Depending on what size you need, duckcreektraders makes 2 different sizes of an emboss plate with the Masonic Emblem.

duckcreektraders has an auction site on ebay and they rotate their emboss items on a regular basis. The Masonic Emblem is not up for auction

right now but you can also go to their website at bunkhousetools.com and contact them about buying any items there... tiptoncompany@gmail.com

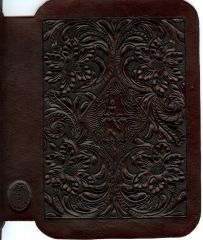

Masonic & Shriner Emboss Plates Pr 1 1/8" & 1"Tall

This is what it says about this plate

The Masonic plate is 1 1/8" tall and the Shriner is 1" tall and are made of a high impact fiberglass reinforced polyurethane. We originally started making these plates to use on short runs where we only needed a few hundred impressions BUT we soon discovered that they were outlasting any of the plates made of printers metal and have much greater detail than most cast metal plates.

The samples were made using a 12 ton hydraulic shop press which should be sufficient for plates of this size or even slightly larger.

These plates are not hammer stamps and should be pressed in using a small press such as the arbor press available from such places as Harbor Freight for under $50 or you could use the Tandy/Leather Factory Imprinter. If you're careful and use a light pressure you could use a hydraulic press, clicker press, or a shop press like we do but the pressure plate should cover the entire top of the plate or if you are using a ram press a heavy piece of flat steel sufficient to cover the entire top of the emboss plate will be necessary.

For more information about the polyurethane embossing plates and their full warranty please visit our website bunkhousetools.com

and

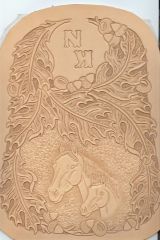

Masonic Emblem Leather Emboss Plate 2 3/8"x2 3/8"

This is what it says about this plate

This plate measures 2 3/8" by 2 3/8" and is made of a high impact fiberglass reinforced polyurethane. We originally started making these plates to use on short runs where we only needed a few hundred impressions BUT we soon discovered that they were outlasting any of the plates made of printers metal and have much greater detail than most cast metal plates.

The samples were made using a 12 ton hydraulic shop press which should be sufficient for plates of this size or even slightly larger.

This plate is not a hammer stamp and should be pressed in using a hydraulic press, clicker press, or a shop press like we do but the pressure plate should cover the entire top of the plate or if you are using a ram press a heavy piece of flat steel sufficient to cover the entire top of the emboss plate will be necessary.

For more information about the polyurethane embossing plates and their full warranty please visit our website bunkhousetools.com

I Hope this helps