-

Posts

5,815 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

yeah - keep that old cast iron alive - I seldom went wrong with that! 😉 I love my 51w but the 2nd type as yours would be even more preferred but I love mine too. Singer crazy me is. 😁

-

often Ebay is a bit cheaper than Amazon - even from the same seller. Just saying...

-

Singer 107 W1 Stitch Length not changing

Constabulary replied to ohLyssa's topic in Leather Sewing Machines

make sure the whole machine incl rod and coarse threading is well oiled and the stitch length mechanism parts are not gummed with old oil. -

basically that's it but I would check the needle hook timing too - that never can be wrong.

-

Singer 107 W1 Stitch Length not changing

Constabulary replied to ohLyssa's topic in Leather Sewing Machines

are all the parts as shown in your diagram present (See text / parts list)? The tip on your adjustment rod is damaged as you already noticed, tip should be very sharp (see picture below). Not sure how much this affects the stitch length regulation. Is the small stud inside the adjustment knurled knob present? Is the coarse threading at end of the top shaft in good order? Please post some pictures. edit: Quick picture of the stud from my 107w1 rod and the top shaft threading. Stud slides inside the coarse threading. -

Check with Fuchs Elektronik in Germany they have the Quick Rotan Service: http://www.fuchselektronik.de/index.php?vid=302&mid=1&lid=2 However - not sure if they are still in business - looks like an early 2000´s website

-

7x23 are slightly longer IIRC. Minor needle bar height adjustment could be necessary but they may work even w/o adjustment.

-

sure: https://www.ebay.com/itm/234079435236 this is with what the 31K48 came ex factory but roller size may vary. however we have not seen your machine and how it is set up. Could be this type as well https://www.ebay.com/itm/143603133032

-

happened to me quite often. Waiting for a better price... for money to come in... lack of time... just being toooo lazy... looking for too long for information... When you see one you want grab it before someone else takes the 1st shot.

-

gear for 29k machine metal workers please read

Constabulary replied to catskin's topic in Leather Sewing Machines

I think I mentioned somewhere that I may have one.... Will check later.... heading to work now... -

I have a complete singer shuttle race for the class 7 not sure if it will fit I have some other bit but have to look for them.

-

Fxck AI - don´t trust it too much. Not sure what needle this subclass is using but you can use different needle systems with the smae shaft diameter but have to alter the needle bar height. That usually it not big deal. Singer 16 (more common is 287 or 1738 as needle system) have a 1.63mm diameter IIRC and 135x17 have 2mm diameter needle shaft. It may work but you have to try it. Or you try to find a needle bar that ex factory is made for 2mm shaft needles. I did that with my old Singer 51w but it using a different needle bar that does not fit the Singer 17. EDIT: oh- BTW I once owned a 34K that ex factory is using a 2mm shaft needle and I had to replace the NB and I took one from a Singer 17 (!!!) and the machine after the NB replacement worked with the 2mm shaft needles but ex factory the NB was made for Singer 16 needles (as yours) so I would just try the needles and adjusts the the NB in height. Worth trying - never say no - just try it. But hand crank the machine before you are using it with a motor. This was my hunt for a Singer 34K NB 10 yrs ago 😅 https://leatherworker.net/forum/topic/66729-singer-needle-bar-i-could-use-some-help/

-

Way cool machine- really! I owned one but it did not suit my needs. I would not buy one again. Why - because why in the world should I pay $25-30 or one (1) needle? Chances are high that you break one and you better have a few spares on hand. Know what I mean? Depending on what you want to sew I would look for a an other model.

-

I had both 34K and 51w (still have it). Is sold the 34K cause I found the 51w and I do not look back. 34K is a bullet proof design, it was built to last but mine had a too tall post and I figured parts situation for the 51w is still good but even for the 34k you still find some new parts that the machine share with other Singer models. If I had too chose again I would always go with the 51w but you don´t always have choices. 34K´s also came with shorter post but sometimes you have to take what pops up on the used machine market. If you are looking "just" for a post bed machine then look for "810 Post Bed". It is more or less based on the 51w. This was my 51w project (1st model 51w):

-

The 17U model was made in Japan the 123 subclass has smaller diameter arm compared with other Class 17 machines and it is using Singer 15 type bobbin cases and bobbins. Apart from the hook / bobbin you should be able to use any other 17U model manual you find online. The subclasses usualy just have minor differences but the main machine often is the same. Check if needle plate and feed dog are present and in good order and see that the machine is complete in the hook area - see parts list for that or post more detailed pictures.

-

Singer 18-2 Problem with part 3037

Constabulary replied to Ghoust6's topic in Leather Sewing Machines

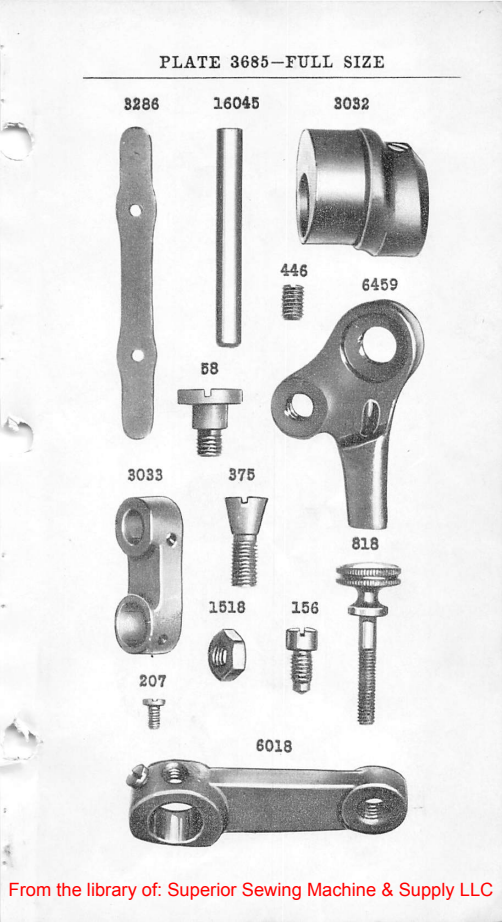

I think the fork is attached to part no 3033 (feed fork connection link) from the rear with a screw (the one which thread you see on your last picture) and the part 3033 is attached to the 6459 (feed regulator = Stitch length adjuster) and to the machine body with a screw and I think this is screw the read arrow is pointing to (see picture below). So I think you have to remove this screw first. The rest is trial and error. I recall it was similar on my Singer 45D91 back then. Look at these parts from the rear side, you should see the parts through the hole. Move the stitch length lever up and down and I think you will notice what I have described. EDIT: I just noticed the video - it shows what I mean. -

upgrading to oldschool singer 132k6 and 132k7

Constabulary replied to VinnyK's topic in Leather Sewing Machines

I once owned a similar machine I stripped mine for parts back then after I found a 132K6 and I do not look back. I think they are not worth upgrading to 132K6 as parts are rare and expensive - IF the upgrade is technically possible at all. But maybe you have luck - dunu. a lot of parts (in general) can be found at College Sewing or Trojan Sewing in the UK or MARFAR in Australia. -

my bad - my feed dog is from a 104-64 - sorry. Anyway, your looks normal to me.

-

does not look worn, it is an oval hole because you can alter the feed doh height I think I have a feed dog to compare I´ll check later today.

-

Singer 18-2 Problem with part 3037

Constabulary replied to Ghoust6's topic in Leather Sewing Machines

I see so it´s the fork. They are attached with 2 screws, one on the lower end and one centered right under the fork end. IIRC the "fork screw" can be reached from a hole under the top shaft bushing behind the hand wheel. -

Singer 18-2 Problem with part 3037

Constabulary replied to Ghoust6's topic in Leather Sewing Machines

maybe you can post pictures and give us some more detailed information cause no one knows what parts 3037 is except we download a parts list an look through it until we find the part you talk about 😉 -

see attachment for different leather needles with different cutting points and how their seam appearance is schmetz_db_schneidspitzen_6s_20190510_en(1).pdf

-

Maybe you can explain what you mean. How thick is the material overall and what needle and thread size are you using and what do you think is "not normal"?