-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

new SD28 / 308 parts are made of "unobtainium" those who have parts usually keep them except they rip apart worn / broken machines. if it was me I´d tried to look up "cheap" toothed feet for top feed machines and see if I can cut and weld the toothed end. maybe: https://de.aliexpress.com/item/32861132738.html https://de.aliexpress.com/item/1005010121787509.html https://de.aliexpress.com/item/1005009251866963.html just a wild idea.... 😉

-

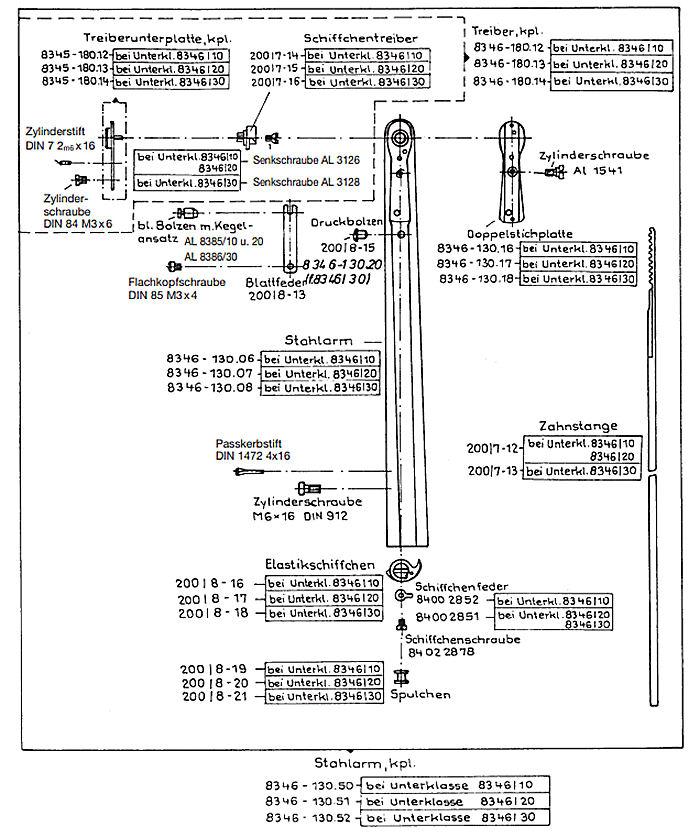

Yes, its a 8346-20 medium hook machine. Top threading seems to be okay but indeed, the "wedges" don´t belong to the machine (check the parts list - see picture below) and are probably part of the problem. I assume when the top tread goes around the hook the thread keeps handing on the wedges - somehow (maybe not but they don´t belong there anyway). Hard to tell what the guy 5 years ago did with the machine. I only can guess what he tried to achieve with the wedges. 1.) Either he tried to "rise" the hook a bit to eliminate a timing issue (Needle bar to high so he tried to bring the hook higher 🤨 or 2.) he tried to compensate wear but I doubt the machine can we worn that much already. So I assume its 1.) What I would do is removing the wedges and lower the needle bar a little bit. Some years ago I translated a 8346 mechanics manual from German to English for one of our members. I´ll check if I can find it and send you the file. It includes all values for timing and how to replace worn shuttle drivers and set the needle bar correctly and so forth. Thats the best I can do from the distance.

-

well they are not all the same, thats why I asked for the model - CLAES has a long history and made patcher machine for many decades. Beside the even older "COLIBRI" and "Patent Elastic" machines they had the Model 201, RPX, 200, 8345 and 8346 - I assume you have the latest 8346, right? Just from the picture I would say you have a tension problem but no timing problem. Can you post pictures of how you have threaded the machines? I assume a loss of top tension for what ever reason.

-

Singer 112W 115 Knee lifter installation

Constabulary replied to DMH's topic in Leather Sewing Machines

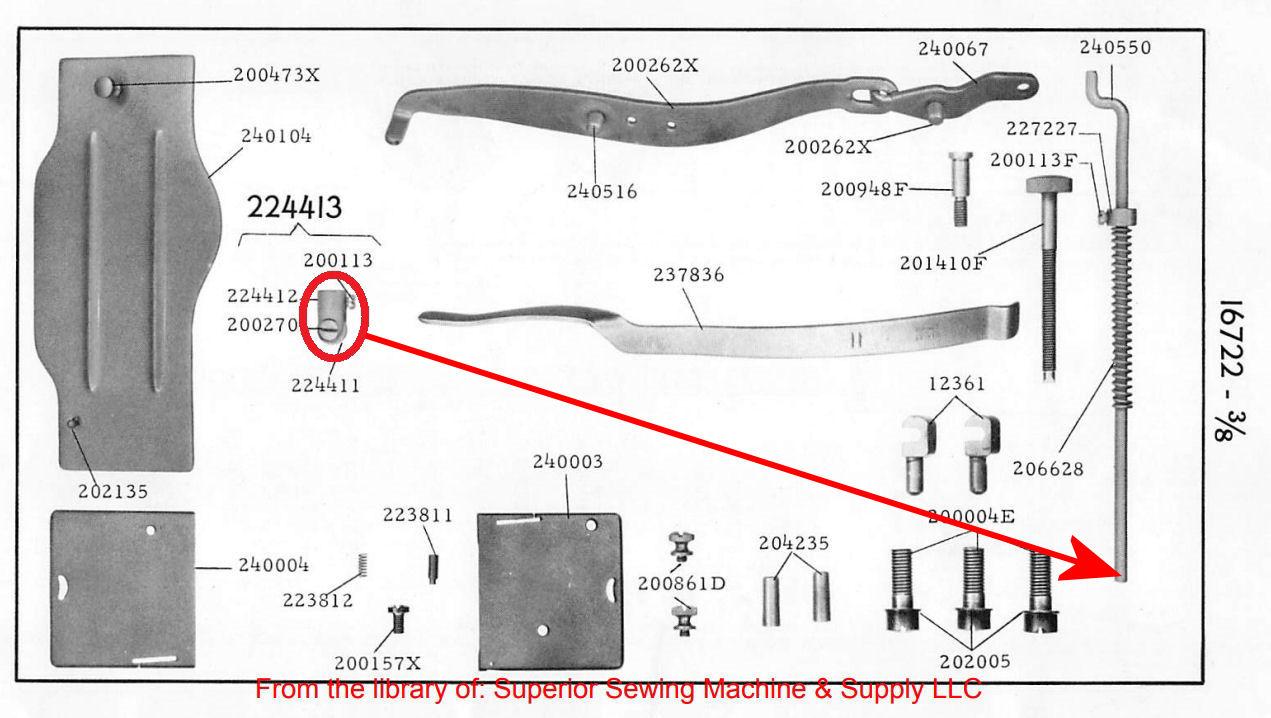

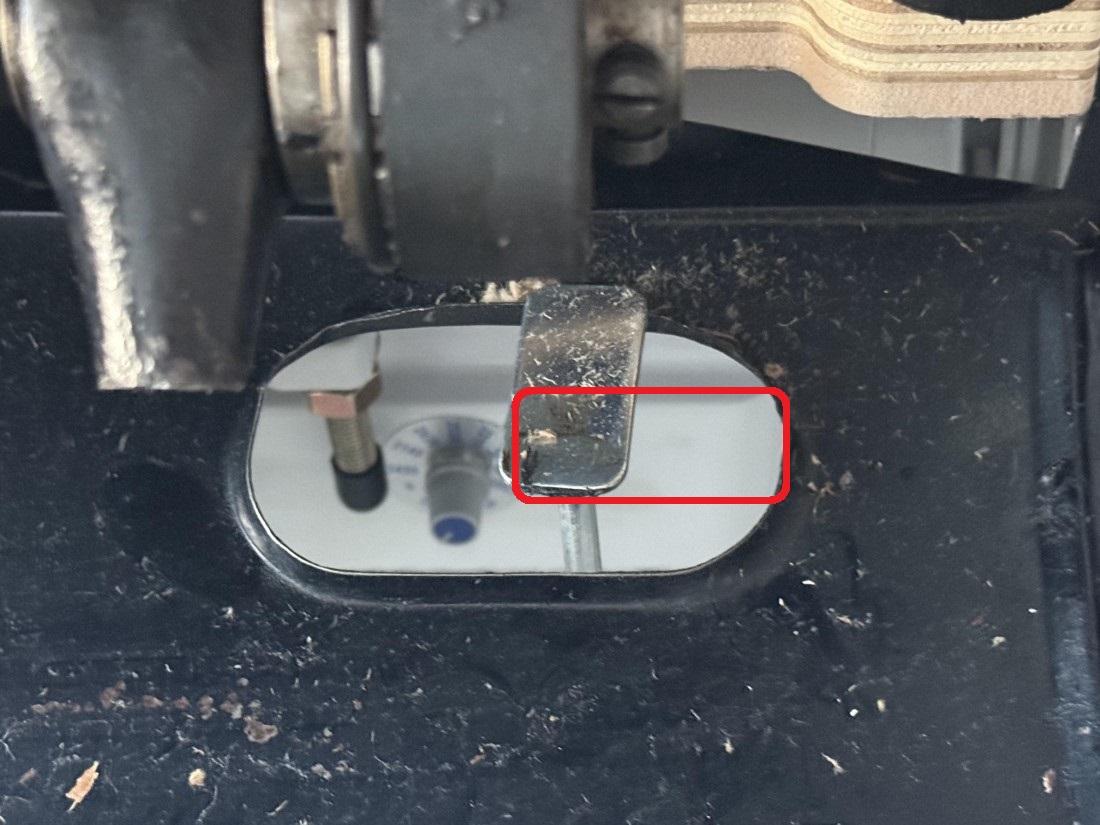

I cannot see how you mounted the lifter but what I can see is that the roller (224413) on the lifting rod (240550) is missing (isn´t it?) and the orientation of the "tab" is wrong. It has to be like the red frame IMO the longer end has to face right. Thats what I can tell the rest is trial and error where you put the foot lifter assy. -

maybe this https://www.ebay.de/itm/385670072955

-

no facetime but I may be able to hep when you explain the problem and post some pictures. What model do you have?

-

I have never seen anything like that - I have no clue! 🤔 I´m not questioning the quality of Pfaff machine but Pfaff IMO made a lot of thing way tooooooo complicated. It it was a Singer 236 I would have a belt driven roller foot.

-

Will this work for a singer 111w154 ?

Constabulary replied to outaluck's topic in Leather Sewing Machines

it will but depends on your expectations regarding sewing speed. You may need a smaller pulley or speed reducer in addition. -

what does the manual or parts list say? I`d guess a drain screw or oil regulating screw for the hook.

-

Singer 112W 115 Knee lifter installation

Constabulary replied to DMH's topic in Leather Sewing Machines

please post pictures of your machine from the rear and when tilt back from the underside and how you have installed the foot lifter. -

the parts list may help you pfaff_471-474-491.pdf

-

Are either of these machines any good?

Constabulary replied to timstips's topic in Leather Sewing Machines

top and bottom picture show a Singer 107w ZigZag machine of some kind, it can sew garment leather. I have one, nice machine but not the best option for leather work. But the one shown has a lot of milage as it seems. I would not buy it as my main / first machine. -

if you are looking for small / narrow foot print feet then these feet here may be an option: https://leatherworker.net/forum/topic/132157-interesting-441-style-presser-feet-for-singer-111w-153w-and-similar-like-341-227r-and-so-forth/

-

My response was a bit short I guess. Well, we have not seen the machines but I would assume that the 211´s are old factory machines that probably have been stored for maybe decades (we do not know, do you?). You for sure will need a new motor (Servo motor + maybe a speed reducer for better speed control) and depending on the wear you may need a new hook and maybe a new timing belt. Replacing a timing belt on a 211 is no fun work IMO due to the shaft bearing on the hand wheels end. So if you are able to replace the parts by your self. And since we have not seen the machine it may need some more bits too. You may need $100+ for the motor + maybe $150 for the speed reducer (if needed) and maybe $50+ for additional parts (all guessing) and your time for repair and adjustment work. So a lot of guessing here. Pictures of the actual machine(s) may help. The machine it self could probably sew what you what (as AlZilla already said) but it is meant for flat work and not really for sewing over thicknesses. There are for sure better machines for leather work. Triple feed machines are a lot more versatile than needle + drop feed machines, especially when it comes to accessories like presser feet and so forth. My 2 cents.

-

its a needle feed + drop feed machine w/o reverse. you find some main information in the service manual (1st google hit on my end) I would not buy it. Singer 211W151.pdf

-

College Sewing is back: https://www.college-sewing.co.uk/catalogsearch/result/index/?cat=3&q=tapered+bore&p=1 but I´m sure most sewing machine dealers in the US can get you tapered bore pulley as well. Maybe worth checking with Toledo Sewing Machines

-

What country do you come from? College Sewing and Trojan Sewing in the UK have tapered bore pulleys. I cannot reach the College Sewing website atm seems it is down for maintenance or so https://www.trojansewing.co.uk/?s=tapered&post_type=product&type_aws=true

-

I'll get a new left toe foot but have to place a new order - thats okay for me considering the fairly low price of the feet. They for sure have something I could use. I also found some interesting cheap feet for the Adler 67, 167, 68, 168, 69, 169, 267 and so forth "line" in their store: https://de.aliexpress.com/item/1005008687919538.html nutin for me Singer Idjit but looks like a good deal for the Adler folks 😉

-

Here is a parts diagram of the Adler 20-20 - hope it helps Adler_Parts_class_20-20.pdf

-

I may have a hard copy of the 20-20 parts list, not sure though. I´ll check that in the days to come... stay tuned... 😉