-

Posts

320 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BigRiverLeather

-

Emp Dummy

BigRiverLeather replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wow, very interesting. I guess I need to be careful on taking John Ring on his word all of the time. I'm surprised he would say they are the same when he is particular about guns like the Sig P228 and P229 non rail which he has different molds for, and the difference is significantly less between those two and the picture of the EMP/1911. Guess I better get me a duncan mold. -

Air Brush

BigRiverLeather replied to rybord's topic in Gun Holsters, Rifle Slings and Knife Sheathes

See now - LW ROCKS! I pick up so many little helpful tidbits. Though that was an easy one, to pick up the phone, it's still good to know it can be done. Thanks! -

Emp Dummy

BigRiverLeather replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use the 3" micro 1911 from Rings. John claimed the dimensions are identical to the .45s. In fact, I've done several and they have all been for EMPs, none for .45s. My customers love the fit, I've even had repeat orders. If you already have that, I'd say save your money unless you want the sight track. -

Toro 3000 Issues / Questions

BigRiverLeather replied to BigRiverLeather's topic in Leather Sewing Machines

FYI, I talked with David and he advised me that the silever know on top adjusts the presser foot tension. 2 full rotations reduced it some. Also, after a day or so then wet molding, the marks all but dissapear. Thread ends - just cutting them short, pulling through to the bottom when I can. 4 strings when pulling the hoslter out - I need to do this when the takeup arm is fully raised. Problem solved. -

Holster Sewing Machines - Lets Talk

BigRiverLeather replied to olliesrevenge's topic in Leather Sewing Machines

I voted for the Toro 300 ecause that is what I just picked up. One problem I had was the inability to locally see different machines working. That would have been nice. The reason I chose the Toro was based on recommendations from 2, we'll call it three since one was second hand, people. That combined with the small price different between the 3000 and the Boss. I fisrt posted a thread in the holster section about ramping up my fledgling business, whether or not to go full time. I mentioned I might pick up a Boss. Several people advised if going full time to go with a Toro or Cobra. One had mentioned he had gone through 2 or 3 (can't remember which) Boss amchines, that they just did not hold up for him. That combined with the fact that at the time I was looking, used Boss machines at a reasonable price for what I might get in a used machine were not easy to find at all. Being new, I wanted to have someone to call if I had a question or problem, so new seemed best. K-Man from KD holsters highly recommended the Toro. Then I went into my local Tandy store and talked with the owner there who has a western holster business. We started talking sewing machines and hes said he has the Toro, LOVES the machine and spoke very highly of David and the customer service at Artison. He also mentioned Eric at Side Guard Holsters, another local guy to me, just picked up his second Toro, one for brown thread so he would not have to take the time to change. That was my 3rd and second hand recommendation. My previous method was a 4 prong diamond chisel punch and heavy waxed thread. This made for a VERY nice look I was afraid I would lose by going to a machine. I now use a 346/277 combo and am very happy with it. My impressions after making a couple of holsters using 8-9 oz HO, sometimes with a 4oz renforcement and an exotic - Definately speeds up production. What took me an hour to 1.5 hours after getting good at hand stitcing would take 10 minutes total, setup and everything. Having done only a few holsters this far, this should speed up a little with experience. I did not see this thread before purchasing which is good, because it either would have dragged out my decision making process going back and forth between the personally recommended Toto and the aparently hghly regarded Cobra, and it probably would have cost me another $300-$400 by going with the Cobra. One thing I have read about in this thread and now am concerned about is the hesitation in the Toro. Sometimes It will just chatter until I give the pedal a quick bump, then it takes off which I don't like, seems like a bad stitch or accident waiting to happen. Other times it just doesn't move at all. At first I thought it was blowing a fuse or the motor needed resetting, and going through the steps to reset gave me no satisfaction. Then I found if I gave the wheel a little help by hand it would take off, again a little to fast for comfort. My motor speed selector was on low. I had really hoped that I had it on high so this would be fixed. This has been my first real "problem" with the machine so Ill have a good chance to see how Artisan's CS is. To date, David, in my opinion, has been as good or better than I could have asked for. He has been very prompt with his replies on questions, called me when I sent an email on some operating questions which I also gained some good technique knowledge from him at that time. He then followed up with an email a day or two later to make sure the things we discussed were working out. I was impressed by that. I'll be calling him tomorrow to ask about the hesitation. I know the OP has already made his decision, but I thought I would post this for future readers trying to make this same decision. -

I made my first production holster last night with my Toro 3000. Everything went pretty good, though I have these marks in my leather. I'm not sure if I can smooth them out when I wet form or if they will still show through. Is there an adjustment I can make to reduce/eliminate these without comprimising anything else? I ground off the groover on the bottom of the needle guide thingy. I can see the that was a good move. Here are pictures of the marks - The other question I have is my thread ends. When I start my stitching, should I be backstitching if I won't be going back over that spot at a later time? What do ya'll do with the top thread? I tried poking it down with an awl but that just cut my thread in the stitch I was trying to poke it down through. At the end I've been back stitching. I hope this is proper. It sure does not seem as secure as when I was saddle stitching by hand then backstitching. OF course with that, my starting stitches were never an issue. When I am at the end of a run I lift the presser (I try to do this when the take up lever is up all the way) and sometimes it will just have the top and bottom thread and other times it will have 4 threads, basically a loop or whatever. This seems odd, but I guess I like it better when this happens because when I cut my thread, I can pull the one piece out and it leaves both ends of my thread on the bottom side, eliminating the need for me to do something with the top thread. I've just been cutting it off close, but there has to be a better way, isn't there?

-

Magazine Pouch

BigRiverLeather replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I'm going to do some more double mag pouches tonight. I offer three basic styles - pancake - I put tension screws on this one, not sure if it is worth the effort or not, but for $10, I'll do anything Here is one for a G30 .45 mag HUGE, but he was happy. This is where I decided al of my mag carriers would have heavier leather on the back The back Double snap with a snap loop on each side and a belt loop with the loop behind the mag pouch. One improvement I am going to make (at least I hope it is) is to use a heavier 8-9 oz leather on the back and 6-7 on the front. That way when I mold it the back should not give as much for the molding keeping the back flatter. I also cant the front mag forward for easier access. -

-

-

My First Sheath

BigRiverLeather replied to MHolzer's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Ok, who here has not facepalmed themselves and said these axact words? NOBODY, that's who! Nice Sheath. Love Chocolate Cherry. Chocolate is a great marketing term. I buy brown sharkskin, but when I sell it it is "Chocolate Sharkskin" -

That sounds easy enough to figure out. I'll take a look at it tonight. Thanks!

-

Just put in my first stitches with my Toro 3000 last night so I am following this close. I wondered how I was going to take care of those grooves. Somebody had mentioned grinding something off on an earlier post I made when I ordered my machine. Would it be to much of a bother to take a picture of what you ground off of the presser foot? Using the double foot sounds like a good idea. I also use the feet as a guide when stitching. I pick a reference point on the front of the presser foot and that is where my stitch line should be. I think of it as kind of like driving a car, looking ahead rather than looking at the hood ornament. I think if I tried to watch the needle t make sure I was on track, I would end up with not-so-straight stitch lines. - Oops, sorry for the hijack.

-

PHR Pocket Holster Revolver 007.jpg

BigRiverLeather posted a gallery image in Our Leatherwork Galleries

From the album: My holsters

© © leatherworker.net

-

PHR Pocket Holster Revolver 005.jpg

BigRiverLeather posted a gallery image in Our Leatherwork Galleries

From the album: My holsters

© © leatherworker.net

-

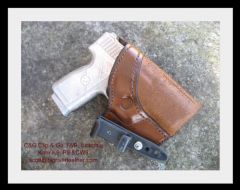

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

-

HRO High Ride OWB w. Sharkskin trimmed reinforcement

BigRiverLeather posted a gallery image in Our Leatherwork Galleries

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

-

From the album: My holsters

© © leatherworker.net

.jpg.d60258221c476480a6e073a8805645bb.jpg)