-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

maybe this manual will help. According to this manual PD seems to be a "pedal warning" Servo Motor Technician User Manual(v3.7 L-Type 4-Bar for ShuangZheng).pdf

-

a personal comment suits better here I´d say. I never hit any like or dislike button - no matter where. But I´m Generation X and not very social media affine anyway.

-

Is this a machine I can use for leather? MA2457R-A1

Constabulary replied to isaac45isaac's topic in Leather Sewing Machines

Yeah, I´m shy with saying so 😁 -

Patcher machines are designed as repair machines and not for producing goods. Keep in mind hat the 29-4 is a century old machine (or older) and they have tiny bobbins that do not hold much thread and the older the 29 / 29K is (the lower the subclass number the older the machine - basically) the more wear they have and wear parts are hard to find for the early 29 / 29K. This may help you to figure more about the 29-4: https://www.google.com/search?client=firefox-b-d&q=29-4+site%3Aleatherworker.net

-

The Textima 17 is a clone of the Singer 17, made in east Germany after the War at around the early 1950s. Not really a heavy duty machine and the bobbin size is quite small. Pfaff 335, Adler 69 come to my mind. Adler 5, 105 or Singer 45K are way heavier but are drop feed machines, some may have a jump foot. CLAES 233 may be something to look for they were quite common in the former East Block and are excellent machines.

-

Is this a machine I can use for leather? MA2457R-A1

Constabulary replied to isaac45isaac's topic in Leather Sewing Machines

I would like to buy that sucker but wrong side of the pond - too bad. That basically is a cylinder arm version of the singer 457G / 457U I´d say. And going back in history I´d guess it comes from a Singer 107w50 - kind of and I would guess the two share some accessories. (Singer crazy me is 😜) -

Singer 51w55 trouble making the feed dogs walk

Constabulary replied to Lu.mi.sewing's topic in Leather Sewing Machines

Do I get you right, you cannot adjust the stitch length, right? Or does the feed do not come high enough out of the needle plate? Please post pictures of your machine. -

Needles and bobbins for Singer 51w28

Constabulary replied to Lostranger's topic in Leather Sewing Machines

Have you read the above linked threads? You do not necessarily have to machine needle bars. If you have the 2nd type 51w (you have not posted pictures yet - I´m not sure if there was a 28 subclass in the early and late 51w model line) the NB diameter is 6.35mm / 1/4" so you can use a Singer 111w needle bar (for triple feed machines) and shorten it as needed and you can use 135x17 or 135x17 needles. 111w NB just cost a few bucks - sample: https://www.ebay.com/itm/162129813710 If you have the 1st type 51w (the one I have - see above thread I have linked) you can use a 111w needle feed NB (Singer # 240020) which has ~8.74mm diameter. But then you have to alter the lower bushing (add a longer one) or add a bushing at the top (that what I did). This may help you or not. Just meant as alternatives to a custom made needle bar. 😉 BTW: This is so far the closest manual for the 1st 51w I could find (see attachment) The 2nd type manual is already linked above. This is the bobbin for your machine if it still has the OEM hook https://www.ebay.com/itm/162656003877 If the needle bar "challenge" is not what you want then your machine ex factory is using needle system 128x2 / 128x3 (short needle with thin shaft) sample: https://www.universalsewing.com/sewing-needles?needle-system=128x20 Singer 51w100 and 52w100 - instructions for using and adjusting(1).pdf -

Needles and bobbins for Singer 51w28

Constabulary replied to Lostranger's topic in Leather Sewing Machines

There is an earlier type 51w based on Wheeler & Wilson and a later type 51w and the two types are using different needle bars and are mechanically different too. So it depends on what you have. I assume you have the earlier type 51w. This thread my help: https://leatherworker.net/forum/topic/96574-singer-51w56-needle-bar-conversion/ Some years ago I have restored an early type 51w and converted its needle bar and I still have the machine. https://leatherworker.net/forum/topic/86292-singer-51w-sv-2-post-bed-machine-restoration/ -

Durkopp Sewing Machine - but which model?

Constabulary replied to Andy Stoneman's topic in Leather Sewing Machines

looks like a Durkopp 291 -

Well, de do not know the details of your machine cause we are not in front of it. So picture may help us to figure things. Have you pulled out the stitch length spindle? There is a pin on the inside oft the dial knob that pin goes into the coarse threading ion the top shaft. You have to push the spindle a bit when "screwing in" the spindle. Do you have a manual for the machine If not here is one. See pages 18, 19 for an x-ray view of the stitch length assembly. Hope this helps a bit. 107W1,W3,W5-inst.pdf

-

Hard to tell what what is wrong w/o having the machine in front of me. The D. 18 is a very special patcher I once restored one but never touched one again. Maybe this thread and the video I have linked may help

-

I think it would help if you could explain what your problem is and maybe post some pictures or link a YT Video.

-

328 needles are often named as 214x1 (for fabric) or 214x2 (for leather) - same needle just a different "name".

-

First of all what stitch length have you dialed? If Zero then you have no movement on the right rod and no feed dog movement. Is the stitch length "assembly" complete and is the spindle insert correctly? Please post some more pictures of your machine. Second - I have a 107w1 as well and too me it looks like the rod on the right, which is the rod for feed dog movement could be installed incorrectly. The screw should be to the rear (this is how it is on my machine) and not on the front side as we can see in the short video. Not sure what is going on on the underside of your machine but could be that something else is installed incorrectly (but this is guessing). I´ll post pictures of my 107w1 later.

-

Hans, the jump foot mechanism on a 45K89 is different compared with the one from the Adler 4 or 5. However at one time Singer had a similar one as Adler. With other words Singer had 2 different jump foot systems on the 45k line.

-

Post some pictures of your machine please. I had a flat bed version of the 45K with I think the same jump foot mechanism but that was some time ago.

-

Help with machine setup/use

Constabulary replied to ZARDOZ the GREAT's topic in Leather Sewing Machines

Threading wire: https://www.ebay.de/itm/162385533414 Screws could be metric too - you never know. I´d re-tap a new and more common thread. -

Main difference btw Adler 67, 167- gk373

Constabulary replied to dudumoko's topic in Leather Sewing Machines

67 has a standard hook (smaller size) and the 167 has a larger hook but is smaller as on your former Juki 563. 267 is the newer version of the 167 - basically. 267 has a different casting. Not speaking about the sub-classes, just the basic machine. -

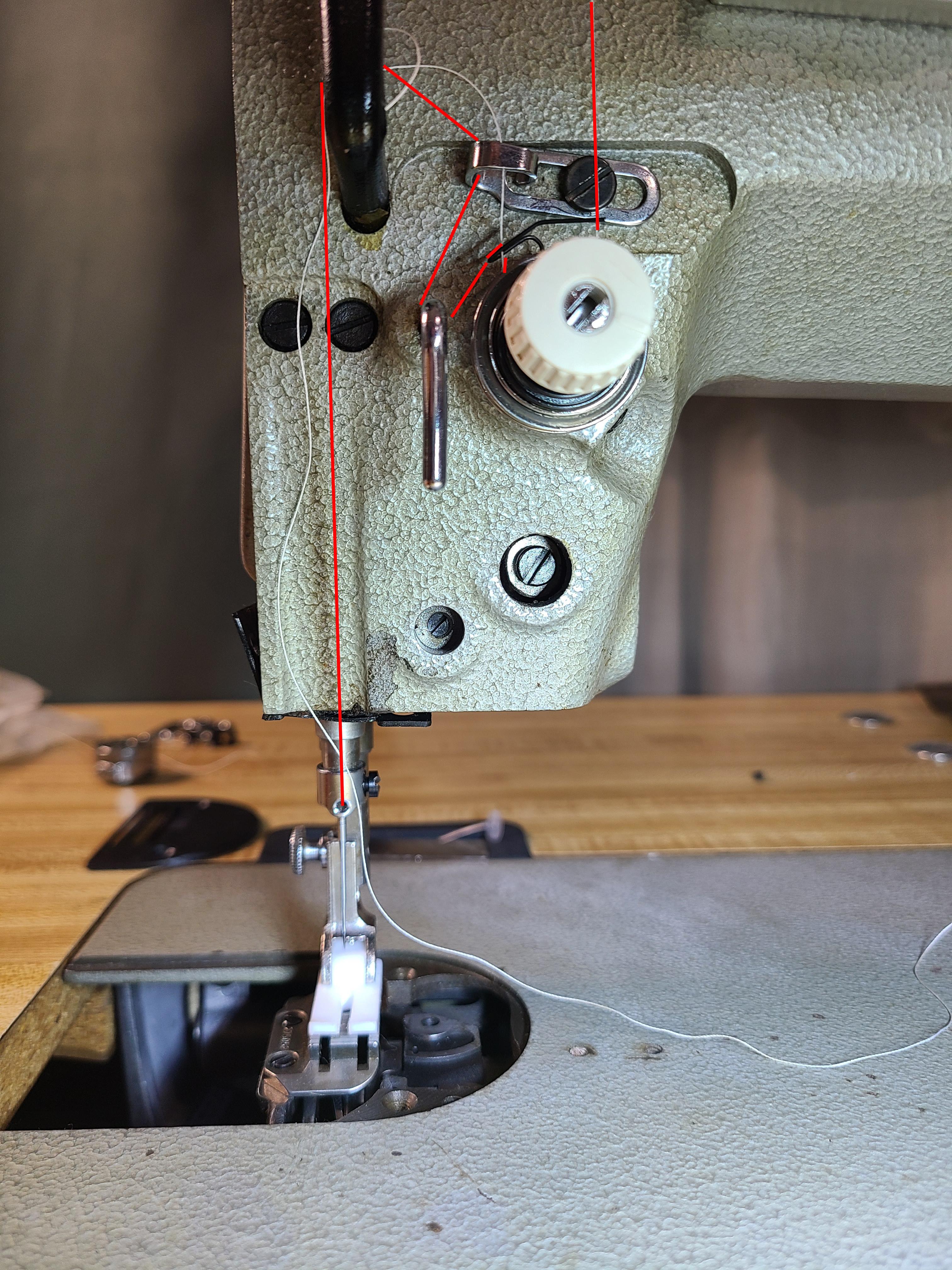

I would guess your foot is for a plain strait stitcher. What number has it? Needle feed feet usually have a longer slit. You can extend the slit on yours with a file or dremel (or similar) or buy a needle feet foot. F.i. check the College Sewing UK Website, they have a section for needle feed feet but should get the feet elsewhere too: https://www.college-sewing.co.uk/parts-by-type/needle-feed-lockstitch-feet.html BTW your top top thread path is wrong, you have left out the hook.

-

sewing some straight seems on scrap leather with a thin needle and thin thread and producing a quality leather goods with maybe a size 22 needle and 138 thread are two different things. If a certain machine is capable to sew leather depends on the product you want to produce, the type and thickness of leather you want to use and the needle and thread size you want to use and o course the overall thickness you want to sew. Thin needles with thin thread will most likely punch through all kind of leather (guess why syringes have super thin needles) then double or triple the leather and and try again. Then try making a proper product. All sewing machines have their limitations.

-

There is 332 and 332LG / 332 LONG which is longer than 332. 332 is for the 30-1, 30-15 and so forth and the 332LG / 332 Long is for 30-7, 30-70 and so forth with a higher foot lift. Alternatively you can use 135x17 and 135x16 needles on your machine (I do this on my 29K71 which is using the same needles as the 30-15). The nomenclature 332 and the longer 332 Long can be confusing especially when the needle tip is left twist (LL)

-

Let me try to explain. You have to close the needle plate. Hold the thread in your have and pull it up slightly when the needle goes down and when the needle comes up again a bit again no longer pull the thread then a loop will be formed which then is caught by the hook. If this does not work then you needle-hook timing most likely needs adjustment or you have to practice. Watch the movement of the needle you will notice the needle goes down, then it comes up a little bit (maybe 2mm or so) and in this moment the thread loop is formed and the hook can catch the top thread loop...

.jpg.8aecfaf4ecba7851e26177adfe5cc6b5.jpg)

.jpg.340d6d2d140c3bcbebd60409432748b4.jpg)