-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Try the "tension release disc" from the old tensioner (the one with he small bar across the center hole) - just a guess. Looks like this one: https://armastore.eu/32572-singer-tension-release-disk

-

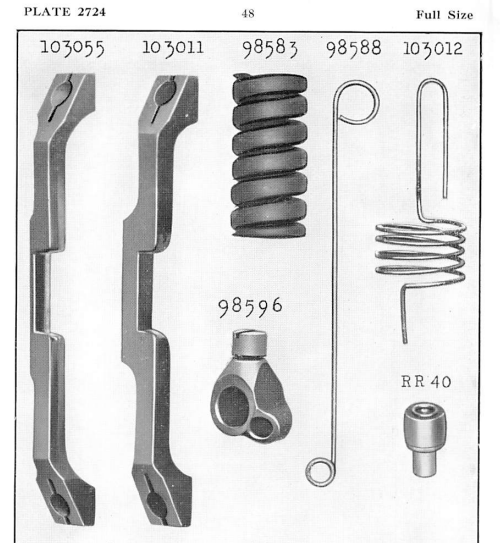

Download for a 133K manual but not exactly for the 133K13 but it may help: https://leatherworker.net/forum/topic/56667-singer-133k-information-wanted/page/6/#findComment-546077 the 2 parts on the left are positioning fingers and you notice the gap, right?

-

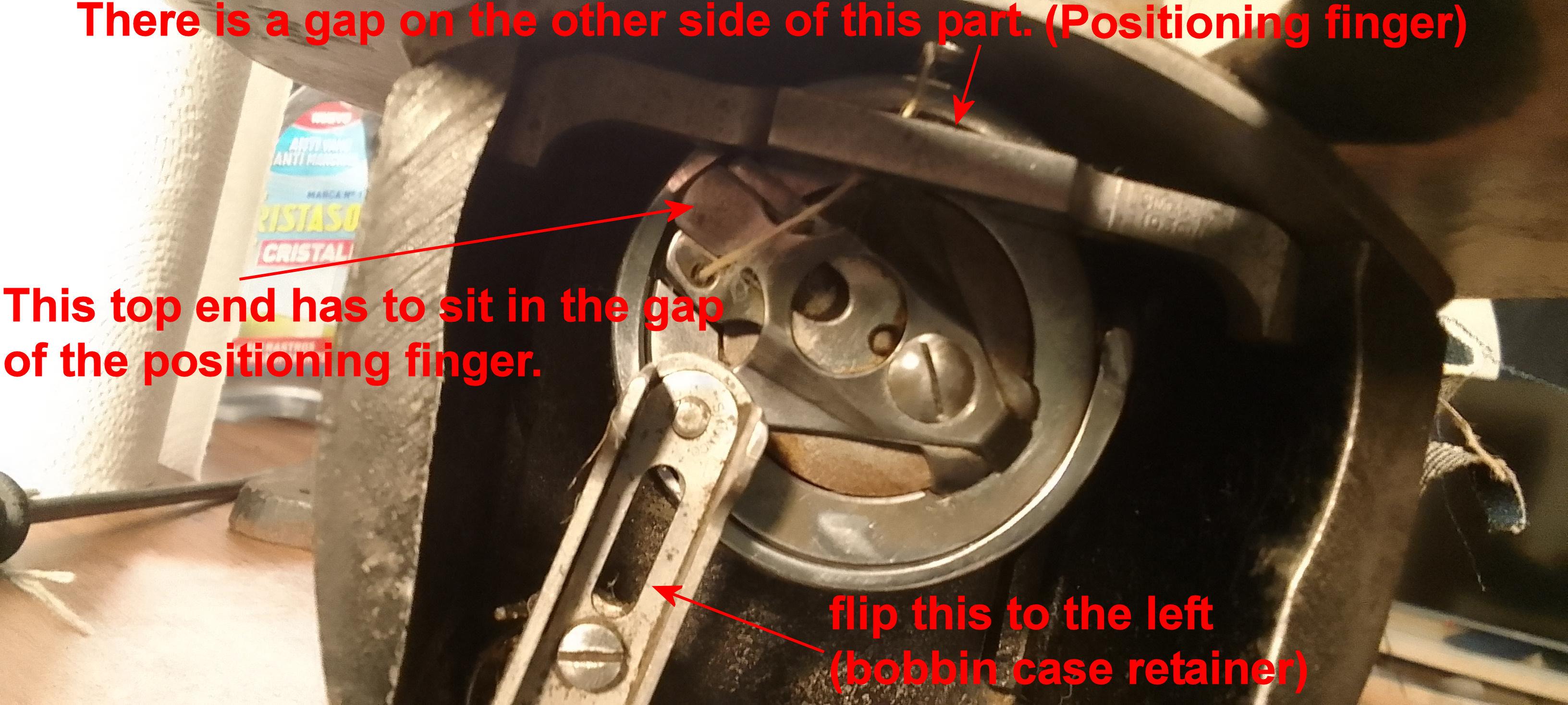

I guess you alreday have figured that is is a darning machine that ex factory is not set up for sewing operations. I once owned 133K3 but it´s long gone. There it a Bobbin case positioning finger that holds the bobbin case in position. You see it in your picture (that part is the "bar" above the hook / bobbin case in your picture). The top end of the bobbin case has to sit in the gap of the positioning finger (remove the needle plate and you have a better view on it and I think you will know what I mean when you see the gap). You only can insert and remove the bobbing case when the hook is in the right potion and you have to flip the bobbin case retainer aside before you can insert the bobbin case. EDIT: hope this helps

-

It has no feed dog so in which way do you think you can use a darning machine for leather work?

-

Pedersen 309 Bobbin case wires question

Constabulary replied to Einherj's topic in Leather Sewing Machines

do you know a dry Ice cleaner in your area? -

quick look on ebay shows me this: https://www.ebay.com/itm/143094497809

-

heating the bushing with a gas blowtorch may help too EDIT: yeah - that! My bad, sorry. 😉

-

What Machine Do I Need to Sew 12 mm Leather

Constabulary replied to OscarRush's topic in Leather Sewing Machines

well, the Singer 45k´s are not what you find very often anymore the "modern equivalent" are FI the Cowboy CB2500 / GA5-1 / Hightex CB105 but they only have drop feed (bottom feed). Noways most leather worker swear on triple feed machines, however IMO heavy needle feed machines like Adler 105-64 are underrated. I have a 45D91 (German made version of the 45K other than that its the same machine) and 12mm is possible but IMO very much limit due to foot lift and the needle system - you need a little reserve and don´t want to run it at its limit all the time. 9-10mm is what I sew mainly but I only do simple leather work like chest handles. I did some archery stuff for a pal and so forth. This is my machine: -

yes - Adler 105 - 64 subclass, needle feed machine with heavy roller foot!

-

Take bobbin assembly out of 1341 cyclinder arm

Constabulary replied to TonyD1948's topic in Leather Sewing Machines

Do not touch screw 1 + 2. Remove the 3 screws from the "bobbin case ring" and the ring (the 1/2 circle thingy) it self, hold the latch in the center and rotate it until it comes out. Underneath it is a screw in the center remove the screw and pull out the hook. When reinstalling it make sure you put it back in the right way - you have a 50% change to reinstall it the wrong way. 😉 Taking a look at the parts list may help you. -

believe it or not - I run a JACK 563 servo (actually 2 of em) for many years and just recently I bought a fxcking cheap Chinese servo (for under 70€ few month ago incl shipping) and it behaves and performs way batter than the Jack - not kidding. It starts at 200 rpm and I can dial down to 100 but than it makes strange sounds. https://de.aliexpress.com/item/1005007257363563.html price on my side of the pond is 88.99€ now incl shipping (Warehouse in Germany). The Jack quality is better, thats for sure but this cheap sucker just performs better. I however have added a speed reducer too, better too slow than too fast and you still have enough end speed. But to each his own...

-

what machine is it a Pfaff 337? There are at least 2 way different Pfaff 337 out there. We need more details. Butt IIRC one of then has no walking foot. Looking up the 335 may help you.

-

Pfaff 471 - rotating the bobbin to the right side

Constabulary replied to MackProvisions's topic in Leather Sewing Machines

check the parts list of your machine and the one with a right side hook post (not sure maybe its the 491) and compare the parts numbers - thats the best bet. If the part numbers are all identical then you may have luck but I doubt it is a good idea. I´d look for a new machine. My 2 cents. 😉 -

Now - more than 3 years later 😉 I checked with a known Chinese Ebay seller of sewing machine parts if he can get me the "Pfaff to Singer KB-PF1" foot converter. Few days later he uploaded a listing to Ebay and I have bought 2 pieces - now waiting for them to arrive. Reason I need them is that I found a Pfaff 341 (needle feed) and there are not really plenty of Pfaff needle feed feet out there but I have a good number of Singer feet so I will see how these converters work and I´ll post pictures when I haven em here. https://www.ebay.com/itm/168042808004?var=467644970296

- 3 replies

-

- presser foot adapter

- kb-pf1

-

(and 2 more)

Tagged with:

-

Pedersen 309 Bobbin case wires question

Constabulary replied to Einherj's topic in Leather Sewing Machines

don´t know for sure but could be a heating device for warming the waxed thread. But its just guessing. EDIT: Rapid E 317 is the same machine AFAIK - see manual page page 8. Rapid E 317.pdf -

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

But the roller tip will not be flush when you have the FBA attached AND put washers under attachment screws or am I missing something 😉 -

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

but then the roller is no longer flush with he needle plate -

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

or you make a flat bed attachment where you can screw on an edge guide or modify yours. I once made this FBA for my Singer 45D91 but on mine I cannot use the 441 roller edge guide but the OEM Singer 45K edge guide that mounts on the flat bed steel plate insert. Note the 3 holes in line. Thats where I can mount guides and accessories. -

Cowboy Outlaw question on accessory compatibility

Constabulary replied to bigsig11010's topic in Leather Sewing Machines

The guide appears to be for the JUKI 441 + clones. So w/o knowing the CB Outlaw but knowing Singer 45K´s, Adler 5 / 105 and so forth I´d say either flat bed or edge guide. A suspended flip up edge guide probably is the better option when working with a flat bed. maybe something like this https://de.aliexpress.com/item/1005008728390412 or check this thread: -

How to ease when sewing leather on a 1341?

Constabulary replied to joetroba's topic in Leather Sewing Machines

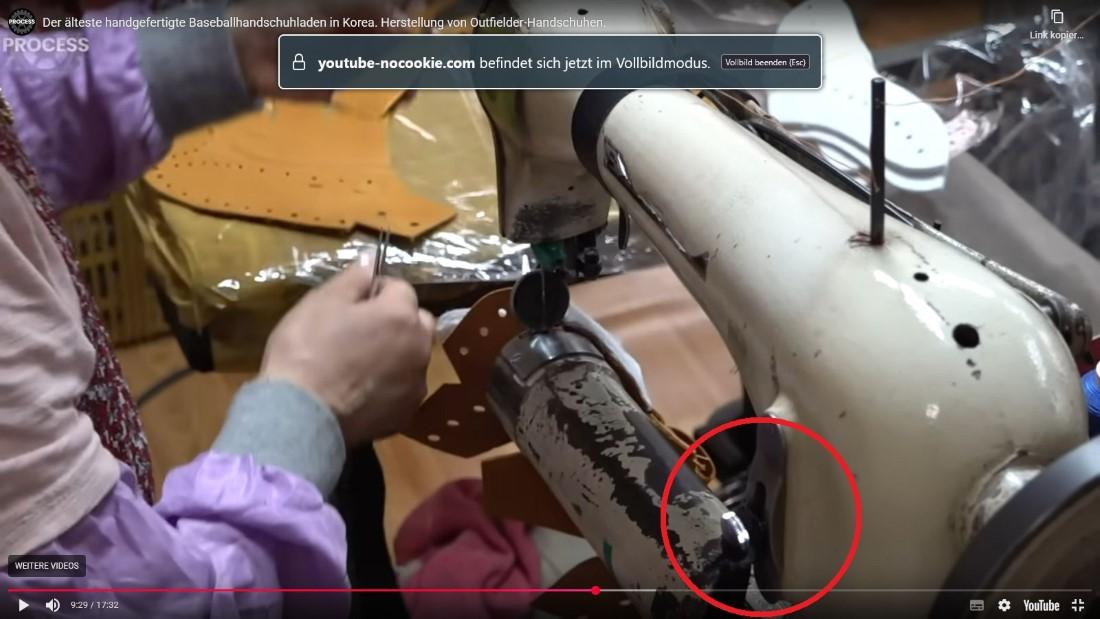

machine seems to be a Singer 17 or Seiko TE-6 and they have supper small bobbin. Surprises me that they sew with fairly think thread this fairly thick leather with a machine like this > not much thread on the bobbin. When I look at the stitch length lever the it seems to me just a screw w/o reverse - or not? However - IIRC there was a reverse device of the Singer Class 7 that did not come with reverse ex factory... Maybe they tinkered something similar. Well.... lots of guessing here. No matter what they do a great job there - I´m quite impressed. EDIT: weeeeell - I´m not sure - new TE-6 have reverse AFAIK but not sure what I see there. EDIT II: Looks like this one - which looks like a non reverse machine -

Domestic sewing machines

Constabulary replied to Curious Observer's topic in Leather Sewing Machines

thread is coming of the spool a bit the odd way. Maybe one of these thingies may be helpful. However if it works for you then don´t mind. 😉