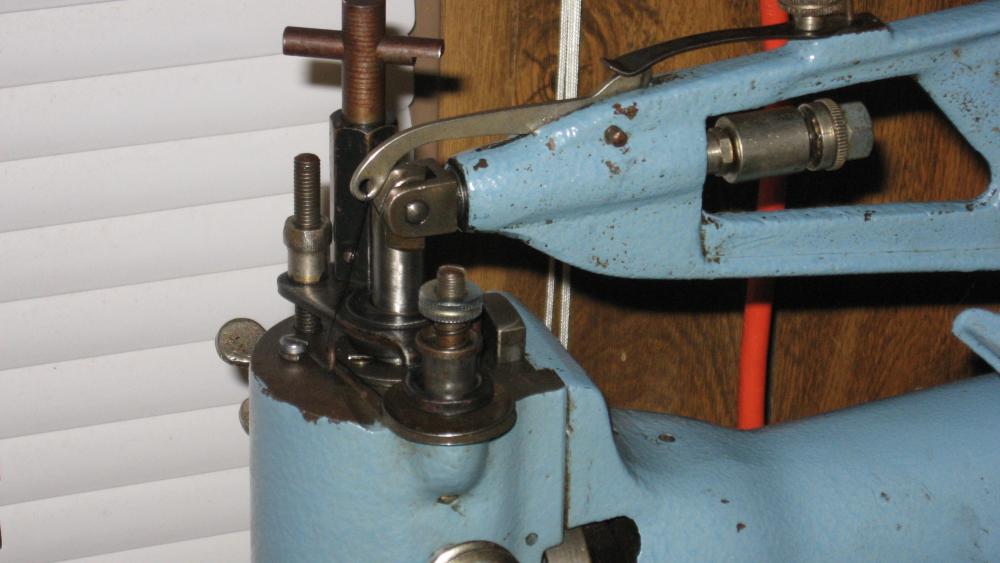

The blue patcher looks just like my 29k172. It is one of the last ones ever made by Singer (mid to late 1970s). I have lots of experience using this machine. Here's what it can and can't do. Sews no more than 1/4 inch compressed thickness. Might manage 5/16" if foot is set to maximum lift. Stitch length will be tiny. Sews chrome tan upper leather. Sews patches onto motorcycle vests and jackets, especially over pockets and sleeves. Great for purse repairs. Can sew fairly close to the toe of a normal flat lace-up shoe. Has an 18" long arm for sewing along boot uppers, or cue stick covers, jacket sleeves, and other cylindrical objects. Can sew in new zippers onto thin leather or cloth jackets Sews light to medium temper veg-tan. Handles thread size 69 through 138 (large bobbin models only). It does best with #69 or #92 bonded thread. The large bobbin holds enough #69 thread to sew a lot of shoes or 10 belts (see last item). The small bobbin models need to have bobbins changed quite often. If using #138 thread it will only sew about 5 belts (large bobbin only) Uses needle system 29x4 and 135x16 (various leather points) and 29x3 and 135x17 (round point). Sews no more than 5 stitches per inch, decreasing with thickness of leather. A worn out drive cam reduces maximum stitch length drastically. If it has the top mounted darning attachment it can sew long stitches manually. This is useful when sewing across closed zipper teeth, where hitting the metal will break the needle. Has a two position throat plate with a large hole on one end (#21, 22 and 23 needles) and a small hole on the other (#20 and under). The needle can be moved sideways as long as the larger needle hole is in place. It sews in any direction, with top feed only. You will have permanent tooth marks on some leathers. Will NOT sew shoe soles Will NOT sew gun holsters Since there are no edge guides, they are not so accurate at sewing belt/strap edges, unless you groove the stitch line first.

-

Are you aware that at least one of our member-dealers, Toledo Industrial Sewing Machines, sells brand new Consew walking foot machines for a little as $995?

-

Every one of our member-dealers sells these needles. They have banner ads on the top of every page. Refresh the page to load a new set of dealer banners. Most have competitive pricing on needles, thread, bobbins, oil and accessories that are used in 441 type machines. In fact, this reminded me to order more system 794 needles from Toledo Industrial Sewing Machines. Ask Bob Kovar about some diamond point needles in #24 and 25. I use them where the usual chisel type S cuts too long of a hole between stitches. The diamond point (actually a triangle cut) gives the thread a longer visual stitch length, top and bottom, and doesn't weaken the trailing edges like an S point might. You can get closer stitches this way.

-

The auction was in Toronto, Canada, not in the USA

-

Yes. The round point are system 7x3 and the leather points are either system 7x4 or 794.

-

Black bonded thread is double dyed making it sometimes act like a coil spring. I had to use Weaver #207 thread to sew a couple dozen rifle slings last Saturday and it kept twisting around posts and guides and even itself. This caused numerous skipped stitches. The Weaver Chestnut brown thread did not have quite as much springiiness. If I find a source of non-coily black bonded thread, I buy more than one spool.

-

Dave4; I know this can be a confusing topic. Sewing machines have so many different designs and capabilities. I started sewing leather in 1984. It started with just a vest, which was a challenges in itself, due to topstitched fringes and thick seams from the 5 ounce leather I used. I tried three different sewing machines before finding the right one. Then I decided to try sewing belts, then other items that pushed the limits of the machines I had. This led to more heavier sewing machines, some of which didn't pan out, despite their size. In fact, I still go after sewing machines when one presents itself as different and is affordable. The old iron Singer sewing machines of yesteryear were built to last a century and then some. I have a rack in from of my leather shop and it has 6 old machines for sale; two of which are aluminum bodied and the rest cast iron. I have rebuilt them and test sew each one with 4-5 ounce leather or suede. One in particular, a 1902 Singer 27, has sewn into 8 ounces of bridle leather with #69 bonded thread. It is a small piece from my scrap drawer and I used it to demo the machine. The customer was amazed, but didn't buy the machine. Go figure. When it comes to golden oldies, here's what I've found. The models with built in motors are to be avoided. They have only the torque left in that pod motor and cannot be ramped up. Overloading them with tough leather makes the motor groan and it starts smelling bad. Models with external motors can be refitted with a 1 or 1.5 amp motor that can punch through leather without bogging down or smoking. The old bullet shuttle 27 types stay in time under load and can sew a little thicker. Almost all these machines max out at 5 stitches to the inch, with most giving only 6 or 7 (a Model 66). None can handle over #69 bonded thread, with some refusing to handle even that. None can sew over 1/4 inch of material effectively. Most are lucky to sew 3/16 inch of cloth. They don't do a good job of transporting leather, except for suede or veg-tan with a rough flesh side. All feed is on the bottom. Domestic sewing machines have fairly weak tension and pressure springs. The pressure spring over the presser foot sometimes has to be cranked down almost all the way to hold down veg-tan leather belts as the needle rises. If the leather lifts with the needle, there are skipped stitches. Increasing the pressure on the foot makes it harder to feed some leathers. People often use a Teflon foot in these situation. Teflon feet are deep top to bottom and take away from the usable sewing clearance. If you forget what the foot is made of and drop it down onto the feed dogs, the teeth leave a lasting impression. The so called walking foot, or even feed attachments are useless on most leathers, other than garment leather. they basically only follow the top layer, without any feed action of their own. They also take away from the clearance under the foot. These are some of the things I have learned about the old domestic sewing machines. They are nice to look at and collectors love them. But, when it comes to sewing leather for a living, they cannot be trusted and cannot be tweaked to exceed their physical limitations. Bottom line: if you are going to sew leather things and get paid, buy a proper leather sewing machine. There are lots of dealers representing our forum, either with banner ads, or simply with their freely givin technical advice. Call them and pose your questions. Most will tell you which machine types will handle your anticipated projects without being at their limits all the time. Some may be too heavy duty for light work and thin thread. There is no all in one sews it all machine that handles from a couple ounces to 3/4 inch, with thread sizes 69 through 415, that doesn't require a lot of readjustment to go between those extremes. Heavy 441 clones are not so good under 6 ounces and may actually eat thin soft leather. Straight stitch industrial machines max out at 1/4 inch or less. Only the heavy duty machines made for upholstery, tents, harness, and webbing are capable of sewing holsters and sheathes, using big needles and thick thread. I hope this helps!

-

A decent condition walking foot machine can usually be found for sale by the owner in the $600 to $800 range. Check your local and nearby Craigslist, under Sewing Machines > Business. But, they are usually upholstery machines with clutch motors and 1:1 pulleys. You will probably have to change to a 2" motor pulley and a 2" shorter v-belt, or buy a new servo motor with a 50mm pulley and matching shorter belt. This will drive your cost up by about $150 or $160. At this point you are better off buying a brand new Consew P-1206RB.

-

If the clones don't improve the design and metals, they will be next to useless. I had to tweak the Boss at my downstate Tandy store last week, to get it to sew. Even then it began binding for no apparent reason. A real tinker's toy.

-

Dave4 asked about the range of thread that machine can handle and tension properly, wondering if it could do #69 through #207. The range is the opposite, going down from #69 bonded thread. No way it can handle anything thicker.

-

Thread gets caught under hook occasionally

Wizcrafts replied to Uwe's topic in Leather Sewing Machines

Uwe; Try re-positioning the slot in the check spring regulator bracket. If that doesn't matter, try lengthening the travel of the spring. -

I corrected my incorrect spelling of your last name, Darren. If you have the bobbins for a 42-5 and can sell them for the price range you mentioned, you'll have buyers on this forum. What woult the International Postage run on items like those? I am referring to the cylindrical bobbins, about an inch long.

-

There is a multi-page Singer 431 owner's manual online, here.

-

Anne Bonny's Locker has been renamed to the owner's actual name: Darren Brosowski - who is alive and well and a frequent commenter on this forum.

-

I just uploaded a 48 page manual for the 42-5 to my server (3.6mb Zip file). I think it is what you all are looking for.

-

I couldn't find a spring for my sliding plate (that covers the bobbin and shuttle area), so I glued earth magnets to its sides. It works as good as the spring loaded original. I use my 42-5 for chaps and similar projects. I've used thread sizes 138, 207 and 277. I think it best to limit it to #24 needles/207 thread. I have enough of those $12 bobbins to preload them with the colors and sizes of thread I use the most. It's currently powered by a 1/3 hp clutch motor, fitted with a 2" pulley. I can feather it to single stitch if I need to. As for replacement parts, I've had no success finding ANY parts, other than bobbins. I'm lucky enough to have gotten lots of leather point needles with the machine, in the correct system 16x64, in sizes from 21 through 25. There is also a pack or two of 16x63 round points in the box. My biggest issue with this machine is its lack of a thread tension release rod. I compensate by hand wheeling back and forth as I pull the work away from the needle. This lets the take-up lever draw thread for me. The spring loaded presser foot does a good job on soft temper leather and the overall feed is positive. Like many of you, I didn't go looking for this machine. It came looking for me and I took it in, like a lost kitty. Now I have a loudly purring, 1926 Singer 42-5. It's neat watching people's faces when I show them the beast.

-

I get 4 to the inch on my 42-5. So, 5 is not standard spec.

-

I think that a one head, 6 needle Melco EMT16 can embroider leather, because Leather is listed in the left sidebar among the items it can sew onto. It sews on hats, baseball caps, jackets and jerseys. An email or phone call to Melco should get an accurate answer. It would be about the cheapest full commercial embroidery machine that I know about.

.jpg.d60258221c476480a6e073a8805645bb.jpg)