-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

vintage Singer 201k for edge binding

Constabulary replied to TonyGreen3455's topic in Leather Sewing Machines

Juki 563 is excellent and 562 as well, the 563 has a larger bobbin. Both share accessories and certain pats with the Singer 111. Seiko STW-8B is another good machine and Singer 111 based as well. -

Singer 51 W 25 Stitch length?

Constabulary replied to Irishleather's topic in Leather Sewing Machines

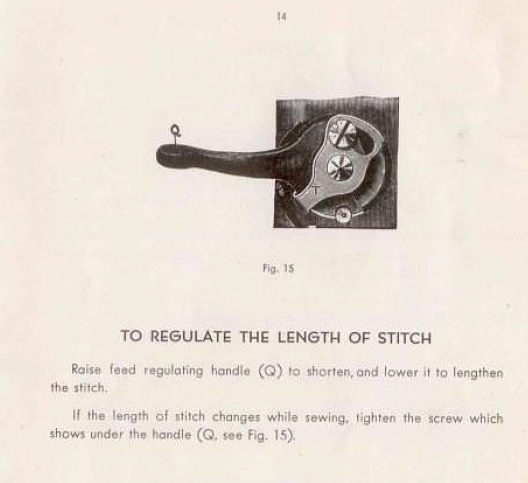

You have an early 51w based on a Wheeler & Wilson machine. The later 51w models look a bit different. I have a similar one that I restored some years ago. https://leatherworker.net/forum/topic/86292-singer-51w-sv-2-post-bed-machine-restoration/ If the lever does not move then loosen the set screw on the front side I have attached manual that will work for your machine. Hope this helps Singer 51w100 and 52w100 - instructions for using and adjusting.pdf -

vintage Singer 201k for edge binding

Constabulary replied to TonyGreen3455's topic in Leather Sewing Machines

Stop bouncing around with these stupid domestic sewing machines. Just don´t force them to sew things that they are not designed for. Having no space at home may be a reason but not a good one. Better invest some time and "brain grease" for setting up a proper industrial sewing machine for "table top use". Get one based on a Singer 111w / 111G - or even better a cylinder arm machine based on singer 153. You can set it up for plain sewing (up to 9mm or even 12mm depending on the subclass) and even for proper binding work. You can get all the accessories you need for these machine for piping work, binding work, different feet, needle plates, feed dogs - just everything. Having that said - setting up certain machines to run leather tape for binding is not a easy task at all (even for industrial sewing machines) - it works but do not expect that you "just" buy this and that and some odds and ends on Ebay or AliExpress and then you are set up for this task. You may run some trials and figure some errors. Guess how I know. You have to start with a proper sewing machine and a proper machine for leather work can never be a stupid domestic machine. Basically you need the right machine for your sewing task. Yes some folks force them to do certain things but they remain domestic machines. Sewing a piece of leather and producing proper leathers goods are 2 way different things! Sooner or later you will run into a sewing situation that a domestic sewing machine never can handle. Guess why so many leather workers have more than just one machine? And some even have one just set up for binding edges. Yes, it costs money and maybe more than you want to spend but life / your leather hobby will be easier with a properly set up sewing machine. read more about binding edges - you may be surprised what you read: https://www.google.com/search?q=binding+site%3Aleatherworker.net%2Fforum&rlz=1C1PRFI_enDE858DE874&oq=binding+site%3Aleatherworker.net%2Fforum&gs_lcrp=EgZjaHJvbWUyBggAEEUYOdIBCTEwNDkzajBqOagCALACAQ&sourceid=chrome&ie=UTF-8 BTW - LW member UWE once set up a portable cylinder arm machine - just to give you an idea that you can set up industrial machine in a space saving way even with a powerful servo motor. Thats what I meant with brain grease. Talking about space saving - I once made a "table box" from some old drawers for my Singer 212G141 because I´m barely using it and it is a bit longer that the 111G1566 and this way I can drop the box into the cutout in the machine table and I just change the drive belt and done. Not ideal but the most space saving way for me to run my double needle machine. So think of singer 111 in a box like this ( see below) and a servo motor mounted in a way as UWE made it for his Adler machine... Its doable and you have a powerful versatile space saving machine then. -

Singer 111w103 new belt seems to have slack?

Constabulary replied to ksteers's topic in Leather Sewing Machines

I´m pretty sure the cog wheel with the safety clutch has the same dimensions as the plain one. Why should it be different when they use the same timing belts? -

Singer 111w103 new belt seems to have slack?

Constabulary replied to ksteers's topic in Leather Sewing Machines

How much slack are you talking about? A little slack is not uncommon especially on the older timing belts with metal cleats / braces. What do the parts list say? Do the 111 models incl. your 101 subclass use the same timing belt? If yes then it maybe be a manufacturing error. Have you used timing belt from the same source / manufacturer before? Or have you bought them here and there. -

Oiling Singer 111G156, mystery part/object

Constabulary replied to bnsmith's topic in Leather Sewing Machines

-

Oiling Singer 111G156, mystery part/object

Constabulary replied to bnsmith's topic in Leather Sewing Machines

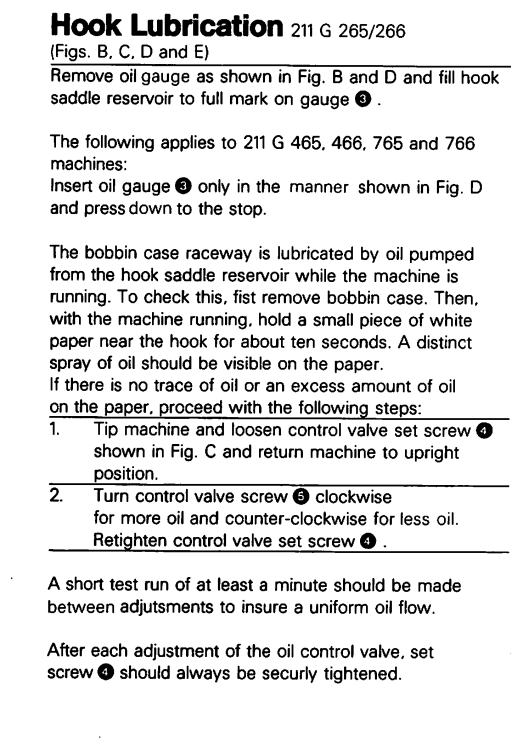

Seems your 111G156 has a different hook saddle and hook. looks like the one I have in my Singer 212G141. Maybe the machine has been "upgraded" once. The hook runs in an oil bath and the stick is an oil dipstick -

Picked up a free triple feed sewing machine today...

Constabulary replied to David916's topic in Leather Sewing Machines

I would NOT buy a direct drive motor for this type of machine. You are loosing the punching power of the large and heavy hand wheel (your machine has a larger one than most of the "standard" machines). I would add a speed reducer & brushless servo motor just as DieselTech said. -

Its hard to evaluate parts from just pictures. I have restored several patcher machines (29K´s, Adler 30 and some less common models) but actually never ran into problems like yours. But what I can tell is that old and new gear box parts often do not play well together. I got my 29K71 parts from College Sewing in the UK but that was before BREXIT. https://www.college-sewing.co.uk/parts-by-machine/singer-sewing-machine-parts/singer-29k-71-parts.html I had a new TOWA shuttle driver that was super tight in the shuttle driving gear but it worked. This was my project approx 10 years ago: https://leatherworker.net/forum/topic/56079-singer-29k71-restoration/ If you ask me I would probably buy all gear box parts (incl the long rack) new from one source but I cannot guarantee that it will work then. Patcher can be pleasure and pain. Such projects sometimes turn into money pits that unfortunately is parts of the "Vintage Machine Restoration Game". From todays perspective it was too expensive to restore my 29K71. I found better 29K71´s for less money (compared with all cost of restoration) BUT I still have the one I restored. But when ever I found OEM Singer parts I replaced them so meanwhile most major parts are OEM again. The springs for the needle bar never seem to fit, the one I got from College sewing was made of soft tin - useless! Same problem with the ball tip spring in the shuttle driver. That was 10 yrs ago - maybe the have improved parts now. But even the OEM Adler 30 needle bar springs (same as for 29K´s) needed to be reworked. Quite a while ago I bought a heap of old sewing machine parts incl. lot of patcher parts (new old stock & used), that included several of these needle bar springs too, none of the fitted w/o reworking them but they were of a way better quality. Sorry but I have no gear box parts just in case you want to ask .

-

make a new post then and you can load additional pictures in it. Or try the edit button an try to load more pictures then. You may get more attention when you post your restoration pics in the sewing machine section: https://leatherworker.net/forum/forum/50-leather-sewing-machines/

-

Adler 205-370 reverse friction.

Constabulary replied to councilman24's topic in Leather Sewing Machines

post a link to that video if you don´t mind -

What is this Singer 241-12 Attachment

Constabulary replied to TZHunter's topic in Leather Sewing Machines

since this is a high speed sewing machine I´d guess it is a puller device. -

Help needed _ cant find roller foot for 45k89

Constabulary replied to Heavenlychoirs77's topic in Suppliers

if a motor is too fast on what ever sewing machine buy a new servo motor they have a way better control. If you need information about leather sewing machines post your questions in the sewing machine section here: https://leatherworker.net/forum/forum/50-leather-sewing-machines/ -

Help needed _ cant find roller foot for 45k89

Constabulary replied to Heavenlychoirs77's topic in Suppliers

These are feet for flatbed machines like Singer 31k, 96k and similar, they are way smaller and the wheel is approx 1/3 wide as the Adler / Singer roller feet we talked about. They also do not fit the foot bar and need modification. I`m also not sure if you can adjust the wheel far enough sideways to fit the 45K feet dogs. -

Help needed _ cant find roller foot for 45k89

Constabulary replied to Heavenlychoirs77's topic in Suppliers

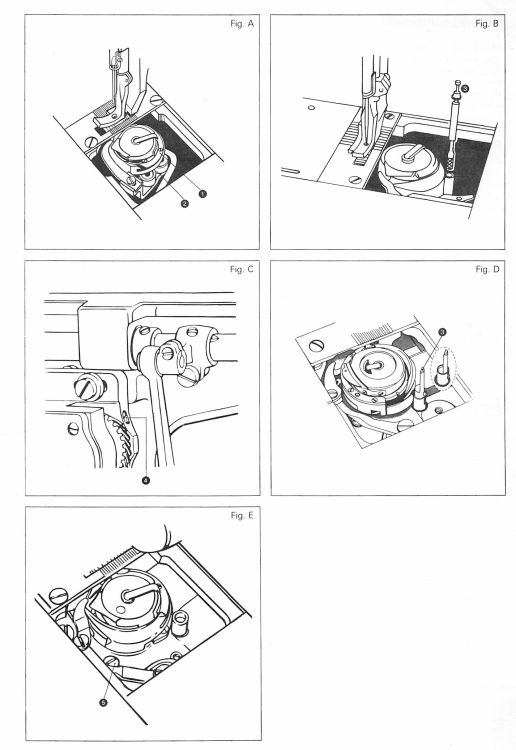

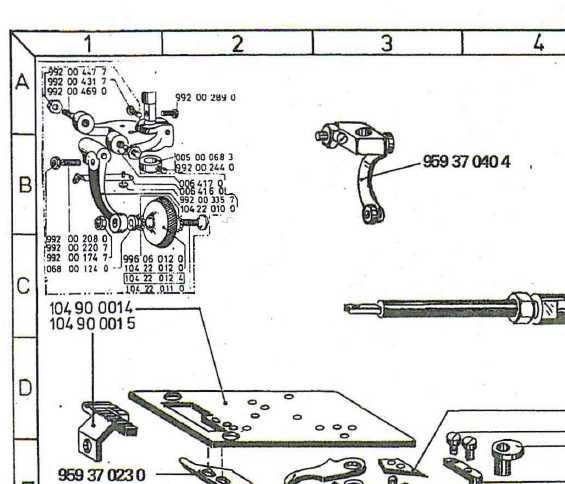

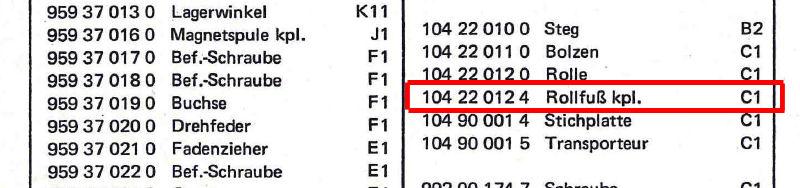

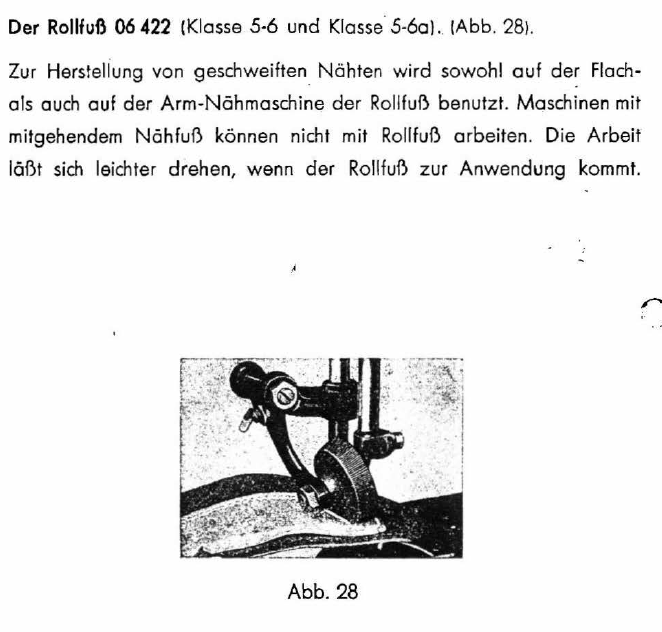

Maybe they no longer have this roller foot or it probably is an old parts number. I just have checked an Adler 204 parts list. It also shows a roller foot but I do not know in which way it is different or if it is even the same. I´m just not 100% sure but I´m almost certain that it will fit. The number is: 104 22 012 4 You can download the parts list here: https://www.supsew.com/download/Durkopp%20Adler/Adler%20204-2.pdf See below pictures. EDIT: Just googled the parts number - looks like College Sewing in the UK can order them. But sit down before you open the link and see the price tag https://www.college-sewing.co.uk/104220124-roller-foot-durkopp-genuine.html -

I also think the Pfaff 335 tension unit could work. Necchi and Pfaff have collaborated for a while afaik. Not a big loss if it fails: https://www.ebay.com/itm/143603134241 If it was me I´d give it a try. I´m pretty sure the Pfaff 335 manual will work for this machine as well. They are not crazy different as it seems.

-

Juki 1541s noise and wheel hard to turn

Constabulary replied to Dbz456's topic in Leather Sewing Machines

Have you tried playing with the foot lift height. I mean how high the feet raise when sewing? Just a guess... See page 36 in the manual Juki-1541-instruction.pdf -

Help needed _ cant find roller foot for 45k89

Constabulary replied to Heavenlychoirs77's topic in Suppliers

Glad when I can help. The 45k and the mentioned Adler machines have the same foot bar diameter and the roller feet slide onto the foot bar. This is an extract from an Adler 4 and 5 Manual: -

Help needed _ cant find roller foot for 45k89

Constabulary replied to Heavenlychoirs77's topic in Suppliers

They are super hard to find and often go for 100€ +/-. Alternatively you can use Adler 4, 5, 104, 105, 164, 165 roller feet. They are pretty much the same but they are as rare as the 45K roller feet. The Adler Parts number for the roller foot is 06422 - maybe you can get one form an official Dürkopp-Adler dealer but expect a price above 100€ -

Maybe its the hook driving gear. Maybe a lack of oil? I´d oil the machine generously. Check the manual for that.

-

or have they cut a channel for covering the top seam. Like using a channel knife in boot making? Just a guess.