-

Posts

895 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by billymac814

-

Cowboy 4500+ Consew 206RB-5 +Claes 20(Central PA)

billymac814 replied to billymac814's topic in Old/Sold

I made a new post to add that info and lowered the prices some but now I can't figure out how to delete this one. -

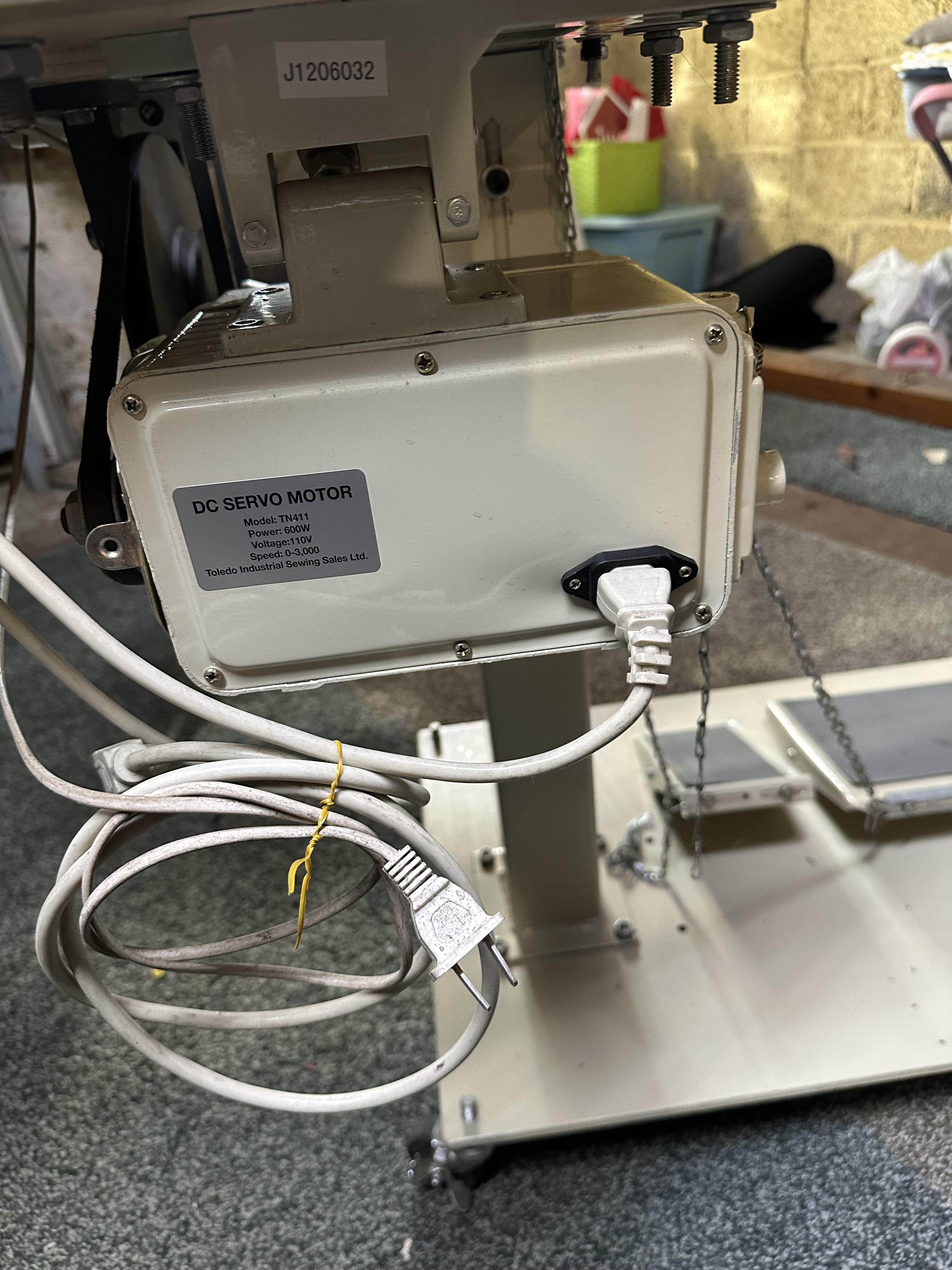

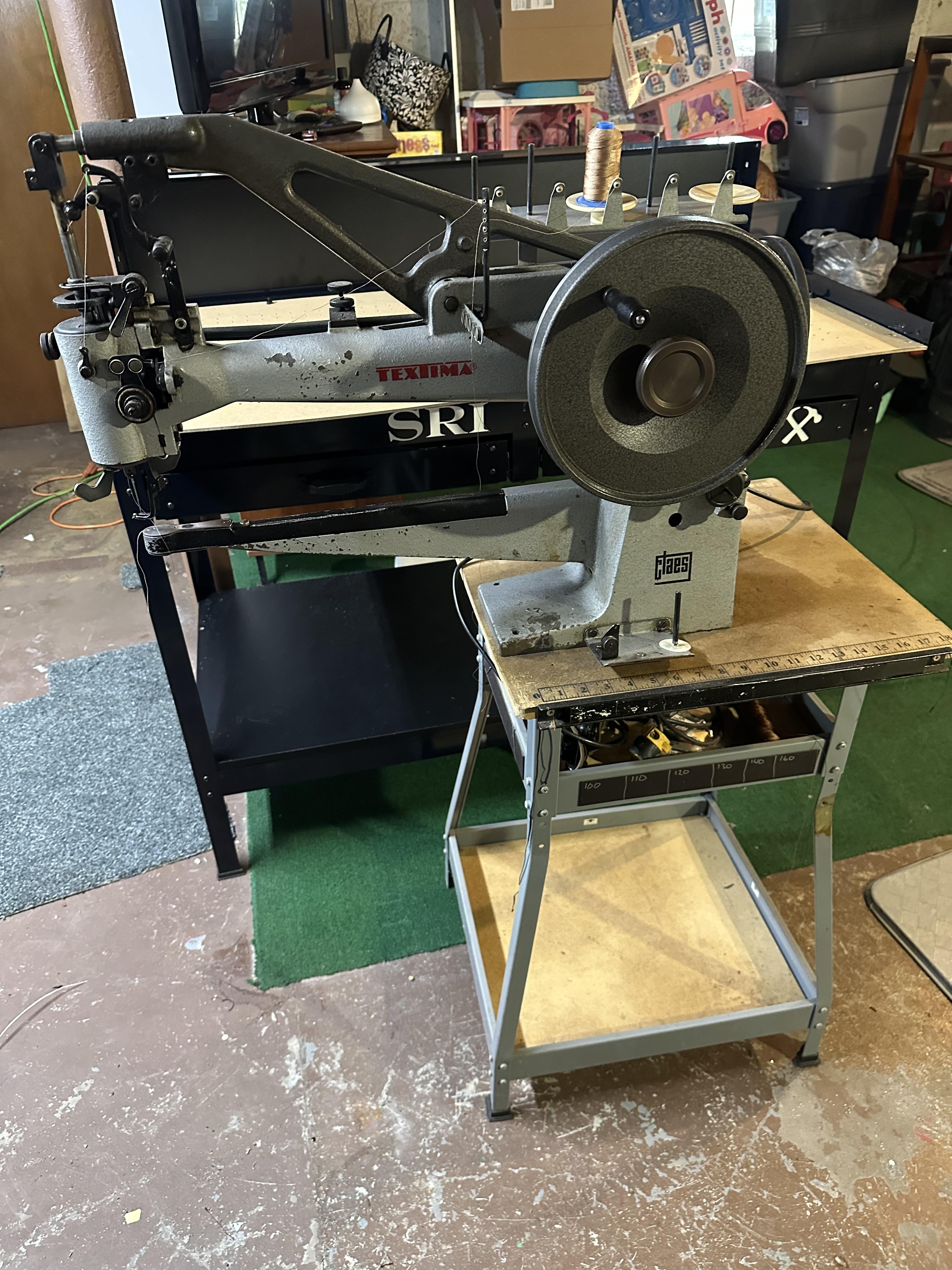

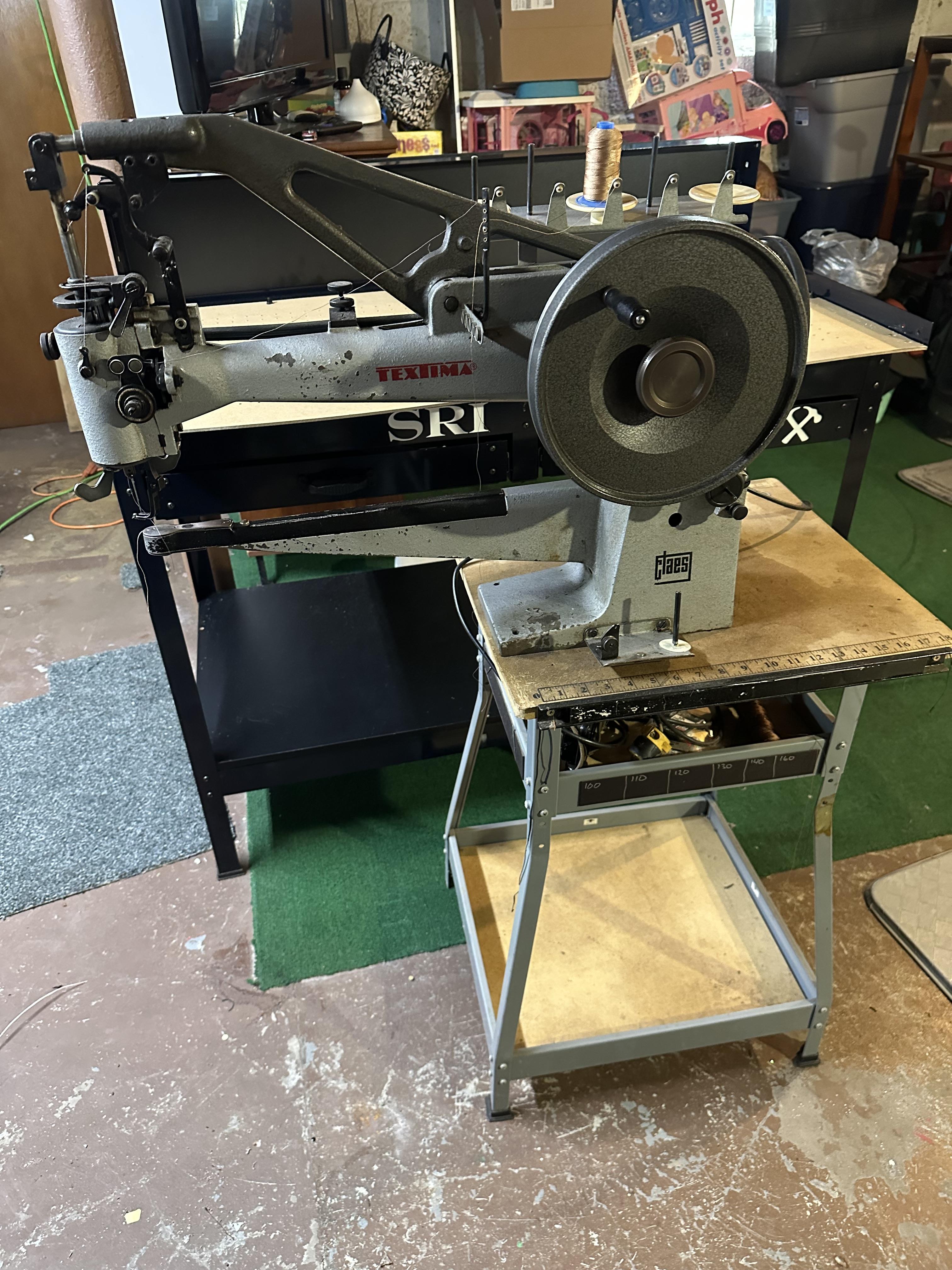

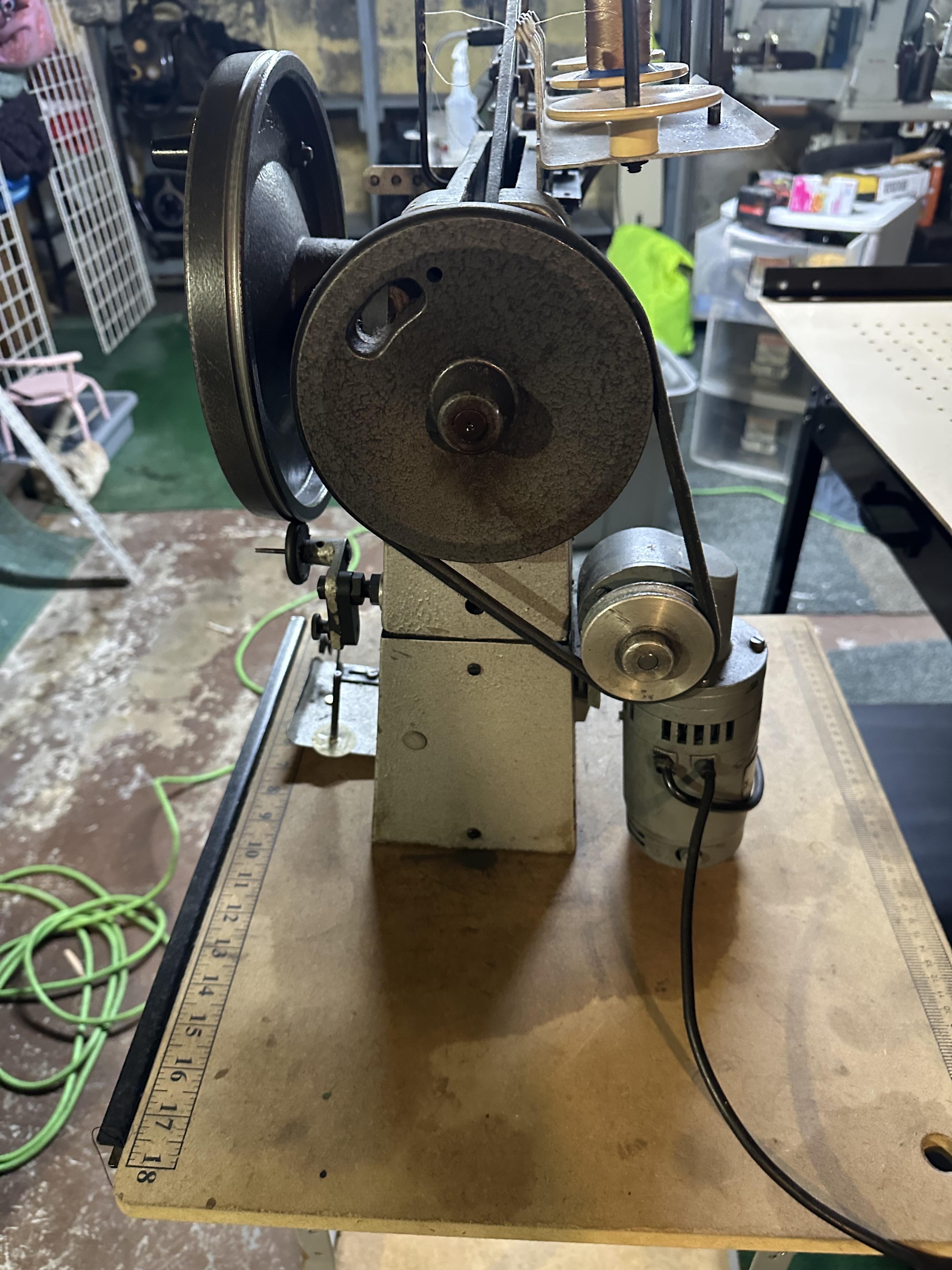

Hello, I have a few machines I’m ready to part with. Cowboy 4500, comes with the whole accessory package with the table and a bunch of feet, lots of extra bobbins and I have thread that’ll go with it in white, black, brown, red etc. also plenty of needles. Has the gear reduction and DC servo motor. Hasn’t been used all that much. New price is about 3400 w/acc package. $1800.00 Consew 206-RB-5. With Servo motor, several feet sets, bobbin, some thread. Thread stand(not pictured). Also not really a ton of usage, table is stained a bit from dye and cement, would probably clean up with some thinner. New price is 1795.00. $800 Last one I’m still debating on letting it go. It’s a Textima patcher which is a rebranded Claes 20. It’s got the good gear reduction motor, I also have 5 extra shuttles which are crazy expensive. Currently mounted to a rather cheap stand but I also have a treadle base for it. New ones are close to 7k. $2000 I also have a Skiver machine I’m going to post in the other section. It’s a dual feed bell sliver w/servo from Toledo Machine, not sure what the new price is on that but I’ll take $600.00 I’d certainly prefer this to be an in person pickup transaction but if you want to pay for freight I do work at a warehouse and have the ability to have them shipped LTL. But there’s nothing better than a road trip to pick up a machine, I traveled all over to pick these up(other than the Consew which I had Freighted in. Zip code is 16602.

-

Cowboy 4500+ Consew 206RB-5 +Claes 20(Central PA)

billymac814 replied to billymac814's topic in Old/Sold

I can’t seem to edit the post on my phone. I’ll try from a computer tomorrow. I’d prefer not to ship but I will if someone wants to pay for it, any of these will have to go LTL, I do work in a warehouse so I can accommodate palletizing any of them. -

Hello, I have a few machines I’m ready to part with. Cowboy 4500, comes with the whole accessory package with the table and a bunch of feet, lots of extra bobbins and I have thread that’ll go with it in white, black, brown, red etc. also plenty of needles. Has the gear reduction and DC servo motor. Hasn’t been used all that much. New price is about 3400 w/acc package. $1900.00 Consew 206-RB-5. With Servo motor, several feet sets, bobbin, some thread. Thread stand(not pictured). Also not really a ton of usage, table is stained a bit from dye and cement, would probably clean up with some thinner. New price is 1795.00. $950 Last one I’m still debating on letting it go. It’s a Textima patcher which is a rebranded Claes 20. It’s got the good gear reduction motor, I also have 5 extra shuttles which are crazy expensive. Currently mounted to a rather cheap stand but I also have a treadle base for it. New ones are close to 7k. $2300 I also have a Skiver machine I’m going to post in the other section. It’s a dual feed bell sliver w/servo from Toledo Machine, not sure what the new price is on that but I’ll take $600.00 Located in Altoona Pa.

-

Yea I originally found them on eBay and they were in the 180+ range but I figured I'd ask bob to see if he had them since it was a Cowboy and he did and it was even a bit cheaper. They are very simple machines and it all comes down to how sharp it is, if its sharp it'll work great, if its not it won't. If you have to really yank on the work your blade isn't sharp.

-

You got a heck of a deal on that for 40 bucks. I definitely would sharpen the blade first, mine was barely useable when I got it, they need to be really really sharp to work good, that applies to any splitter. Lap skiving is just skiving thick to thin, like if you were going to skive the end of a strap, you start off at the thickness of the belt and taper it out. That is really all I use this cowboy splitter for, if I need to split anything I prefer the crank splitter. I'd like to get a wider one sometime soon

-

Please Help Identify This Antique Sewing Machine

billymac814 replied to brahdaa's topic in Leather Sewing Machines

Yea it would definitely be ashame to scrap this machine. Where are you located? I would relieve you of it for the right price assuming you're not too far. -

Where To Find Bunk Wheels?

billymac814 replied to billymac814's topic in Shoes, Boots, Sandals and Moccassins

I found the picture of a bunking wheel. -

Where To Find Bunk Wheels?

billymac814 replied to billymac814's topic in Shoes, Boots, Sandals and Moccassins

I couldn't find a picture of the bunk wheel but here's a picture of the impression one makes though there are various designs. Also contacting the big manufacturers is a good suggestion but I believe they use a machine to do it which isn't feasible for me. I've asked the guy who resoled this shoe and he told me about that UK company but they are the ones who haven't got back to me yet. I'm going to keep trying though. -

Where To Find Bunk Wheels?

billymac814 replied to billymac814's topic in Shoes, Boots, Sandals and Moccassins

Thanks for the links. I have fudge wheels but they are normally used on the welt not the sole. The bunk wheel is a bit different and normally have a type of edge guide on them. I suppose I'll have to keep trying to get a hold of that one company and see if they ever respond. I have been watching Bruce Johnson's site for one for a while now but none has come up that I've seen. Ill see if I can find a picture of one, I use to have one. -

Does anyone know of a place I can buy a bunk wheel and handle to put designs on shoe soles? I've only found one place that makes them and they are in the UK and they haven't responded to my emails. I think their name is Artford or something like that. Part of the problem I think I'm having is when you google search bunk wheel it brings up a lot of trailer stuff and if I add shoe repair or shoe making I don't get much. I'd appreciate the help, used is fine too if its useable.

-

Contact if you have one or know where I can find one. These put the designs along the bottom of a leather sole right outside of the stitching.

-

I do a lot of repairs on this style of belts where they come un done. All 4 stitches are done with one strand of thread. Make your first stitch then go between the straps and do the next, then on a diagonal to the next and then across to the last one. If you leave the ends long you can tie them off in between the straps and glue the knot.

-

If you ever come to Altoona and don't want a ton for it let me know

-

That is a cool stand, would get in the way though if you're sewing luggage or anything. If you ever want to have your go at another patcher Rick I have a 29k-58 that I'd sell. It's in good condition and would be better than a 29-4. It was my back up but now with the Claes I got I use my Adler as a backup and I really don't need 3. I have a 29-4 as decoration too, they look cool!

-

What are you going to do with them? They are finicky machines that have no throat to speak of so they are only foot for soles, you might get away sewing a belt on them but it wouldn't be my first choice. I have 2 K models. The g model is better than the F and the K better than the G and the L better than the K. They don't sell for very much because there's very little market for them these days. How much is he asking? What's the guy using to see soles on if the one is missing parts and he only used the other one once? What model of McKay does he have? If its a 296 or other chain stitch model there's not much beside shoe repair you'd want to use it for. If its a lock stitch I would get it and keep or sell it. I'd be interested in a lock stitch if it is one and you get it and want to sell it and are not too far away! Lot of IFS there huh?

-

How are they different? Could be dealer preferences maybe. The cowboy shoes to go a full loop around the second disk but I used mine for a long time with just a half loop, it made pulling thread out a lot easier and worked fine. I wouldn't over think it, thread it up and if it works good then leave it alone.

-

What's The Deal With Rifle Slings For Weddings?

billymac814 replied to Chief31794's topic in Leatherwork Conversation

I just recently had someone wanting rifle slings for his wedding, he wanted dear heads on them too just like that. And then I told him how much 12 would be.............. -

It wasn't much work for me on my setup. I'd do a little more than a stropping, start with some fine sandpaper and then the strop and they should be good to go. I actually really like mine, the blade is much finer on them than those really heavy thick ones. When I use my heavy Osborne strap end punches they are so thick and the bevel is so steep it creates an angled cut, that doesn't happen with these ones. They are well worth the price. Your great grand kids may not end up with them but if you take care of them they should last a long time.

-

I'd also like to get the little wonder for rivets and things.

-

If you're only setting the one side and using a screw on the other it'll be perfect for that, if you're doing both it would be nice to have two of them if you're setting a lot of them. Some day I'm going to get a second one.

-

Karina, I have a 1" belt sander that I have set up for sharpening with really fine belts that for up to 5 micron and then a leather belt filled with compound to polish them up. Now that they are sharp they cut easier than some of my better ones because the cutting surface is thinner so it goes through with less resistance. Just make sure you're only cutting leather or other soft materials and have a good cutting surface under them and they will do fine, I cut a belt that had some wire crap on it, I thought it was plastic at first but it wasn't, it nicked the blade up a bit. I'm still happy with mine though for the price, I'm still thinking about the pointed ones but they just don't look like a normal English point.

-

I did mine like Dwight.