-

Posts

5,823 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Is this a factory speed reducer?

Constabulary replied to hemiyota's topic in Leather Sewing Machines

yes it reduces speed BUT it is also a clutch system for a permanent running motor. -

Help wanted to get my Pfaff 26 running!

Constabulary replied to ben27's topic in Leather Sewing Machines

The number is not correct - when I google it it comes up with "Gewindestift" which is a screw. https://www.bischof-naehmaschinen.de/products/91-001-109-15-gewindestift the parts number of the complete needle clamp is 91-006 770-92. I have several needle clamps but I´m not sure which could work. I´ll take a look of what I have.... BTW - there should be no additional tensioner above the main tension unit there should be just a 3 hole thread guide or similar thread guide. -

yes, there is a short pin on the underside of the swing plate that goes into the slot in the feed dog and the moving feed dog governs the swing plated. It engages with nothing. You can put a screw driver in the slot and with a little twist you can widen the slot a little bit so you have more friction between the spindle and the inside of the drive shaft and that IMO is for holding the spindle in place otherwise it could probably move and alter the stitch length. That what I think. 😉

-

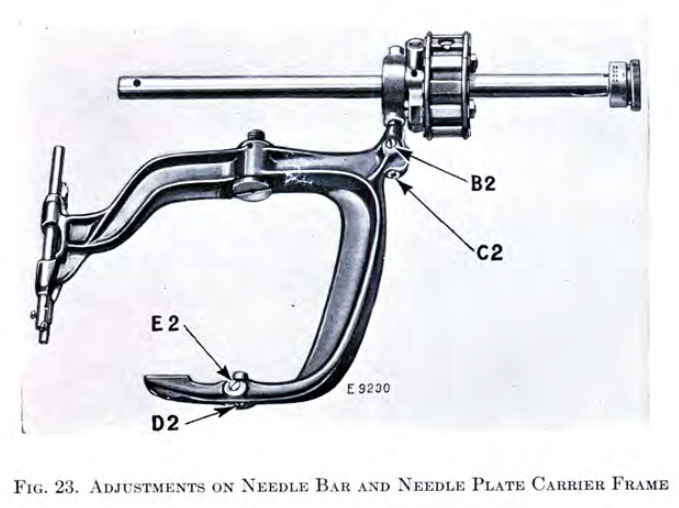

real triple feed but feed dog goes back and forth only on 108w cylinder machines. But a different triple feed system compared with f.i. 111w or 153w. Extract from the 108w manual: This is my 108w20 binding edge of a WWII radio back pad. https://www.youtube.com/watch?v=oY5KjWLJREo Regarding SV machines:

-

108w20: Total length from inside of the knob to spindle tip is approx 116mm and the machined tip is approx 13.23mm. But I´m not a machinist - the measures are close but probably but not 100% correct. EDIT: cheapest new hook I found was on Amazon: https://www.amazon.com/460243-HSH-8-20-DURKOPP-Binding-Machine/dp/B0F7K6LCRD

-

here: 108w on top and 111 below - tip shape is different but I think you can machine a 111 spindle to make it work for the 108w. The knobs seem to be the same. So I think this spindle is a good candidate for reworking https://www.ronsew.com/feed-regulating-spindle-224122-for-singer-112w115/ But in the end decision is yours - I only can give "part hints".

-

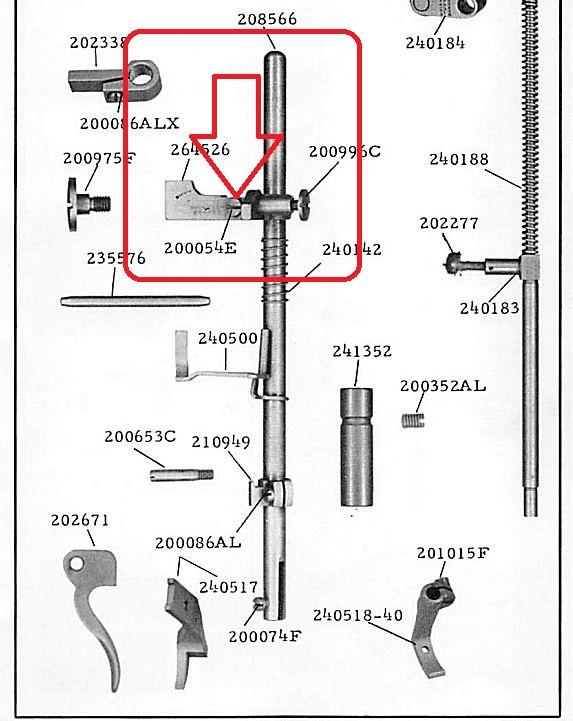

I have a 111 feed spindle somewhere so I can compare the length and tip shape with my 108w20 machine.... stay tuned EDIT: Top: 111 feed spindle (224122 on spindle shaft) Center: 107w feed spindle Bottom: 108w feed spindle (208540 on spindle shaft)

-

you still can find some 108w / 108K parts f.i. at college sewing in the UK. But you have to enter the parts number or "search word" for certain parts to find them cause they do not have all the "108 parts" listed in the right machine section. https://www.college-sewing.co.uk/catalogsearch/result/index/?cat=9&q=108w https://www.college-sewing.co.uk/catalogsearch/result/index/?cat=9&q=108k They have the feed dog that can govern the binder attachment plate: https://www.college-sewing.co.uk/224704c-feed-dog-singer-108w.html and the swinging attachment plate: https://www.college-sewing.co.uk/224738-binder-swing-base-singer-108w.html Certain Singer feed regulating spindles also can still be found but they most likely need a modification in length (at least) and the stitch length number on the knob may not match but you at least can "get something". https://parts.jacksew.com/feed-reg-spindle-generic-202310/ https://www.ronsew.com/feed-regulating-spindle-224122-for-singer-112w115/

-

Threading industrial sewing machines is basically the same. If your manual is bad look for a manual for similar machines with a similar thread tension unit. It´s not crazy different - really. Once you understood the threading you basically can thread all machines. The problem also could be the needle hook timing.

-

I have a 212 (112 predecessor) and I never use left twist thread (IMO that only is necessary for decorative reasons on visible seams - if wanted) and I would not recommend any bonded thread at all. I mainly sew heavy canvas. Polyester or Poly-Cotton thread is what IMO works best. Look for Aman SERAFIL for leather or for Jeans look for Aman RASANT or SABA ( I prefer RASANT). Look for fine burs or worn in groves in your thread path and the hook and polish them. Also check the needle hook distance and needle height. The needle could be a tad to high.

-

Singer 29-4 and Adler 30-1 & Kunpeng Feed Motion Rebuild

Constabulary replied to Ole South's topic in Leather Sewing Machines

as far as I can tell the OEM Singer hinge screws work for the new Chinese made BCL´s but Adler 30´s have different hinge screws (different threading). But you probably have to rework the "ring" of the new BCL to make it work for older 29K´s (older than 29K71 and the like) I did that some years ago with a 29K1- 6 replies

-

- 29-4

- adler 30-1

-

(and 1 more)

Tagged with:

-

Singer 112W 115 Knee lifter installation

Constabulary replied to DMH's topic in Leather Sewing Machines

-

here is a 112w manual but the machine in the manual has a different stitch length mechanism everything else should be the same. Have you threaded both needle from the correct? 112W139-inst.pdf

- 16 replies

-

- singer 112w

- double needle

-

(and 1 more)

Tagged with:

-

Parts for Singer IIIw155 - which "List of Parts" to use???

Constabulary replied to LMP's topic in Leather Sewing Machines

its actually 111w155 - I doubt there is a mechanical difference, maybe its a different plating on the metal parts (chrome vs nickel or vs blueing or something) either of the parts will work, I´m very sure about that. -

I may have an original one - will check in the days to come.

-

I´d say this new fancy Pfaff machine range is not wide spread already. I doubt there is much experience with this type of machine yet. But why should a top class manufacturer like Pfaff have needle bar issues? Well, you never know but I seriously doubt this cause they for sure have experience from the older models and why should a simple part like a needle bar cause issues? If there was / is a known issue then your Pfaff dealer should know about it and should provide a replacement.

-

Adler 20 And Singer 7 are "quite equal" if that helps... A modern variant of the Singer 7 is the SEIKO SLH-2B (kind of) https://www.college-sewing.co.uk/parts-by-machine/seiko-sewing-machine-parts/seiko-slh-2b-2b-1-2b-fh1-parts.html?p=2

-

Measuring Screws for Replacement

Constabulary replied to friquant's topic in Leather Sewing Machines

But you can print it out 😆 may take a few moments... 😉 -

what parts do you have?

-

Measuring Screws for Replacement

Constabulary replied to friquant's topic in Leather Sewing Machines

thanks, did not know what to look for 😉 -

Measuring Screws for Replacement

Constabulary replied to friquant's topic in Leather Sewing Machines

Posting an AliExpress link may help 😉 -

Try the "tension release disc" from the old tensioner (the one with he small bar across the center hole) - just a guess. Looks like this one: https://armastore.eu/32572-singer-tension-release-disk

-

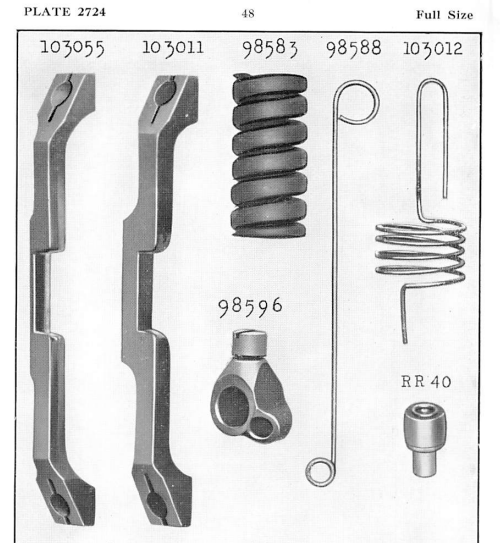

Download for a 133K manual but not exactly for the 133K13 but it may help: https://leatherworker.net/forum/topic/56667-singer-133k-information-wanted/page/6/#findComment-546077 the 2 parts on the left are positioning fingers and you notice the gap, right?