-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

as far as I know the singer attachment screws fit: https://www.ebay.com/itm/143367841409

-

main question from my point is what do you want to do with the machine? Just darning I guess cause the machine has no feed system to feed the material for achieving a constant and equal stitch length.

-

I´ll check my records but I don´t think I have a parts list. Your pictures are fairly small Its hard to tell what is going on... BTW I once uploaded a few more files here, some are for a similar Adler machine but the basics are the same. https://leatherworker.net/forum/topic/113978-old-pfaff/?tab=comments#comment-737306

-

Increasing the foot lift and decreasing the foot pressure can help to gain a little bit stitch length. Other than that it most likely is the bell crank lever tip that is worn down. You can buy made in China Bell Crank levers new but you often have to modify them to make them work for the ancient 29K models. Some years ago I did that on a 29K1 and it worked. Or you rebuild the bell crank lever tip by brazing or welding and file it into shape again. The tip diameter is ~5mm on a new bell crank lever. But keep in mind other parts on your machine may be worn too so it could be more than just the bell crank lever. This was my restoration 10 years ago: https://leatherworker.net/forum/topic/60554-29k1-pre-christmas-barn-find/ And this is the bell crank lever https://www.ebay.com/itm/162385595622?

-

Please post pictures of your machine and the parts you have problems with. The Singer 17 is a very similar machine if you need a manual look up a Singer 17 Manual. However here is a German language manual for your machine. Not sure if the Singer 17 parts are interchangeable but in case you do not find a spring I would try a complete new Singer 17 or Singer 16 tension unit. Not a big loss if it does not fit: https://www.ebay.com/itm/191942998278 https://www.ebay.com/itm/143871720894 Pfaff_23_Manual_-_German.pdf

-

328 and 214 are the same - 214 is more the US & Anglo "name" and 328 is more the continental European "name" for the same needle. 214 / 328 have different shaft diameter depending on the needle size. This is quite unique and I do not recall a 2nd needle system having this. I have not seen enough 216 needle though. I run my 132K with 214 / 328 and so I did with the former 133K. Maybe this older thread helps too:

-

You know that the 133K18 is a darning machine, right? I had a 133K3 and own a 132K6 - you can use 214 / 328 needles they are almost the same as the 216 needles.

-

we recently had a similar issue with a 153w both have a similar adjuster for stitch length. So maybe this helps:

-

check with LW member SHOEPARCHER he may have what you need https://leatherworker.net/forum/profile/7239-shoepatcher/

-

The German DHL / Postal Service website still states (Dec. 17th) that they atm do not ship to Cananda. I guess things have piled up on the Canadian side and have to delivered first. I have an eye on it a keep you updated. Website is in German language https://www.dhl.de/de/privatkunden/pakete-versenden/weltweit-versenden/land/kanada.html

-

The screws are still available. The singer screw # is SS135D or can be found with parts number 412845 sometimes. This is a UK dealer but you will find it in the US as well https://www.college-sewing.co.uk/ss135d-spindle-singer-29k-71.html

-

Here are the measures of my part. Diameter: ~24mm Hole round to flat side: ~5mm Hole round to round side: ~5.5mm Maybe yours is a bit worn and is bit flattened over the years. So i would say it either fits as is or can be reworked a little bit to make it work. Let me know what you think. EDIT: Just figured the Canadian Postal Workers are on strike.

-

BTW I cannot open the HEIC files in post #3. Anyway - I found the part but I have to find my caliper to verify the measures. Later...

-

I had one a some years ago. Cool needle feed machine but it was nearly useless for what I did and hand cranking is so annoying when you want to sew longer seams so really nothing I would recommend nowadays but for f.i. for the custom shoe trade (and the like) a really well made machine but needles are rare and expensive. I´ll check for the part this weekend or on Monday.

-

I may have the tension part in in the 2nd picture, can you give me the outer diameter and the measures of the center hole with the flat side.

-

are you sure it is the gear and not a jammed thread in the hook / bobbin case area?

-

ISMACS has a comparative table for old / new sizes of sewing machine needles: https://ismacs.net/singer_sewing_machine_company/singer-needle-sizes-1950.html Hope it helps

-

Landis #1 Early Christmas Gift

Constabulary replied to alfredleatherworks's topic in Leather Sewing Machines

Aaron Martin in Canada has 331 needles: https://shop.aaronmartin.com/331LR-200-Schmetz-Needle/item/331LR-200 -

Landis #1 Early Christmas Gift

Constabulary replied to alfredleatherworks's topic in Leather Sewing Machines

So cool! Reminds me of my former DVSG / BUSMC #6 HM. I sold it a while ago but found a good new home in Great Britain but I´m still looking at the pictures sometimes . I unfortunately had not enough work for it and it took too much space. I oiled mine with 10w40 motor oil. My #6HM took System 331 needles but I´m not sure what the Landis needs. Good luck with this lovely chunk of cast iron! -

Have you checked the manual for that? Looks like there is one included. Bob was a bit faster...

-

Adding a servo to my Singer 211g166

Constabulary replied to Sparky68's topic in Leather Sewing Machines

I would go with the 750W motors. Having more power cannot be wrong. -

Forward and reverse stitching length adjustment

Constabulary replied to Moti's topic in Leather Sewing Machines

Other than that maybe this thread will help. -

Forward and reverse stitching length adjustment

Constabulary replied to Moti's topic in Leather Sewing Machines

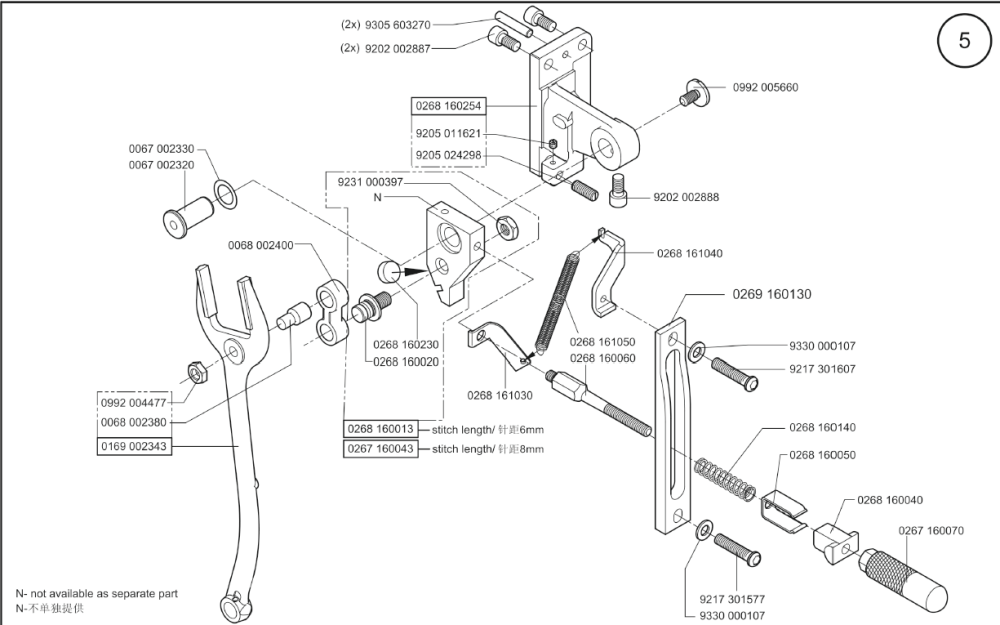

How significant is the stitch length difference? Have you compared your stitch length adjuster with the parts list to see if all components are present? I do not know the 269 so I´m just asking - is "bulge" on part #0268 160040 symmetrical? If not try to install it rotated by 180°. It sometimes happens on certain Pfaff machines that this part is installed the wrong way so it affects the stitch length so its probably a similar problem here. -

Why is my sewing machine giving me these stitches?

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

read the manual for your machine there should be a section for how to increase the height of lift for the lifting and vibrating presser foot -

Singer 153k103 stitch length adjustment

Constabulary replied to Lugubrious's topic in Leather Sewing Machines

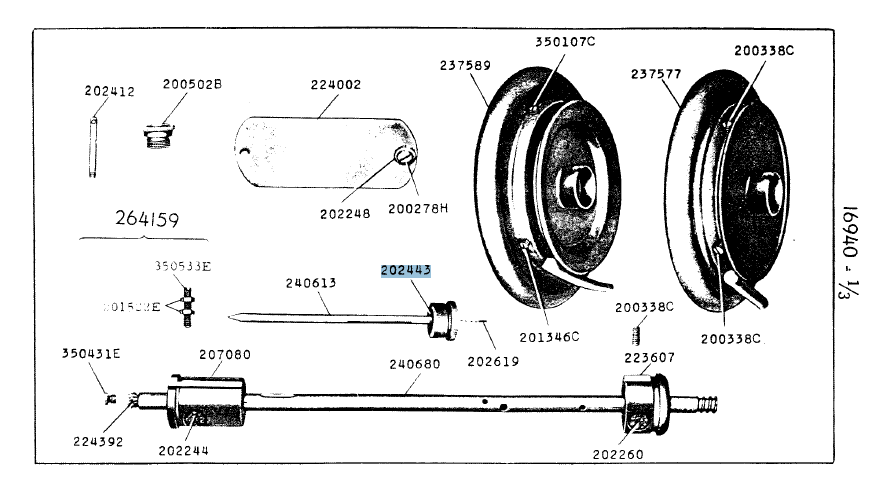

just yesterday I looked at the spindle on my Singer 108w and it looked like the pin is replaceable. I cross checked another 153w pats list and pound the pin as spare. Parts # is 202443 And I found it online: https://parts.jacksew.com/pin-generic-202443/